Abstract

Data-driven innovations (DDI) have significantly impacted firms’ operations thanks to the massive exploitation of huge data. However, to leverage big data and achieve supply chain innovation, a variety of complementary resources are necessary. In this study, we hypothesise that supply chain innovation (SCI) is dependent on firms’ big data analytics capabilities (BAC). Furthermore, we propose that this relation is mediated by two crucial capabilities of agility and adaptability that enable firms to efficiently meet the challenges of supply chain ambidexterity. Finally, we also test the moderating role of technology uncertainty in our research model. We collected data from 386 manufacturing firms in Pakistan and tested our model using structural equation modelling. The results confirmed our initial hypotheses that agility and adaptability both mediated our baseline relationship of BAC and big data innovation in supply chains. We further found support for the moderating role of technology uncertainty. Furthermore, technology uncertainty moderates the relationship between BAC and SCI. This study extends the current literature on digital analytics capabilities and innovation along the supply chain. Practically, our research suggests that investment in big data can result in affirmative consequences, if firms cultivate capabilities to encounter supply chain ambidexterity through agility and adaptability. Accordingly, we suggest that managers belonging to manufacturing firms need to build up these internal capabilities and to monitor and assess technology uncertainty in the environment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Digitalisation has led to radical changes in products/services, processes, and entire business models throughout value chains (Nambisan et al., 2017). Organisations across a wide spectrum of operations have adopted digital technologies to transform their operations (Van Alstyne et al., 2016) as a result of technological advancements of the Fourth Industrial Revolution called Industry 4.0 (i4.0) (Ardito, Messeni Petruzzelli, et al., 2019; Hahn, 2020). Indeed, big data and advanced analytics are considered to be ‘game changers’ (Waller & Fawcett, 2013) in operations management (OM), and BAC enables novel operations to complement or reinstate conventional business models (Akter et al., 2019).

Companies are exerting significant effort to develop digital capabilities to unearth innovative ideas that could improve their competitive advantage (Dubey et al., 2018); this is a useful way of aiding organisations to be more innovative (Bresciani, Ciampi, et al., 2021; Günther et al., 2017; Johnson et al., 2017). In turn, DDI may improve organisational outcomes (Akter et al., 2019; Ferraris et al., 2019) through both intentional and direct collaborative, as well as co-innovation processes (Bresciani, Ciampi, et al., 2021). However, there are a handful of unknowns about the associations among the capabilities of big data and firm innovation (Appio et al., 2021; Ghasemaghaei & Calic, 2020).

In recent years, due to the increased pace of digital technologies, academics and practitioners alike have shifted their attention to DDI in operations (Akter & Wamba, 2016; Akter et al., 2016, 2021; Bresciani, Ferraris, et al., 2021). Nevertheless, the majority of the literature fails to explain the underlying processes of the DDI (Appio et al., 2021). Thus, there is a lack of studies exploring this process of technological capabilities as a means to embrace innovations (Bresciani, Ferraris, et al., 2021; McAfee et al., 2012) and surprisingly little empirical research is available on the DDI, with the exception of a few empirical papers (see Božič & Dimovski, 2019; Chatterjee et al., 2021; Duan et al., 2020; Mikalef et al., 2019), even when companies are heavily investing in big data (Mikalef et al., 2019).

We aim to address this gap by carrying out an empirical study to explore the impact of big data analytics and furthermore examine the underlying mechanisms through which it is leveraged to enhance firms’ DDI. This research extends the current conversation on BAC by Mikalef et al. (2019) and Wamba, Akter, et al. (2020), Wamba, Dubey, et al. (2020)) and postulates that big data is a predecessor for SCIs as well. SCI encompasses all those technological processes including new and novel changes in operations, procurement, and logistics that not only boost the efficiency and effectiveness of processes but also improve value creation (Seo et al., 2014). Most importantly, we propose that to realise the remunerations of BAC in achieving DDI, organisations need certain rudimentary capabilities that are essential for firm survival; they also need to adopt and maintain a combination of these capabilities to assimilate and exploit BAC (Mikalef et al., 2020) and to be innovative along their supply chains (Tan et al., 2015).

