Abstract

The surge of e-commerce has revolutionized distribution channels, escalating from simple single-channel frameworks to complex multi-channel and omni-channel networks. In particular developments in information technology and rising customer expectations have popularized the transition from multi- to omni-channel distribution, where the classic brick-and-mortar stores can also be part of the omni-channel distribution strategy. This evolution poses intricate challenges for manufacturers, especially in the integration and optimization of these channels. Thus, there is a strong need for an in-depth analysis of how manufacturers navigate the transition across diverse distribution channels to meet the varying needs of different customer segments. To this end, we investigate single-, multi-, and omni-channel distribution strategies for the case of a manufacturer selling both standard and customized products to different customer segments with varying preferences. A central contribution of this research is the creation of an integrated optimization model that resolves a location-routing problem, designing a complex and realistic supply chain configuration suitable for an omni-channel distribution system. This model strategically serves to fragmented customer demands through multiple shopping and delivery options. The outcomes of our study indicate that an omni-channel distribution system is a viable approach, capable of serving more customer segments while simultaneously minimizing logistics costs. In addition, we offer a detailed analysis of the cost implications of in-store pickup versus home-delivery options, providing a comprehensive evaluation of their respective impacts on total logistics costs and customer responsiveness.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The significance of e-commerce is escalating quickly in today’s economy. According to Statista, global online retail revenues achieved a milestone of $4.89 trillion in 2021, with expectations to climb to $6.39 trillion by 2024 (Worldwide eMarketer, Statista 2021). The rise of e-commerce has transformed distribution models, evolving from straightforward single-channel (SC) structures to intricate multi-channel (MC) and omni-channel (OC) systems (Abhishek et al., 2015; Cattani et al., 2006; Ryan et al., 2013). In MC settings, the manufacturer adopts an entirely owned direct sales channel (i.e., a physical or online channel) in addition to its existing independently owned retailers. This allows the manufacturer to compete with the retailer by adding a direct channel. In the literature, this practice is referred to as manufacturer encroachment (Arya et al., 2007; Tahirov & Glock, 2022). Meanwhile, OC systems include the synergetic management of multiple available channels and customer touchpoints to provide a flexible shopping experience to customers (Verhoef et al., 2015).

The channel transition poses new strategic, tactical, and operational challenges for manufacturers, especially in the integration and optimization of these channels (Ailawadi & Farris, 2017; Hübner et al., 2016a, 2016b). For example, starting a new distribution channel or a fulfilment center involves a location decision and is, therefore, a strategic decision; in contrast, the effective management of the emerging channel conflicts between a manufacturer and a retailer (i.e., after encroachment) is a tactical decision (Coughlan et al., 2014). Operational issues are related to ordering, fulfilment, inventory, and logistics decisions, and they need to be handled efficiently.

In the face of rapidly changing consumer expectations and the growing e-commerce landscape, it is essential for manufacturers to address these challenges. Effective management and integration of distribution channels are imperative for manufacturers to increase market share, reach customers, and improve service while maintaining cost-effectiveness (Arya et al., 2007; Cattani et al., 2006; Chopra, 2018; Gao et al., 2020). However, there is a lack of research addressing the mentioned managerial challenges, especially from a manufacturer’s perspective as they transition between different distribution channels.

Our research is inspired by the essential demand for a comprehensive investigation into the variety of managerial decisions surrounding channel transitions and the subsequent effects of these decisions on a manufacturer’s operational processes. The study seeks to answer the following key questions:

-

1.

How do manufacturers configure their distribution channels to meet the demands of various customer segments?

-

2.

How do manufacturers evaluate and select the most cost-effective distribution channels?

From a modelling perspective, the formulation of an omni-channel (OC) distribution network presents a greater level of complexity when compared to single-channel and multi-channel configurations. Our primary objective is to construct a comprehensive model for the manufacturer’s OC distribution system. This model will integrate both routing and location decisions while accounting for the diverse shopping preferences of customers.Footnote 1 In the operations research literature, location and routing decisions are jointly investigated in the location-routing problem (LRP). In this research field, the three types of decisions (strategic, tactical, and operational) are not investigated simultaneously in the context of channel transitions. Furthermore, in the related literature, only a few studies (e.g., Aksen et al., 2008; Janjevic et al., 2020) report on the granularity of customer demand (i.e., segmented customers and their preferences for various product types) and OC distribution systems (i.e., multiple shopping and pickup options), which leads to several opportunities in this research stream. In this respect, central to our study is the next critical question that is of substantial importance:

-

3.

How do manufacturers’ location and routing choices impact their channel strategies and operational efficiency in meeting diverse customer demands within an omnichannel distribution system?

Given the paucity of existing literature, we propose an integrated optimization model that includes an LRP for the design of a combined two-echelon supply chain for an OC distribution system with fragmented customer demand met over multiple shopping and delivery options. To expand our investigation, we incorporate customer responsiveness, a crucial aspect for decision-makers striving to remain competitive, in our model. Additionally, to tackle more realistic scenarios, we have formulated an efficient solution approach. The work in hand contributes to the literature by.

-

Analyzing the manufacturer’s three (SC, MC, and OC) distribution network design choices through the lens of the attendant location and routing decisions.

-

Exploring the effect of the number of open locations and in-store pickup options on channel decisions.

-

Developing a decomposition solution method for the omni-channel LRP to solve large-scale instances efficiently.

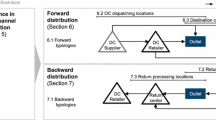

The remainder of this paper is organized as follows. Section 2 discusses the related literature and defines the research gap addressed in this study. Section 3 outlines the formal problem description, and Sect. 4 presents the model formulations. In Sect. 5, we present the computational complexity of the proposed model and solution methods. The computational study is described in Sect. 6. In Sect. 7, we extend the proposed model and conduct additional analyses. Finally, Sect. 8 concludes the paper.

2 Background and literature

We draw on and contribute to three research streams to establish our study: (I) manufacturer encroachment and channel strategy, (II) omni-channel operations, and (III) the capacitated location-routing problem (CLRP).

2.1 Manufacturer encroachment and channel strategy

Manufacturers vend their products through intermediaries such as wholesalers and retailers; however, in practice, many manufacturers (e.g., Apple and Nike) also act as retailers and sell products directly to end customers through their physical stores (outlets) or online channels. Developments in information technology have triggered manufacturers to adopt wholly owned direct sales (online) channels in addition to their existing conventional (offline) channels. This channel selection decision can lead to competition between manufacturers and retailers; this type of competition is referred to as manufacturer encroachment (Arya et al., 2007).

A recent systematic review of manufacturer encroachment by Tahirov and Glock (2022) reported that the manufacturer’s channel selection process comprises two phases: (I) developing multi-channel strategies and (II) managing the (multiple) channels. For the first phase, the authors outline the major determinant factors (e.g., customer preference, information asymmetry, and market environment) that force the manufacturer to adopt a direct sales channel; customer preference is identified as the most important factor that plays a significant role in the channel design of our work. With respect to the second phase, the authors present major tactical (e.g., pricing, coordination and product differentiation) and operational decisions (e.g., inventory, delivery, and assortment) made by the manufacturer while managing multi-channel distribution systems. Within the literature on manufacturer encroachment, a large body of research addresses tactical issues under the “dual-channel supply chain” topic, wherein the studies primarily investigate either an efficient pricing strategy, a coordination mechanism, or both, using game-theoretic models. Chiang et al., (2003) studied a scenario in which the manufacturer is the Stackelberg leader and sets wholesale and direct channel prices by considering a customer acceptance (preference) parameter for the direct channel. The authors showed that a desired equilibrium for both parties can be reached, for a given customer acceptance parameter where the manufacturer uses the direct channel as a strategic tool for threatening the retailer with cannibalization. This strategy encourages the retailer to reduce its price, which leads to a sales uplift at the retailer, and the manufacturer’s profit can increase indirectly. Tsay et al., (2004) suggested that adding a direct channel can improve the overall efficiency of a dual-channel distribution system when the manufacturer adjusts the wholesale price as a game leader. The authors proposed two mechanisms: referral to direct (i.e., the retailer functions as a showroom and receives commission for diverting) and referral to reseller (i.e., the retailer fulfills the entire demand) that decrease the operational costs for both parties. Arya et al., (2007) investigated a model in which the wholesale price is first established by the manufacturer, and then, the retailer decides on the optimal order quantity. The authors suggest that manufacturer encroachment can help both parties if the manufacturer decreases the wholesale price significantly, and if the retailer provides high-level retail services.

