Abstract

Circular supplier evaluation aims at selecting the most suitable suppliers with zero waste. Sustainable circular supplier selection also considers socio-economic and environmental factors in the decision process. This study proposes an integrated method for evaluating sustainable suppliers in intelligent circular supply chains using fuzzy inference and multi-criteria decision-making. In the first stage of the proposed method, supplier evaluation sub-criteria are identified and weighted from economic, social, circular, and Industry 4.0 perspectives using a fuzzy group best–worst method followed by scoring the suppliers on each criterion. In the second stage, the suppliers are ranked and selected according to an overall score determined by a fuzzy inference system. Finally, the applicability of the proposed method is demonstrated using data from a public–private partnership project at an offshore wind farm in Southeast Asia.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Supplier selection methods are designed to methodically and thoroughly determine the best suppliers who propose the best value for money. Companies must control and manage their supply chain productivity by minimizing costs and satisfying customer requirements (Mirzaee et al., 2018; Parkouhi & Ghadikolaei, 2017). Supplier selection problems involve multiple and often conflicting quantitative and qualitative criteria (Guarnieri & Trojan, 2019). Companies have also embarked on including sustainability in their supply chains in response to pressure from their shareholders and stakeholders. Lu et al. (2007) argue collaboration and cooperation with green suppliers and purchasing environmentally friendly raw materials is the initial stage in applying a green supply chain in this process. Other researchers, such as Govindan et al. (2020b) and Perçin (2022), show that circular suppliers can address the sustainability agenda in companies. Circular and sustainable suppliers aim at zero waste by taking advantage of both forward and reverse flows in supply chains (Perçin, 2022). The fourth industrial revolution (Industry 4.0) has transformed the economy by bringing relevant changes to the supply chains through the Internet of Things (IoT), cyber-physical systems, and smart factories (Pivoto et al., 2021). Today’s supply chains are designed considering disruptive technological transformations (Fatorachian & Kazemi, 2021). Industry 4.0 technologies can help companies prepare for unpredictable disasters (Choi et al., 2022). The industrial revolution considerably benefits the performance in supply chains, from planning and sourcing to final delivery (Rad et al., 2022). In this regard, market needs are met with better quality of products and punctuality in the delivery of products, the possibility of product customization, the tracking and traceability of products, and the design of supply chains towards the minimization of pack size.

Environmental management has emerged as one of the most essential organizational strategies for mitigating harmful ecological effects (Barros et al., 2021; Pizzi et al., 2021). These harmful environmental effects reflect both the production and consumption perspectives in operations. The circular economy is one of the practical options for overcoming these challenges by adopting sustainable development approaches (Lopes de Sousa Jabbour et al., 2018). Moving to the total value of sustainable development will require overcoming many organizational challenges (Wamba et al., 2023). Cooperation with a sustainable circular supplier is a practical and effective solution for increasing environmental and social impacts in organizations (Alavi et al., 2021; Kumar et al., 2021).

Today’s industrial revolution brings resilience into supply chains to reach the minimum possible internal and external disruptions through practical data analysis (Kusi-Sarpong et al., 2021). In addition, customer satisfaction is greatly valued and improved, and the inventory volume is vastly reduced. This industrial revolution also dealt with desirable monitoring, engagement of local supplies, and attachment to a higher rate of sustainability than ever (Xie et al., 2020). When looking at the literature on sustainable supply chain (SSC), one will come up with the two new concepts of Industry 4.0 and circular economy (CE), which are not practiced well. Industry 4.0 and the circular economy are highly influential in shaping the future of supply chains. To name some capabilities of Industry 4.0, one can refer to enhanced communication, transparency, and data availability during the supplier selection process (Asif et al., 2022). Considering all these benefits, decision-makers are highly recommended to benefit from Industry 4.0 technologies in their decision-making processes and supplier selection.

This paper proposes a fuzzy inference decision support system based on the fuzzy group best–worst method (BWM) for sustainable supplier selection in intelligent circular supply chains. In the first stage, economic, social, circular, and Industry 4.0 criteria are considered evaluation criteria, and their relevant sub-criteria are formulated by expert opinions and the literature review. A multi-criteria decision-making (MCDM) technique is used to evaluate each supplier’s performance on each criterion. A novel fuzzy group BWM is proposed to weigh each sub-criteria. In the second stage, a fuzzy inference system (FIS) is developed to calculate the final score of suppliers by establishing a non-linear relationship between the final score and the supplier’s score on each criterion. The suppliers’ scores on the economic, social, circular, and Industry 4.0 criteria are inputs in the fuzzy group BWM, and the suppliers’ final performance scores are considered outputs of the FIS. The purpose of this study is to answer the following questions:

-

What sub-criteria are suitable for evaluating suppliers from the economic, social, circular, and Industry 4.0 perspectives?

-

What is a practical approach for evaluating and ranking the suppliers?

-

How can we evaluate and validate the effectiveness of the proposed approach?

Addressing these research questions will result in the following contributions:

-

Identifying a comprehensive set of economic, social, circular, and Industry 4.0 criteria for supplier evaluation;

-

Developing a novel approach to evaluate and rank the suppliers using a fuzzy group BWM and FIS;

-

Validating the applicability and efficacy of the proposed approach with a real-world case study.

The remainder of this paper is organized as follows. Section 2 presents a literature review. The proposed approach is presented in Sect. 3. In Sect. 4, the application of the proposed approach is demonstrated through a real-world case study. Finally, the managerial implications and conclusion are presented in Sects. 5 and 6, respectively.

2 Literature review

This section consists of two sub-sections. First, the supplier evaluation criteria are examined from four perspectives: economic, circular, social, and Industry 4.0. Then, the BWM-based approaches used in the supplier selection area are reviewed.

2.1 Supplier evaluation criteria

The supplier selection problem is an MCDM problem of high complexity and includes contradictory criteria. Identifying appropriate and effective criteria is a key factor in supplier selection that strongly depends on the studied business context.

In general, supplier evaluation criteria can be categorized into two groups of economic and non-economic criteria. In the literature, various categories have been presented based on the nature of the problem under study. In this article, we categorize supplier evaluation criteria into four groups including economic, circular, social, and Industry 4.0. In the following, each group of criteria is examined.

2.1.1 Economic criteria for supplier evaluation

Since a large part of production costs are related to purchasing costs, organizations and companies look for suppliers that provide raw materials at a low price. Therefore, the cost is one of the most critical economic criteria in the supplier selection process, used in almost all articles. The cost criterion has been applied in different categories, such as product cost, price, operational costs, transportation costs, and cost of logistics services. Economic criteria for evaluating suppliers are not limited to cost criteria only; quality, risk, and on-time delivery are other widely used economic criteria in this field. Table 1 shows the most critical economic criteria for selecting suppliers in manufacturing industries.

2.1.2 Circular criteria for supplier evaluation

In recent decades, increasing pressure from the government and people on the one hand, and creating a competitive environment on the other hand, has required industrial owners and manufacturers to move towards a green supply chain. The first step in achieving environmental goals is to collaborate with green suppliers. Green suppliers are suppliers who, in addition to economic criteria, also pay attention to environmental factors in designing, manufacturing, packaging, and distributing products. The concept of green supplier was first proposed by Noci (1997), who presented a rating approach to evaluate suppliers from an environmental point of view. The literature review shows that pollution control, green technology, green packaging, and environmental management systems are among the most widely used green criteria for evaluating suppliers. In recent years, with the emergence of CE, companies have structured their environmental activities with the aim of moving towards zero waste. Kannan et al. (2020) were the first researchers to apply the concept of CE to the supplier selection problem. Kusi-Sarpong et al. (2021), Alavi et al. (2021), and Mina et al. (2021) are among the other pioneers of this field who have elaborately interpreted the circular criteria in the supplier selection problem. Table 2 reports the most critical circular criteria for selecting suppliers in manufacturing industries.

2.1.3 Social criteria for supplier evaluation

In addition to economic and environmental criteria, social criteria should also be included to evaluate suppliers from the sustainability perspective. Evaluating suppliers considering all three dimensions of sustainability has received much attention in recent years. Meanwhile, the studies of the previous decades paid less attention to the social dimension (Memari et al., 2019). Occupational health and safety, rights of employees and stakeholders, information disclosure, and child and forced labor are among the most well-known and widely used social criteria in the supplier selection problem. Table 3 provides some essential social criteria for the supplier selection problem in manufacturing industries, which are extracted from the literature.

2.1.4 Industry 4.0 criteria for supplier evaluation

The circular business model requires companies and organizations to strictly stick to non-stop monitoring and increasing the lifecycle of their products. Therefore, the strong need for supporting these technologies is felt more than ever (Geissdoerfer et al., 2020). The integration of CE into businesses and companies, in itself, needs some significant changes into the production process of companies (Chen et al., 2020). One of these changes can be the entry of new technologies like smart ones that can be enhanced via Internet/wireless technology in such a way that the green environment will not be threatened (Dantas et al., 2021).

To pursue this objective, Industry 4.0 can have a highly prominent role due to its increasing popularity among companies, its eco-friendly nature, and its benefits in the production process. This industry is referred to as the fourth industrial revolution since it has been founded upon internet technologies, which is focused on smart production and services (Lin, 2018).

Nowadays, the owners of industries use internet-based technologies to increase their efficiency and improve their performance. It is imperative to evaluate suppliers from the Industry 4.0 perspective in some industries before committing to cooperating with a supplier. Table 4 displays some of the most important Industry 4.0 criteria for evaluating suppliers in manufacturing industries.

2.2 Supplier selection methods

The evolution of new strategies for selecting and evaluating sustainable suppliers is one of the most promising developments in SSC management. In supply chain management, the MCDM approaches are frequently used for choosing suppliers. Due to their adaptability and simplicity of use, MCDM approaches have become increasingly popular for resolving green and socially responsible supply chain problems involving multiple, often competing, criteria. The analytical hierarchy process (AHP) is a well-accepted MCDM technique for resolving issues associated with evaluating and selecting suppliers.

In recent years, with the emergence of the BWM, attention was shifted from AHP to BWM; because this method has fewer pairwise comparisons and higher consistency compared to AHP. Many researchers have applied the BWM to evaluate and select suppliers. Some researchers have also used the combination of BWM with other methods for this purpose. In Table 5, articles that have used the BWM method in the supplier selection problem have been reviewed.

2.3 Fuzzy inference system

FIS is a non-linear system that originates from integrating expert system technology and fuzzy logic (Govindan et al., 2020a). FIS comprises several fuzzy IF–THEN rules obtained from expert opinion. These rules are effective in mimicking the human reasoning process. Readers can refer to Tavana et al. (2019) for the advantages of FIS and its flexible rules.

