Abstract

Three-dimensional compressible Direct Numerical Simulations have been used to investigate the localised forced ignition of statistically planar biogas/air mixing layers for different levels of turbulence intensity and biogas composition. The biogas is represented by a \(\hbox {CH}_4\)/\(\hbox {CO}_2\) mixture and a two-step mechanism capturing the variation of the unstrained laminar flame speed with equivalence ratio and \(\hbox {CO}_2\) dilution was used. The mixture composition was found to significantly affect the flame kernel development which was reflected in the diminished growth rate of the burned gas volume with increasing \(\hbox {CO}_2\) dilution. A successful ignition of \(\hbox {CH}_4\)/\(\hbox {CO}_2\)/air mixing layer gives rise to a tribrachial flame structure involving fuel-rich and lean premixed branches on either side of the diffusion flame stabilised on the stoichiometric mixture fraction iso-surface. The most probable edge flame speed decreases in time and converges to a value that is at most equal to its laminar theoretical limit, and can even locally become negative for large values of the dilution and/or turbulence intensity. The decomposition of the edge flame speed showed a negligible or negative contribution of the mixture fraction surface displacement speed, while the displacement speed of the fuel mass fraction surface appeared as the dominant contributor. Finally, the edge flame speed dependences to the fuel mass fraction and mixture fraction gradients, fuel mass fraction iso-surface curvature and tangential strain rate have been analysed and found, within the dilution values considered, qualitatively similar to those of undiluted mixtures regardless of the amount of \(\hbox {CO}_2\), although quantitative differences were observed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Fossil fuel combustion provides most of the primary energy required for power generation and transportation, and will likely remain predominant in the foreseeable future, especially for engineering applications requiring high energy density such as aircraft gas turbines. However, the fossil fuel reserves in the world are finite which calls for its replacement with alternative renewable sources. Biogas is now a widely accepted sustainable fuel and can be used either as a complement or a replacement, as well as used in similar applications as natural gas. Its major components are methane and \(\hbox {CO}_2\), but it is difficult to produce with a fixed composition when generated from biological sources (Vasavan et al. 2018), and if the variations are large enough to affect the ignition, this may ultimately lead to adverse effects on the subsequent flame propagation (Lieuwen et al. 2008).

Experimental studies of forced ignition of biogas/air mixtures reported that the carbon dioxide content, that can be quite large (5–40% by volume), acts as a heat sink leading to higher energy requirement for ignition as well as a slower and cooler flame (Forsich et al. 2004; Biet et al. 2014; Galmiche et al. 2011). Mulla et al. (2016) reported similar conclusions for the laser ignition of methane/air mixtures diluted with \(\hbox {CO}_2\). The \(\hbox {CO}_2\) dilution can thus hinder the flame kernel formation and potentially lead to flame extinction for biogas/air fueled gas turbines (Mordaunt and Pierce 2014). Lafay et al. (2007) also showed a significant modification of the reaction zone structure and flame stability with the addition of \(\hbox {CO}_2\) in a gas turbine configuration.

The forced ignition of inhomogeneous mixtures has applications in gas turbine relight in the aerospace industry and in direct-injection engines in the automotive industry. It was extensively studied experimentally by Lefebvre and Ballal (2010) that showed that an increase in turbulence intensity adversely affected the ignition event. Furthermore, over the last decade, Direct Numerical Simulation (DNS) has greatly contributed to the fundamental understanding and subsequent modelling of the complex phenomena encountered in combustion. The analysis of DNS data revealed the effects of turbulence intensity, mixture fraction gradients and scalar dissipation rate on the ignition success and the subsequent self-sustained combustion (Chakraborty et al. 2007; Chakraborty and Mastorakos 2006; Hesse et al. 2009). Interested readers are referred to Mastorakos (2009, 2017) for an extensive review of the different studies undertaken on the different aspects of ignition.

A number of analytical (Dold 1989; Hartley and Dold 1991; Ruan et al. 2012; Buckmaster 2002), experimental (Chung 2007; Ko and Chung 1999; Takita et al. 2003, 2004; Won et al. 2005) and numerical (Echekki and Chen 1998; Im and Chen 1999, 2001; Yoo and Im 2005) studies have focused on the structure and propagation characteristics of the flames arising from the localised forced ignition of laminar inhomogeneous mixtures. This type of flames is characterised by a self-propagating edge flame stabilised around the stoichiometric mixture fraction surface and plays a pivotal role in flame stabilisation and extinction (Chung 2007; Domingo and Vervisch 1996; Karami et al. 2015; Turquand d’Auzay and Chakraborty 2021; Karami et al. 2016). In the presence of low strain rates, the flame is tribrachial with a leading edge stabilised between two premixed flames (one rich and one lean) with tail of non-premixed (diffusion) flame. When the strain rate increases, one of the two branches often collapses on the diffusion flame giving the flame a comet-like shape (Buckmaster 1996).

Relatively few studies have focused on the propagation of edge flames in turbulent partially-premixed mixtures (Chakraborty and Mastorakos 2006; Hesse et al. 2009; Pantano 2004; Karami et al. 2016; Richardson and Mastorakos 2007; Jiménez and Cuenot 2007; Heeger et al. 2009; Turquand d’Auzay et al. 2019a; Krisman et al. 2017; Im and Chen 1999). Investigations by Echekki and Chen (1998) and Im and Chen (1999, 2001) showed a strong negative correlation of the edge flame displacement speed with both the flame stretch and the flame front curvature rather than with the scalar dissipation rate. In localised forced ignition, however, the scalar dissipation rate has been shown to be one of the main parameter governing the edge flame speed and fuel reaction rate, with a correlation that could be positive or negative depending on the location within the flame front. Previous studies of partially premixed mixtures forced ignition have also highlighted the key role played by the edge flame in the flame kernel growth rate (Im and Chen 1999, 2001; Richardson and Mastorakos 2007; Chakraborty and Mastorakos 2006).

However, the majority of these computational studies have focused on the effects of curvature, strain rate, and scalar gradient dependences of the density-weighted displacement speed of a fuel mass fraction isosurface intersecting with stoichiometric mixture fraction iso-surface (Chakraborty and Mastorakos 2006; Hesse et al. 2009; Pantano 2004; Echekki and Chen 1998; Im and Chen 2001, 1999; Richardson and Mastorakos 2007; Jiménez and Cuenot 2007; Heeger et al. 2009). The displacement speed of the mixture fraction iso-surface also affects the edge flame speed but was usually not accounted for. Furthermore, to the best of the authors knowledge, the aforementioned numerical studies have mostly considered fuels such as methane, hydrogen, etc. but not compound fuels such as biogas. Thus, the effects of the uncertain combustion behaviours arising from the interaction of various amount of methane and \(\hbox {CO}_2\) on the ignition process and the subsequent edge flame propagation are yet to be analysed in detail.

In this work, the analysis of three-dimensional compressible DNS simulations have been carried out to investigate the influences of turbulence intensity and \(\hbox {CO}_2\) dilution on the localised forced ignition of inhomogeneous \(\hbox {CH}_4\)/\(\hbox {CO}_2\)/air mixing layers and subsequent flame propagation statistics in inhomogeneous mixtures. The effect of \(\hbox {CO}_2\) dilution on the reaction kinetics is accounted for by using a two-step chemical mechanism (Westbrook and Dryer 1981; Bibrzycki and Poinsot 2010), with an equilibrium between the oxidation of CO and the dissociation of \(\hbox {CO}_2\). The objectives of this work are thus to understand the effects of \(\hbox {CO}_2\) dilution and turbulence intensity on (i) the flame structure arising from the ignition of biogas mixtures and (ii) the edge flame speed statistics resulting from a successful ignition.

In the following sections, the mathematical background as well as the numerical database will be briefly presented [a more extensive presentation of the DNS database is provided in Turquand d’Auzay et al. (2019a)]. Subsequently, the temporal evolution, flame-turbulent interaction and edge flame speed statistics will be presented and discussed. Finally, the main findings will be summarised in the last section of this paper.

2 Thermo-chemistry and Ignition Modelling

In the case of a large parametric DNS analysis involving several parameters such as turbulence intensity, biogas composition and mixing layer thickness, it becomes impractical to carry out computations with detailed chemistry and a reduced mechanism must be sought. Furthermore, single-step chemistry is unable to capture the dilution effects on the flame speed and temperature as it can not account for the presence of carbon dioxide in the biogas. Thus, a two-step mechanism which accounts for the presence of both \(\hbox {CH}_4\) and \(\hbox {CO}_2\) is used (Westbrook and Dryer 1981). In this mechanism, the first step is responsible for the fuel oxidation, while the second accounts for the equilibrium between the CO oxidation and \(\hbox {CO}_2\) dissociation (see Table 1).