Besides the pricing strategy, product differentiation is another powerful mechanism to handle channel conflicts between manufacturers and retailers, and it has been investigated both analytically (Cao et al., 2010; Ha et al., 2016; Li et al., 2018; Raza et al., 2019) and empirically (Vinhas et al., 2005; Du et al., 2018). A manufacturer can increase its profit if it can sell products with different characteristics, e.g., in terms of quality, functionality, or product complementarity, to different customer segments. For example, Dell offers its consumers the ability to configure a computer (i.e., customized product) on the company website before ordering (Rodríguez et al., 2015). This was another motivation for considering multiple products in our study. Cao et al., (2010) studied a scenario in which two competing manufacturers open their own retail stores in addition to those of existing independent retailers by considering demand uncertainty, product substitution, and market share. Their findings indicated that the manufacturers’ profits increase if they use a dual-channel configuration with higher demand uncertainty and low product substitutability (which occurs for products with many design attributes). The authors also suggested that manufacturers tend to distribute staple products over an indirect channel because they are highly substitutable and have a low level of demand uncertainty. Based on the case reported by Raza et al., (2019), a single manufacturer can sell a standard product over a direct channel and a green product through a retail channel at various prices. Their proposed model aims to find the optimal values of selling and product differentiation price, greening effort (investment), and inventory level while assuming that the manufacturer and retailer are risk averse. The findings indicate that selling products at different prices diminishes demand cannibalization between channels and leads to revenue growth for the two parties. Du et al., (2018) supported analytical research by conducting an empirical study (at Haier, a Chinese appliance company) wherein selling identical products through both online and offline channels causes channel conflicts and a price war between manufacturers and retailers. The company follows a differentiation strategy and sells customized products through an online channel and standard products through retail stores to ensure that both parties are better off.

2.2 Omni-channel operations

The definition and evolution of omni-channel operations have been addressed from various aspects such inventory replenishment strategies, delivery lead time, or routing, in the extant literature (Risberg, 2022). Yet, most of the studies investigated omni-channel operations (i.e., omni-channel retailing) from a retailer perspective. Goedhart et al., (2022), for instance, studied the challenges retailers face in replenishing and allocating inventories across different channels, particularly focusing on a brick-and-mortar store fulfilling both in-store and online orders. They proposed both a precise method and problem-specific heuristics for inventory replenishment and rationing specifically tailored for omni-channel retail environments. The work of Paul et al., (2019a, 2019b) investigated the potential of leveraging spare capacity in vehicles that replenish store inventories to minimize online order fulfillment costs. The novelty of their work is the development of a MILP model and an efficient heuristic to address the capacitated vehicle routing associated with this capacity sharing strategy. Momen and Torabi (2021) proposed a stochastic and dynamic game model which considers pricing and delivery lead time decisions jointly. They analyzed the impact of demand uncertainty on optimal pricing and delivery decisions, by means of a data-driven, distributionally robust approach. Arslan et al., (2021) and Difrancesco et al., (2021) studied fulfillment platforms and inventory management under uncertainty. Arslan et al., (2021) proposed a two-stage stochastic model that enables them to explore ship-from-store and urban fulfillment platform strategies in terms of profitability, sales loss reduction, and fast delivery capabilities. Difrancesco et al., (2021) developed a simulation-based approach which determines the optimal timing for batching online orders, starting the in-store picking and delivery processes, and the optimal numbers of pickers and packers needed. Recently, Snoeck et al., (2023) also presented a model that integrates tactical inventory decisions with strategic facility activation decisions in last-mile network design. They reported that pooling additional online inventory with physical store inventories can lead to higher store service levels but also causes inventory cannibalization, though the benefits to the online network generally outweigh these costs. Abdulkader et al., (2018) introduced a novel type of vehicle routing problem tailored to omni-channel retail distribution systems. Their problem focuses on a model where a group of retail stores, served from a distribution center using a fleet of vehicles, also distribute products to consumers based on inventory availability. They employed two solution approaches, i.e., a two-phase heuristic and a multi-ant colony algorithm and new benchmark instances that can be utilized to compare the results. The study by Liu et al., (2022) also focused on modeling a vehicle routing problem in omni-channel retailing. They employed a multi-objective approach to optimize the distribution network, with the first objective function aiming to minimize the cost of the distribution network and the second maximizing customer convenience. Zhao et al., (2023) investigated the impact of consumer perceptions of product freshness on the selling strategies of firms in a fresh food supply chain. They explored two retail modes: the dual-channel retailing strategy (DCRS), where food is sold both in-store and online, and the omni-channel buy-online-and-pick-up-in-store (BOPS) strategy. Their findings suggested that the reference freshness effect influences pricing, with prices tending to be higher in BOPS mode at high reference freshness levels, but higher in DCRS mode at low reference freshness and with a large BOPS channel. Li et al., (2022) studied the effect of store density to adoption of BOPS services. They concluded that medium-distance store density positively influences BOPS adoption, while high density at shorter distances has a negative impact. The study also examines how customer characteristics like channel preference and online purchase experience modify these effects. Jiu et al., (2022) contributed to this research stream by considering replenishment, allocation, and fulfillment decisions in a capacitated retail network over a multi-period horizon. Their robust two-phase approach is employed to solve first replenishment, then the allocation and fulfillment quantities decisions. Gao and Su (2017) also examined the impact of BOPS on retail operations. Their findings suggested that all products cannot be ideal for BOPS, especially those already selling well in stores, as BOPS can reveal real-time inventory status and potentially reduce store traffic. They also pointed out that to align incentives and avoid overstocking issues, sharing BOPS revenue between store and online channels can be viable strategy.

2.3 Capacitated location-routing problem

The LRP was conceptualized in the 1960s (e.g., Maranzana, 1965; Von Boventer, 1961) and further developed in the late 1970s (e.g., Harrison, 1979) and the early 1980s (e.g., Laporte & Nobert, 1981) because of the emergence of the integrated logistics concept and expansion of international trade (Min et al., 1998). The synthetic expression \(\lambda /{M}_{1} \dots /{M}_{\lambda -1}\) for an LRP was first introduced by Laporte (1988) and then enhanced by Boccia et al., (2011). Based on this expression, \(\lambda \) denotes the number of layers and \({M}_{1}/\dots /{M}_{\lambda -1}\) represents the type of routes linking the layers. In addition, \(R\) is used for dedicated routes to differentiate the routes, and \(T\) is used for multiple node routes. The overline on letters \(R\) and \(T\) specifies where location decisions are made. For example, \((3/R/\overline{T}\)) refers to an LRP comprising three layers: \(R\) routes between the first and second layers, \(T\) routes between the second and third layers, and location decisions for secondary (i.e., starting points of routes are referred to as primary facilities) facilities (Boccia et al., 2011).

The existing literature is abundant with many variants of the LRP. They have been classified in accordance with the number and types of locations, types of fleets, characteristics of demand (i.e., deterministic or stochastic), number of network layers, and solution methods, etc. (Nagy et al., 2007). We refer interested readers to reviews on the LRP to gain a comprehensive overview (Min et al., 1998; Nagy et al., 2007; Prodhon et al., 2014; Cuda et al., 2015; Schneider et al., 2017). We aim to discuss only selected studies primarily of two-echelon as well as a few multi-echelon capacitated LRPs that pertain to our work in terms of modelling and our proposed conceptual framework (i.e., last-mile distribution networks for the OC setting).