Fuzzy logic modeling can be categorized into the Mamdani (Mamdani & Assilian, 1993) and the Takagi–Sugeno-Kang (Sugeno, 1985) methods. The Mamdani models refer to a fuzzy set of antecedents and their consequences as the model’s elements. The antecedents of the Mamdani models also exist in the Takagi–Sugeno-Kang models. It is noteworthy that linear equations are the consequences of the Takagi–Sugeno-Kang models. Fuzzy relational equation models mainly aim at these fuzzy relation matrices according to input–output process data. When it comes to the performance of multi-parameter synthetic evaluation and weighting inputs and fuzzy rules, the pitfalls of Takagi–Sugeno-Kang FIS turn up. The advantages of the Mamdani model can be summarized in its high legibility and understandability. Consequently, it is claimed that Mamdani FIS is superior to similar models concerning output expression (Govindan et al., 2020a).

A large number of researchers have presented hybrid approaches based on FIS and MCDM methods in various fields, such as transportation (Zarrinpanjeh et al., 2022), project portfolio selection (Tavana et al., 2019), finance (Veeramani et al., 2022), and healthcare (Karasan et al., 2022) among others. The combination of FIS and MCDM methods in supplier selection has received more attention than in other areas. Jain et al. (2020) proposed a practical approach for sustainable supplier evaluation by integrating fuzzy AHP, TOPSIS, and FIS. Fallahpour et al., (2021a, 2021b) developed a fuzzy inference decision support system based on BWM for sustainable supplier evaluation. Similarly, with the help of fuzzy BWM and FIS, a dynamic decision support system for the sustainable supplier selection problem in a circular supply chain was configured by Alavi et al. (2021). A hybrid framework based on the fuzzy preference programming method and FIS for green supplier evaluation was developed by Saghafinia et al. (2022).

3 Proposed approach

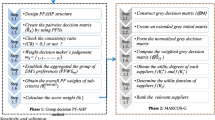

In manufacturing industries, procurement costs comprise a large part of production costs. Cooperation with the appropriate suppliers can be significantly effective in reducing production costs and increasing the quality of products. In recent decades, with the emergence of Industry 4.0, manufacturing industries have moved their activities towards sustainable production, relying on the CE concept. In such a situation, the supplier selection problem becomes more complicated; because evaluating and selecting suppliers deals with conflicting and intertwined economic, social, circular, and Industry 4.0 criteria. This paper develops a novel sustainable circular supplier evaluation approach by combining fuzzy group BWM and FIS. The general structure of the proposed approach is depicted in Fig. 1.

The presented approach includes two stages, as follows:

Stage 1 Calculating the score of suppliers for each criterion

Each criterion’s sub-criteria weights are calculated using the fuzzy group BWM in this stage. This stage consists of the following steps:

Step 1.1 In this step, the economic, social, circular, and Industry 4.0 aspects are considered supplier evaluation criteria. The sub-criteria of these criteria are recognized by investigating the literature and applying the knowledge of experts.

Step 1.2 In this step, experts identify the best and the worst sub-criteria. Each expert performs this operation independently.

Step 1.3 In this step, the best sub-criterion of each criterion is compared with other sub-criteria of that criterion in pairs by the verbal phrases displayed in Table 6 to determine the fuzzy best-to-others vector. These operations are performed for each expert independently.

Step 1.4 In this step, the worst sub-criterion of each criterion is compared with other sub-criteria of that criterion in pairs by the verbal phrases displayed in Table 6 to determine the fuzzy others-to-worst vector. These operations are performed for each expert separately.

Step 1.5 In this step, we calculate the weight of sub-criteria by applying the fuzzy optimization model developed by Govindan et al. (2022). This model is given below.

Notations

\(c \in \left\{ {1,2,...,C} \right\}\) | Criterion |

|---|---|

\(i \in \left\{ {1,2,...,n} \right\}\) | Sub-criterion |

\(i_{c}\) | Sub-criterion i of criterion c |

\(k \in \left\{ {1,2,...,K} \right\}\) | Decision-maker |

\(s \in \left\{ {1,2,...,S} \right\}\) | Supplier |

\(\tilde{\vartheta }_{{i_{c} k}} = (\dot{\vartheta }_{{i_{c} k}} ,\ddot{\vartheta }_{{i_{c} k}} ,\dddot \vartheta_{{i_{c} k}} )\) | The fuzzy best-to-others vector obtained from expert k |

\(\tilde{\eta }_{{i_{c} k}} = (\dot{\eta }_{{i_{c} k}} ,\ddot{\eta }_{{i_{c} k}} ,\dddot \eta_{{i_{c} k}} )\) | The fuzzy others-to-worst vector obtained from expert k |

\(\tilde{\psi }_{bk} = (\dot{\psi }_{bk} ,\ddot{\psi }_{bk} ,\dddot \psi_{bk} )\) | The fuzzy weight of the best sub-criterion based on the opinion of expert k |

\(\tilde{\psi }_{wk} = (\dot{\psi }_{wk} ,\ddot{\psi }_{wk} ,\dddot \psi_{wk} )\) | The fuzzy weight of the worst sub-criterion based on the opinion of expert k |

\(\tilde{\psi }_{{i_{c} k}} = (\dot{\psi }_{{i_{c} k}} ,\ddot{\psi }_{{i_{c} k}} ,\dddot \psi_{{i_{c} k}} )\) | The fuzzy weight of the sub-criterion i based on the opinion of expert k |

\(\begin{gathered} \tilde{\alpha }_{k} = (\alpha_{k} ,\alpha_{k} ,\alpha_{k} ) \hfill \\ \sum\limits_{k} {\alpha_{k} } = 1 \hfill \\ \end{gathered}\) | The weight of expert k |

\(\tilde{\theta }_{k} = (\dot{\theta }_{k} ,\ddot{\theta }_{k} ,\dddot \theta_{k} )\) | \(Max\left\{ {\left| {\tilde{\psi }_{bk} - \tilde{\psi }_{ik} \times \tilde{\vartheta }_{ik} } \right|,\left| {\tilde{\psi }_{ik} - \tilde{\psi }_{iw} \times \tilde{\eta }_{ik} } \right|} \right\}\) |

Mathematical model

Assume that the optimal value of the objective function is represented by \(\theta_{k}^{*}\). In this case, the mathematical model presented in Eq. (1) is transformed as follows.

It should be noted that the model presented in Eq. (2) should be developed separately for each criterion’s sub-criteria. The optimal values of the decision variables (i.e., the weights of sub-criteria and objective function) are determined by solving the proposed model. If \(\theta_{k}^{*}\) is less than 0.1 for each k, there is consistency in pairwise comparisons; otherwise, pairwise comparisons must be corrected.

The \(\alpha_{k}\) values are determined based on criteria such as work experience and job position. The work experience criterion was used to give weight to the experts because all the experts had a managerial position. The process of weighing the experts is given in the case study section.

Step 1.6: This step determines the score of the suppliers for each sub-criterion. To this end, experts must score the suppliers for each sub-criterion by the verbal phrases shown in Table 7. Therefore, \((\dot{\gamma }_{{i_{c} ks}} ,\ddot{\gamma }_{{i_{c} ks}} ,\dddot \gamma_{{i_{c} ks}} )\) represents the score assigned to supplier s in sub-criterion \(i_{c}\) by expert k.

Step 1.7: In this step, first, the fuzzy score of suppliers for each criterion is calculated by Eq. (3). Then, the average defuzzified score of suppliers for each criterion is determined using Eq. (4).

where \((\dot{\lambda }_{cks} ,\ddot{\lambda }_{cks} ,\dddot \lambda_{cks} )\) and \(\mu_{cs}\) represent the fuzzy and average defuzzified score of suppliers for each criterion. It should be noted that \(\mu_{cs}\) is considered as the input variable of FIS.

Stage 2: Calculating the final score of suppliers using FIS

In this stage, the final score of each supplier is calculated by the FIS. This stage consists of four steps, which are given below:

Step 2.1: This step aims at forming all the membership functions about input and output variables in the proposed FIS. It is noteworthy that Mamdani FIS is employed in designing the proposed FIS. The input variables include economic, circular, social, and Industry 4.0 criteria, and the output variables in the FIS include the suppliers’ scores. The number of input variables and their membership functions determine the number of fuzzy inference rules. When the number of membership functions for the input variables increases, the number of rules will also increase exponentially. However, the accuracy does not necessarily improve.

On the other hand, the number of rules is not affected by the increase in the number of membership functions for the output variables. The accuracy will still improve in this situation. Therefore, five and seven membership functions were considered for the input and output variables to efficiently manage the number of rules and avoid additional complexity and processing time.

Step 2.2: Expert opinions are used to extract the fuzzy inference rules. For this purpose, experts link the input and output variables in the FIS through an “if–then” questionnaire. The following relationship is what may be formed between the input and output variables:

If economic is …, circular is …, social is …, and Industry 4.0 is …, then the score is …

Based on this relationship, all the membership functions are put in the blank space one by one for economic, circular, social, and Industry 4.0. Thus, one can refer to 54 non-iterative rules when there are four input variables and five membership functions. Experts select a suitable membership function for output variables to design the FIS based on each rule.

Step 2.3: In this step, every potential supplier is assigned an economic, circular, social, and Industry 4.0 score according to Step 1.7, and this score is inserted in the rule reviewer as input in the proposed FIS. Afterward, each supplier comes with a final score.

Step 2.4: The suppliers are ranked based on their scores in this step. The supplier with the highest score is selected as the most preferred supplier.

4 Case study

The emissions of greenhouse gasses, particularly CO2, have witnessed an intense increase due to increased human activity and energy consumption, such as fossil fuels. Nonetheless, the energy needs of the Association of Southeast Asian Nations (ASEAN) are met almost exclusively by fossil fuels, with renewables making up only a minor percentage: renewables accounted for only 14% of the region’s energy mix in 2019. The region has taken a long time to build its renewable energy sector, despite the supportive official policies and investment climate. However, ASEAN is committed to diversifying its energy sources and raising renewables by 2025. Yet, the energy transition in the ASEAN member states is moving at a snail’s pace. Annual investments of USD 27 billion in renewable energy are required if ASEAN is to meet its goal of 23% renewables in the primary energy supply by 2025. After giving those above and from their research, Vakulchuk et al. (2023) conclude that “the ASEAN countries need to improve their position in rankings of the renewable energy investment climate.” This brings about the urgency for the emergence of new energy sources so that the economy can experience even more economic growth and the environment will not be damaged (Triani et al., 2023). Public–private cooperation could help accelerate the pace of change. Not only ASEAN but many countries have been involved in bringing renewable energy sources (e.g., hydropower, wind power, geothermal, solar, tidal, and biomass) into use (Dong et al., 2022). In ASEAN countries, offshore wind power development shows promise (Thuy & Nhut, 2023).