It is also worth mentioning that pioneering analytical studies on edge flames (Buckmaster 1996, 2002; Dold 1989; Hartley and Dold 1991; Ruetsch et al. 1995) have been conducted for single-step irreversible Arrhenius type chemistry. The findings of these studies have been found to be consistent with subsequent detailed chemistry DNS studies (Echekki and Chen 1998; Im and Chen 1999, 2001). Additionally, it has been found that the statistical behaviour of the edge flame displacement speed including its strain rate, curvature and scalar gradient dependences from single-step chemistry DNS (Chakraborty and Mastorakos 2006; Chakraborty et al. 2010; Hesse et al. 2009, 2012; Karami et al. 2015, 2016) was qualitatively consistent with both detailed chemistry DNS (Echekki and Chen 1998; Im and Chen 1999, 2001) and experimental findings (Chung 2007; Ko and Chung 1999; Heeger et al. 2009). The current study thus reaches a compromise by adopting a chemical mechanism that is more detailed in comparison with the previously mentioned single-step analyses, largely thanks to the addition of the \(\text {CO}_2 \rightleftharpoons 0.5 \text {O}_2 + \text {CO}\) reaction that allows for a better prediction of the flow expansion around the flame (Peters and Williams 1987).

The rate constants are expressed using an Arrhenius-type equation (Poinsot and Veynante 2005) that follows,

where \(A_j\) is the pre-exponential constant, \(\beta _j\) is the temperature exponent, \(E_{a,j}\) is the activation energy of the reaction and \(\hat{T}\) is the dimensional temperature. The reaction progress rates are then estimated with

where N is the number of species involved in reaction j and \(n_{lj}\) is the stoichiometric coefficient of species l in reaction j.

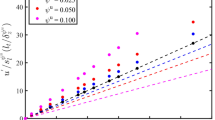

In order to accurately capture the laminar burning velocity across a wide range of equivalence ratio values, the modified Arrhenius coefficients presented by Bibrzycki and Poinsot (2010) are used and listed in Table 1. A pre-exponential adjustment (PEA) similar to the one proposed by Bibrzycki and Poinsot (2010) was also applied and tailored such that the laminar flame speed obtained for rich \(\hbox {CH}_4\)–air mixtures closely matches with the GRI-Mech 3.0 values (Smith et al. 2018) (see Fig. 1).

Following previous DNS studies of localised forced ignition of both inhomogeneous and homogeneous mixtures (Baum and Poinsot 1995; Chakraborty and Mastorakos 2006; Chakraborty et al. 2007; Patel and Chakraborty 2015, 2016; Turquand d’Auzay et al. 2019a), all the species are considered as calorically perfect gas with equal heat capacities at constant pressure (\(C_p\)). The species diffusion is accounted for using Fick’s law, while the transport coefficients such as viscosity (\(\mu\)), thermal conductivity (\(\lambda\)) and density weighted mass diffusivity (\(\rho D\)) are similar and independent of temperature for all species. Furthermore, the Lewis number of all species is constant and equal to unity.

The combustion of biogas can be represented by the following global equation,

where the diluent is taken as \(\hbox {CO}_2\) in this work. Following Galmiche et al. (2011), the biogas composition is defined using the dilution percentage \(\psi\) that represents the molar fraction of \(\hbox {CO}_2\) in the reactants,

An alternative definition of the biogas composition relies on the dilution percentage \(\psi _f\) that represents the molar fraction of the \(\hbox {CO}_2\) in the fuel blend (i.e. \(\hbox {CH}_4\) + \(\hbox {CO}_2\)), such that,

which is related to the first definition through \(\psi _f = 10.52 \psi / \left( 9.52 \psi + 1 \right)\).

Laminar flame speed for \(\hbox {CH}_4\)/\(\hbox {CO}_2\)/air mixtures computed with (lines) SENGA+ and (symbols) Cantera (a) for different biogas compositions and equivalence ratios compared to GRI 3.0 results and (b) for a stoichiometric mixture and different biogas compositions alongside the experimental data of Galmiche et al. (2011)

Figure 1 presents the unstrained laminar burning velocity of a \(\hbox {CH}_4\)/\(\hbox {CO}_2\)/air mixtures for different values of the dilution percentage and equivalence ratio normalised by the stoichiometric \(\hbox {CH}_4\)/air burning velocity \(s_l^0\). The results are compared with the reference data obtained with both GRI-Mech 3.0 (Smith et al. 2018) and the 2-step mechanism using Cantera (Goodwin et al. (2018)). For all equivalence ratios, the trend is correctly predicted by the current framework. However, the flame speed is slightly overestimated by the 2-step mechanism, especially around stoichiometry for diluted mixtures. A decrease in flame speed as \(\psi\) increases is visible for all equivalence ratios, confirming that the heat release and fuel consumption rates both decrease as \(\psi\) increases. Consequently, the burned gas temperature also decreases as \(\psi\) increases (not shown here). As \(\psi\) increases, the quantitative agreement between the laminar burning velocity predictions from the 2-step chemistry and the experimental (Galmiche et al. 2011) and detailed chemistry data (Smith et al. 2018) deteriorates, and this is found for all equivalence ratio values. It is clear that the over-prediction of the laminar burning velocity becomes dominant for \(\psi \geqslant 0.1\), leading to the choice of limiting the dilution to a maximum value of \(\psi _\text {max} = 0.05\) in this paper.

Furthermore, considering that the edge flame speed remains directly proportional to the laminar burning velocity of the stoichiometric mixture \(s_l^0\) (Ruetsch et al. 1995) as well as the accuracy of the present mechanism in capturing \(\hbox {CO}_2\) dilution effects (at least for \(\psi \leqslant 0.05\)), the qualitative nature of the edge flame speed statistics is expected to be correctly captured. Note that any inaccuracy in predicting the laminar flame speed would be reflected proportionally in the laminar edge flame speed (Ruetsch et al. 1995). However, the edge flame speed for turbulent flames normalised by the corresponding laminar edge flame speed is unlikely to be significantly affected by the choice of this 2-step chemical mechanism given the range of dilution considered here.

Within the range of dilution values considered in this work (\(\psi _\text {max} = 0.05\)), the theoretical maximum possible mass fraction of \(\hbox {CO}_2\) varies between 0.15 and 0.21 for \(\psi = 0\) and \(\psi = 0.05\) respectively, which is similar to what is found in the burned gas mixture of stoichiometric combustion of propane–air, methanol–air mixtures (Echekki and Chen 1998), etc. In practice, these values are likely to be lower due to the equilibrium between CO oxidation and \(\hbox {CO}_2\) dissociation. Given this moderate increase in \(\hbox {CO}_2\) mass fraction in the burned gas as well as the limited extent of the computational domain and the absence of walls, it is unlikely that the radiation effects would be of leading order. Note that this work presents one of the first DNS analysis of edge flame propagation for biogas-air (and more broadly compound) mixtures, and accordingly, simplifying assumptions have been made such as the absence of both radiation effects and soot formation. Finally, it is worthwhile to note that these assumptions are commonly adopted in edge flames studies, both analytical (Buckmaster 1996, 2002; Dold 1989; Hartley and Dold 1991; Ruetsch et al. 1995) and computational (Echekki and Chen 1998; Im et al. 1998; Im and Chen 1999; Karami et al. 2015, 2016; Krisman et al. 2017; Pantano 2004).

The mixture composition is locally described in terms of the mixture fraction \(\xi\) defined using Bilger’s definition (Bilger 1980) such that,

where \(\beta = 2 Y_C / W_C + 0.5 Y_H / W_H - Y_O / W_O\), with \(\beta _\text {ox}\) and \(\beta _\text {fu}\) being the value of \(\beta\) in the oxidiser and fuel streams respectively, \(Y_k\) and \(W_k\) denoting the atomic mass fractions and weights respectively. The stoichiometric mixture fraction value is thus expressed as \(\xi _\text {st} = - \beta _\text {ox} / ( \beta _\text {fu} - \beta _\text {ox} )\).

The extent of the chemical reactions completion is measured by a progress variable denoted c defined as a function of \(Y_{\text {CH}_4}\) such that,

where \(Y_{\text {CH}_4}^{\max } (\xi ) = \xi Y_{\text {CH}_4}^\infty\) is the maximum possible value of the \(\hbox {CH}_4\) mass fraction for a given value of \(\xi\), \(Y_{\text {CH}_4}\) and \(Y_{\text {CH}_4}^\infty\) are the local and pure fuel stream mass fractions of \(\hbox {CH}_4\) and \(Y_{\text {CH}_4}^\text {eq}\) is the local equilibrium fuel mass fraction that depends on the local value of \(\xi\).