Ambrosino et al., (2005) investigated a four-layer distribution network design problem that involves facility, warehousing, transportation, and inventory decisions under both static and dynamic scenarios. The authors formulated two types of mathematical programs: the first is based on the warehouse LRP introduced by Perl et al., (1985) and the second is based on flow variables and constraints. For Aksen et al., (2008), the retailer makes location (brick-and-mortar stores) and routing decisions to satisfy the demand for both walk-in (i.e., who visit the nearest stores in person) and online customers. In the developed model, the authors assume that the roles of walk-in and online customers could be exchanged. That is, online customers buy online; however, they prefer picking up the item at the nearest store, whereas a walk-in customer may purchase a bulky good in the store, but prefer to receive home delivery. Boccia et al., (2011) proposed three different mixed-integer programming formulations for a two-echelon capacitated LRP (\(2E- CLRP\)) wherein location decisions are made for both primary and secondary facilities along with two different routing decisions. Lee et al., (2010), Contardo et al., (2012), and Zhao et al., (2017) studied the \(2E- CLRP\) by proposing exact and heuristic solution methods. The computational results of these studies indicate that the developed heuristics can find good solutions in a reasonable time and outperform extant heuristics. Lin et al., (2009) investigated three-echelon distribution systems that comprise location and two-level routing decisions with two types of clients (big and small). The developed model was implemented in a national finished goods distribution system for label-stock manufacturers. Their analysis suggests that the inclusion of big clients in first-level routing reduces the total logistics cost. Within the context of urban logistics services (ULS), Winkenbach et al. (2016) proposed a large-scale deterministic MILP model to solve the \(2E- CLRP\) with transportation mode choice. Further, they developed an optimal routing cost estimation formula and an optimization heuristic that enabled them to achieve their goal within a reasonable time with a small optimality gap to solve the large-scale MILP real case instances. Govindan et al., (2014) formulated an LRP with time-window constraints by considering greenhouse gas emissions in perishable goods freight. Their work aimed to optimize two objectives: total operational costs and environmental effects. The authors also introduced a hybrid metaheuristic algorithm based on multi-objective particle swarm optimization and an adapted multi-objective variable neighborhood search to solve the developed multi-objective model. Their developed solutions outperformed existing benchmark algorithms based on a genetic algorithm method. Hamidi et al., (2012) developed a four-layer multi-product LRP that considers location, allocation, routing, and transshipment decisions. They solved a small-sized problem using a numerical solver and obtained the exact solutions for the developed model. Later, Hamidi et al., (2014) proposed a heuristic method to solve the same model. Their results indicate that the proposed method (i.e., based on the greedy randomized adaptive search procedure and tabu search) solves the problem efficiently. Based on a case study of last-mile distribution reported by an e-commerce platform, Janjevic et al., (2019) investigated a last-mile distribution network in which the location of both satellite facilities (SFs) and collection-and-delivery points (CDPs, i.e., as an additional fulfilment option), allocation of client segments to active SFs, and vehicle size and routing decisions were optimized. They formulated an extended routing cost approximation approach to estimate the near-optimal route length for deliveries to CDPs and individual customers. The authors further developed a problem-specific heuristic that enables them to solve those problems in a reasonable time to make large-scale problem instances more tractable. Their results suggest that the integration of CDPs into a network can significantly reduce the cost of a company. In an OC environment, Janjevic et al., (2020) studied a last-mile LRP with multiple time-differentiated delivery services, transportation modes, and product-exchange options. From the literature, the authors extended existing closed-form continuum approximations of the optimal routing cost and utilized these approximations in the developed three-echelon capacitated LRP by considering location decisions, delivery service offerings, transportation mode choices, and product-exchange alternatives. Their results suggested that an integrated optimization approach leads to better network design performance and a reduction in total logistics cost.

2.4 Literature gap

Our review has identified several key gaps in the literature, which highlight the importance and novelty of our study in the context of manufacturer encroachment, omni-channel operations, and the capacitated location-routing problem (CLRP).

The vast majority of studies on manufacturer encroachment and manufacturer channel strategy investigate a single echelon supply chain network configuration that comprises single manufacturers distributing products directly (online, store, or both) and through a retail channel (Tahirov & Glock, 2022). Our study extends this by exploring more complex network configurations, which are more reflective of contemporary distribution systems, particularly in an omni-channel setting. Today, many firms switch their distribution systems from multi-channel to OC settings (Ailawadi, 2021; Verhoef et al., 2015). However, OC is primarily interpreted as a retail concept because the related literature (Cui et al., 2021; He et al., 2019; Verhoef et al., 2015; Wei et al., 2020) has exclusively addressed this phenomenon from the perspective of a retailer (Jindal et al., 2021). More exactly, the existing literature on OC operations is extensive yet predominantly concentrates on specific aspects like inventory management, replenishment strategies, delivery lead times, and routing, primarily from a retailer's perspective, without addressing these elements in a cohesive, joint manner. In practice, however, it is common for a manufacturer to vend products to end consumers through its direct channel in addition to existing intermediaries such as retailers or wholesalers (Ailawadi, 2021). In this case, manufacturers can either use the extant (or prospective) nearby stores as a fulfilment center or as pickup points (i.e., buy online pick-up in-store, BOPS), which are key elements in the OC distribution system as they both offer flexibility to customers and boost store sales (Ailawadi, 2021; Paul et al., 2019a, 2019b). Therefore, our research fills this critical void by examining omni-channel distribution systems from the perspective of the manufacturer, a perspective that has been largely neglected in existing literature (Ailawadi, 2021; Tahirov & Glock, 2022).

Moreover, our study uniquely addresses the integration of strategic, tactical, and operational challenges that arise when transitioning from a single channel to a multi-channel or from a multi-channel to an OC. These comprehensive considerations are missing in the manufacturer encroachment, omni-channel, and LRP literature, where these three types of decisions are yet to be investigated simultaneously. Our study aims to provide a thorough and integrated analysis of these decisions, offering a more holistic perspective on the complexities involved.

Our proposed third scenario (Omni-channel configuration) represents a significant methodological advancement within the Location Routing Problem (LRP) research stream. While there is a notable body of literature on LRP, studies that delve into the granular characteristics of customer demand and OC distribution systems remain scarce. To date, only a few studies have explored OC settings (Aksen et al., 2008; Janjevic et al., 2020) and the complexities of managing multiple products (Hamidi et al., 2012). Our study’s methodological contribution is particularly distinctive in the LRP field. The developed capacitated LRP extends beyond existing studies by simultaneously considering multiple products and diverse customer segments. This includes a novel approach to capturing the dynamics of customer behavior, such as the inclusion of a BOPS option, which reflects the evolving nature of consumer preferences. Additionally, our model integrates a customer service level parameter, offering a more nuanced understanding of how different service strategies impact distribution efficiency. We have also enriched our model by incorporating customer response time as a variable. This modification allows us to derive deeper managerial insights, particularly regarding the timeliness and responsiveness of the distribution network in an OC environment. This comprehensive approach provides a more realistic representation of the complexities inherent in modern distribution networks, setting our work apart from the existing LRP literature and highlighting its practical relevance to today’s retail and distribution challenges.

We present the major model attributes of the existing research and our study in Table 1 to differentiate our work from the most closely related studies. Furthermore, we note that none of the contributions in the current literature propose a strategic network design model that simultaneously considers (1) the manufacturer channel selection strategy; (2) diverse shopping/pick-up options and products that form heterogeneous demand zones; (3) location decisions that utilize retailers’ physical stores as fulfilment and pick-up points; and (4) incorporation of a service level parameter that affects the manufacturer’s channel selection strategy considerably and customer response time decision. In summary, we present a novel framework that integrates multiple aspects of manufacturer encroachment, OC operations, and CLRP, thereby contributing to both academic research and practical applications in supply chain management. Therefore, this study aims to fill a significant gap and contribute to the related literature.