Hence, the ASEAN options to set up an offshore wind farm in cooperation with the private sector is the concern of this case study. In this regard, through initial evaluation, it has identified six qualified suppliers out of many suppliers. In this section, the performance of suppliers is evaluated using the proposed approach and with the help of the knowledge of four experienced experts in the field of offshore wind energy. The demographic information for the experts is reported in Table 8. As shown in this table, the work experience of the two experts is 5–10 years, and the work experience of the other two is 10–15 years. A weight of 0.3 is considered for managers with more than ten years of experience, while a weight of 0.2 is assigned to those with less than ten years of experience. The following presents the process of evaluating suppliers using the proposed approach.

Stage 1: In this stage, the weight of the sub-criteria is calculated using fuzzy group BWM, and finally, the score of suppliers is determined for each criterion. This stage consists of 7 steps, which are given below:

Step 1.1: In this step, sub-criteria for evaluating suppliers were identified from economic, circular, social, and Industry 4.0 aspects by reviewing the literature and employing the knowledge of experts. These sub-criteria are presented in Table 9.

Step 1.2: In this step, each expert determines the best and worst sub-criteria separately, as shown in Table 10.

Step 1.3: In this step, the experts compare the best sub-criteria of each criterion with other sub-criteria of that criterion via the verbal phrases presented in Table 6. The fuzzy best-to-others vectors obtained from these comparisons for economic sub-criteria are reported in Table 11. Also, the fuzzy best-to-others vectors for other sub-criteria are shown in “Appendix A”.

Step 1.4: In this step, the experts compare the worst sub-criteria of each criterion with other sub-criteria of that criterion via the verbal phrases presented in Table 6. The fuzzy others-to-worst vectors obtained from these comparisons for economic sub-criteria are reported in Table 12. Also, the fuzzy others-to-worst vectors for other sub-criteria are shown in “Appendix A”.

Step 1.5: In this step, the fuzzy optimization model shown in Eq. (2) is developed by the vectors presented in Tables 11 and 12. It should be noted that this model is non-linear because it includes absolute value equations. The linearized model is presented in “Appendix B”.

\(Min(0.2 \times \theta_{1}^{*} + 0.3 \times \theta_{2}^{*} + 0.3 \times \theta_{3}^{*} + 0.2 \times \theta_{4}^{*} )\) | ||

\(s.t.\) | ||

\(\left| {(\dot{\psi }_{SCR11,1} ,\ddot{\psi }_{SCR11,1} ,\dddot \psi_{SCR11,1} ) - (2/3,1,3/2) \times (\dot{\psi }_{SCR12,1} ,\ddot{\psi }_{SCR12,1} ,\dddot \psi_{SCR12,1} )} \right| \le (\theta_{1}^{*} ,\theta_{1}^{*} ,\theta_{1}^{*} )\) | \(\begin{gathered} \frac{{\dot{\psi }_{SCR11,1} + 4 \times \ddot{\psi }_{SCR11,1} + \dddot \psi_{SCR11,1} }}{6} + \frac{{\dot{\psi }_{SCR12,1} + 4 \times \ddot{\psi }_{SCR12,1} + \dddot \psi_{SCR12,1} }}{6} + \hfill \\ \frac{{\dot{\psi }_{SCR13,1} + 4 \times \ddot{\psi }_{SCR13,1} + \dddot \psi_{SCR13,1} }}{6} + \frac{{\dot{\psi }_{SCR14,1} + 4 \times \ddot{\psi }_{SCR14,1} + \dddot \psi_{SCR14,1} }}{6} + \hfill \\ \frac{{\dot{\psi }_{SCR15,1} + 4 \times \ddot{\psi }_{SCR15,1} + \dddot \psi_{SCR15,1} }}{6} + \frac{{\dot{\psi }_{SCR16,1} + 4 \times \ddot{\psi }_{SCR16,1} + \dddot \psi_{SCR16,1} }}{6} = 1 \hfill \\ \end{gathered}\) | |

\(\left| {(\dot{\psi }_{SCR11,1} ,\ddot{\psi }_{SCR11,1} ,\dddot \psi_{SCR11,1} ) - (3/2,2,5/2) \times (\dot{\psi }_{SCR13,1} ,\ddot{\psi }_{SCR13,1} ,\dddot \psi_{SCR13,1} )} \right| \le (\theta_{1}^{*} ,\theta_{1}^{*} ,\theta_{1}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR11,1} ,\ddot{\psi }_{SCR11,1} ,\dddot \psi_{SCR11,1} ) - (7/2,4,9/2) \times (\dot{\psi }_{SCR14,1} ,\ddot{\psi }_{SCR14,1} ,\dddot \psi_{SCR14,1} )} \right| \le (\theta_{1}^{*} ,\theta_{1}^{*} ,\theta_{1}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR11,1} ,\ddot{\psi }_{SCR11,1} ,\dddot \psi_{SCR11,1} ) - (3/2,2,5/2) \times (\dot{\psi }_{SCR15,1} ,\ddot{\psi }_{SCR15,1} ,\dddot \psi_{SCR15,1} )} \right| \le (\theta_{1}^{*} ,\theta_{1}^{*} ,\theta_{1}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR11,1} ,\ddot{\psi }_{SCR11,1} ,\dddot \psi_{SCR11,1} ) - (5/2,3,7/2) \times (\dot{\psi }_{SCR16,1} ,\ddot{\psi }_{SCR16,1} ,\dddot \psi_{SCR16,1} )} \right| \le (\theta_{1}^{*} ,\theta_{1}^{*} ,\theta_{1}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR12,1} ,\ddot{\psi }_{SCR12,1} ,\dddot \psi_{SCR12,1} ) - (5/2,3,7/2) \times (\dot{\psi }_{SCR14,1} ,\ddot{\psi }_{SCR14,1} ,\dddot \psi_{SCR14,1} )} \right| \le (\theta_{1}^{*} ,\theta_{1}^{*} ,\theta_{1}^{*} )\) | \(\begin{gathered} \frac{{\dot{\psi }_{SCR11,2} + 4 \times \ddot{\psi }_{SCR11,2} + \dddot \psi_{SCR11,2} }}{6} + \frac{{\dot{\psi }_{SCR12,2} + 4 \times \ddot{\psi }_{SCR12,2} + \dddot \psi_{SCR12,2} }}{6} + \hfill \\ \frac{{\dot{\psi }_{SCR13,2} + 4 \times \ddot{\psi }_{SCR13,2} + \dddot \psi_{SCR13,2} }}{6} + \frac{{\dot{\psi }_{SCR14,2} + 4 \times \ddot{\psi }_{SCR14,2} + \dddot \psi_{SCR14,2} }}{6} + \hfill \\ \frac{{\dot{\psi }_{SCR15,2} + 4 \times \ddot{\psi }_{SCR15,2} + \dddot \psi_{SCR15,2} }}{6} + \frac{{\dot{\psi }_{SCR16,2} + 4 \times \ddot{\psi }_{SCR16,2} + \dddot \psi_{SCR16,2} }}{6} = 1 \hfill \\ \end{gathered}\) | |

\(\left| {(\dot{\psi }_{SCR13,1} ,\ddot{\psi }_{SCR13,1} ,\dddot \psi_{SCR13,1} ) - (3/2,2,5/2) \times (\dot{\psi }_{SCR14,1} ,\ddot{\psi }_{SCR14,1} ,\dddot \psi_{SCR14,1} )} \right| \le (\theta_{1}^{*} ,\theta_{1}^{*} ,\theta_{1}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR15,1} ,\ddot{\psi }_{SCR15,1} ,\dddot \psi_{SCR15,1} ) - (3/2,2,5/2) \times (\dot{\psi }_{SCR14,1} ,\ddot{\psi }_{SCR14,1} ,\dddot \psi_{SCR14,1} )} \right| \le (\theta_{1}^{*} ,\theta_{1}^{*} ,\theta_{1}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR16,1} ,\ddot{\psi }_{SCR16,1} ,\dddot \psi_{SCR16,1} ) - (2/3,1,3/2) \times (\dot{\psi }_{SCR14,1} ,\ddot{\psi }_{SCR14,1} ,\dddot \psi_{SCR14,1} )} \right| \le (\theta_{1}^{*} ,\theta_{1}^{*} ,\theta_{1}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR11,2} ,\ddot{\psi }_{SCR11,2} ,\dddot \psi_{SCR11,2} ) - (2/3,1,3/2) \times (\dot{\psi }_{SCR12,2} ,\ddot{\psi }_{SCR12,2} ,\dddot \psi_{SCR12,2} )} \right| \le (\theta_{2}^{*} ,\theta_{2}^{*} ,\theta_{2}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR11,2} ,\ddot{\psi }_{SCR11,2} ,\dddot \psi_{SCR11,2} ) - (3/2,2,5/2) \times (\dot{\psi }_{SCR13,2} ,\ddot{\psi }_{SCR13,2} ,\dddot \psi_{SCR13,2} )} \right| \le (\theta_{2}^{*} ,\theta_{2}^{*} ,\theta_{2}^{*} )\) | \(\begin{gathered} \frac{{\dot{\psi }_{SCR11,3} + 4 \times \ddot{\psi }_{SCR11,3} + \dddot \psi_{SCR11,3} }}{6} + \frac{{\dot{\psi }_{SCR12,3} + 4 \times \ddot{\psi }_{SCR12,3} + \dddot \psi_{SCR12,3} }}{6} + \hfill \\ \frac{{\dot{\psi }_{SCR13,3} + 4 \times \ddot{\psi }_{SCR13,3} + \dddot \psi_{SCR13,3} }}{6} + \frac{{\dot{\psi }_{SCR14,3} + 4 \times \ddot{\psi }_{SCR14,3} + \dddot \psi_{SCR14,3} }}{6} + \hfill \\ \frac{{\dot{\psi }_{SCR15,3} + 4 \times \ddot{\psi }_{SCR15,3} + \dddot \psi_{SCR15,3} }}{6} + \frac{{\dot{\psi }_{SCR16,3} + 4 \times \ddot{\psi }_{SCR16,3} + \dddot \psi_{SCR16,3} }}{6} = 1 \hfill \\ \end{gathered}\) | |