Supply chain managers sometimes have to decide upon the trade-off between flexibility and efficiency (Eisenhardt et al., 2010). Recently, however, many researchers have maintained that firms can pursue both of these conflicting but complementary strategies by adopting ambidextrous capabilities (Aslam et al., 2018; Ojha et al., 2018). This particular capability opposes the previously believed notion that organisations need to choose between efficient (for current products) or responsive (for new products) supply chains (Fisher, 1997). Thus, companies need to embrace strategies that can swiftly counter short-term changes in demand and supply through agility and react to long-term changes in their environment by reorganising their supply chains through adaptability capabilities (Lee, 2004). In this way, supply chain ambidexterity capabilities are an emerging theoretical perspective for enhancing innovation and performance across the supply chain components (Lee & Rha, 2016).

In a similar vein, although considered to be a “cliché”, it is a common fact that businesses nowadays are faced with uncertain environments and markets are becoming more diverse and ephemeral, meaning businesses are forced to introduce innovative products to maintain and increase their market share (Ferraris et al., 2019). Consequently, varying market demand and increasing competitive pressure are driving innovations in manufacturing technologies (Awan et al., 2021). Accordingly, managers overlooking supply chain operations in such manufacturing organisations face the challenging situation of handling a huge amount of data in the exploitation of existing technologies to seek constancy and effectiveness, on one hand; and exploring new technologies to achieve competitive advantage on the other (Andriopoulos & Lewis, 2009). Thus, we propose that technology uncertainty may have an impact on the relationship between BAC and SCI.

Researchers have highlighted the need to investigate the core elements of big data realisation in firms and subsequently explore its mechanisms if we are to obtain any significant implications for theory and practice from it (Constantiou & Kallinikos, 2015). They have further stressed the need to explore how it results in better innovation output through overcoming the challenges of ambidexterity. Grounded on the resource based view (RBV) and dynamic capabilities theories, our research aims to solve two critical research questions: RQ1) Does supply chain ambidexterity mediate the relationship between BAC and SCI? RQ2) Does an environmental factor, specifically technology uncertainty, moderate this relation?

Thus, our research aims to address several gaps in the current literature. First, the impact of BAC on innovation entails rigorous theoretical underpinnings and empirical analysis as this domain is still in its embryonic stage. Although quite a few studies have explored the consequences of BAC such as firm performance, the question of how firms can enhance innovation across their supply chains has not been answered completely. Moreover, current studies have restricted themselves to the exploration of the effect of SCI on firm level outcomes, and very few researchers have explored the antecedents of SCI like BAC. Finally, consistent with the RBV and dynamic capabilities theories, it is crucial for both supply chain and information systems managers to completely understand the impact of the ambidextrous capabilities of supply chains under technological uncertainty and their overall effect on innovation across value chains.

Our research thus offers three vital implications for the interconnected domains of operations and supply chain management. First, it theorises and empirically authenticates a framework that elucidates the part BAC plays in nurturing SCI. Second, our research untangles the link between BAC and SCI by answering our research questions of when (moderation of technology uncertainty) and how (mediation of supply chain ambidexterity capabilities) this relationship works; thereby shedding light on important underlining mechanisms and factors. Finally, this research may prove to be beneficial for the manufacturing sector belonging to a developing country with relation to the adoption of BAC. This unique institutional context could become an intriguing platform for exploring the significance of these capabilities for harnessing SCIs fuelled by BAC. As a result, it would be beneficial for the organisations to understand how and when they could use big data analytics for improving innovation in their supply chains.