The heat addition by the ignitor for the localised forced ignition is accounted for by the addition of a source term \(q'''\) to the energy equation. The source term follows a Gaussian distribution in the radial direction from the ignition point and is expressed as (Vázquez-Espí and Liñán 2001, 2002; Wandel 2014; Chakraborty and Mastorakos 2006; Chakraborty et al. 2007; Turquand d’Auzay et al. 2019a, b; Neophytou et al. 2010),

where r is the distance from the ignitor centre and \(R_\text {sp}\) is the characteristic width of the energy deposition. The constant \(A_\text {sp}\) is determined through the total ignition power \(\dot{Q}\) and a volume integration reading,

where \(a_\text {sp}\) is a parameter determining the total energy input, \(\tau = ( T_\text {ad}^0 - T_0 )/T_0\) is the heat release parameter (\(T_0\) and \(T_\text {ad}^0\) are the reactants and stoichiometric adiabatic \(\hbox {CH}_4\)/air flame temperatures respectively), \(\delta _z^0\) is the Zel’dovich flame thickness of the stoichiometric \(\hbox {CH}_4\)/air flame (\(\delta _z^0 = D_0 / s_l^0\) where \(D_0\) is the reactants mass diffusivity), and \(\mathcal {H}\) is an Heaviside function that ensures that the energy deposition ends at \(t = t_\text {sp}\). This duration is expressed as \(t_\text {sp} = b_\text {sp} t_f\) where \(b_\text {sp}\) is a parameter determining the energy deposition duration and \(t_f = \delta _z^0 / s_l^0\) is a characteristic chemical time scale. Experimental studies suggest \(0.2 \leqslant b_\text {sp} \leqslant 0.4\) for the optimum spark duration (Ballal and Lefebvre 1977).

3 Edge Flame Speed and Miscellaneous Definitions

Following Karami et al. (2015, 2016), the edge flame is defined as the intersection of a mixture fraction and a fuel mass fraction iso-surfaces. To measure the triple flame speed and statistics, it is necessary to define a new coordinate system attached to the edge flame that follows Karami et al. (2015, 2016) and is illustrated in Fig. 2.

The normal vector on the fuel mass fraction iso-surface pointing towards the reactants is denoted by \(\mathbf {N_y}\) while the normal vector on the mixture fraction iso-surface pointing towards the oxidiser is denoted by \(\mathbf {N_z}\). The vector \(\mathbf {T_1}\) is further defined as being the vector tangent to both the mixture fraction and fuel mass-fraction iso-surfaces, while \(\mathbf {T_2}\) is normal to \(\mathbf {T_1}\) pointing towards the reactants and tangent to the mixture fraction iso-surface.

These vectors are defined as follows,

In this coordinate system, the movement of the edge flame is directly related to the movements of the \(Y_\text {fu}\) and \(\xi\) iso-surfaces relative to the local flow. Thus, the mixture fraction iso-surface moves at a speed that is \(s_z \mathbf {N_z}\), while the fuel mass-fraction one moves with the speed \(s_d \mathbf {N_y}\), where the respective displacement speeds are (Karami et al. 2015, 2016; Chakraborty and Mastorakos 2006; Chakraborty et al. 2007; Hesse et al. 2009; Neophytou et al. 2010),

where \(\dot{\omega }_\text {fu}\) is the fuel reaction rate. Note that a positive value of \(s_d\) (\(s_z\)) indicates a propagation of the fuel mass fraction (mixture fraction) iso-surface towards the reactants (oxidiser), and vice versa.

The edge flame speed is defined as \(s_e = \mathbf {V_e} \cdot \mathbf {T_2}\), where \(\mathbf {V_e}\) is the overall velocity of the triple point and is written as \(\mathbf {V_e} = s_z \mathbf {N_z} + s_e \mathbf {T_2}\). The velocity \(s_e\) is thus the projection of \(\mathbf {V_e}\) in the plane of the mixture fraction iso-surface. By taking the dot product of the previous relation with \(\mathbf {N_y}\) and defining \(k = \mathbf {N_y} \cdot \mathbf {N_z}\) it may be shown that (Karami et al. 2015, 2016),

The edge flame speed can further be decomposed into two components arising respectively from the displacement speed of the mixture fraction and fuel mass fraction iso-surfaces such that \(s_e = s_d^+ + s_z^+\), where \(s_d^+ = s_d / \sqrt{1 - k^2}\) and \(s_z^+ = - k s_z / \sqrt{1 - k^2}\).

In this work, the edge flame will always refer to the intersection between the stoichiometric mixture fraction iso-surface and the reacting portion of the flame front selected such that all points of the edge flame will satisfy \(\xi = \xi _\text {st}\) and \(0.55 \leqslant c \leqslant 0.95\) (i.e. where the fuel reaction rate is non negligible).

Two parameters, the fuel mass fraction iso-surface curvature (\(\kappa _m\)) and the tangential strain rate acting on the fuel mass fraction iso-surface (\(a_T\)) are known to influence the edge flame speed propagation and are defined as follows,

4 Direct Numerical Simulation Database

The three-dimensional compressible DNS code SENGA+ (Jenkins and Cant 1999), in which the conservation equations for mass, momentum, species and energy are solved on a Cartesian grid with uniform cell size \(\Delta \text {x}\) has been used. The code employs a 10th-order central difference scheme for the internal points and the order of accuracy gradually decreases to a one-sided 2nd-order scheme at the non-periodic boundaries for the spatial differentiation. The time advancement is carried out using a 3rd-order low-storage Runge-Kutta scheme. The non-periodic boundary conditions are specified using the Navier-Stokes Characteristic Boundary Conditions (NSCBC) technique.

The computational domain is cubic with a size of \(67 \delta _z^0\) or \(9.25 l_t\) where \(l_t\) is the integral length scale, and discretised with \(360^3\) cells. This ensures 12 points across the thermal thickness of the stoichiometric \(\hbox {CH}_4\)/air laminar flame (\(\delta _\text {th}^0 = ( T_\text {ad}^0 - T_0 ) / \max ( | \nabla \hat{T} |_l )\)) but also that \(\eta _k / \Delta \text {x} \geqslant 1.2\), where \(\eta _k\) is the Kolmogorov length scale. The boundaries are periodic in the y and z-directions, and partially non-reflecting in the streamwise direction (x).

In this work, the oxidiser mass fraction in air is \(Y_{\text {O}_2}^\infty = 0.233\), while both \(Y_{\text {CH}_4}^\infty\) and \(\xi _\text {st}\) are function of \(\psi\) (\(Y_{\text {CH}_4}^\infty = 1.0, \, 0.574, \, 0.396\) and \(\xi _\text {st} = 0.055, \, 0.092, \, 0.128\) for \(\psi = 0.0, \, 0.025\) and 0.05 or \(\psi _f = 0.0, \, 0.212\) and 0.356 respectively). The initial mixing layer is initialised in the direction of inhomogeneity (taken as x-direction here) by imposing a mixture fraction profile consistent with the solution of the unsteady one-dimensional diffusion equation (Mastorakos et al. 1997),

where \(x_0\) is the location of the point with mixture fraction \(0.5 \xi _0\), \(\xi _0\) is the maximum value of the mixture fraction in the fuel stream and \(\delta _\theta\) denotes the characteristic width of the initial profile. Both \(x_0\), \(\xi _0\) and \(\delta _\theta\) are kept constant throughout the study, with \(\xi _0 / \xi _\text {st} = 2\), \(x_0/L = 0.5\) (where L is the computational domain length thus indicating that the stoichiometric mixture location is initially always positioned at \(x/L = 0.5\)) and \(\delta _\theta / \delta _z^0 = 10\). The initial profiles of \(\hbox {CH}_4\), \(\hbox {CO}_2\) and O\(_2\) are finally imposed using \(Y_{\text {CH}_4} = \xi Y_{\text {CH}_4}^\infty\), \(Y_{\text {CO}_2} = \xi ( 1 - Y_{\text {CH}_4}^\infty )\) and \(Y_{\text {O}_2} = ( 1- \xi ) Y_{\text {O}_2}^\infty\).