\(\left| {(\dot{\psi }_{SCR11,2} ,\ddot{\psi }_{SCR11,2} ,\dddot \psi_{SCR11,2} ) - (7/2,4,9/2) \times (\dot{\psi }_{SCR14,2} ,\ddot{\psi }_{SCR14,2} ,\dddot \psi_{SCR14,2} )} \right| \le (\theta_{2}^{*} ,\theta_{2}^{*} ,\theta_{2}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR11,2} ,\ddot{\psi }_{SCR11,2} ,\dddot \psi_{SCR11,2} ) - (2/3,1,3/2) \times (\dot{\psi }_{SCR15,2} ,\ddot{\psi }_{SCR15,2} ,\dddot \psi_{SCR15,2} )} \right| \le (\theta_{2}^{*} ,\theta_{2}^{*} ,\theta_{2}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR11,2} ,\ddot{\psi }_{SCR11,2} ,\dddot \psi_{SCR11,2} ) - (3/2,2,5/2) \times (\dot{\psi }_{SCR16,2} ,\ddot{\psi }_{SCR16,2} ,\dddot \psi_{SCR16,2} )} \right| \le (\theta_{2}^{*} ,\theta_{2}^{*} ,\theta_{2}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR12,2} ,\ddot{\psi }_{SCR12,2} ,\dddot \psi_{SCR12,2} ) - (5/2,3,7/2) \times (\dot{\psi }_{SCR14,2} ,\ddot{\psi }_{SCR14,2} ,\dddot \psi_{SCR14,2} )} \right| \le (\theta_{2}^{*} ,\theta_{2}^{*} ,\theta_{2}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR13,2} ,\ddot{\psi }_{SCR13,2} ,\dddot \psi_{SCR13,2} ) - (3/2,2,5/2) \times (\dot{\psi }_{SCR14,2} ,\ddot{\psi }_{SCR14,2} ,\dddot \psi_{SCR14,2} )} \right| \le (\theta_{2}^{*} ,\theta_{2}^{*} ,\theta_{2}^{*} )\) | \(\begin{gathered} \frac{{\dot{\psi }_{SCR11,4} + 4 \times \ddot{\psi }_{SCR11,4} + \dddot \psi_{SCR11,4} }}{6} + \frac{{\dot{\psi }_{SCR12,4} + 4 \times \ddot{\psi }_{SCR12,4} + \dddot \psi_{SCR12,4} }}{6} + \hfill \\ \frac{{\dot{\psi }_{SCR13,4} + 4 \times \ddot{\psi }_{SCR13,4} + \dddot \psi_{SCR13,4} }}{6} + \frac{{\dot{\psi }_{SCR14,4} + 4 \times \ddot{\psi }_{SCR14,4} + \dddot \psi_{SCR14,4} }}{6} + \hfill \\ \frac{{\dot{\psi }_{SCR15,4} + 4 \times \ddot{\psi }_{SCR15,4} + \dddot \psi_{SCR15,4} }}{6} + \frac{{\dot{\psi }_{SCR16,4} + 4 \times \ddot{\psi }_{SCR16,4} + \dddot \psi_{SCR16,4} }}{6} = 1 \hfill \\ \end{gathered}\) | |

\(\left| {(\dot{\psi }_{SCR15,2} ,\ddot{\psi }_{SCR15,2} ,\dddot \psi_{SCR15,2} ) - (5/2,3,7/2) \times (\dot{\psi }_{SCR14,2} ,\ddot{\psi }_{SCR14,2} ,\dddot \psi_{SCR14,2} )} \right| \le (\theta_{2}^{*} ,\theta_{2}^{*} ,\theta_{2}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR16,2} ,\ddot{\psi }_{SCR16,2} ,\dddot \psi_{SCR16,2} ) - (3/2,2,5/2) \times (\dot{\psi }_{SCR14,2} ,\ddot{\psi }_{SCR14,2} ,\dddot \psi_{SCR14,2} )} \right| \le (\theta_{2}^{*} ,\theta_{2}^{*} ,\theta_{2}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR12,3} ,\ddot{\psi }_{SCR12,3} ,\dddot \psi_{SCR12,3} ) - (2/3,1,3/2) \times (\dot{\psi }_{SCR11,3} ,\ddot{\psi }_{SCR11,3} ,\dddot \psi_{SCR11,3} )} \right| \le (\theta_{3}^{*} ,\theta_{3}^{*} ,\theta_{3}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR12,3} ,\ddot{\psi }_{SCR12,3} ,\dddot \psi_{SCR12,3} ) - (5/2,3,7/2) \times (\dot{\psi }_{SCR13,3} ,\ddot{\psi }_{SCR13,3} ,\dddot \psi_{SCR13,3} )} \right| \le (\theta_{3}^{*} ,\theta_{3}^{*} ,\theta_{3}^{*} )\) | ||

\(\left| {(\dot{\psi }_{SCR12,3} ,\ddot{\psi }_{SCR12,3} ,\dddot \psi_{SCR12,3} ) - (7/2,4,9/2) \times (\dot{\psi }_{SCR14,3} ,\ddot{\psi }_{SCR14,3} ,\dddot \psi_{SCR14,3} )} \right| \le (\theta_{3}^{*} ,\theta_{3}^{*} ,\theta_{3}^{*} )\) | \(\dot{\psi }_{SCR11,1} \le \ddot{\psi }_{SCR11,1} \le \dddot \psi_{SCR11,1} ;\quad \dot{\psi }_{SCR12,1} \le \ddot{\psi }_{SCR12,1} \le \dddot \psi_{SCR12,1} ;\) | |

\(\left| {(\dot{\psi }_{SCR12,3} ,\ddot{\psi }_{SCR12,3} ,\dddot \psi_{SCR12,3} ) - (3/2,2,5/2) \times (\dot{\psi }_{SCR15,3} ,\ddot{\psi }_{SCR15,3} ,\dddot \psi_{SCR15,3} )} \right| \le (\theta_{3}^{*} ,\theta_{3}^{*} ,\theta_{3}^{*} )\) | \(\dot{\psi }_{SCR13,1} \le \ddot{\psi }_{SCR13,1} \le \dddot \psi_{SCR13,1} ;\quad \dot{\psi }_{SCR14,1} \le \ddot{\psi }_{SCR14,1} \le \dddot \psi_{SCR14,1} ;\) | |

\(\left| {(\dot{\psi }_{SCR12,3} ,\ddot{\psi }_{SCR12,3} ,\dddot \psi_{SCR12,3} ) - (5/2,3,7/2) \times (\dot{\psi }_{SCR16,3} ,\ddot{\psi }_{SCR16,3} ,\dddot \psi_{SCR16,3} )} \right| \le (\theta_{3}^{*} ,\theta_{3}^{*} ,\theta_{3}^{*} )\) | \(\dot{\psi }_{SCR15,1} \le \ddot{\psi }_{SCR15,1} \le \dddot \psi_{SCR15,1} ;\quad \dot{\psi }_{SCR16,1} \le \ddot{\psi }_{SCR16,1} \le \dddot \psi_{SCR16,1} ;\) | |

\(\left| {(\dot{\psi }_{SCR11,3} ,\ddot{\psi }_{SCR11,3} ,\dddot \psi_{SCR11,3} ) - (5/2,3,7/2) \times (\dot{\psi }_{SCR14,3} ,\ddot{\psi }_{SCR14,3} ,\dddot \psi_{SCR14,3} )} \right| \le (\theta_{3}^{*} ,\theta_{3}^{*} ,\theta_{3}^{*} )\) | \(\dot{\psi }_{SCR11,2} \le \ddot{\psi }_{SCR11,2} \le \dddot \psi_{SCR11,2} ;\quad \dot{\psi }_{SCR12,2} \le \ddot{\psi }_{SCR12,2} \le \dddot \psi_{SCR12,2} ;\) | |

\(\left| {(\dot{\psi }_{SCR13,3} ,\ddot{\psi }_{SCR13,3} ,\dddot \psi_{SCR13,3} ) - (2/3,1,3/2) \times (\dot{\psi }_{SCR14,3} ,\ddot{\psi }_{SCR14,3} ,\dddot \psi_{SCR14,3} )} \right| \le (\theta_{3}^{*} ,\theta_{3}^{*} ,\theta_{3}^{*} )\) | \(\dot{\psi }_{SCR13,2} \le \ddot{\psi }_{SCR13,2} \le \dddot \psi_{SCR13,2} ;\quad \dot{\psi }_{SCR14,2} \le \ddot{\psi }_{SCR14,2} \le \dddot \psi_{SCR14,2} ;\) | |

\(\left| {(\dot{\psi }_{SCR15,3} ,\ddot{\psi }_{SCR15,3} ,\dddot \psi_{SCR15,3} ) - (3/2,2,5/2) \times (\dot{\psi }_{SCR14,3} ,\ddot{\psi }_{SCR14,3} ,\dddot \psi_{SCR14,3} )} \right| \le (\theta_{3}^{*} ,\theta_{3}^{*} ,\theta_{3}^{*} )\) | \(\dot{\psi }_{SCR15,2} \le \ddot{\psi }_{SCR15,2} \le \dddot \psi_{SCR15,2} ;\quad \dot{\psi }_{SCR16,2} \le \ddot{\psi }_{SCR16,2} \le \dddot \psi_{SCR16,2} ;\) | |

\(\left| {(\dot{\psi }_{SCR16,3} ,\ddot{\psi }_{SCR16,3} ,\dddot \psi_{SCR16,3} ) - (2/3,1,3/2) \times (\dot{\psi }_{SCR14,3} ,\ddot{\psi }_{SCR14,3} ,\dddot \psi_{SCR14,3} )} \right| \le (\theta_{3}^{*} ,\theta_{3}^{*} ,\theta_{3}^{*} )\) | \(\dot{\psi }_{SCR11,3} \le \ddot{\psi }_{SCR11,3} \le \dddot \psi_{SCR11,3} ;\quad \dot{\psi }_{SCR12,3} \le \ddot{\psi }_{SCR12,3} \le \dddot \psi_{SCR12,3} ;\) | |

\(\left| {(\dot{\psi }_{SCR16,4} ,\ddot{\psi }_{SCR16,4} ,\dddot \psi_{SCR16,4} ) - (2/3,1,3/2) \times (\dot{\psi }_{SCR11,4} ,\ddot{\psi }_{SCR11,4} ,\dddot \psi_{SCR11,4} )} \right| \le (\theta_{4}^{*} ,\theta_{4}^{*} ,\theta_{4}^{*} )\) | \(\dot{\psi }_{SCR13,3} \le \ddot{\psi }_{SCR13,3} \le \dddot \psi_{SCR13,3} ;\quad \dot{\psi }_{SCR14,3} \le \ddot{\psi }_{SCR14,3} \le \dddot \psi_{SCR14,3} ;\) | |

\(\left| {(\dot{\psi }_{SCR16,4} ,\ddot{\psi }_{SCR16,4} ,\dddot \psi_{SCR16,4} ) - (2/3,1,3/2) \times (\dot{\psi }_{SCR12,4} ,\ddot{\psi }_{SCR12,4} ,\dddot \psi_{SCR12,4} )} \right| \le (\theta_{4}^{*} ,\theta_{4}^{*} ,\theta_{4}^{*} )\) | \(\dot{\psi }_{SCR15,3} \le \ddot{\psi }_{SCR15,3} \le \dddot \psi_{SCR15,3} ;\quad \dot{\psi }_{SCR16,3} \le \ddot{\psi }_{SCR16,3} \le \dddot \psi_{SCR16,3} ;\) | |