2 Literature review

2.1 Underlying theories

Our research uses the RBV and dynamic capabilities theories to comprehend the real reasons why firms decide to adopt ambidextrous supply chain capabilities to achieve SCI. As one of the most influential and ground-breaking theories, RBV helps explain the resource characterisation essential for attaining sustainable competitive advantage (Barnrey et al., 2001). As per the tenets of RBV, this competitive advantage is gained by the organisations through developing and adopting resources that are valued, unusual, incomparable, and difficult to copy (Barney, 1991). Researchers have used the theoretical lens of RBV in explaining digital capabilities as essential for attaining strategic competitive advantage (see Elia et al., 2021); this theory has also been used to help explain innovative performance as a result of digital capabilities (Mikalef et al., 2020; Wamba & Akter, 2019). Thus, RBV signifies the importance of resource heterogeneity in creating dynamic capabilities for competitive advantage (Hitt et al., 2016; Ketokivi, 2016).

Dynamic capabilities are highly valued capabilities that organisations possess to differentiate them from their competitors (Schreyögg & Kliesch-Eberl, 2007). According to Winter (2003) and Teece (2012), these dynamic capabilities are clearly different from ordinary capabilities. Conventional capabilities that are viewed as the normal resource base of the firm (Pezeshkan et al., 2016) are characterised by their in-depth integration into firm routines to increase the efficiency of its activities (Teece, 2012). These may involve the implementation of the various functions that are (technically) necessary to complete job duties and responsibilities traversing a variety of operations and managerial processes (Teece, 2014). In a similar vein, the dynamic capabilities theory also affirms the capabilities of a firm to search, integrate, and translate knowledge from its environment to develop an agile and adaptive competitive advantage (Teece et al., 1997). Hence, dynamic capabilities can help us to comprehend how companies expand and revamp their capabilities to respond to technology changes (Shamim et al., 2019). Competitive advantage can be achieved by recombining resources; indeed, having unique resources can make the recombination better than doing it with normal resources. Thus, many researchers have used both RBV and dynamic capabilities theories to explain the capabilities for DDI (Pan et al., 2015; Sultana et al., 2021, 2022; Wu, 2010).

The literature supports the building blocks, namely the resources, capabilities, and activities, for successfully adopting and implementing a digital transformation strategy (Ardito, Scuotto, et al., 2019; Correani et al., 2020). Researchers also argue that sustained innovation outcomes and quick responses to the changes in their environments are dependent upon firms’ strong dynamic capabilities (Felin & Powell, 2016). Consequently, using the theories of RBV and dynamic capabilities, this study considers big data capabilities as an antecedent of SCI with the intervening influence of supply chain ambidexterity capabilities, and also proposes that technology uncertainty moderates this relationship.

2.2 Main constructs and hypotheses development

2.2.1 Big data analytics capabilities

A large percentage of technology spending is invested in digital transformations, and organisations around the globe have spent trillions of dollars on adopting digital technologies and so it is both important and integral to understand how this data can be transformed into innovation (Appio et al., 2021). Many companies end up with a significant amount of data as a result of interactions with their customers and use this information to make intelligent decisions for innovation (Ardito, Messeni Petruzzelli, et al., 2019; Fortunato et al., 2017). This entails many opportunities for companies to obtain benefits and create value through developing new and innovative solutions for their customers (Del Vecchio et al., 2018) and enhancing efficiency through cost reduction (Chen et al., 2012). BAC has been defined as “a holistic process that involves the collection, analysis, use, and interpretation of data for various functional divisions with a view to gaining actionable insights, creating business value, and establishing competitive advantage” (Srinivasan & Swink, 2018; Wamba, Akter, et al., 2020; Wamba, Dubey, et al., 2020, p 2).

2.2.2 Supply chain innovation

Big data capabilities can provide opportunities for all types of organisations, irrespective of their size or structure, to innovate through dynamic and scalable data analysis (Del Vecchio et al., 2018). Innovations in the digital era entail the critical values of the social networks in which firms operate and which span across a variety of stakeholder relationships including suppliers, customers, and competitors (Del Vecchio et al., 2018). Companies can innovate at the firm, team, and supply chain levels. In this vein, we define SCI as “an integrated change from incremental to radical changes in product, process, marketing, technology, resource and/or organization, which are associated with all related parties, covering all related functions in the supply chain and creating value for all stakeholders” (Gao et al., 2017, p. 27).