3 Problem description

We address a strategic distribution network design problem for parcel-sized, imperishable, non-food products sold by a manufacturing company. To lend decision support from the manufacturer’s perspective, we analyze various distribution network designs, which include single-channel (Scenario 1), multi-channel (Scenario 2), and OC (Scenario 3) designs. We also explore how customer composition, in terms of shopping and product preferences, affects the efficiency of the planned network design. We distinguish the following customer segments (Gauri et al., 2021):

-

Segment—T prefers shopping for standard products in brick-and-mortar stores (i.e., retail stores).

-

Segment—C prefers buying customized products and getting items via a last-mile delivery service, which is realized directly by the manufacturer’s warehouse.

-

Segment—S prefers buying standard products and getting items via a last-mile delivery service, which is fulfilled through dark stores (DS) located at a retail store (R).

-

Segment—BOPS prefers shopping online and picking products (i.e., both standard and customized products) up in a dark store.

These customer segments constitute various demand zones, and each demand zone has a weight that denotes the number of clients existing in it. These demand zones must be met with low logistics costs under various channel configurations and service levels (\(\alpha \)). That is, depending on the capability of a distribution channel (i.e., a channel can be insufficient to reach all customer segments), a defined service level enforces that at least \(\alpha \%\) of all weighted customer zones must be served according to their preferences. This, in turn, enables us to compare the logistics costs of the proposed channel configurations.

Thus, we consider the following scenarios:

3.1 Scenario 1 single-channel configuration

-

Problem addressed: Limited to serving Segment-T customers preferring in-store shopping for standard products.

-

Model application: Focuses on the logistics of replenishing physical stores with heavy trucks. This scenario tests the network's ability to efficiently serve a specific customer segment under a traditional retail model, revealing potential limitations in reaching other segments (Fig. 1a).

3.2 Scenario 2 multi-channel configuration

-

Problem addressed: Aims to serve Segment-C, which prefers customized products delivered directly from the warehouse.

-

Model application: Integrates a differentiated product strategy to avoid channel conflicts, using urban vans for delivery. This scenario examines how well the network adapts to online shopping preferences and customized product demands, assessing the effectiveness of a multi-channel approach versus a single-channel model (Fig. 1b).

3.3 Scenario 3: omni-channel distribution network

-

Problem addressed: Designed to satisfy all customer segments, including the complexities of serving both standard and customized product demands.

-

Model application: Extends the multi-channel system to include last-mile deliveries for standard products (Segment-S) through a dedicated location that is used for the fulfilment or pick-up of online orders inside an existing retailer’s store, which is termed “dark storesFootnote 2” (Frederick et al., 2018; Hübner et al., 2016b). This scenario evaluates the network's capacity to offer a comprehensive solution that encompasses various shopping and delivery preferences, highlighting the logistical challenges and potential benefits of an omni-channel approach (Fig. 1c).

Each scenario is designed to assess various facets of the distribution network from the manufacturer's perspective, considering the diverse preferences and behaviors of different customer segments. By examining these scenarios, the model can highlight potential inefficiencies, identify areas for optimization, and propose effective solutions that balance customer satisfaction with logistical practicality. The focus is on optimizing the number of dark stores, vehicles, and routing decisions within each scenario to minimize logistics costs while meeting customer needs as defined by their respective segments. The intended configuration for each scenario is described in Fig. 1. The investigated distribution network comprises the following:

-

Manufacturer (\(M\)): The manufacturer ships both types of products to retailer stores via heavy trucks. In addition, the manufacturer delivers customized products to Segment—C customer zones using urban vans. The production capacity of the manufacturer is assumed to be infinite.

-

Brick-and-mortar stores (\(R\)): Brick-and-mortar stores belong to independent retail companies. They are located near customers; the functions of these stores are twofold: in-store sales and dark store sales. In-store sales are the conventional in-person shopping type. The dark stores (\(DS\)) are used as fulfilment centers for online orders of standard products delivered by urban vans, and they also serve as pickup points for both types of products purchased online by BOPS customers.

-

In-store captive customer zones (\(T\)): These zones patronize conventional (offline) channels.

-

Last-mile delivery customer zones for customized products (\(C\)): These zones include customers shopping for customized products online and receive orders delivered from the manufacturer’s warehouse.

-

Last-mile delivery customer zones for standard products (\(S\)): These zones contain customers shopping for standard products online and receive their orders shipped via dark store.

-

BOPS customers (i.e., proper subset of segment \(C\) and \(S\); dark gray and blue nodes in Fig. 1c) if they are located near (i.e., \(\le \phi \) given distance range) to an opened dark store; otherwise, they are served via last-mile delivery through the manufacturer’s depot and open dark store, respectively.

4 Model development

The notations used in this study are summarized in Table 2, and all models are developed based on the following assumptions:

-

We consider two product types (standard and customized); these items are produced by the manufacturer and are in unlimited supply.

-

The demand of each customer zone for a product type is deterministic, and demand splitting is not allowed; that is, either the entire demand of a customer is satisfied or none at all. Since we are proposing a model for strategic decision support, in practice, the demand of a customer zone may be a forecast or an estimate depending on the demographics and population density of the respective area.

-

The total demand and weight of the set of traditional customers \(T\) is equivalent to the total demand and weight of the set of retail stores \(R\) such that the total demand and weight of \(T\) customers is distributed equally among the retail stores. The demand of traditional customers is satisfied directly in retail stores where customers purchase and pick up products. No shipments are made from retail stores to traditional customers.

-

Demand nodes (\(T, S, \& C)\) represent various customer zones comprising multiple neighboring customers that may or may not overlap geographically. Distances between neighboring customers are presumed to be very short, and the times for unloading and serving are assumed to be zero.

-

Dark stores are located in the retailer’s physical stores and have identical capacities; the set of potential dark stores \(DS\) is equivalent to the set of retail stores \(R\).

-

We consider two types of vehicles with different capacities. All vehicles of the same type have an identical capacity.

-

Each vehicle is utilized at most once for a single tour.

-

Each customer zone \(s\in S\) and \(c\in C\) must be served by a single open dark store and the manufacturer, respectively. Customer zones (\(S\cup C\)) located near (i.e., \(\le \phi -\) within a given distance range) a retailer are defined as BOPS customers and can be assigned to an open dark store to pick up their order. In that case, they do not need to be visited by a delivery truck.

-

All distances between nodes are measured via the Euclidean metric.

4.1 Single-channel distribution scenario (Model S)

The first scenario aims to optimize the transportation and fixed costs of using heavy trucks to supply the retail stores. The problem is identical to the single depot capacitated vehicle routing problem (CVRP) with a homogenous fleet (e.g., Kulkarni & Bhave, 1985; Laporte, 1992; Salhi et al., 2014, etc.), multiple products, and service-level constraints. Appendix A provides the formal model. Note that there is no optimization problem to solve in the second layer, because customers have no choice but to shop in-store, the only channel available in this scenario. Customers who want a home delivery cannot be served.

4.2 Multi-channel distribution scenario (Model M)

In this scenario, the manufacturer adopts the multi-channel distribution system in which the manufacturer ships customized goods to last-mile delivery customer zones via urban vans in addition to replenishing physical stores with standard products. The objective of this model is to minimize the transportation and fixed costs of using each vehicle type. Similar to Model S, this problem can be modeled as two separate CVRP, one for the replenishment of the retailers from the manufacturer using heavy trucks, and one for the delivery of customized products from the manufacturer to the home-delivery customers using urban vans. A combined formal model is presented in Appendix A.

4.3 Omni-channel distribution scenario (Model O)

The manufacturer makes both strategic (i.e., opening a dark store at a retailer’s store) and operational (i.e., routing) decisions. This problem was defined as a combined two-echelon LRP. Our problem type matches that of the \(3/T/T\) setting. In our case, the first \(T\) contains two different multiple-node routes from the manufacturer to the retailer’s stores (i.e., between the first and second levels) and from the manufacturer to the last-mile customer zones for the customized products (i.e., between the first and third levels). The proposed model differs from the classical warehouse LRP (Perl & Daskin, 1985) and aims to solve a more complex problem, which includes three different routing decisions: multiple products, multiple vehicles, and various shopping and pick-up options for different types of customer zones. The mathematical programming formulation of this model is inspired by models proposed by Ambrosino et al., (2005) and Boccia et al. (2011), which incorporate multiple products, various purchase and pickup options, and service levels for segmented customer zones. The objective of the developed model is minimizing the total cost, which includes the facility-fixed opening cost, fixed cost of using a vehicle, and routing costs. The proposed model is formulated as.