\(\left| {(\dot{\psi }_{SCR16,4} ,\ddot{\psi }_{SCR16,4} ,\dddot \psi_{SCR16,4} ) - (7/2,4,9/2) \times (\dot{\psi }_{SCR13,4} ,\ddot{\psi }_{SCR13,4} ,\dddot \psi_{SCR13,4} )} \right| \le (\theta_{4}^{*} ,\theta_{4}^{*} ,\theta_{4}^{*} )\) | \(\dot{\psi }_{SCR11,4} \le \ddot{\psi }_{SCR11,4} \le \dddot \psi_{SCR11,4} ;\quad \dot{\psi }_{SCR12,4} \le \ddot{\psi }_{SCR12,4} \le \dddot \psi_{SCR12,4} ;\) | |

\(\left| {(\dot{\psi }_{SCR16,4} ,\ddot{\psi }_{SCR16,4} ,\dddot \psi_{SCR16,4} ) - (5/2,3,7/2) \times (\dot{\psi }_{SCR14,4} ,\ddot{\psi }_{SCR14,4} ,\dddot \psi_{SCR14,4} )} \right| \le (\theta_{4}^{*} ,\theta_{4}^{*} ,\theta_{4}^{*} )\) | \(\dot{\psi }_{SCR13,2} \le \ddot{\psi }_{SCR13,2} \le \dddot \psi_{SCR13,2} ;\quad \dot{\psi }_{SCR14,2} \le \ddot{\psi }_{SCR14,2} \le \dddot \psi_{SCR14,2} ;\) | |

\(\left| {(\dot{\psi }_{SCR16,4} ,\ddot{\psi }_{SCR16,4} ,\dddot \psi_{SCR16,4} ) - (3/2,2,5/2) \times (\dot{\psi }_{SCR15,4} ,\ddot{\psi }_{SCR15,4} ,\dddot \psi_{SCR15,4} )} \right| \le (\theta_{4}^{*} ,\theta_{4}^{*} ,\theta_{4}^{*} )\) | \(\dot{\psi }_{SCR15,2} \le \ddot{\psi }_{SCR15,2} \le \dddot \psi_{SCR15,2} ;\quad \dot{\psi }_{SCR16,2} \le \ddot{\psi }_{SCR16,2} \le \dddot \psi_{SCR16,2} ;\) | |

\(\left| {(\dot{\psi }_{SCR11,4} ,\ddot{\psi }_{SCR11,4} ,\dddot \psi_{SCR11,4} ) - (5/2,3,7/2) \times (\dot{\psi }_{SCR13,4} ,\ddot{\psi }_{SCR13,4} ,\dddot \psi_{SCR13,4} )} \right| \le (\theta_{4}^{*} ,\theta_{4}^{*} ,\theta_{4}^{*} )\) | \(\dot{\psi }_{SCR11,1} ,\dot{\psi }_{SCR12,1} ,\dot{\psi }_{SCR13,1} ,\dot{\psi }_{SCR14,1} ,\dot{\psi }_{SCR15,1} ,\dot{\psi }_{SCR16,1} > 0;\) | |

\(\left| {(\dot{\psi }_{SCR12,4} ,\ddot{\psi }_{SCR12,4} ,\dddot \psi_{SCR12,4} ) - (5/2,3,7/2) \times (\dot{\psi }_{SCR13,4} ,\ddot{\psi }_{SCR13,4} ,\dddot \psi_{SCR13,4} )} \right| \le (\theta_{4}^{*} ,\theta_{4}^{*} ,\theta_{4}^{*} )\) | \(\dot{\psi }_{SCR11,2} ,\dot{\psi }_{SCR12,2} ,\dot{\psi }_{SCR13,2} ,\dot{\psi }_{SCR14,2} ,\dot{\psi }_{SCR15,2} ,\dot{\psi }_{SCR16,2} > 0;\) | |

\(\left| {(\dot{\psi }_{SCR14,4} ,\ddot{\psi }_{SCR14,4} ,\dddot \psi_{SCR14,4} ) - (2/3,1,3/2) \times (\dot{\psi }_{SCR13,4} ,\ddot{\psi }_{SCR13,4} ,\dddot \psi_{SCR13,4} )} \right| \le (\theta_{4}^{*} ,\theta_{4}^{*} ,\theta_{4}^{*} )\) | \(\dot{\psi }_{SCR11,3} ,\dot{\psi }_{SCR12,3} ,\dot{\psi }_{SCR13,3} ,\dot{\psi }_{SCR14,3} ,\dot{\psi }_{SCR15,3} ,\dot{\psi }_{SCR16,3} > 0;\) | |

\(\left| {(\dot{\psi }_{SCR15,4} ,\ddot{\psi }_{SCR15,4} ,\dddot \psi_{SCR15,4} ) - (3/2,2,5/2) \times (\dot{\psi }_{SCR13,4} ,\ddot{\psi }_{SCR13,4} ,\dddot \psi_{SCR13,4} )} \right| \le (\theta_{4}^{*} ,\theta_{4}^{*} ,\theta_{4}^{*} )\) | \(\dot{\psi }_{SCR11,4} ,\dot{\psi }_{SCR12,4} ,\dot{\psi }_{SCR13,4} ,\dot{\psi }_{SCR14,4} ,\dot{\psi }_{SCR15,4} ,\dot{\psi }_{SCR16,4} > 0\) |

The model presented in Appendix B is run by a CPLEX solver using GAMS software to calculate the fuzzy weight of economic sub-criteria and consistency indicators. In the same way, the weight of other sub-criteria is calculated. Table 13 shows the weight of the sub-criteria and the values of consistency indicators for the sub-criteria of each criterion. As seen in Table 13, consistency indicator values for all experts are less than 0.1. Therefore, the calculated weights for the sub-criteria are confirmed.

Step 1.6: In this step, the experts evaluate the suppliers’ performance for each sub-criterion using the verbal phrases shown in Table 7. Table 14 shows the results of this evaluation.

Step 1.7: In this step, the fuzzy and average defuzzified scores of suppliers are calculated by Eqs. (3) and (4), respectively, which are displayed in Tables 15 and 16.

Stage 2: In this step, the final score of the suppliers is calculated using a FIS. The proposed FIS implementation process is given in four steps below.

Step 2.1: This step determines the membership functions for input and output variables. The proposed FIS states that economic, circular, social, and Industry 4.0 criteria are input variables, and suppliers’ final scores are output variables. The input and output variables’ membership functions are shown in Figs. 2a and b.

Step 2.2: The experts connected the input and output variables determined by the membership functions. The result of this operation led to the creation of 625 fuzzy inference rules (online resources). A screenshot of the rules defined in FIS is displayed in Fig. 3. In addition, the relationship between input and output variables (fuzzy inference rules) in three-dimensional space is depicted in Fig. 4. For example, in Fig. 4a, economic and circular criteria are input variables, the final score is output variable, and all change between 0 and 1. The graphical representation in Fig. 4a illustrates an increase in output values as the input values of economic and circular rise. In other words, the sensitivity of the output value is proportionate to both economic and circular. Similarly, the relationship between input and output variables can be analyzed in Fig. 4b–f.

Step 2.3: In this step, the scores calculated in step 1.7 for suppliers for each criterion are considered as input variables. The proposed FIS calculates the final score of suppliers using these input variables. Figure 5 shows the output of FIS in MATLAB software. This figure is related to the final score of supplier 1. In Table 17, the final scores of suppliers are reported.

Step 2.4: Finally, suppliers are ranked based on their scores in this step. Table 18 shows the prioritization of suppliers.

Based on the results, supplier 2, with a final score of 0.672, and supplier 3, with a final score of 0.598, are rated as the best and worst suppliers, respectively. The results presented in Table 17 show that the final score of supplier 5 is only 0.001 less than the final score of supplier 1. Therefore, it is expected that the two suppliers do not have a significant difference in their criteria scores with each other. But the results of Table 16 show that the score of Supplier 5 in three economic, social, and circular criteria is significantly lower than Supplier 1, and the score of Supplier 5 in the Industry 4.0 criterion is better than that of Supplier 1. Two conclusions can be drawn from this. First, the final score of suppliers is not a linear combination of their criteria scores. Second, the Industry 4.0 criterion score has a significant impact on the final score of suppliers.

4.1 Discussion

The literature review denotes many approaches/methods to evaluate/select the suppliers, some of which have applied classical techniques, and others have used conjunction of two or more techniques. Each technique may suffer from disadvantages in addition to its advantages. Combining techniques makes it possible to strengthen the disadvantages or weaknesses of one technique with another technique. Based on this logic, this paper develops an efficient approach to evaluate and rank the sustainable circular supplier in the Industry 4.0 era. The proposed approach consists of the combination of fuzzy group BWM and FIS. Our approach is computationally composed of two parts. In the first part, the score of the suppliers is calculated for each criterion. It should be noted that the score of suppliers in each criterion is a linear combination of the score of suppliers in the sub-criteria of that criterion. In this way, the weight of the sub-criteria is calculated by fuzzy group BWM, and by using the calculated weights, a linear relationship is created between the score of each criterion and the score of its sub-criteria. It is important to note that the final score of suppliers is not a linear combination of their criteria scores. For this purpose, in the second part of the proposed approach, a decision support system based on FIS defines the logical and non-linear relationship between the criteria and the final score of suppliers. It can be concluded from the results presented in Tables 16 and 17 that the Industry 4.0 criterion has a relatively large effect on the output of FIS (final score of suppliers). For example, see the calculated results for suppliers 1 and 5 in Table 16. Supplier 1 is 9.5%, 5.2%, and 13.2% superior to Supplier 5 in economic, circular, and social criteria, respectively.

Meanwhile, supplier 5 is only 9.8% superior to supplier 1 in the Industry 4.0 criterion. At first glance at the results of Table 16, we expect that the final score of Supplier 1 significantly differs from the final score of Supplier 5. Still, Table 17 denotes that Supplier 1 performs only 0.001 better than Supplier 5. Therefore, it can be concluded that the Industry 4.0 criterion plays a relatively large role in the final score of suppliers. Because fuzzy inference rules follow a non-linear structure, it is difficult to examine the importance of other criteria in the final score of suppliers. For this purpose, we consider two virtual suppliers, one with the same performance as Supplier 2 (the best supplier) and the other with the same performance as Supplier 3 (the worst supplier) in all criteria except one. Our goal is a sensitivity analysis of the FIS output variable for input changes. Based on this, we define four scenarios for virtual Supplier 1 and four scenarios for virtual Supplier 2, as shown in Table 19. We have assumed that the virtual suppliers 1 and 2 have a 10% better performance in one criterion than suppliers 2 and 3 in all scenarios,

As shown in Table 19, the Industry 4.0 criterion is the most effective criterion for FIS output. Economic, social, and circular criteria are placed after this criterion.