Innovation has been traditionally associated with activities, processes, strategies, and structures at the firm level (Roger, 2003). However, SCI entails those practices and activities that are involved in the supply chain processes (both upstream and downstream) to improve efficiency and stakeholder satisfaction (Seo et al., 2014). An example of such innovation is the capability of a logistics organisation to cultivate and maintain innovativeness by adding value to the service provision (Wagner, 2008). SCI enables firms to tactfully meet and exceed the demand for improved competitiveness (Afraz et al., 2021).

2.2.3 Supply chain ambidexterity capabilities

This capability is a noteworthy attribute pertaining to supply chains that enables firms to alleviate or diminish the negative impact of disruptions in supply chains and accordingly enhances their performance (Aslam et al., 2018); and thus it is defined as “…an organization’s supply chain to be simultaneously agile, so that it can quickly respond to short-term market changes, and adaptable, so the resource base and structure of the supply chain can be configured to achieve longer-term efficiency gains” (p. 2270). Wamba, Akter, et al. (2020), Wamba, Dubey, et al. (2020)) maintained that BAC can help enhance supply chain ambidexterity (taken as SAG and SAD) leading to higher firm performance outcomes.

2.2.4 Big data analytics capabilities and supply chain innovation

Research at the organisational level investigates as to how firm capabilities, processes, and routines lead to DDI (Appio et al., 2021). Researchers argue that dynamic capabilities by themselves may not bring about competitive advantages and the intermediary mechanisms of innovation capabilities are instead required to fulfil this objective (Mikalef et al., 2019). This is based on the arguments proposed by Eisenhardt and Martin (2000), who maintained that such capabilities may be essential; however, they are not necessary circumstances for adding value to the business. Based on this argument, we also maintain that dynamic capabilities are only realised in achieving higher competitive advantage when they maintain a specific level of innovation in their supply chains.

Researchers have argued that dynamic capabilities strengthen firm performance by facilitating new, as well as novel ways of operations and processes (Zahra et al., 2006). The majority of the multinational enterprises operating from developed economies including Facebook, Uber, and Microsoft endeavour to capture value through big data as an element of the i4.0 plan (Shamim et al., 2017). Big companies like Vodafone have also used digital platforms to create new value for customers in their businesses by collecting and leveraging data (Correani et al., 2020). Accordingly, firms belonging to developing nations like China are also exploiting the benefits that big data has to offer (Zeng & Glaister, 2018).

More recently, literature reviews also supported the notion that the mechanisms and consequences of these dynamic capabilities include innovation and that different types of innovation are directly or indirectly associated with them (Schilke et al., 2018). Additionally, Aydiner et al. (2019) established a positive and significant relation between the adoption of BDA with firm level performance. Similarly, Mikalef et al., (2019, 2020) identified that BAC significantly contributed to the innovation process of both incremental and radical types. Liu et al. (2020) also explored the role of BAC in the design innovations of manufacturing SMEs and concluded that firms need certain capabilities and tools to comprehensively utilise the benefits of digital technologies like big data.

BAC establish the foundations upon which intelligent supply chains can improve the current functions and processes of the firms (Ardito, Scuotto, et al., 2019; Sanders & Ganeshan, 2015; Zhan & Tan, 2020). In this way, such digital technologies enable firms to maintain their superior competitive performance across global supply chains (Hazen et al., 2016). Supply chains generate a great deal of big data as retailers and manufacturers collect data from diverse sources including RFID labels, GPS devices, and inventory and warehouse data (Choi et al., 2017; Gandomi & Haider, 2015). Many big companies like Walmart have utilised supply chains governed by information systems and hence improved their operating productivity through BAC (Zhan & Tan, 2020). Consequently, many decision-making processes across the supply chain (e.g., electronic procurement, inventory tracking, and order fulfillment) are more effective and efficient (Fisher & Raman, 2017). Thus, supporting the notion that BAC may have great effects on the supply chain processes of the firms through leveraging big data for innovation (Bresciani, Ciampi, et al., 2021), we propose our baseline hypothesis as:

H1(baseline)

BAC has a significant effect on SCI in the firms

2.2.5 The moderating role of technology uncertainty

Numerous environmental factors could impact the relationship between BAC and SCI. Sousa and Voss (2008) maintain that supply chain management processes are dependent upon a complex set of environmental factors. Many researchers have taken BAC as dynamic and critical resources for the firm under the influence of many contextual factors (Akter et al., 2016; Aydiner et al., 2019), thus we also maintain that technology uncertainty can play a crucial rule in realising these capabilities. Past researchers have mainly explored the impact of environmental dynamism (Dubey et al., 2020; Wamba, Akter, et al., 2020; Wamba, Dubey, et al., 2020) within the BAC-performance link. We propose technology uncertainty, as a crucial environmental factor in dynamic capabilities theory, may impact the relationship between BAC and SCI.

Technology uncertainty corresponds to the new and significant changes in the characteristics of products/services and operational procedures specific to a sector (Oh & Rhee, 2008; Stock & Tatikonda, 2008). Technology uncertainty can also significantly impact manufacturers as it may reduce firms’ capabilities and impose new challenges for supply chain managers in the successful adoption of technology capabilities (Xiao et al., 2019). Technology uncertainty is a by-product of the rapid pace of innovation in products, processes, and technologies themselves. It has the potential to interrupt and hamper the swift movement of resources through supply chains and create complications for several actors involved in these operations (Xiao et al., 2019). Such challenging issues have the potential to harm finished products that fail to meet customer requirements and can thus affect the whole of the supply chain (Fynes & Voss, 2002); at the same time, however, they may also improve firms’ organisational capabilities. Thus, it is in the interest of incumbent firms to comprehensively understand and proactively address issues created by technology uncertainties in their supply chains.

Due to rapid technological advances, the global capacity for information storage doubles every three years and thus firms require more storage and higher speeds to assemble, accumulate, and access big data (Chen & Zhang, 2014). Technologies have shaped the way we perform our jobs and have helped us to improve them in a number of ways. The availability of suitable technologies can lead to the enhancement of the capability to use other technologies (Shamim et al., 2019). Researchers argue that BAC facilitated the development of problem solving strategies, and competences centred around big data also require the adoption as well as the utilisation of cutting edge technologies (McAfee et al., 2012). For this reason, technology uncertainty may have a significant impact on organisations, as researchers have previously discovered the substantial influence of technology uncertainty on supplier participation resulting in increased supply chain productivity (Xiao et al., 2019).

Although BAC is clearly associated with enhanced performance outcomes in organisations, there may still be numerous technological concerns that must be investigated to integrate such capabilities in organisations (Ardagna et al., 2016). To survive the evolving world of innovative technologies, firms tend to heavily invest in novel technologies to increase their dynamic capabilities (Akhtar et al., 2018; Tan et al., 2017), hoping to improve their innovation outcomes. Nevertheless, researchers maintain that dynamic capabilities may operate under diverse mechanisms of operation and can result in different types of outcomes depending on how they are applied (Mikalef et al., 2020). Thus, we propose that the BAC-SCI relationship is positively moderated by technology uncertainty in such a way that BAC leads to higher SCI under the influence of higher technological uncertainty. Following these arguments, we propose our next hypothesis as:

H2

Technological uncertainty positively moderates the relationship between BAC and SCI