Minimize

Subject to

The objective function (O1) comprises five cost elements: fixed opening cost for dark store locations, fixed usage cost for each vehicle type and transportation cost for three routes. The constraints are summarized as follows: Constraint (O2) imposes that at least \(\alpha \) percent of all customer nodes must be served according to their preferences, i.e., it is the service level constraint. Constraint (O3) ensures that if a client on a first-type route (\(r, r\in R\)) is served, it must be visited by exactly one heavy truck (\(h, h\in H\)). Constraints (O4) and (O5) ensure that if a client on the second- (\(c, c\in C\)) and third-type route (\(s, s\in S\)) are served without being assigned to an opened dark store as a BOPS customer, then it must be visited by exactly one urban van (\(u, u\in U\)). Those constraints also enforce that BOPS customers (i.e., located within the given maximum allowable coverage distance) must be assigned either to a dark store or be served by a route originating from the dark store and the manufacturer, but not both. The next three constraints (O6), (O7), and (O8) for each route guarantee that for each vehicle type, the number of entering arcs in a node is equal to the number of leaving ones. Constraints (O9), (O10), and (O11) impose that each vehicle can be used a maximum of once on a tour. For each vehicle, constraints (O12), (O13) and (O14) ensure that the quantity of each product type shipped by a vehicle cannot exceed its capacity if that vehicle is used. Constraint (O15) ensures that an opened dark store can satisfy the demand of customer zones \(S\) and the near customers (\(S\cup C\)) assigned as BOPS customers, up to its capacity. For every type of product, constraint (O16) ensures that the sum of the flow originating from the manufacturer matches the combined demand of the customers, encompassing both \(S\) and BOPS (\(S\cup C\)). Constraints (O17) and (O18) ensure that the flow of products (\(p\in P\)) from the manufacturer to the retailer's stores occurs positively only when both locations are serviced by the same vehicle. Constraint (O19) links the routing and assignment variables. More exactly, a client \(s, s\in S\), can only be assigned to a location \(r, r\in R\), if the dark store at that store is active and a route from that location through that client exists. In the literature, this is also referred to as a chain barring constraint. Constraint (O20) ensures that each customer \(s, s\in S\), either as a last-mile delivery or BOPS customer, must be assigned to one opened dark store \(k, k\in DS\), if it is served. Constraints (O21), (O22), and (O23) are constraints that eliminate subtours on each route. The last set of constraints (O24) express integrality and non-negativity constraints.

5 Solution methods

The LRP comprises two NP-hard problems: facility location and vehicle routing. LRPs are therefore NP-hard problems that are solved using various heuristic methods. Caballero et al., (2007) for example, utilized a tabu search-based metaheuristic for a multi-objective LRP, efficiently serving 335 customers, representing the maximum size of instances, within 413 s. Tuzun and Burke (1999) implemented a two-phase tabu search algorithm for the LRP, solving instances with 100 to 200 customers within 3.5 to 20.02 s. Ambrosino et al., (2009) introduced a heuristic based on multi-exchange techniques for a regional fleet assignment LRP, successfully solving both randomly generated instances (20–420 customers) and a real-world case (200 customers). This approach effectively addressed instances, especially those exceeding 40 customers where a commercial solver failed, all within a 25 h computational limit. To address a novel variant of the two-echelon vehicle routing problem featuring time windows and covering options, Yu et al., (2021) formulated an adaptive large neighborhood search (ALNS) algorithm. This method incorporates local search strategies across both first and second echelon networks. The efficacy of the ALNS algorithm was evaluated on datasets generated with customer counts ranging between 21 and 200. Janjevic et al., (2019) implemented a constructive heuristic approach, integrating both breadth-first and depth-first search strategies, to identify the optimal mix of satellite facilities and collection-and-delivery points, alongside the allocation of customers, aiming to minimize the total cost of the network. Given the extensive scale of the problem, involving 15,550 customers, they employed a route cost approximation technique. Note that the above studies commonly explore new aspects of the LRP which complicates the benchmarking of their proposed solutions with extant instances. As a result, they typically either generate new instances or adjust existing ones to align with their particular problem set. This problem-specific nature of most LRPs has given rise to a diverse range of solution approaches aimed at addressing large-scale, or realistic, problems.

Thus, we propose a heuristic method based on a decomposition of the proposed model into sub-problems, that is, location-allocation and capacitated vehicle routing problems, to solve practical-size problems within a reasonable solution time. We advocate that prior to routing decisions, making location (i.e., in our case DS) decisions via a metaheuristic, followed by solving the allocation problem via a default solver, can be an efficient approach (see Sect. 6) in terms of solution quality and time. We, therefore, employ a tabu search mechanism (Glover, 1990) to decide on the number of dark stores to open, and by means of a default solver (i.e., Gurobi 9.1.2), we solve an assignment problem sequentially to assign the first \(S\) customers to the nearest opened dark stores. The reason for prioritizing customer \(S\) is that they can be served only through dark stores. In addition, the manufacturer aims to minimize the number of open dark stores because of fixed costs and additional operations. Then, we assign the nearest \(C\) customers (i.e., BOPS) to open dark stores if they have available capacity (Phase 1). We use a solver based on the famous Lin–Kernighan heuristic (Lin & Kernighan, 1973) (Phase 2) to solve the routing problems. Finally, we calculate the total cost (Phase 3). Figure 2 summarizes the general structure of the proposed solution method. In a nutshell, the bold notations describe best found values of the decision variables and objective function (i.e., \({\varvec{y}}-\) opened DS; \({\varvec{z}}-\) assignment of customer zones (\(S\cup C\)) to the opened DS; \({\varvec{x}},\boldsymbol{ }{{\varvec{x}}}^{\boldsymbol{^{\prime}}}\)& \({\varvec{r}}-\) routes; \({\varvec{f}}-\) number of vehicle per type, \({\varvec{\Phi}}-\) objective value of ACSP model) and the remaining ones are major input parameters (i.e., \(Loc-\) location coordinates; \(D-\) demand of demand points). Note that \(\{{S}{\prime}, BS\}\) and \(\{{C}{\prime}, BC\}\) are the proper subsets of the \(S\) and \(C\) sets and denote home delivery and BOPS customer zones, respectively. Considering the major assumptions presented in Subsection 3.1, we outline the detailed procedures of the proposed sequential heuristic as explained below.

Phase 1: First off, we open all dark stores and solve the allocation problem using the Gurobi 9.1.2 solver that assigns customer zone \(s, s\in S\), to the nearest locations (ACSP—allocation of customer zones for standard products). The output of this solution allows us to obtain the initial objective value and maximum number of open dark stores (\({N}_{max}\)) to which at least one client is assigned. Then, we calculate the minimum number of required dark stores (i.e., \({N}_{min}=\lceil\sum_{s\in s}{D}_{s}/K\rceil\), where \({D}_{s}\) and \(K\) denote the demand of \(s, s\in S\), customer zones, and dark store capacity, respectively), which are considered as input (fixed locations) parameters in the following allocation problem.

5.1 ACSP model

Minimize

Subject to

In the above formulation, \({z}_{sk}\) and \({\eta }_{s}\) represent binary decision variables. The former denotes the assignment of customer zone \(s, s\in S\), to the opened dark store \(k, k\in DS\), whereas the latter represents whether a customer zone \(s\) is served. The remaining notations indicate the input parameters, i.e., distance (\({c}_{sk})\), symbolic transportation cost that equals to 1 \((\zeta )\), demand \(({D}_{s})\), dark store capacity \((K)\), number of clients/people existing in each customer zone \(s\) \(({w}_{s})\), percentage of the total number of clients that must be served (\(\alpha )\), the opened dark stores obtained from TS algorithm \(({y}_{k}^{TS})\), and fixed opening cost for a dark store \(\left(F\right).\) Note that the distance \({c}_{sk}\) between DS and customers is a surrogate for the actual routing cost to reduce computational complexity.