Standard values have been chosen for the Prandtl number (\(\text {Pr} = 0.7\)) and the ratio of specific heat (\(\gamma = 1.4\)). Although the heat capacity of \(\hbox {CO}_2\) is greater than that of N\(_2\) by about 40% at low temperature, they become equal when the temperature reaches about 600K. Thus, the mixture is preheated to \(T_0 = 590\)K leading to \(\tau = 3\), such that the error made by using the assumption of equal \(C_p\) for all species is reduced. Moreover, for higher temperature values, the difference of heat capacity between the two species is at most 6%, thus making any inaccuracies introduced using the assumption of constant \(C_p\) small. Furthermore, the mixture considered in this analysis are predominantly composed of N\(_2\), with \(Y_{\text {N}_2} \approx 0.55\) and \(Y_{\text {CO}_2} \approx 0.15\) in the pure fuel stream for the case with \(\psi = 0.05\), resulting in a mixture heat capacity close to that of N\(_2\). Thus, the assumption of constant and equal heat capacity can be used without compromising the accuracy of the simulations (this can also be seen on Fig. 1b, where the results of the 2-step mechanism using Cantera and temperature dependent heat capacities for all species are almost identical to those obtained with SENGA+).

The width, duration and power of the energy deposition are unaltered throughout the study and are taken to be \(R_\text {sp} / \delta _z^0 = 1.5\), \(b_\text {sp} = 0.2\) and \(a_\text {sp} = 3.5\), thus ensuring that at least thermal runaway occurs in all cases. The ignitor centre is positioned at the centre of the domain and thus always at \(\xi = \xi _\text {st}\) in mixture fraction space.

The flame turbulence interaction takes place under decaying isotropic homogeneous turbulence that is generated using Rogallos’s standard pseudo-spectral method (Rogallo 1981) with prescribed initial velocity fluctuations (\(u'\)) and integral length scale (\(l_t\)). The initial turbulence obeys the Batchelor-Towsend spectrum (Batchelor and Townsend 1949), with an integral length scale ratio of \(l_t / \delta _z^0 = 7.25\). Three values of the turbulence intensity have been considered here with \(u'/s_l^0 = 0.0, \, 4.0, \, 8.0\), which corresponds to \(u'/s_l^{0,\psi } = 0, \, 5.1, \, 10.2\) for \(\psi = 0.05\) respectively where \(s_l^{0,\psi }\) denotes the unstrained laminar burning velocity of the adiabatic stoichiometric \(\hbox {CH}_4\)/\(\hbox {CO}_2\)/air flame with dilution \(\psi\).

The simulations have been carried out until at least \(t / t_\text {sp} = t^+ = 10\) (where \(t^+\) provides a measure of time in terms of the chemical time-scale \(t_f\)), and up to \(t^+ = 20\) if it was unclear whether the flame kernel growth was already self-sustained or not.

The nine simulations considered in this analysis are referred to as follows, D00, D025 and D05 refer to \(\psi = 0.0, \, 0.025\) and 0.05 respectively, u00, u04 and u08 refer to initial \(u'/s_l^0 = 0.0, \, 4.0\) and 8.0 respectively, and thus D05u04 refers to the case with \(\psi = 0.05\) and initial \(u'/s_l^0 = 4.0\) and constitute a subset of the larger database presented in Turquand d’Auzay et al. (2019a).

5 Results and Discussion

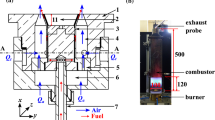

5.1 Effects of the Turbulence Intensity and \(\hbox {CO}_2\) Content on the Temporal Evolution

To understand the effects of both the turbulence intensity and biogas composition on the overall ignition performance, the temporal evolutions of the maximum non-dimensional temperature \(T_{\max }^+\) (where \(T^+ = ( \hat{T} - T_0 )/(T_\text {ad}^0 - T_0 )\)) and the volume defined by \(c \geqslant 0.9\) normalised by the energy deposition volume \(V_\text {sp} = ( 4/3 ) \pi R_\text {sp}^3\) are shown in Fig. 3.

The behaviour observed here agrees with earlier computational studies (Turquand d’Auzay et al. 2019b; Chakraborty and Mastorakos 2006; Chakraborty et al. 2007), with a rapid increase of the maximum temperature value during the energy deposition until it first reaches a value larger than the adiabatic temperature of the stoichiometric \(\hbox {CH}_4\)/air mixture (\(T^+ = 1\)) and then a maximum at \(t^+ = 1\). At \(1 \leqslant t^+ \leqslant 4\), the large thermal gradient present at the centre of the energy deposition region induces a large heat transfer rate to the cold reactants and leads to a rapid decrease of the maximum temperature. In case of successful propagation, \(T^+_{\max }\) stabilises to a value at most equal to the adiabatic flame temperature of the diluted stoichiometric mixture (\(T_\text {ad}^{0,\psi }\)). In the other cases, \(T^+_{\max }\) drops to a value too low to sustain combustion and the kernel eventually quenches (e.g. D05u08).

The temporal evolution of the burned gas volume is similar to what has been previously observed (Chakraborty et al. 2007), it decreases monotonically as \(u'/s_l^0\) increases. This is explained by an increase of the turbulent diffusivity (\(D_t \sim u' l_t\)) which alters the competition between the heat release and the thermal diffusion by increasing the latter. However, as the present work considers decaying turbulence, both the turbulent diffusivity and turbulent heat transfer rate decrease with time which results in an increasing growth rate. Consistent with the decrease of the laminar burning velocity shown in Fig. 1, the burned gas volume also decreases monotonically as \(\psi\) increases. Note that the difference is very small at early times as the growth is mainly driven by the very large temperature values (and thus very large flame speeds) found in the energy deposition region. The temporal evolution of \(V_{c \geqslant 0.9}/V_\text {sp}\) depends on the competition between the heat release due to combustion and the heat transfer from the hot gas kernel to the surrounding cold mixture, and the growth indicates that the former overcomes the latter. In the D05u04 and D00u08 cases, the heat transfer from the kernel supersedes the combustion heat release once the energy deposition effects have subsided (e.g. \(T^+_\text {max}\) decreases and converges towards the adiabatic flame temperature of the stoichiometric mixture). Consequently, a decrease in the burned gas volume can be observed, but as turbulence decays with time, so does the heat transfer to the surrounding mixture. The heat release rate from combustion is thus able to overcome again the heat transfer rate such that the kernel can resume its growth. In the most extreme cases, the shrinking of the kernel can also lead to a global quenching, which is indicated by the burned gas volume decreasing to zero (e.g. D05u08 and D025u08, whose evolution is not shown here for conciseness but follows that of D05u08).

Thus, both the turbulence and mixture composition strongly affect the flame kernel resulting from a thermal runaway. This is explained by the \(\hbox {CO}_2\) influence on the burning velocity and the heat release rate per unit flame area, while the turbulence affects both the flame surface area and the turbulent diffusivity. Hence the competition between the overall heat release (combined effect of the flame surface area and consumption rate per unit surface area) and the heat transfer rates is governed by both \(\psi\) and \(u'/s_l^0\) and ultimately decides on the success of the energy deposition.

5.2 Flame-Turbulence Interaction

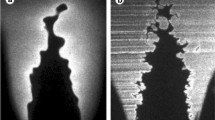

Before analysing the flame structure in more details, it is worthwhile to visualise its development in three-dimensions as to understand better the interplay between the mixture fraction and fuel mass fraction gradients (i.e. the mixture fraction and fuel mass fractions iso-surface curvatures and the scalar dissipation rate), as well as the topology of the edge flame. Figure 4 illustrates the temporal evolution of the kernel development by showing both the stoichiometric mixture fraction and \(T^+ = 0.6\) iso-surfaces for different turbulence intensities.

A triple flame is found along the intersection between these two iso-surface, that visibly drives the kernel growth under laminar conditions. For the case D00u00, the \(\xi = \xi _\text {st}\) iso-surface remains unchanged in time whereas the volume defined by the temperature iso-surface increases in time. The growth rate is particularly pronounced along the \(\xi = \xi _\text {st}\) iso-surface compared with the relatively limited expansion of the kernel in the direction of the mixture fraction gradient, where mixtures outside the flammability range are encountered. This highlights the key role played by the triple flame propagation in the kernel development.