2.2.6 The mediating role of supply chain ambidexterity capabilities

According to Eckstein et al., (2015, p. 3028), “… the direct performance effects are often crucial, but they seem incapable of fully capturing the complexity of the business reality.” Eckstein et al.’s statement is vital to fully comprehend the intervening mechanisms of BAC and innovation in supply chains. It is a common notion that firms must somehow balance the conflicting processes and capabilities within their fabric of operations if they truly wish to leverage the influence of BAC in their operations (Abbasi et al., 2016; Conboy et al., 2020). It is both interesting and important to know how digital technologies enable firms to develop both dynamic competencies (Appio et al., 2021) and new competencies (D’Ippolito et al., 2019). These technologies may transform supply chains (Vendrell-Herrero et al., 2016) and also help them to reconfigure customer relationships (Porter & Heppelmann, 2014), thereby reshaping industry competition (D’Ippolito et al., 2019). Previous literature has maintained that BAC is significantly associated with supply chain visibility and performance at the organisational and supply chain levels (Akter et al., 2016; Mikalef et al., 2020; Srinivasan & Swink, 2018). Researchers have also argued that the positive impact of BAC is achieved by mitigating the impact of changes in demand in supply chains (Lee et al., 2000), thus making them more responsive (Chen et al., 2015; Lu & Ramamurthy, 2011) and adaptable (Dubey et al., 2018; Wamba, Akter, et al., 2020; Wamba, Dubey, et al., 2020), subsequently improving value creation (Wei & Wang, 2010) and enhancing the efficiencies and effectiveness of operations and processes.

BAC may help supply chain managers to explore and recognise rapid changes in technologies and allow them to plan and deploy responsive strategies to respond to such changes effectively (Dubey et al., 2018). Similarly, Blome et al. (2013) contend that supply chain agility helps managers to quickly respond to supply chain disruptions and thus minimise the costs incurred due to these disruptions (Hendricks & Singhal, 2005). Agile supply chains result in better synchronised supply and demand processes and subsequently reduce the holding and maintenance costs of inventory and logistics (Eckstein et al., 2015). Additionally, agility enables firms to decrease the replacement time, improve production output, and adjust the processes by customising the products (Lee, 2004). An increasing number of researchers have established that a relationship exists between SAG and cost effectiveness (see Eckstein et al., 2015; Gligor et al., 2016). Therefore, focusing on the aforementioned arguments, our next set of hypotheses is stated below:

H3a

BAC has a positive relationship with SAG.

H3b

SAG has a positive impact on SCI.

H3c

SAG mediates the relationship between BAC and SCI.

Likewise, BAC hugely impacts the operational processes and supply chain management in the effective management of operations, systems, and processes as these competencies assist firms in embracing the fluctuations seen in the environment and thus gain a competitive advantage by improving effectiveness and efficiency (Zhan & Tan, 2020). In this way, these capabilities allow firms to add value and quality to their innovative services and products (Kunc & O’Brien, 2018). This capability of analysing data from different processes across the supply chain can improve customer relationship management, reduce their response time, and enable them to handle the technical uncertainties in their environment (Demirkan & Delen, 2013; Sanders & Ganeshan, 2015).

Firms tend to capitalise on BAC for improving their visibility, flexibility, and adaptability in their supply chain management operations (Wang et al., 2016). Eckstein et al. (2015) argue that SAG and SAD have substantial effects on both financial and functioning outcomes. Christopher and Holweg (2011) maintain that outsourcing to suppliers and other vendors is a true indicator of supply chain flexibility and improves firms’ access to resources and capabilities. Besides, methods of significantly improving firm performance and reducing costs include the vertical and horizontal integration of suppliers, finding new channels and markets, and finally enhancing buyer–supplier relationships involved in product or process innovation (Lee, 2004). Therefore, we maintain that SAD, as a dynamic capability, may lead to higher quality and delivery times (Marin-Garcia et al., 2018) and also help supply chains to innovate in times of technological changes. Thus, we propose our next hypotheses:

H4a

BAC has a positive relationship with SAD.

H4b

SAD has a positive relationship with SCI.

H4c

SAD mediates the relationship between BAC and SCI.

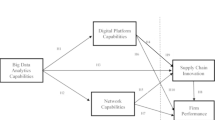

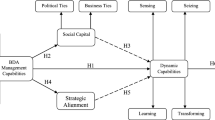

The theoretical model studied in the research is shown in Fig. 1.