We employ a tabu search (TS) procedure to make location (i.e., dark store) decisions. We employ two types of moves (swap and insert) to obtain a good configuration of dark stores. Once the \({N}_{min}\) number of dark stores is selected randomly, the incumbent solution is evaluated based on the objective value (1) of the sequentially solved model (1–6). Our overall best solution includes three elements: number of dark stores (\(N\)), list of the best locations, and objective value (1). Subsequently, swap moves are performed by keeping \(N\) constant. To this end, we employ a function (i.e., getNeighbors (bestLocation)) that swaps open and closed facilities. That is, one entry among the opened dark stores is randomly selected and it is changed to be closed; another entry among the closed ones is selected and set to be opened. The swap moves are performed to evaluate all closed dark stores within the internal termination condition (i.e., 300 CPUs.). Then, an insert move is performed by increasing the number of open dark stores by one. This process continues until the number of dark stores reaches \({N}_{max}\).

The locations in a neighbor solution that improves the incumbent solution are declared tabu and kept in the tabu list until the tabu list size reaches \(\xi =\lceil |DS|/4\rceil \)(Tsubakitani & Evans, 1998). We follow a “first in, first out” rule to update the tabu list; this means that after a number of entries in the tabu list, the first element of the tabu list is deleted once its size (row) equals \(\xi \). This procedure is outlined in Algorithm 1.

Based on the obtained outputs (i.e., number, location and unused capacity of the opened dark stores) and given parameters (i.e., distance from \(c, c\in C\), to the opened dark store \(k, k\in DS\), and manufacturer), we assign customer zones \(c, c\in C\), to the opened dark stores. Here, three constraints must be ensured: a customer zone \(c\) must be located within distance \(\phi \) from the opened dark store, the dark store must have an available capacity and the desired percentage (\(\alpha \)) of the total number of clients must be served. If there are more customer zones \(c\) that fulfill these criteria than can be served given the limited capacity of the opened dark stores, we prioritize those zones \(c\) that are the farthest from the manufacturer plant. Finally, along with the assigned \(c, c\in C\), customers, customers \(s, s\in S\), (assigned by solving model ACSP) located within the distance \(\phi \) from the opened dark store are determined as BOPS customers and removed from the \(\{0\}\cup C\) and \(R\cup S\) nodes, respectively, while solving the routing problems in Phase 2.

Phase 2: In this phase, the following steps are performed to solve the routing problems:

-

Step 1: Solve the CVRP from the manufacturer to the last-mile delivery customer zones for the customized product via urban van by considering updated \(M\cup C\) nodes.

-

Step 2: Solve the CVRP from the manufacturer to the retailer via a heavy truck. The retailers’ demands for standard products are updated by considering the assigned \(S\) and \(C\) customers’ demand for standard and customized products, respectively.

-

Step 3: Solve CVRPs from each opened dark store to the last-mile delivery customer zones for standard products via an urban van considering updated \(R\cup S\) nodes.

-

Step 4: Calculate the cost of the solution.

Note that in Step 1 and Step 2, more customers may be served than is necessary to satisfy the service level constraints \((O2)\). Therefore, the most expensive tours are removed until the desired percentage (\(\alpha \)) of the total weighted number of clients that must be served is reached. For Step 3, this constraint has already been considered during the allocation problem ACSP (Constraint (4)).

We used the Lin–Kernighan–Helsgaun (LKH) heuristic solver, which is an efficient implementation of the Lin–Kernighan heuristic (Lin & Kernighan, 1973) in terms of solution performance and quality (Helsgaun, 2009; Taillard & Helsgaun, 2019). The focal concept in the Lin–Kernighan algorithm is the definition of allowable moves that facilitates the subset of \(r\)-opt moves to be considered while transforming a tour into a shorter tour (Helsgaun, 2000). Specifically, we use the LKH-3 (downloaded from http://akira.ruc.dk/~keld/research/LKH-3/, LKH 3.0.7, May 2022) version, which is an extension of LKH-2 (which primarily solves TSPs) and can solve vehicle routing problems with capacity effectively. LKH-3 transforms the problem into standard symmetric traveling salesman problems and utilizes penalty functions to manipulate constraints (Helsgaun, 2017).

Phase 3: Finally, we add the number of opened dark stores (Phase 1) multiplied by the fixed opening cost and logistics costs obtained from Phase 2 (Step 4) to calculate the total cost, that is, the objective function (\(O1\)).

6 Computational study

This section presents the numerical experiments conducted to explore the performance of the proposed solution methods and outlines the managerial implications of the channel transition of an encroaching manufacturer. In the following subsections, we first describe the instance data and computational environment, followed by computational results and the analysis of the proposed model.

6.1 Instances and computational environment

Two sets of instances were used in the computational study. The first set is adapted from the famous “Barreto set” (Barreto et al., 2007) of LRP instances, composed of 18 instances with the number of customers \(n\) ranging from 12 to 318, number of capacitated locations (corresponding to retailers/potential dark stores) \(k\) ranging from 2 to 15, and various capacitated vehicles. We use the given capacity for \(u, u\in U\), urban delivery van type vehicles because the “Barreto set” contains only one type of vehicle, for each instance; however, the given capacities are increased by 4 for \(h, h\in H\), heavy truck type capacities. The “Barreto set” is interpreted as small and medium size instances that can be solved via a numerical solver; therefore, they are included for benchmarking.

Moreover, we generate new instances. Set \(L\) involves 20 large instances with \(n=1000\) customer zones. These instances are generated closely to the real-world case based on data from a fashion company operating in Berlin, Germany. Our proposed model (OC) captures the company’s distribution network configuration where standard and customized athletic footwear are vended through retail stores and the company’s website, respectively. Recently, offering customized products (i.e., usually via online channels) has become more popular among footwear companies along with standard products (e.g., https://www.nike.com/nike-by-you). We obtain the number and location of retail stores and factory (i.e., the central warehouse of the factory) within the Berlin metropolitan area using publicly available information. We use ArcGIS 10.3 and Google Earth Pro software to retrieve the exact two-dimensional (\(x,y\)) coordinates (i.e., from the Universal Transverse Mercator (UTM) 39 WGS 84) of locations (i.e., retail stores and factory warehouse) and corners of the rectangular area, whose area is roughly equivalent to the Berlin metropolitan area (Fig. 3). First, we converted coordinates from meters to kilometers, and then, within the rectangle’s boundary, we generate \({x}_{i}\), i.e., between the interval (370, 416) and \({y}_{i}\), i.e., between the interval (5800, 5837) coordinates for each customer zone \(i, i\in S\cup C\). For L instances, the demand of each customer zone per product type (\({D}_{jp}, j\in T\cup S\cup C, p\in P\)) and the capacity of dark stores (\(K\)) are generated uniformly in the range of [1,100] and [5000, 10000], respectively. The vehicle capacity for each type was considered \({Q}_{u}=1000\) and \({Q}_{h}=10000\). The fixed opening cost of a dark store is a linear function of the capacity values and calculated as \(\left[ {0.25 {\sf C}\!\!\!\!\raise.8pt\hbox{=} /unit \cdot K} \right]\).

For each set of instances, we randomly split the total customer zones among the three types of customer segments \(j, j\in T\cup S\cup C\). To this end, we generated a uniformly distributed random number \({q}_{j}\in [\mathrm{1,10}]\). Then, we set the customer counts \({n}_{j}\) for each segment \(j\) such that the ratio of customer counts \({n}_{1}:{n}_{2}:{n}_{3}\) corresponds to the random ratios \({q}_{1}:{q}_{2}:{q}_{3}\). Afterwards, we round each \({n}_{j}\) to either the next largest or smallest integer, where the sum total must be equal to the total number of customer zones (e.g., for the \(L\) instances, the total customer zones–1000 may be split into \(6:5:3\) ratios, and this implies that the number of customers per segment \(T, S, \& C\) is 429, 357, and 214, respectively). The weight (\({w}_{j}, j\in T\cup S\cup C\)) for each customer zone is a uniformly distributed random number ranging from \([1, {D}_{j}]\). The fixed cost of using a vehicle (\({G}_{h}, {G}_{u}\)) and transportation cost (\({t}_{h},{t}_{u}\)) per vehicle type are considered (15, 6) and (8, 3), respectively. Finally, the distance range \(\phi \) for BOPS customers is considered less than \(3 km\). Dataset for \(L\) instances can be downloaded via this https://doi.org/10.5281/zenodo.7049674.