Sustainable business management is an approach for leading a business towards sustainability by integrating economic, social, and environmental aspects. In recent years, with the emergence of Industry 4.0, the role of this criterion in improving the sustainability of businesses has been demonstrated (Bai et al., 2022; Javaid et al., 2022). One of the ways to improve the sustainability of companies is to cooperate with suppliers who have satisfactory performance in economic, circular, social, and Industry 4.0 aspects. The literature review shows that the Industry 4.0 criterion plays a significant role in sustainability because it can effectively improve the economic, environmental, and social performance of SCNs (Patyal et al., 2022). The results obtained from the sensitivity analysis also confirm that Industry 4.0 significantly affects suppliers’ final scores. Therefore, businesses must cooperate with suppliers who pay attention to Industry 4.0 criteria and triple bottom line aspects.

5 Managerial implications

Sustainability can improve organizational competitiveness. Sustainable business management is a practical approach to business development that integrates economic, environmental, and social activities. With the emergence of the CE concept, sustainable business management has become more critical in organizations. The main goal of CE is to reduce waste and move towards zero waste, which leads to minimizing costs, reducing energy and resource consumption, and increasing the efficiency of SCNs. Considering multiple and often conflicting criteria in supplier selection is a difficult task. Hence, this paper develops a practical approach to evaluate suppliers from economic, circular, social, and Industry 4.0 perspectives effectively and efficiently. The proposed approach makes it possible to assess the performance of each supplier from different perspectives. Finally, using a non-linear combination of criteria, the final score of the supplier is calculated. Another feature of the proposed approach is considering the weight of experts. This gives experts with more experience and knowledge more influence in the evaluation process. The proposed approach can be used as a decision support system to help with sustainable supplier evaluations and selection in organizations. While the proposed approach is used for sustainable supplier selection here, it could be easily used to solve many business problems involving multiple and often conflicting criteria in uncertain environments.

6 Conclusion

This paper presents a decision support system for evaluating and prioritizing suppliers in public–private partnership projects. The proposed approach consists of two stages. In the first stage, the performance of six potential suppliers is evaluated from economic, circular, social, and Industry 4.0 perspectives by a novel group BWM method. In the second stage, non-linear relationships between the input variables (four criteria) and the final score are mapped with the help of the fuzzy inference rules and an FIS structure. The proposed FIS includes 625 rules. The data from the offshore wind farm project in this study and the knowledge of four experts are used to validate the proposed approach. A sensitivity analysis showed the FIS output is more sensitive to Industry 4.0 criteria than others.

When the sub-criteria of each criterion are intertwined, the proposed approach cannot provide an accurate weight for the sub-criteria. In such a situation, interdependencies between sub-criteria should be calculated by methods such as DEMATEL or weighted influence non-linear gauge system (WINGS). Recently, with the emergence of Industry 5.0, some researchers have moved their research in this direction. To our knowledge, sustainable circular supplier selection in the Industry 5.0 era is an open topic that has not been investigated. Therefore, it is suggested that future studies focus on these issues.

References

Aboutorab, H., Saberi, M., Asadabadi, M. R., Hussain, O., & Chang, E. (2018). ZBWM: The Z-number extension of Best Worst Method and its application for supplier development. Expert Systems with Applications, 107, 115–125.

Alavi, B., Tavana, M., & Mina, H. (2021). A dynamic decision support system for sustainable supplier selection in circular economy. Sustainable Production and Consumption, 27, 905–920.

Amiri, M., Hashemi-Tabatabaei, M., Ghahremanloo, M., Keshavarz-Ghorabaee, M., Zavadskas, E. K., & Banaitis, A. (2021). A new fuzzy BWM approach for evaluating and selecting a sustainable supplier in supply chain management. International Journal of Sustainable Development & World Ecology, 28(2), 125–142.

Asadabadi, M. R., Ahmadi, H. B., Gupta, H., & Liou, J. J. (2022). Supplier selection to support environmental sustainability: The stratified BWM TOPSIS method. Annals of Operations Research, 322, 1–24.

Asif, M., Searcy, C., & Castka, P. (2022). Exploring the role of Industry 4.0 in enhancing supplier audit authenticity, efficacy, and cost effectiveness. Journal of Cleaner Production, 331, 129939.

Bai, C., Orzes, G., & Sarkis, J. (2022). Exploring the impact of Industry 4.0 technologies on social sustainability through a circular economy approach. Industrial Marketing Management, 101, 176–190.

Barros, M. V., Salvador, R., do Prado, G. F., de Francisco, A. C., & Piekarski, C. M. (2021). Circular economy as a driver to sustainable businesses. Cleaner Environmental Systems, 2, 100006.

Camci, A., Ertürk, M. E., & Gül, S. (2022). A novel fermatean fuzzy analytic hierarchy process proposition and its usage for supplier selection problem in Industry 4.0 transition. In q-Rung Orthopair Fuzzy Sets (pp 405–437). Springer, Singapore.

Chai, N., Zhou, W., & Jiang, Z. (2023). Sustainable supplier selection using an intuitionistic and interval-valued fuzzy MCDM approach based on cumulative prospect theory. Information Sciences, 626, 710–737.

Chang, T. W., Pai, C. J., Lo, H. W., & Hu, S. K. (2021). A hybrid decision-making model for sustainable supplier evaluation in electronics manufacturing. Computers & Industrial Engineering, 156, 107283.

Chen, L. H., Hung, P., & Ma, H. W. (2020). Integrating circular business models and development tools in the circular economy transition process: A firm-level framework. Business Strategy and the Environment, 29(5), 1887–1898.

Cheraghalipour, A., Paydar, M. M., & Hajiaghaei-Keshteli, M. (2018). Applying a hybrid BWM-VIKOR approach to supplier selection: A case study in the Iranian agricultural implements industry. International Journal of Applied Decision Sciences, 11(3), 274–301.

Choi, T. M., Kumar, S., Yue, X., & Chan, H. L. (2022). Disruptive technologies and operations management in the Industry 4.0 era and beyond. Production and Operations Management, 31(1), 9–31.

Dantas, T. E., De-Souza, E. D., Destro, I. R., Hammes, G., Rodriguez, C. M. T., & Soares, S. R. (2021). How the combination of Circular Economy and Industry 4.0 can contribute towards achieving the Sustainable Development Goals. Sustainable Production and Consumption, 26, 213–227.

Dong, F., Li, Y., Gao, Y., Zhu, J., Qin, C., & Zhang, X. (2022). Energy transition and carbon neutrality: Exploring the non-linear impact of renewable energy development on carbon emission efficiency in developed countries. Resources, Conservation and Recycling, 177, 106002.

Ecer, F., & Pamucar, D. (2020). Sustainable supplier selection: A novel integrated fuzzy best worst method (F-BWM) and fuzzy CoCoSo with Bonferroni (CoCoSo’B) multi-criteria model. Journal of Cleaner Production, 266, 121981.

Fallahpour, A., Wong, K. Y., Rajoo, S., Fathollahi-Fard, A. M., Antucheviciene, J., & Nayeri, S. (2021a). An integrated approach for a sustainable supplier selection based on Industry 4.0 concept. Environmental Science and Pollution Research. https://doi.org/10.1007/s11356-021-17445-y

Fallahpour, A., Yazdani, M., Mohammed, A., & Wong, K. Y. (2021b). Green sourcing in the era of industry 4.0: Towards green and digitalized competitive advantages. Industrial Management & Data Systems. https://doi.org/10.1108/IMDS-06-2020-0343

Fatorachian, H., & Kazemi, H. (2021). Impact of Industry 4.0 on supply chain performance. Production Planning & Control, 32(1), 63–81.

Feng, J., & Gong, Z. (2020). Integrated linguistic entropy weight method and multi-objective programming model for supplier selection and order allocation in a circular economy: A case study. Journal of Cleaner Production, 277, 122597.

ForouzeshNejad, A. A. (2022). Leagile and sustainable supplier selection problem in the Industry 4.0 era: a case study of the medical devices using hybrid multi-criteria decision making tool. Environmental Science and Pollution Research. https://doi.org/10.1007/s11356-022-22916-x

Garg, C. P., & Sharma, A. (2020). Sustainable outsourcing partner selection and evaluation using an integrated BWM–VIKOR framework. Environment, Development and Sustainability, 22(2), 1529–1557.

Geissdoerfer, M., Pieroni, M. P., Pigosso, D. C., & Soufani, K. (2020). Circular business models: A review. Journal of Cleaner Production, 277, 123741.

Govindan, K., Mina, H., & Alavi, B. (2020a). A decision support system for demand management in healthcare supply chains considering the epidemic outbreaks: A case study of coronavirus disease 2019 (COVID-19). Transportation Research Part E: Logistics and Transportation Review, 138, 101967.

Govindan, K., Mina, H., Esmaeili, A., & Gholami-Zanjani, S. M. (2020b). An integrated hybrid approach for circular supplier selection and closed loop supply chain network design under uncertainty. Journal of Cleaner Production, 242, 118317.

Govindan, K., Nasr, A. K., Karimi, F., & Mina, H. (2022). Circular economy adoption barriers: An extended fuzzy best–worst method using fuzzy DEMATEL and supermatrix structure. Business Strategy and the Environment, 31(4), 1566–1586.

Guarnieri, P., & Trojan, F. (2019). Decision making on supplier selection based on social, ethical, and environmental criteria: A study in the textile industry. Resources, Conservation and Recycling, 141, 347–361.

Gupta, H., & Barua, M. K. (2017). Supplier selection among SMEs on the basis of their green innovation ability using BWM and fuzzy TOPSIS. Journal of Cleaner Production, 152, 242–258.

Hailiang, Z., Khokhar, M., Islam, T., & Sharma, A. (2023). A model for green-resilient supplier selection: Fuzzy best–worst multi-criteria decision-making method and its applications. Environmental Science and Pollution Research, 30, 1–24.

Jain, N., Singh, A. R., & Upadhyay, R. K. (2020). Sustainable supplier selection under attractive criteria through FIS and integrated fuzzy MCDM techniques. International Journal of Sustainable Engineering, 13(6), 441–462.

Javad, M. O. M., Darvishi, M., & Javad, A. O. M. (2020). Green supplier selection for the steel industry using BWM and fuzzy TOPSIS: A case study of Khouzestan steel company. Sustainable Futures, 2, 100012.

Javaid, M., Haleem, A., Singh, R. P., Suman, R., & Gonzalez, E. S. (2022). Understanding the adoption of Industry 4.0 technologies in improving environmental sustainability. Sustainable Operations and Computers, 3, 203–217.