Under turbulent conditions (i.e. cases D00u04 and D00u08), the \(\xi = \xi _\text {st}\) iso-surface gets significantly deformed and wrinkled by the fluid motion which visibly impedes the edge flame propagation and decreases the kernel growth rate. This is mostly due to the combined action of large mixture fraction and fuel mass fraction gradients and iso-surface curvature. The kernel shape is also significantly affected by the surrounding fluid motion and its shape increasingly departs from the laminar one as the value of \(u'/s_l^0\) increases. Similarly to the laminar conditions, the kernel develops more readily in slightly rich mixtures as evidenced by the absence of hot regions in the lean part of the domain at late times (e.g. D00u08 at \(t^+ = 21\)). Furthermore, the absence of intersection between the temperature and mixture fraction iso-surfaces indicates that the lean branch of the triple flame may have collapsed on the stoichiometric mixture fraction as reported by Buckmaster (1996).

Temporal evolution of the (blue) \(\xi = \xi _\text {st}\) and (red) \(T^+ = 0.6\) iso-surfaces for (top to bottom) D00u00, D00u04 and D00u08 cases at time (left to right) \(t^+ = 7, \, 14\) and 21. Note that the fuel-rich regions (\(\xi \geqslant \, \xi _\text {st}\)) are found for \(x^+ \leqslant 0\) while fuel-lean regions (\(\xi \leqslant \xi _\text {st}\)) are found for \(x^+ \geqslant \, 0\)

The dimensionless temperature (\(T^+\)), normalised fuel mass fraction (\(Y_{\text {CH}_4}^+ = Y_{\text {CH}_4} / ( 2 \xi _\text {st} Y_{\text {CH}_4}^\infty )\)) and normalised fuel reaction rate magnitude (\(\dot{\omega }_{\text {CH}_4}^+ = | \dot{\omega }_{\text {CH}_4} | / \max { | \dot{\omega }_{\text {CH}_4} |}\)) contours are shown in Fig. 5 for the laminar cases D00u00 and D05u00 at \(t^+ = 17.5\) in the xy mid-plane.

Contours of \(T^+\), \(Y_{\text {CH}_4}^+\) and \(\dot{\omega }_{\text {CH}_4}^+\) for cases D00u00 and D05u00 at \(t^+ = 17.5\) in the \(x^+-y^+\) mid-plane where \(x^+ = ( x - L/2 ) / \delta _z^0\) and \(y^+ = ( y - L/2 ) / \delta _z^0\). The white dash-dotted line denotes \(\xi = \xi _\text {st}\) location, and the arrows exemplarily illustrate the presence of some triple points

A triple flame structure at the stoichiometric mixture fraction iso-surface is visible for both D00u00 and D05u00 cases on Fig. 5. The fuel reaction rate magnitude appears larger around the stoichiometric mixture fraction iso-surface than towards the lean and rich sides. The peak is observed for slightly rich mixtures, which is consistent with the earlier findings of Fig. 1, while two premixed flames are visible on both the rich and lean sides of the diffusion flame stabilised on the \(\xi _\text {st}\) iso-surface. This finding is in good agreement with the observations previously reported by Ray et al. (2001) where using detailed chemistry simulations, the peak reaction rate magnitude was also observed for fuel-rich mixtures. The lean flame starts to extinguish along the symmetry axis, suggesting that mixtures whose mixture fraction is locally below the lean flammability limit are encountered.

Neither the shape nor the flame structure appear affected by the mixture composition, although as shown in Fig. 3, the growth rate is, which is also consistent with Fig. 1. Similarly, in the case where \(\hbox {CO}_2\) is present, the burned gas temperature has been found to be consistently lower than in the undiluted case, and this trend strengthens with increasing dilution.

Same as Fig. 5 for cases D00u04 and D05u04 at \(t^+ = 12.25\)

Figure 6 presents the contours of \(T^+\), \(Y_{\text {CH}_4}^+\) and \(\dot{\omega }_{\text {CH}_4}^+\) for the turbulent cases D00u04 and D05u04 at \(t^+ = 12.25\). The previous observations qualitatively hold, but as turbulent motions wrinkle the flame front, the kernel shape is significantly affected and deviates considerably from the laminar shape. Note that as the flames studied here are nominally in the thickened flame regime, instances of local thickening may be observed due to the penetration of energetic eddies into the preheat zone.

The amount of \(\hbox {CO}_2\) dilution does not qualitatively change these observations, although, similarly to the laminar cases, the kernel growth rate is smaller and the burned gas temperature decreases when \(\hbox {CO}_2\) is added to the mixture.

5.3 Edge Flame Speed PDF and Its Components

As shown in Figs. 4, 5 and 6, the presence of a triple-flame is evident following successful ignition. As the kernel growth rate is governed directly by the propagation of the triple point, it is instructive to analyse the effects of the \(\hbox {CO}_2\) dilution and turbulence intensity on the edge flame propagation behaviour. Following Ruetsch et al. (1995) and accounting for the presence of \(\hbox {CO}_2\) in the mixture, the theoretical laminar edge flame speed can be expressed as \(s_e^\psi = s_l^{0,\psi } \sqrt{ \rho _0 / \rho _b^{0,\psi }}\), where \(\rho _b^{0,\psi }\) is the burned gas density for the stoichiometric diluted mixture. By using the fact that \(\rho _b^{0,\psi } \sim \rho _0 / ( 1 + \tau ^\psi )\) in unity Lewis number adiabatic stoichiometric combustion (\(\tau ^\psi = ( T_\text {ad}^{0,\psi } - T_0 ) / T_0\)), one gets : \(s_e^\psi = s_l^{0,\psi } \sqrt{ 1 + \tau ^\psi }\).

The Probability Density Functions (PDFs) of \(s_e / s_e^\psi\) are shown in Fig. 7a for \(u'/s_l^0 = 4\) at different time instants, while the cases with \(u'/s_l^0 = 8\) behave qualitatively similarly. At early times, the most probable values of the edge flame speeds of both diluted and undiluted mixtures are greater than their respective theoretical limit due to the lasting effects of the energy deposition. As time progresses, the PDFs broaden and the probability of locally finding a negative value of the edge flame speed becomes non zero and increases with increasing \(\psi\). A peak near \(s_e^\psi / s_e \approx 1\) can still be observed for both dilution values which suggests that the edge flame propagates at a speed that is consistent with the theoretical estimates in the regions in which the conditions allow for its propagation.

The flame kernel shrinks and it fails to exhibit self-sustained propagation when the probability of finding a negative value of \(s_e\) becomes larger than the one of finding a positive one, i.e. when the mean edge flame speed \(\langle s_e \rangle\) becomes negative. Figure 7b presents the temporal evolution of \(\langle s_e \rangle\) for different cases. As seen previously, the mean value is initially very large but decays relatively fast to a value smaller than the theoretical limit at \(t^+ \approx 3\) at which point different behaviours can be observed. For low values of \(u'/s_l^0\), the mean value stabilises at a value slightly smaller than the theoretical limit, and this value decreases with \(\psi\). This is explained by the small size of the kernel in the diluted mixtures compared to that in undiluted ones, which increases the flame area to volume ratio which in turns acts to increase the heat transfer rate from the hot gas kernel compared to the undiluted mixture. As the dilution increases, \(\langle s_e \rangle\) also decreases and may assume negative values suggesting that the edge flame mostly retreats along the \(\xi _\text {st}\) surface (e.g. cases D05u04 and D05u08). As the turbulence level increases, \(\langle s_e \rangle / s_e^\psi\) appears consistently lower for the diluted cases than in the undiluted ones.

Figure 8 presents the decomposition of the edge flame speed into its different components, i.e. \(s_z^+\) and \(s_d^+\) for different cases. For laminar conditions (see Fig. 8a), the mixture fraction field remains almost unchanged which implies \(s_z \approx 0\), and in turn implies that \(s_e \approx s_d\). In the turbulent cases, the most probable value of the contribution arising from \(s_z^+\) remains close to 0.0. On the other hand, the most probable value of the \(s_d^+\) contribution corresponds to the theoretical limit of the edge flame speed (i.e. \(s_l^{0,\psi } \sqrt{ 1 + \tau ^\psi }\)), indicating that this surface propagates locally against the local flow field. Overall, the displacement of the \(\xi = \xi _\text {st}\) surface contributes only moderately but negatively to the edge flame speed as observed from the most probable value of the edge flame speed being smaller than the most probable value of the contribution arising from \(s_d^+\). The addition of \(\hbox {CO}_2\) does not qualitatively change these conclusions but its main effect appears to be the increase of the probability of finding negative values of \(s_d^+\), and to skew the PDFs of \(s_z^+\) towards the negative values. It can be noted that in cases where the mixture fraction surface has a velocity distribution with a non-zero mean along the edge flame, these conclusions might not hold entirely, and this is beyond the scope of the current investigation and thus will not be addressed further.