All instances are solved on a PC with an Intel Core-i7-6700 CPU, 3.40 GHz, and 8 GB RAM using Windows 10 Pro × 64. To solve these instances, the solution methods (Sect. 5) are implemented in Python 3.8.8. For benchmarking and for solving the allocation subproblem, Gurobi 9.1.2 is employed as the default solver.

6.2 Computational results

The computational study has two objectives. We study the computational performance of the proposed decomposition metaheuristic technique, and we perform several analyses to provide managerial implications for a manufacturer designing its supply chain network using this technique on the L instances.

6.2.1 Computational performance

Recall that we used the “Barreto set” for benchmark purposes. Thus, 18 instances were solved using the Gurobi solver and our proposed solution methods. Because Gurobi was not capable to solve even some small- and medium-sized instances within a reasonable time interval with a 0% optimality gap, we set the solution time limit to 36,000 CPU seconds for all runs. We recorded the best objective (upper bound-UB, i.e., the best feasible solution), the best bound (lower bound-LB), and the optimality gap (\(Ga{p}_{Gurobi}\)). The optimality gap was obtained as follows: \(Ga{p}_{Gurobi}=\frac{UB-LB}{UB} \cdot 100\). Furthermore, to compare the solution quality and time of our proposed solution methods, we also recorded the best objective and solution time (CPU sec.) for each instance, solved using our decomposition metaheuristic. The objective values of the Gurobi (UB) and the decomposition heuristic were compared by employing the gap (\(Gap=\frac{U{B}_{Gurobi}-Best Obj{.}_{decomposition metaheuristic}}{U{B}_{Gurobi}}\cdot 100\)). Table 3 presents the benchmark results.

Table 3 indicates that Gurobi can obtain optimal (i.e., with 0% gap) solutions for only two unrealistically small instances (14th and 18th) in a few CPU seconds. However, optimal solutions could not be obtained for the remaining instances within the time limit; instead, the UB and LB were determined. The 17th instance could not be loaded into memory during the pre-solve phase, and therefore, the best bound of the instance could not be obtained. For our proposed solution method, the results indicate that it obtains the same objective values as Gurobi for two small instances (14th and 18th). In general, the results clearly indicate that our problem-specific decomposition metaheuristic outperforms Gurobi in terms of solution quality, with a − 23.51% gap and 17.98 CPU s solution time.

We solve the \(L\) instances and report the results in terms of the best objective values and solution times to pose more of a computational challenge to our decomposition metaheuristic (see Table 4). The average solution time is 81.03 CPUs, which is a reasonable solution time interval for such large instances, given the strategic nature of the problem.

6.2.2 Managerial insights

Apart from algorithmic performance, we investigate the managerial implications crucial for practitioners aiming to optimize their supply chain network design. For this purpose, we reuse the set \(L\) instances solved by our proposed heuristic.

6.2.2.1 Comparison of three network configurations

We address a manufacturing company planning to expand its market penetration and reach various customer segments. The company wants to analyze three distribution network designs: single-channel, multi-channel, and OC. For such strategic decisions, the company must make a trade-off between the total logistics cost and customer service level (SL). For example, shipping customized products directly from the factory to consumers is certainly more expensive from a logistics perspective than only selling standard products through mass-market retail stores. However, adding another shipping channel opens up completely new markets, allowing selling customized products with presumably higher margins. This is expressed in our models through the service level \(\alpha \). For the three developed models (SC, MC, and OC), tuning the \(\alpha \) parameter (in the S2 and O2 constraints, respectively) enabled us to observe changes in the logistics cost per channel type with changes in \(\alpha \). The SC distribution system can only serve the \(T\) segment, the MC distribution system can serve \(T \& C\) segments, and only the OC distribution system can serve all three (\(T, C, \& S\)) segments. Consequently, only the OC system can achieve a service level of 100%, provided that there are any customers that are interested in receiving standard products via home delivery. The initial value of the \(\alpha \) parameter is considered 0.10 (or 10% service level) and increased by 0.10 up to 1 (or 100% SL). The average objective value (total logistics cost) of all \(L\) instances is calculated for each \(\alpha \) value. Figure 4a shows the observed changes. The chart reports that, between 10 and 20%, the SC distribution system is costlier than MC and OC distribution systems, which incur the same amount of logistics cost. The reason is that the MC and OC distribution systems are more flexible and capable to serve certain numbers of last-mile delivery customer zones for customized product via urban van which is cheaper than heavy truck.

The costs of all three channel configurations become equal when the service level reaches 30%. The company can serve only 30% of total customers via SC, because only the customers satisfied with shopping for standard products in-shop can be reached. A further increase in the service level (i.e., starting from 30%) is possible via MC and OC distribution systems; however, MC cannot serve more than 60% SL, because it does not allow home-delivery of standard products from a dark store. The company can serve all customer segments only via the OC distribution system; however, the total logistics cost increases gradually. Further, it is insightful to observe that there is a steep rise in logistics costs when SL exceeds 90%. This may be the threshold for the company during decision making. As can be seen, in the range of [0.10, 0.60] of the α value, MC and OC incur the same logistics cost; however, OC is more flexible than MC and can lead to a lower cost at a certain SL. That is, OC is capable to serve last-mile delivery customers for standard products (S) over a dark store while serving physical stores. But, the fixed opening cost for a dark store enforces that OC behaves in the way MC does. Hence, it can be interesting to observe the logistics cost of the three distribution systems by discarding the fixed opening cost of dark stores. From the manufacturer’s perspective, in practice, this can be realized by either using its outlets (i.e., 0 cost for opening a DS) or stores of an independent retailer in exchange for various incentive schemes (i.e., considerably low cost for opening a DS). Figure 4b illustrates the observed changes wherein in the range [0.3, 0.6] of the \(\alpha \) value, OC outperforms MC in terms of logistics cost. Further, the logistics cost of OC also has a gentle rise when the SL increases. In summary, it is crucial to make effective decisions on supply chain network design to define the company policy for the customer service level. In this context, our investigation suggests that MC and OC outperform SC distribution system in terms of logistics cost. Moreover, our analysis shows that OC is an economically viable distribution system for achieving a cost-effective supply chain (i.e., if fixed opening cost of the dark store is discarded or significantly decreased) and meeting the expectations of various customer segments in terms of shopping and product preferences. Based on the above analysis, the following insight can be drawn:

Insight 1: Omni-channel (OC) distribution systems offer greater flexibility and potential cost-effectiveness compared to single-channel (SC) and multi-channel (MC) systems, particularly when serving diverse customer segments and aiming for higher service levels. The OC system’s efficiency increases notably when the fixed costs for establishing dark stores are minimized or eliminated, highlighting its viability for a cost-effective and customer-responsive supply chain network design.