Kannan, D., Mina, H., Nosrati-Abarghooee, S., & Khosrojerdi, G. (2020). Sustainable circular supplier selection: A novel hybrid approach. Science of the Total Environment, 722, 137936.

Karasan, A., Erdogan, M., & Cinar, M. (2022). Healthcare service quality evaluation: An integrated decision-making methodology and a case study. Socio-Economic Planning Sciences, 82, 101234.

Kaur, H., & Singh, S. P. (2021). Multi-stage hybrid model for supplier selection and order allocation considering disruption risks and disruptive technologies. International Journal of Production Economics, 231, 107830.

Kumar, P., Singh, R. K., & Kumar, V. (2021). Managing supply chains for sustainable operations in the era of industry 4.0 and circular economy: Analysis of barriers. Resources, Conservation and Recycling, 164, 105215.

Kusi-Sarpong, S., Gupta, H., Khan, S. A., Chiappetta Jabbour, C. J., Rehman, S. T., & Kusi-Sarpong, H. (2021). Sustainable supplier selection based on industry 4.0 initiatives within the context of circular economy implementation in supply chain operations. Production Planning & Control. https://doi.org/10.1080/09537287.2021.1980906

Lin, K. Y. (2018). User experience-based product design for smart production to empower industry 4.0 in the glass recycling circular economy. Computers & Industrial Engineering, 125, 729–738.

Liu, C., Rani, P., & Pachori, K. (2022). Sustainable circular supplier selection and evaluation in the manufacturing sector using Pythagorean fuzzy EDAS approach. Journal of Enterprise Information Management, 35(45), 1040–1066.

Lopes de Sousa JabbourJabbour, A. B. C. J. C., Godinho Filho, M., & Roubaud, D. (2018). Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Annals of Operations Research, 270, 273–286.

Lu, L. Y., Wu, C. H., & Kuo, T. C. (2007). Environmental principles applicable to green supplier evaluation by using multi-objective decision analysis. International Journal of Production Research, 45(18–19), 4317–4331.

Mamdani, E. H., & Assilian, S. (1993). An experiment in linguistic synthesis with a fuzzy logic controller. In Readings in fuzzy sets for intelligent systems (pp. 283–289). Morgan Kaufmann.

Masoomi, B., Sahebi, I. G., Fathi, M., Yıldırım, F., & Ghorbani, S. (2022). Strategic supplier selection for renewable energy supply chain under green capabilities (fuzzy BWM-WASPAS-COPRAS approach). Energy Strategy Reviews, 40, 100815.

Matthess, M., Kunkel, S., Xue, B., & Beier, G. (2022). Supplier sustainability assessment in the age of Industry 4.0–Insights from the electronics industry. Cleaner Logistics and Supply Chain, 4, 100038.

Memari, A., Dargi, A., Jokar, M. R. A., Ahmad, R., & Rahim, A. R. A. (2019). Sustainable supplier selection: A multi-criteria intuitionistic fuzzy TOPSIS method. Journal of Manufacturing Systems, 50, 9–24.

Miguel, P. L., & Tonelli, M. J. (2023). Supplier diversity for socially responsible purchasing: An empirical investigation in Brazil. International Journal of Physical Distribution & Logistics Management, 53(1), 93–114.

Mina, H., Kannan, D., Gholami-Zanjani, S. M., & Biuki, M. (2021). Transition towards circular supplier selection in petrochemical industry: A hybrid approach to achieve sustainable development goals. Journal of Cleaner Production, 286, 125273.

Mirzaee, H., Naderi, B., & Pasandideh, S. H. R. (2018). A preemptive fuzzy goal programming model for generalized supplier selection and order allocation with incremental discount. Computers & Industrial Engineering, 122, 292–302.

Nasr, A. K., Tavana, M., Alavi, B., & Mina, H. (2021). A novel fuzzy multi-objective circular supplier selection and order allocation model for sustainable closed-loop supply chains. Journal of Cleaner Production, 287, 124994.

Noci, G. (1997). Designing ‘green’vendor rating systems for the assessment of a supplier’s environmental performance. European Journal of Purchasing & Supply Management, 3(2), 103–114.

Ojadi, F., Kusi-Sarpong, S., Orji, I. J., Bai, C., Gupta, H., & Okwara, U. K. (2023). A decision support framework for socially responsible supplier selection in the Nigerian banking industry. Journal of Business & Industrial Marketing. https://doi.org/10.1108/JBIM-03-2022-0139

Omair, M., Noor, S., Tayyab, M., Maqsood, S., Ahmed, W., Sarkar, B., & Habib, M. S. (2021). The selection of the sustainable suppliers by the development of a decision support framework based on analytical hierarchical process and fuzzy inference system. International Journal of Fuzzy Systems, 23(7), 1986–2003.

Orji, I. J., & Ojadi, F. (2021). Investigating the COVID-19 pandemic’s impact on sustainable supplier selection in the Nigerian manufacturing sector. Computers & Industrial Engineering, 160, 107588.

Ortiz-Barrios, M., Cabarcas-Reyes, J., Ishizaka, A., Barbati, M., Jaramillo-Rueda, N., & de Jesús Carrascal-Zambrano, G. (2021). A hybrid fuzzy multi-criteria decision making model for selecting a sustainable supplier of forklift filters: A case study from the mining industry. Annals of Operations Research, 307(1), 443–481.

Parkouhi, S.V., & Ghadikolaei, A. S. (2017). A resilience approach for supplier selection: using Fuzzy Analytic Network Process and grey VIKOR techniques. Journal of Cleaner Production, 161, 431–451.

Patyal, V. S., Sarma, P. R. S., Modgil, S., Nag, T., & Dennehy, D. (2022). Mapping the links between Industry 4.0, circular economy and sustainability: A systematic literature review. Journal of Enterprise Information Management, 35(1), 1–35.

Perçin, S. (2022). Circular supplier selection using interval-valued intuitionistic fuzzy sets. Environment, Development and Sustainability, 24(4), 5551–5581.

Pivoto, D. G., de Almeida, L. F., da Rosa Righi, R., Rodrigues, J. J., Lugli, A. B., & Alberti, A. M. (2021). Cyber-physical systems architectures for industrial internet of things applications in Industry 4.0: A literature review. Journal of Manufacturing Systems, 58, 176–192.

Pizzi, S., Corbo, L., & Caputo, A. (2021). Fintech and SMEs sustainable business models: Reflections and considerations for a circular economy. Journal of Cleaner Production, 281, 125217.

Qazvini, Z. E., & Maleki, M. R. (2022). A triple bottom line multi-criteria decision making framework for supplier selection. International Journal of Management and Decision Making, 21(2), 144–160.

Qin, J., & Liu, X. (2019). Interval type-2 fuzzy group decision making by integrating improved best worst method with COPRAS for emergency material supplier selection. In Type-2 fuzzy decision-making theories, methodologies and applications (pp. 249–271). Springer, Singapore.

Rad, F. F., Oghazi, P., Palmié, M., Chirumalla, K., Pashkevich, N., Patel, P. C., & Sattari, S. (2022). Industry 4.0 and supply chain performance: A systematic literature review of the benefits, challenges, and critical success factors of 11 core technologies. Industrial Marketing Management, 105, 268–293.

Rahman, M. M., Bari, A. M., Ali, S. M., & Taghipour, A. (2022). Sustainable supplier selection in the textile dyeing industry: An integrated multi-criteria decision analytics approach. Resources, Conservation & Recycling Advances, 15, 200117.

Rasmussen, A., Sabic, H., Saha, S., & Nielsen, I. E. (2023). Supplier selection for aerospace & defense industry through MCDM methods. Cleaner Engineering and Technology, 12, 100590.

Rezaei, J., Nispeling, T., Sarkis, J., & Tavasszy, L. (2016). A supplier selection life cycle approach integrating traditional and environmental criteria using the best worst method. Journal of Cleaner Production, 135, 577–588.

Rostami, O., Tavakoli, M., Tajally, A., & GhanavatiNejad, M. (2022). A goal programming-based fuzzy best–worst method for the viable supplier selection problem: A case study. Soft Computing. https://doi.org/10.1007/s00500-022-07572-0

Saghafinia, A., Fallahpour, A., Asadpour, M., & Abedian, M. (2022). Green supplier selection in a fuzzy environment: FIS and FPP approaches. Cybernetics and Systems. https://doi.org/10.1080/01969722.2022.2138118

Salimian, S., Mousavi, S. M., & Antucheviciene, J. (2022). An interval-valued intuitionistic fuzzy model based on extended VIKOR and MARCOS for sustainable supplier selection in organ transplantation networks for healthcare devices. Sustainability, 14(7), 3795.

Sari, I. U., Pesek, A., & Bozukyan, K. (2022). Supplier Selection After Pandemic in SMEs Using Fuzzy Best Worst Method and Fuzzy WASPAS. In International conference on intelligent and fuzzy systems (pp. 387–395). Springer, Cham.

Shang, Z., Yang, X., Barnes, D., & Wu, C. (2022). Supplier selection in sustainable supply chains: Using the integrated BWM, fuzzy Shannon entropy, and fuzzy MULTIMOORA methods. Expert Systems with Applications, 195, 116567.

Sordi, A., Tate, W. L., & Huang, F. (2022). Going beyond supplier diversity to economic inclusion: Where are we now and where do we go from here? Journal of Purchasing and Supply Management, 28(2), 100751.

Stević, Ž, Pamučar, D., Puška, A., & Chatterjee, P. (2020). Sustainable supplier selection in healthcare industries using a new MCDM method: Measurement of alternatives and ranking according to COmpromise solution (MARCOS). Computers & Industrial Engineering, 140, 106231.

Sugeno, M. (1985). Industrial applications of fuzzy control. Elsevier.

Tavana, M., Khosrojerdi, G., Mina, H., & Rahman, A. (2019). A hybrid mathematical programming model for optimal project portfolio selection using fuzzy inference system and analytic hierarchy process. Evaluation and Program Planning, 77, 101703.

Tavana, M., Shaabani, A., Di Caprio, D., & Bonyani, A. (2021). An integrated group fuzzy best-worst method and combined compromise solution with Bonferroni functions for supplier selection in reverse supply chains. Cleaner Logistics and Supply Chain, 2, 100009.

Thuy, N. D. P., & Nhut, L. M. (2023). An Investment in Oversea Wind Power Project—NSEC’S Experiences for Vietnam. In Contemporary economic issues in Asian countries: Proceeding of CEIAC 2022, Volume 2 (pp. 527–543). Singapore: Springer Nature Singapore.