5.4 Local Curvature, Strain Rate and Scalar Gradient Dependence of the Edge Flame Speed

Finally, it is worthwhile to consider the influence of the biogas composition on the influence of strain rate, curvature and scalar gradients on the local behaviour of the edge flame speed \(s_e\). These statistics are presented in Figs. 9, 10 and 11 at \(t^+ = 1.75, \, 5.25\) and 8.75 to illustrate the time evolution at different stages after thermal runaway, i.e. shortly after the end of the energy deposition, in a transition state where the energy deposition effects may still be observable and after these effects have completely subsided, respectively.

As shown in Fig. 9a and similarly to previous studies on localised ignition of mixing layers (Chakraborty and Mastorakos 2006), the edge flame speed appears weakly correlated with \(|\nabla Y_\text {fu} |\) at early times, but the correlation strengthens with time. For large values of the gradient, i.e. \(|\nabla Y_\text {fu} |\times \delta _z^\psi / Y_{\text {fu}}^\infty \approx 0.35\), this correlation sign changes to negative while for both moderate and small values of \(|\nabla Y_\text {fu} |\) it remains positive. At \(t^+ = 5.25\), negative values of the edge flame speed are visible at low values of \(|\nabla Y_\text {fu} |\), but this tendency disappears later. This coincides with the time at which the triple flame structure is fully established following the decay of the thermal runaway effects induced by the localised ignition. It can indeed be observed from Fig. 3 that in the cases where a successful self-sustained kernel growth is obtained, for \(t^+ \geqslant 5\), \(T^+_\text {max}\) stabilises to a time independent value corresponding the stoichiometric adiabatic temperature of the diluted mixture. Small values of \(|\nabla Y_\text {fu} |\) in the progress variable range \(0.55 \leqslant c \leqslant 0.95\) at early stages of the flame kernel evolution imply a depletion of fuel due to high temperature, which in turn leads to negative values of \(s_e\) due to the contributions of \(s_z\) and the molecular diffusion component of \(s_d\). Once the edge flame structure is established beyond the period of influence of external energy deposition, the mean edge flame speed assumes positive values for all values of \(|\nabla Y_\text {fu} |\times \delta _z^\psi / Y_\text {fu}^\infty\). The addition of \(\hbox {CO}_2\) does not qualitatively affect these conclusions, especially at early times where \(\langle s_e \rangle _{|Y_\text {fu} |}\) is similar regardless of the value of \(\psi\). However, a difference arises in the value of \(|\nabla Y_\text {fu} |\times \delta _z^\psi / Y_\text {fu}^\infty\) at which the peak edge flame speed is found, which increases with \(\psi\). Furthermore, across most of the range of \(|\nabla Y_\text {fu} |\), the normalised mean edge flame speed decreases as \(\psi\) increases, which indicates potential long lasting effects of the stretch rate history. Indeed, without these long lasting effects caused by the increased curvature of the fuel mass fraction iso-surface as \(\psi\) increases, the normalised edge flame speed curves should collapse.

Figure 9b presents the mean value of \(s_e\) conditioned on \(|\nabla \xi |\). Following previous studies (Chakraborty and Mastorakos 2006), a similar non monotonic \(|\nabla \xi |\) dependence of \(s_e\) has been observed here. For the non-premixed mode of combustion, an increase of \(|\nabla Y_\text {fu} |\) acts to increase \(|\nabla \xi |\), whereas in the premixed mode, an increase of \(|\nabla Y_\text {fu} |\) may be associated with small values of \(|\nabla \xi |\). At early times, irrespective of the biogas composition, a weak negative correlation has been found between \(|\nabla \xi |\) and \(|\nabla Y_\text {fu} |\) for the cases with \(u'/s_l^0 = 4.0\), as visible in Fig. 10. Thus, the combination of positive \(s_e\) and \(|\nabla Y_\text {fu} |\) correlation and negative correlation between \(|\nabla \xi |\) and \(|\nabla Y_\text {fu} |\) leads to the negatively correlated branch of \(s_e\) and \(|\nabla \xi |\). However, at later times (i.e. \(t^+ \geqslant 8.0\)) and regardless of the dilution, the interdependence between \(|\nabla \xi |\) and \(|\nabla Y_\text {fu} |\) becomes non monotonic and shows a positively correlated branch (see Fig. 10). This eventually leads to a predominantly positive correlation between \(s_e\) and \(|\nabla \xi |\). Increasing the amount of \(\hbox {CO}_2\) in the fuel stream does not qualitatively change these correlations, however, for large values of \(|\nabla \xi |\times \delta _z^\psi / \xi _\text {st}\), the value \(\langle s_e \rangle _{|\nabla \xi |} / s_e^\psi\) remains identical irrespective of the \(\hbox {CO}_2\) dilution.

Finally, the edge flame speed dependence on the tangential strain rate and on the fuel mass fraction iso-surface curvature are shown in Fig. 11 for the cases D00u04 and D05u04. It is evident from Fig. 11a that \(s_e\) is mostly negatively correlated with the curvature of the fuel mass fraction iso-surface, and the strength of this correlation increases with time. At early times, the negative correlation is almost linear, albeit weak, while at a later time a positively correlated branch appears for moderately positive values of the curvature, which originates from the non-linear curvature \(\kappa _m\) dependence of the sum of the normal diffusion and reaction components of the fuel mass fraction displacement speed with \(\kappa _m\) as reported in previous studies (Chakraborty et al. 2010; Hesse et al. 2009, 2012). It can be noted that the mixture composition seems to have only a relatively minor effect on the mean value of \(s_e\) conditioned upon \(\kappa _m\) as all curves almost collapse onto a single one and this irrespective of the time.

Figure 11b presents the edge flame speed response to the strain rate tangential to the fuel mass fraction iso-surface, that exhibits a moderately positive correlation that becomes strongly non-monotonic for intermediate times before weakening considerably at later times, while the magnitude of \(a_T\) decreases monotonously. This decrease in magnitude of \(a_T\) is due to the decaying nature of the turbulent field in which the kernel develops. Note that this might be different in presence of a turbulence generating mechanism, e.g. mean shear, but this is beyond the scope of the current investigation. The strong non-linear \(a_T\) dependence of \(s_e\) is consistent with previous findings (Chakraborty et al. 2010; Hesse et al. 2009, 2012) in which this was attributed to the fuel mass fraction displacement speed components (reaction, tangential and normal diffusion) correlation trends with the tangential strain rate, whose relative strengths lead to the complex overall behaviour observed here. Long after the effects of the energy deposition have subsided (e.g. \(t^+ \geqslant 5\)), a strong effect of the mixture composition can be noted on the mean value of \(s_e\) conditioned upon \(a_T\), much larger than observed from the response of \(s_e\) to \(|\nabla \xi |\), \(|\nabla Y_\text {fu} |\) or \(\kappa _m\). This is particularly visible when the turbulence has not yet significantly decayed (\(t^+ \approx 5.25\)), where for small positive values of \(a_T\), the mean value of \(s_e\) decreases strongly as \(\psi\) increases. On the contrary, for large values of \(a_T\), larger mean edge flame speed are obtained as \(\psi\) increases (within the considered range). This stronger influence of the mixture composition appears directly linked to the larger curvature found for the diluted mixture. Indeed, a negative correlation between the tangential strain rate and the fuel mass fraction curvature has been observed previously both experimentally (Renou et al. 1998) and numerically (Chakraborty and Cant 2004; Chakraborty 2007; Klein et al. 2006). This negative correlation is compounded here by the strong heat sink effect of added \(\hbox {CO}_2\) due to the chemical heat release. Thus, the edge flame develops in regions with high positive values of \(\kappa _m\) leading to small values of the tangential strain rate as \(\psi\) increases. This in turn leads to a smaller edge flame speed due to the positive correlation between \(s_e\) and \(a_T\) existing at all times for small values of \(a_T\) as shown in Fig. 11b. This difference in strain rate history during the kernel development directly leads to a decreasing mean edge flame speed with dilution at late times, even in the laminar case as observed in Fig. 7b where the mean edge flame speed was smaller than its theoretical estimate.

The findings regarding the edge flame speed statistics gathered from Figs. 7, 8, 9, 10 and 11 indicate that as the qualitative nature of the edge flame propagation does not change with the addition of \(\hbox {CO}_2\), the combustion models developed for conventional fuels (e.g. \(\hbox {CH}_4\)/air mixtures) are likely to hold in the case of partially-premixed biogas/air turbulent combustion.