6.2.2.2 Effect of the number of dark stores

In the OC model, dark stores play a crucial role in consolidating last-mile delivery and in-store pick-up services. Naturally, minimizing the number of opened dark stores is a major objective of the proposed model because opening a dark store incurs additional costs. Meanwhile, the transportation costs decrease as the number of dark stores rises, because the average distance for last-mile deliveries is less and more customers have the BOPS option. In addition, a higher number of BOPS customers reduces the complexity of last-mile routing operations as well. In this respect, we investigate how the number of DS affects the transportation costs. In our numerical study of the \(L\) instances, two dark stores were established in most cases (85%). Therefore, we run those instances (i.e., by setting \(\alpha {\text{to}} 100 \%\)) for various dark store counts, i.e., from \({N}_{min}\) to \({N}_{max}\) inclusively, as Algorithm 1 enables us to retrieve the best locations, allocation and objective value for each \(N\) between \({N}_{min}\) and \({N}_{max}\). Figure 5 depicts the results. The transportation costs drop gradually with an increase in the number of dark stores. The results suggest that opening the third dark store decreases the transportation costs by 16%, whereas opening the 4th dark store decreases the preceding (i.e., corresponding to opening 3 dark stores) transportation costs by 18%, followed by 23% (from 4 to 5). As can be seen, opening five dark stores has a more positive impact on reducing transportation costs, whereas opening the next two dark stores (6th and 7th) does not affect the transportation costs. On average, opening one more dark store leads to a decrease in transportation cost by 19%; this can provide sound insights for a company during decision making regarding channel design. If a company wants to gain competitive advantages, offering multiple pickups or return points to customers can be a wise strategy in terms of customer satisfaction. Moreover, as mentioned above, if a manufacturer can significantly reduce (or completely avoid) the fixed cost of opening a dark store, in this case opening a feasible number of dark stores (i.e., in our case 5) can reduce the transportation costs. Therefore, understanding the effect of opening additional dark stores can facilitate an effective decision-making process. The findings from this analysis bring us to the following insight:

Insight 2: In an omni-channel distribution system, strategically increasing the number of dark stores leads to a notable decrease in transportation costs, mainly due to shorter delivery routes and more BOPS options. However, there is a diminishing return on cost savings with the addition of each new store, indicating a need for a balanced approach in the number of dark stores.

6.2.2.3 Effect of in-store pickup

In the proposed OC model, customers (i.e., \(S\cup C\)) located within a defined distance range are assigned to an open dark store as BOPS customers. The in-store pickup concept is a significant element of the OC distribution system and offers a flexible shopping experience to customers. Thus, we investigate the effect of BOPS customers on total logistics costs. Further, we performed this analysis on the set of \(L\) instances where \(\alpha =100\%\). For all instances, the average BOPS customers are roughly equal to 5% (i.e., 4.82%) of the total home delivery customers (both \(S\) and \(C\)). We assume this value to be a baseline scenario. Then, we turn home-delivery customers into BOPS customers by increasing 5% for a new scenario. To this end, for \(S\) customers, a randomly selected node is removed from its route and assigned as a BOPS customer to the corresponding DS from which the route originated. For \(C\) customers, a randomly selected node is assigned to the nearest opened DS and removed from the route. The procedure repeats until achieving the required percentage. Afterwards, we record the average objective value for each instance. Figure 6 illustrates the results.

In general, the logistics cost declines as we increase BOPS customers. The logistics costs drop dramatically by between 5 and 20%; subsequently, they decline more slowly. This investigation shows that an increase in BOPS customers leads to a reduction in the total logistics costs. Companies can leverage this and invest some effort in motivating online shoppers to pick up in-store (e.g., by offering special discounts or redeeming bonus points). Moreover, having data on costs saved enables the company to determine the investment budget for promotional activities. Besides cost savings, this initiative can give rise to making the complicated last-mile delivery operations easy within city limits and achieving sustainability. This analysis yields the following insight:

Insight 3: Increasing the number of BOPS customers in the omni-channel distribution model significantly reduces logistics costs. This approach also can streamline last-mile delivery operations and contribute to greater sustainability in the supply chain.

7 Extension

The aim of this section is to illustrate the integration of customer responsiveness into our proposed OC distribution model. The original OC model focuses on minimizing the total cost, which includes fixed costs for vehicle usage, the opening cost of dark stores, and routing or transportation costs. However, in the context of last-mile delivery, the customer’s demand for prompt delivery emerges as a crucial competitive factor for manufacturers.

To address this, we propose a modification to our model, shifting its focus from solely minimizing transportation costs to reducing the customer’s response (wait) time. This shift entails incorporating a time-based delivery cost into our objective function. To facilitate this, we introduce a new decision variable, \({\tau }_{i}\), representing the delivery time to node \(i\), where \(i\) is an element of the set \(R\cup S\cup C\). The cost associated with the delivery time to node \(i\) is denoted as \(\pi \), measured in Euros per hour \(({\sf C}\!\!\!\!\raise.8pt\hbox{=} /hour)\). Estimating the value of \(\pi \) is complex and could depend on various factors, such as the distributor's salary, the type of vehicle used, and the speed of delivery. For the purposes of this extended model, under a standard shipping plan (3 business days), we assume \(\pi\) to be 0.069 \({\sf C}\!\!\!\!\raise.8pt\hbox{=} /hour\).

To further refine our model, we focus on calculating the arrival time for each node in hours. This is achieved using the existing distance matrix from our original model, which allows us to calculate the arrival time (i.e., \({\lambda }_{ij}\), \(\forall \) \(i,j\in R\cup S\cup C\)) by dividing the distance \(({d}_{ij})\) between each node pair \(({N}^{1},{N}^{2},{N}^{3})\) by the average speed of the corresponding vehicle type (\({\gamma }_{v}\), where \(v\in H\cup U\)). For this purpose, we assume average speeds of 80 \(km/hour\) for heavy truck \(({\gamma }_{h})\) and 50 \(km/hour\) for urban van \(({\gamma }_{u}).\) The revised objective function, therefore, aims to minimize a combination of fixed vehicle usage costs, dark store opening costs, and the newly integrated time-based delivery costs, balancing cost efficiency with enhanced customer responsiveness.

\({\text{Minimize}}\)

\(\mathrm{Subject to}\)

In the outlined OC scenario, the modified model incorporates both the existing constraint sets from the original framework (i.e., \({\text{O}}2\dots {\text{O}}24\)) and the newly introduced constraints (E2 to E5). These sets, identified as E2, E3, and E4, calculate the arrival times at each node while simultaneously preventing sub-tours. In these constraints, \(M\) represents a sufficiently large number. The final constraint, E5, is introduced to ensure the non-negativity of the decision variables.

7.1 Numerical study

We conduct a numerical study on our \(L\) instances to obtain further insights. Our objective is to investigate the impact of location and different shopping/picking options on the manufacturer's decision-making, especially in terms of customer responsiveness. Consequently, we carry out two types of analyses akin to those discussed in the preceding section. Initially, we analyze the effect of the number of operational dark stores on the average cost associated with customer arrival time, which includes delivery costs. To achieve this, we consider two dark stores as a baseline scenario, then we run all \(L\) instances (i.e., by setting \(\alpha {\text{to}} 100 \%\)) for various dark store counts, i.e., from \({N}_{min}\) to \({N}_{max}\) inclusively, as Algorithm 1 Footnote 3 enables us to retrieve the best locations, allocation and objective value for each \(N\) between \({N}_{min}\) and \({N}_{max}\). Figure 7 illustrates the results.

The results show that opening a third dark store leads to a more significant reduction in delivery costs by 5.52%, whereas the addition of a fourth dark store only marginally decreases these costs by 0.37%. Notably, opening additional dark stores beyond this point does not further reduce delivery costs. This finding aligns with our previous analysis (see Fig. 5), underscoring the crucial role of location in decision-making. This suggests that manufacturers should meticulously consider location when designing their distribution systems. In today’s e-commerce and omni-channel marketing and distribution landscape, the value of retailers’ physical stores has grown, prompting manufacturers and retailers to collaborate closely for mutual advantage. Manufacturers can use retailers’ physical locations to expedite deliveries and offer convenient pickup options for online orders, which can also drive more customers to the retail stores (Ailawadi & Farris, 2017; Jindal et al., 2021).

Our subsequent analysis investigates the impact of BOPS customers on the delivery cost within the modified OC model. Similar to the approach in the previous subsection (6.2.2.3), we start with a baseline scenario where 5% of the total home delivery customer zone is designated. We then gradually transform these home-delivery customers into BOPS customers, increasing by 5% for each new scenario. Following this, we record the average delivery cost for each case. The outcomes of this analysis are illustrated in Fig. 8