Tian, Z. P., Zhang, H. Y., Wang, J. Q., & Wang, T. L. (2018). Green supplier selection using improved TOPSIS and best-worst method under intuitionistic fuzzy environment. Informatica, 29(4), 773–800.

Tong, L. Z., Wang, J., & Pu, Z. (2022). Sustainable supplier selection for SMEs based on an extended PROMETHEE II approach. Journal of Cleaner Production, 330, 129830.

Triani, M., Tambunan, H. B., Dewi, K., & Ediansjah, A. S. (2023). Review on greenhouse gases emission in the association of Southeast Asian Nations (ASEAN) countries. Energies, 16(9), 3920.

Tushar, Z. N., Bari, A. M., & Khan, M. A. (2022). Circular supplier selection in the construction industry: A sustainability perspective for the emerging economies. Sustainable Manufacturing and Service Economics, 1, 100005.

Vakulchuk, R., Overland, I., & Suryadi, B. (2023). ASEAN’s energy transition: How to attract more investment in renewable energy. Energy, Ecology and Environment, 8(1), 1–16.

Veeramani, C., Venugopal, R., & Muruganandan, S. (2022). An exploration of the fuzzy inference system for the daily trading decision and its performance analysis based on fuzzy MCDM methods. Computational Economics. https://doi.org/10.1007/s10614-022-10346-3

Wamba, S. F., Fotso, M., Mosconi, E., & Chai, J. (2023). Assessing the potential of plastic waste management in the circular economy: A longitudinal case study in an emerging economy. Annals of Operations Research, 1–23.

Wang, C. N., Nguyen, N. A. T., Dang, T. T., & Lu, C. M. (2021). A compromised decision-making approach to third-party logistics selection in sustainable supply chain using fuzzy AHP and fuzzy VIKOR methods. Mathematics, 9(8), 886.

Wang, C. N., Nguyen, T. T. T., Dang, T. T., & Nguyen, N. A. T. (2022a). A Hybrid OPA and fuzzy MARCOS methodology for sustainable supplier selection with technology 4.0 evaluation. Processes, 10(11), 2351.

Wang, X., Wang, H., Xu, Z., & Ren, Z. (2022b). Green supplier selection based on probabilistic dual hesitant fuzzy sets: A process integrating best worst method and superiority and inferiority ranking. Applied Intelligence, 52(7), 8279–8301.

Wei, Q., & Zhou, C. (2022). A multi-criteria decision-making framework for electric vehicle supplier selection of government agencies and public bodies in China. Environmental Science and Pollution Research. https://doi.org/10.1007/s11356-022-22783-6

Wu, C., Lin, Y., & Barnes, D. (2021). An integrated decision-making approach for sustainable supplier selection in the chemical industry. Expert Systems with Applications, 184, 115553.

Wu, Q., Zhou, L., Chen, Y., & Chen, H. (2019). An integrated approach to green supplier selection based on the interval type-2 fuzzy best-worst and extended VIKOR methods. Information Sciences, 502, 394–417.

Xie, Y., Yin, Y., Xue, W., Shi, H., & Chong, D. (2020). Intelligent supply chain performance measurement in Industry 4.0. Systems Research and Behavioral Science, 37(4), 711–718.

Xing, Y., Cao, M., Liu, Y., Zhou, M., & Wu, J. (2022). A Choquet integral based interval Type-2 trapezoidal fuzzy multiple attribute group decision making for Sustainable Supplier Selection. Computers & Industrial Engineering, 165, 107935.

Yazdani, M., Torkayesh, A. E., & Chatterjee, P. (2020). An integrated decision-making model for supplier evaluation in public healthcare system: the case study of a Spanish hospital. Journal of Enterprise Information Management.

Yazdani, M., Torkayesh, A. E., Stević, Ž, Chatterjee, P., Ahari, S. A., & Hernandez, V. D. (2021). An interval valued neutrosophic decision-making structure for sustainable supplier selection. Expert Systems with Applications, 183, 115354.

Yucesan, M., Mete, S., Serin, F., Celik, E., & Gul, M. (2019). An integrated best-worst and interval type-2 fuzzy TOPSIS methodology for green supplier selection. Mathematics, 7(2), 182.

Zarrinpanjeh, N., Javan, F. D., Azadi, H., Viira, A. H., Kurban, A., & Witlox, F. (2022). Commuters’ accessibility to transportation lifelines in Karaj city, Iran: A fuzzy approach. Sustainable Cities and Society, 85, 104037.

Funding

Open access funding provided by University of Gothenburg.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A

See Tables

20,

21,

22,

23,

24, and

25.

Appendix B

\(Min(0.2 \times \theta_{1}^{*} + 0.3 \times \theta_{2}^{*} + 0.3 \times \theta_{3}^{*} + 0.2 \times \theta_{4}^{*} )\) | |

\(s.t.\) | |

\(\begin{gathered} \dot{\psi }_{SCR11,1} \le 2/3 \times \dot{\psi }_{SCR12,1} + \theta_{1}^{*} ;\quad \ddot{\psi }_{SCR11,1} \le \ddot{\psi }_{SCR12,1} + \theta_{1}^{*} ;\quad \dddot \psi_{SCR11,1} \le 3/2 \times \dddot \psi_{SCR12,1} + \theta_{1}^{*} ; \hfill \\ \dot{\psi }_{SCR11,1} \ge 2/3 \times \dot{\psi }_{SCR12,1} - \theta_{1}^{*} ;\quad \ddot{\psi }_{SCR11,1} \ge \ddot{\psi }_{SCR12,1} - \theta_{1}^{*} ;\quad \dddot \psi_{SCR11,1} \ge 3/2 \times \dddot \psi_{SCR12,1} - \theta_{1}^{*} ; \hfill \\ \end{gathered}\) | \(\begin{gathered} \frac{{\dot{\psi }_{SCR11,1} + 4 \times \ddot{\psi }_{SCR11,1} + \dddot \psi_{SCR11,1} }}{6} + \frac{{\dot{\psi }_{SCR12,1} + 4 \times \ddot{\psi }_{SCR12,1} + \dddot \psi_{SCR12,1} }}{6} + \hfill \\ \frac{{\dot{\psi }_{SCR13,1} + 4 \times \ddot{\psi }_{SCR13,1} + \dddot \psi_{SCR13,1} }}{6} + \frac{{\dot{\psi }_{SCR14,1} + 4 \times \ddot{\psi }_{SCR14,1} + \dddot \psi_{SCR14,1} }}{6} + \hfill \\ \frac{{\dot{\psi }_{SCR15,1} + 4 \times \ddot{\psi }_{SCR15,1} + \dddot \psi_{SCR15,1} }}{6} + \frac{{\dot{\psi }_{SCR16,1} + 4 \times \ddot{\psi }_{SCR16,1} + \dddot \psi_{SCR16,1} }}{6} = 1 \hfill \\ \end{gathered}\) |

\(\begin{gathered} \dot{\psi }_{SCR11,1} \le 3/2 \times \dot{\psi }_{SCR13,1} + \theta_{1}^{*} ;\quad \ddot{\psi }_{SCR11,1} \le 2 \times \ddot{\psi }_{SCR13,1} + \theta_{1}^{*} ;\quad \dddot \psi_{SCR11,1} \le 5/2 \times \dddot \psi_{SCR13,1} + \theta_{1}^{*} ; \hfill \\ \dot{\psi }_{SCR11,1} \ge 3/2 \times \dot{\psi }_{SCR13,1} - \theta_{1}^{*} ;\quad \ddot{\psi }_{SCR11,1} \ge 2 \times \ddot{\psi }_{SCR13,1} - \theta_{1}^{*} ;\quad \dddot \psi_{SCR11,1} \ge 5/2 \times \dddot \psi_{SCR13,1} - \theta_{1}^{*} ; \hfill \\ \end{gathered}\) | |

\(\begin{gathered} \dot{\psi }_{SCR11,1} \le 7/2 \times \dot{\psi }_{SCR14,1} + \theta_{1}^{*} ;\quad \ddot{\psi }_{SCR11,1} \le 4 \times \ddot{\psi }_{SCR14,1} + \theta_{1}^{*} ;\quad \dddot \psi_{SCR11,1} \le 9/2 \times \dddot \psi_{SCR14,1} + \theta_{1}^{*} ; \hfill \\ \dot{\psi }_{SCR11,1} \ge 7/2 \times \dot{\psi }_{SCR14,1} - \theta_{1}^{*} ;\quad \ddot{\psi }_{SCR11,1} \ge 4 \times \ddot{\psi }_{SCR14,1} - \theta_{1}^{*} ;\quad \dddot \psi_{SCR11,1} \ge 9/2 \times \dddot \psi_{SCR14,1} - \theta_{1}^{*} ; \hfill \\ \end{gathered}\) | |

\(\begin{gathered} \dot{\psi }_{SCR11,1} \le 3/2 \times \dot{\psi }_{SCR15,1} + \theta_{1}^{*} ;\quad \ddot{\psi }_{SCR11,1} \le 2 \times \ddot{\psi }_{SCR15,1} + \theta_{1}^{*} ;\quad \,\dddot \psi_{SCR11,1} \le 5/2 \times \dddot \psi_{SCR15,1} + \theta_{1}^{*} ; \hfill \\ \dot{\psi }_{SCR11,1} \ge 3/2 \times \dot{\psi }_{SCR15,1} - \theta_{1}^{*} ;\quad \ddot{\psi }_{SCR11,1} \ge 2 \times \ddot{\psi }_{SCR15,1} - \theta_{1}^{*} ;\quad \dddot \psi_{SCR11,1} \ge 5/2 \times \dddot \psi_{SCR15,1} - \theta_{1}^{*} ; \hfill \\ \end{gathered}\) | \(\begin{gathered} \frac{{\dot{\psi }_{SCR11,2} + 4 \times \ddot{\psi }_{SCR11,2} + \dddot \psi_{SCR11,2} }}{6} + \frac{{\dot{\psi }_{SCR12,2} + 4 \times \ddot{\psi }_{SCR12,2} + \dddot \psi_{SCR12,2} }}{6} + \hfill \\ \frac{{\dot{\psi }_{SCR13,2} + 4 \times \ddot{\psi }_{SCR13,2} + \dddot \psi_{SCR13,2} }}{6} + \frac{{\dot{\psi }_{SCR14,2} + 4 \times \ddot{\psi }_{SCR14,2} + \dddot \psi_{SCR14,2} }}{6} + \hfill \\ \frac{{\dot{\psi }_{SCR15,2} + 4 \times \ddot{\psi }_{SCR15,2} + \dddot \psi_{SCR15,2} }}{6} + \frac{{\dot{\psi }_{SCR16,2} + 4 \times \ddot{\psi }_{SCR16,2} + \dddot \psi_{SCR16,2} }}{6} = 1 \hfill \\ \end{gathered}\) |