3 Methods and measures

The current study adopts a positivist epistemological approach and the sample for testing the proposed model consisted of manufacturing firms operating in Pakistan. In particular, we opted for the purposive sampling technique based on the fact that our sample represents managers working in manufacturing firms. As a result, the selection criteria for our sample included those respondents who were working as a manager, especially on supply chain related operations. For accurate and appropriate data collection, a detailed procedure was used. First, a request was sent to the HR departments of four hundred public and private companies; they were provided with details of the study and assured that any information collected would be anonymous and only used for research. Moreover, in the selection of firms we only contacted those firms that belonged to a variety of sectors listed on the Pakistan Stock Exchange (PSX) and registered with the Securities and Exchange Commission of Pakistan (SECP). We collected data through emails; the HR department provided the email address of the respondents. The final sample of the research comprised supply chain professionals/practitioners working in manufacturing firms. The manufacturing firms in our sample belonged to various sectors like food and beverages, steel, textiles, Fast Moving Consumer Goods (FMCG), pharmaceutical, automotive, consumer electronics, chemical, etc. The link for the survey questionnaire was sent to professionals who agreed to participate in the study and who confirmed that they possessed the relevant information regarding the supply chain operations. We received 406 responses as a result of the initial request and subsequent reminders. Before entering data into the software, we carefully reviewed each respondent and responses that were not complete were discarded. Finally, 386 responses were confirmed for data entry and further analysis. The demographic information of the respondents is discussed in Table 1.

Scale items were asked on a seven-point Likert scale in order to maintain consistency in the data. The researchers employed a five-item scale developed by Dubey et al. (2019a) to measure BAC. Five-item scales developed by Whitten et al. (2012) and Wamba, Akter, et al. (2020), Wamba, Dubey, et al. (2020)) were also used to measure supply chain agility. Similarly, five items were selected to measure SAD capability using the scale established by Whitten et al. (2012) and Wamba, Akter, et al. (2020), Wamba, Dubey, et al. (2020)). Technology uncertainty was operationalised through the scale suggested by Xiao et al. (2019) and constructed using the items presented by Chen and Paulraj (2004) and Zhou & Benton (2007). Finally, SCI was measured by employing a six-item scale developed by Kwak et al. (2018). The items are presented in Table 3.

4 Results

4.1 Measurement model

The current study conducted a series of confirmatory factor analyses in the latest version of AMOS to verify the model’s fitness. The current study model is based on five variables: BAC, SAG, SAD, SCI, and technology uncertainty. To ensure that each variable is discriminant from the other variables and fit for further analyses, the five-factor model was compared with four, three, two, and finally one-factor models. Moreover, this study applied threshold values to assess the model’s fitness. More specifically on the recommendation of previous researchers, this study looked into models such as χ2, Comparative Fit Index (CFI), Incremental Fit Index (IFI), Tucker-Lewis index; TLI, Standardised Root Mean Square Residual (SRMSR), Adjusted Goodness-of-fit (AGFI), and Root Mean Square Error of Approximation (RMSEA) (Carmines et al., 1981; Hu & Bentler, 1999). The base model reflected satisfactory results in comparison with the rest of the models, as x2 = 1.92 (below 3), CFI, IFI, and TLI values were more than 0.90. RMSEA = 0.04, AGFI = 0.87 (greater than 0.80), and SRMR = 0.06 (less than 0.08) (see Table 2).

4.2 Validity testing for the measurement model

In the current study, reflective measurement model validity was assessed through both convergent and discriminant validity as per the recommendations of previous authors (Hair et al., 2017). To test the convergent validity, Average Variance Extracted (AVE) was utilised. As per the guidelines, this value must be higher than 0.5 (Chin, 2010; Hair et al., 2017). Similarly, the values for the composite reliability (CR) must be more than 0.70 (Fornell & Larcker, 1981). In our model, the AVE values of all constructs ranged from 0.50 to 0.62 and CR values ranged from 0.80 to 0.89, as seen in Table 3. Thus, on the basis of these results, convergent validity is confirmed.