6 Conclusions

The expected increase in the use of biogas (\(\hbox {CH}_4\)/\(\hbox {CO}_2\)/air) in engineering applications requires a thorough understanding of the uncertain combustion behaviour stemming from the interaction between \(\hbox {CH}_4\) and \(\hbox {CO}_2\). Of particular interests are the onset of combustion and the subsequent flame propagation in partially-premixed mixtures for which previous studies have shown the presence of a triple flame (edge flame) structure. To this end, three-dimensional Direct Numerical Simulations of an igniting unsteady statistically planar biogas/air mixing layer have been used to investigate the effects of the fuel composition on the ignition success and on the edge flame behaviour. The ignition is represented by a Gaussian source term in the energy equation, while a two-step mechanism accounting for the effects of \(\hbox {CO}_2\) dilution on the unstrained laminar flame speed has been used.

The ignition and propagation behaviours of \(\hbox {CH}_4\)/\(\hbox {CO}_2\)/air mixtures were found qualitatively consistent with that of previous \(\hbox {CH}_4\)/air studies in terms of the responses to the variations of turbulence intensity, mixture fraction gradient magnitude, etc. After the energy deposition, the biogas composition has a significant influence on the kernel growth rate, that is, an increase in dilution leads to a smaller growth rate, which negatively affects the propagation success and may lead to flame quenching depending on the turbulent conditions.

The kernel growth rate is driven by the propagation of an edge flame along the stoichiometric mixture fraction surface, and this behaviour is observed in all cases irrespective of the amount of \(\hbox {CO}_2\) dilution. The speed at which this edge flame propagates along the mixture fraction surface and its dependence on the scalar gradients have been analysed in detail. It has been shown that in the cases in which self-sustained propagation was achieved, the most probable value of the edge flame speed was at most equal to its theoretical limit, but in the presence of \(\hbox {CO}_2\), a value smaller than the theoretical limit has been obtained. The mixture fraction displacement speed component of the edge flame speed was found to contribute negatively albeit almost negligibly to the overall edge flame speed, while the dominant propagation mode arises due to the displacement speed of the fuel mass fraction iso-surface irrespective of the turbulence intensity or mixture composition.

Finally, the current analysis focused on the effects of \(\hbox {CO}_2\) dilution on the scalar gradient, curvature and strain rate dependences of the edge flame speed statistics. It was found that, within the range of parameters considered here, the findings previously reported by Chakraborty and co-workers (Chakraborty and Mastorakos 2006; Hesse et al. 2009) were not qualitatively affected by the presence of \(\hbox {CO}_2\). This leads to the main conclusion that combustion models developed for conventional fuels (e.g. \(\hbox {CH}_4\)/air mixtures) are likely to hold in the case of partially-premixed biogas/air turbulent combustion, provided that the dilution effects on the laminar burning velocity and adiabatic flame temperature are correctly accounted for. However, it should be noted that this analysis being one of the first focusing on the effects of \(\hbox {CO}_2\) dilution on the edge flame statistics, simplifying assumptions had to be made related to the chemical mechanism, transport properties and soot/radiation effects in the interest of a detailed parametric analysis. Therefore, further analyses including the effects of detailed chemistry, transport and soot/radiation effects will be needed for a more comprehensive fundamental understanding.

References

Ballal, D.R., Lefebvre, A.H.: Spark ignition of turbulent flowing gases. In: 15th Aerospace Sciences Meeting, vol. 155, AIAA, Reston, Virginia, pp. 129–155 (1977). https://doi.org/10.2514/6.1977-185

Batchelor, G.K., Townsend, A.A.: The nature of turbulent motion at large wave-numbers. Proc. R. Soc. A Math. Phys. Eng. Sci. 199(1057), 238–255 (1949)

Baum, M., Poinsot, T.: Effects of mean flow on premixed flame ignition. Combust. Sci. Technol. 106(1–3), 19–39 (1995)

Bibrzycki, J., Poinsot, T.: Reduced chemical kinetic mechanisms for methane combustion in O2/N2 and O2/CO2 atmosphere. Work. note ECCOMET WN/CFD/10/17, CERFACS (2010)

Biet, J., Ndem, M., Idir, M., Chaumeix, N.: Ignition by electric spark and by laser-induced spark of ultra-lean CH 4/air and CH4/CO2/air mixtures at high pressure. Combust. Sci. Technol. 186(1), 1–23 (2014)

Bilger, R.: Turbulent flows with nonpremixed reactants. In: Libby, P., Williams, F. (eds.) Turbulent Reacting Flows, Topics in Applied Physics, vol. 44, pp. 65–113. Springer, Berlin (1980)

Buckmaster, J.: Edge-flames and their stability. Combust. Sci. Technol. 115(1–3), 41–68 (1996)

Buckmaster, J.: Edge-flames. Prog. Energy Combust. Sci. 28(5), 435–475 (2002)

Chakraborty, N.: Comparison of displacement speed statistics of turbulent premixed flames in the regimes representing combustion in corrugated flamelets and thin reaction zones. Phys. Fluids 19(10), 1–20 (2007)

Chakraborty, N., Cant, R.S.: Unsteady effects of strain rate and curvature on turbulent premixed flames in an inflow-outflow configuration. Combust. Flame 137(1–2), 129–147 (2004)

Chakraborty, N., Mastorakos, E.: Numerical investigation of edge flame propagation characteristics in turbulent mixing layers. Phys. Fluids 18(10), 1–18 (2006)

Chakraborty, N., Mastorakos, E., Cant, R.S.: Effects of turbulence on spark ignition in inhomogeneous mixtures: A direct numerical simulation (DNS) study. Combust. Sci. Technol. 179(1–2), 293–317 (2007)

Chakraborty, N., Hesse, H., Mastorakos, E.: Numerical investigation of edge flame propagation behavior in an igniting turbulent planar jet. Combust. Sci. Technol. 182, 1747–1781 (2010)

Chung, S.H.: Stabilization, propagation and instability of tribrachial triple flames. Proc. Combust. Inst. 31, 877–892 (2007)

Dold, J.: Flame propagation in a nonuniform mixture: analysis of a slowly varying Triple Flame. Combust. Flame 76(1), 71–88 (1989)

Domingo, P., Vervisch, L.: Triple flames and partially premixed combustion in autoignition of non-premixed turbulent mixtures. Symp. Combust. 26(1), 233–240 (1996)

Echekki, T., Chen, J.H.: Structure and propagation of methanol-air triple flames. Combust. Flame 114(1–2), 231–245 (1998)

Forsich, C., Lackner, M., Winter, F., Kopecek, H., Wintner, E.: Characterization of laser-induced ignition of biogas-air mixtures. Biomass Bioenergy 27(3), 299–312 (2004)

Galmiche, B., Halter, F., Foucher, F., Dagaut, P.: Effects of dilution on laminar burning velocity of premixed methane/air flames. Energy Fuels 25(3), 948–954 (2011)

Goodwin, D.G., Moffat, H.K., Speth, R.L.: Cantera: An object-oriented software toolkit for chemical kinetics, thermodynamics, and transport processes, Version 2.4.0 (2018). http://www.cantera.org. https://doi.org/10.5281/zenodo.1174508

Hartley, L.J., Dold, J.: Flame propagation in a nonuniform mixture: analysis of a propagating triple-flame. Combust. Sci. Technol. 80(1–3), 23–46 (1991)

Heeger, C., Böhm, B., Ahmed, S.F., Gordon, R., Boxx, I., Meier, W., Dreizler, A., Mastorakos, E.: Statistics of relative and absolute velocities of turbulent non-premixed edge flames following spark ignition. Proc. Combust. Inst. 32(2), 2957–2964 (2009)

Hesse, H., Chakraborty, N., Mastorakos, E.: The effects of the Lewis number of the fuel on the displacement speed of edge flames in igniting turbulent mixing layers. Proc. Combust. Inst. 32, 1399–1407 (2009)

Hesse, H., Malkeson, S.P., Chakraborty, N.: Displacement speed statistics for stratified mixture combustion in an igniting turbulent planar jet. J. Eng. Gas Turbines Power 134(5) (2012)

Im, H.G., Chen, J.H.: Structure and propagation of triple flames in partially premixed hydrogen-air mixtures. Combust. Flame 119(4), 436–454 (1999)

Im, H.G., Chen, J.H.: Effects of flow strain on triple flame propagation. Combust. Flame 126(1–2), 1384–1392 (2001)

Im, H.G., Chen, J.H., Law, C.K.: Igintion of hydrogen-air mixing layer in turbulent flows. In: Twenty-Seventh Symposium on Combustion, pp. 1047–1056 (1998)

Jenkins, K.W., Cant, R.S.: Direct numerical simulation of turbulent flame kernels. In: Proceedings of Second AFOSR Conference on DNS LES, pp. 191–202 (1999). https://doi.org/10.1007/978-94-011-4513-8_17

Jiménez, C., Cuenot, B.: DNS study of stabilization of turbulent triple flames by hot gases. Proc. Combust. Inst. 31(1), 1649–1656 (2007)

Karami, S., Hawkes, E.R., Talei, M., Chen, J.H.: Mechanisms of flame stabilisation at low lifted height in a turbulent lifted slot-jet flame. J. Fluid Mech. 777, 633–689 (2015)

Karami, S., Hawkes, E.R., Talei, M., Chen, J.H.: Edge flame structure in a turbulent lifted flame: a direct numerical simulation study. Combust. Flame 169, 110–128 (2016)

Klein, M., Chakraborty, N., Jenkins, K.W., Cant, R.S.: Effects of initial radius on the propagation of premixed flame kernels in a turbulent environment. Phys. Fluids 18(5), 055102 (2006)

Ko, Y.S., Chung, S.H.: Propagation of unsteady tribrachial flames in laminar non-premixed jets. Combust. Flame 118(1–2), 151–163 (1999)

Krisman, A., Hawkes, E.R., Chen, J.H.: Two-stage autoignition and edge flames in a high pressure turbulent jet. J. Fluid Mech. 824, 5–41 (2017)

Lafay, Y., Taupin, B., Martins, G., Cabot, G., Renou, B., Boukhalfa, A.M.: Experimental study of biogas combustion using a gas turbine configuration. Exp. Fluids 43(2–3), 395–410 (2007)

Lefebvre, A.H., Ballal, D.R.: Gas Turbine Combustion: Alternative Fuels and Emissions, 3rd edn. CRC Press, Boca Raton (2010)

Lieuwen, T., McDonell, V., Petersen, E., Santavicca, D.: Fuel flexibility influences on premixed combustor blowout, flashback, autoignition, and stability. J. Eng. Gas Turbines Power 130(1), 011506 (2008)

Mastorakos, E.: Ignition of turbulent non-premixed flames. Prog. Energy Combust. Sci. 35(1), 57–97 (2009)

Mastorakos, E.: Forced ignition of turbulent spray flames. Proc. Combust. Inst. 36(2), 2367–2383 (2017)

Mastorakos, E., Baritaud, T.A., Poinsot, T.: Numerical simulations of autoignition in turbulent mixing flows. Combust. Flame 109(1–2), 198–223 (1997)

Mordaunt, C.J., Pierce, W.C.: Design and preliminary results of an atmospheric-pressure model gas turbine combustor utilizing varying CO2 doping concentration in CH4 to emulate biogas combustion. Fuel 124, 258–268 (2014)

Mulla, I.A., Chakravarthy, S.R., Swaminathan, N., Balachandran, R.: Evolution of flame-kernel in laser-induced spark ignited mixtures: a parametric study. Combust. Flame 164, 303–318 (2016)

Neophytou, A., Mastorakos, E., Cant, R.S.: DNS of spark ignition and edge flame propagation in turbulent droplet-laden mixing layers. Combust. Flame 157(6), 1071–1086 (2010)

Pantano, C.: Direct simulation of non-premixed flame extinction in a methane - air jet with reduced chemistry. J. Fluid Mech. 514, 231–270 (2004)

Patel, D., Chakraborty, N.: Effects of energy deposition characteristics on localised forced ignition of homogeneous mixtures. Int. J. Spray Combust. Dyn. 7(2), 151–174 (2015)

Patel, D., Chakraborty, N.: Effects of mixture distribution on localized forced ignition of stratified mixtures: a direct numerical simulation study. Combust. Sci. Technol. 188(11–12), 1904–1924 (2016)

Peters, N., Williams, F.: The asymptotic structure of stoichiometric methane-air flames. Combust. Flame 68(2), 185–207 (1987)

Poinsot, T., Veynante, D.: Theoretical and Numerical Combustion, 2nd edn. Edwards, London (2005)

Ray, J., Najm, H.N., Mccoy, R.B.: Ignition front structure in a methane-air jet. In: The Joint Meeting of the US Sections of the Combustion Institute, pp. 1–15 (2001)

Renou, B., Boukhalfa, A.M., Puechberty, D., Trinité, M.: Effects of stretch on the local structure of freely propagating premixed low-turbulent flames with various Lewis numbers. Symp. Combust. 27(1), 841–847 (1998)

Richardson, E.S., Mastorakos, E.: Numerical investigation of forced ignition in Laminar counterflow non-premixed methane-air flames. Combust. Sci. Technol. 179(1–2), 21–37 (2007)

Rogallo, R.S.: Numerical experiments in homogeneous turbulence. Technical Report, NASA Ames (1981)

Ruan, S., Swaminathan, N., Bray, K.N., Mizobuchi, Y., Takeno, T.: Scalar and its dissipation in the near field of turbulent lifted jet flame. Combust. Flame 159(2), 591–608 (2012)

Ruetsch, G.R., Vervisch, L., Liñán, A.: Effects of heat release on triple flames. Phys. Fluids 7(6), 1447–1454 (1995)

Smith, G., Golden, D., Frenklach, M., Moriarty, N., Eiteneer, B., Goldenberg, M., Bowman, C., Hanson, R., Song, S., Gardiner, W., Lissianski, V., Qin, Z.: Gri-Mech 3.0. http://www.me.berkeley.edu/gri-mech/version30/text30.html (2000). Accessed 25 Feb (2018)

Takita, K., Sakaguchi, S., Masuya, G.: Premixed edge flame in a counterflow field with a stretch rate gradient. Combust. Flame 132(3), 343–351 (2003)

Takita, K., Sado, M., Masuya, G., Sakaguchi, S.: Experimental study of premixed single edge-flame in a counterflow field. Combust. Flame 136(3), 364–370 (2004)

Turquand d’Auzay, C., Chakraborty, N.: The localised forced ignition and early stages of flame development in a turbulent planar jet. In: Proceedings of Combustion Institute (2021)

Turquand d’Auzay, C., Papapostolou, V., Ahmed, S.F., Chakraborty, N.: Effects of turbulence intensity and biogas con the localized forced ignition of turbulent mixing layers. Combust. Sci. Technol. 191(5–6), 868–897 (2019a)

Turquand d’Auzay, C., Papapostolou, V., Ahmed, S.F., Chakraborty, N.: On the minimum ignition energy and its transition in the localised forced ignition of turbulent homogeneous mixtures. Combust. Flame 201, 104–117 (2019b)

Vasavan, A., de Goey, P., van Oijen, J.: Numerical study on the autoignition of biogas in moderate or intense low oxygen dilution nonpremixed combustion systems. Energy Fuels 32(8), 8768–8780 (2018)

Vázquez-Espí, C., Liñán, A.: Fast, non-diffusive ignition of a gaseous reacting mixture subject to a point energy source. Combust. Theory Model. 5(3), 485–498 (2001)

Vázquez-Espí, C., Liñán, A.: Thermal-diffusive ignition and flame initiation by a local energy source. Combust. Theory Model. 6(2), 297–315 (2002)

Wandel, A.P.: Influence of scalar dissipation on flame success in turbulent sprays with spark ignition. Combust. Flame 161(10), 2579–2600 (2014)

Westbrook, C.K., Dryer, F.L.: Simplified Reaction Mechanisms for the Oxidation of Hydrocarbon Fuels in Flames. Combust. Sci. Technol. 27(1–2), 31–43 (1981)

Won, S.H., Kim, J., Hong, K.J., Cha, M.S., Chung, S.H.: Stabilization mechanism of lifted flame edge in the near field of coflow jets for diluted methane. Proc. Combust. Inst. 30(1), 339–347 (2005)

Yoo, C.S., Im, H.G.: Transient dynamics of edge flames in a laminar nonpremixed hydrogen-air counterflow. Proc. Combust. Inst. 30(1), 349–356 (2005)

Acknowledgements

The authors are grateful to the British Council for financial support and to EPSRC (ARCHER, Cirrus) and Newcastle University (Rocket) for computational support

Funding

The work was supported by the British Council (Newton Grant).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Turquand d’Auzay, C., Papapostolou, V. & Chakraborty, N. Effects of Biogas Composition on the Edge Flame Propagation in Igniting Turbulent Mixing Layers. Flow Turbulence Combust 106, 1437–1459 (2021). https://doi.org/10.1007/s10494-020-00210-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10494-020-00210-5