Moreover, Henseler et al.’s (2015) Heterotrait-Monotrait (HTMT) method was employed to verify discriminant validity. HTMT values less than 0.85 confirmed the discriminant validity. Table 4 illustrates that the HTMT values of all five constructs are lower than 0.85. Moreover, the Maximum Shared Variance (MSV) values of all five variables were less than their AVE values, confirming discriminant validity. We can therefore conclude that the HTMT and MSV results validate adequate discriminant validity for the current measurement model.

In order to discover any relationship between the demographic variables and the study variables, we used the one-way ANOVA method and checked for F statistics to test the variance. The results confirmed that the dependent and mediating variables were insignificantly related to the demographic variables.

4.3 Correlation

Mean, standard deviation, and correlation of the constructs were also computed and displayed in Table 5. The BAC was positively associated with SAG (r = 0.47 p < 0.01), SAD (r = 0.44 p < 0.01), SCI (r = 0.47 p < 0.01), and TUC (r = 0.29 p < 0.01). Next, SAG was considerably linked with SAD (r = 0.51 p < 0.01), SCI (r = 0.44 p < 0.01), and TUC (r = 0.26 p < 0.01). Moreover, SAD was positively linked with SCI (r = 0.53 p < 0.01) and TUC (r = 0.38 p < 0.01). Finally, SCI was considerably connected with TUC (r = 0.47 p < 0.01).

4.4 Hypotheses testing

After establishing discriminant and convergent validity, the proposed direct and indirect hypotheses were tested in AMOS. The first hypothesis of the study predicted that BAC would be positively related to SCI. This relationship was supported as per the values of coefficient of regression and the significance level (β = 0.56, p < 0.001). Hypotheses 3a and 4a stated that BAC is positively associated with SAG and SAD, respectively. The result supported these relationships, as indicated by the regression coefficient for BAC and SAG (β = 0.55, p < 0.001) and for BAC and SAD (β = 0.44, p < 0.001). Similarly, the relationship between SAG and SCI (β = 0.53, p < 0.001) and SAD and SCI (β = 0.54, p < 0.001) was also found to be significant, thus leading to the acceptance of both Hypotheses 3b and 4b. The values are shown in Table 6.

Moreover, Hypotheses 3c stated that SAG mediates the relationship between BAC and SCI. The mediation analysis was also performed through structural equation modelling with bootstrap 5000 and a confidence interval of 95%. When SCI was regressed on both BAC and SCI, the previous regression coefficient between BAC and SCI reduced in size; the indirect effect was β = 0.17, p < 0.001 and the confidence interval values fall between 0.11 and 0.24; for reference, see Table 7. Subsequently, the results confirmed that SAG intervenes in the relationship between BAC and SCI. Similarly, Hypothesis 4c proposed that SAD also intervenes in the relationship between BAC and SCI, and the same procedure was employed. The indirect effect was β = 0.24, p < 0.001 and confidence interval values were between 0.17 and 0.23 (for reference, please see Table 7), thereby giving evidence of Hypothesis 4c.

To test the moderation effect of technology uncertainty on the relationship between BAC and SCI, Preacher and Hayes (2004) model 1 was employed. The study followed the recommendation of Aiken et al. (1991), meaning the predictors were mean centred to test the hypotheses. The study found the moderation effect of technology uncertainty to be positive and significant on the relationship between BAC and SCI (Table 8) by displaying the values (Effect = 0.21, SE = 0.03, p < 0.001). Further, as shown in Fig. 2, slopes test was also aligned with the proposed hypothesis; with high technology uncertainty, the relationship between BAC and SCI was strong. Thus, the proposed hypothesis is accepted.

5 Discussion and implications

Due to insufficient empirical and quantitative studies on this important and upcoming topic, the potential significance of big data cannot be fully comprehended, and it could lead to the inefficient implementation of BAC in firms (Mikalef et al., 2019). It is therefore imperative to comprehend the fundamental mediating and moderating mechanisms of DDI and our study aims to fill this gap. Consequently, our research explores the mechanisms that enable big data analytics to enhance firms’ SCI and tries to fully understand what part uncertainties in technologies play in it. To accomplish this research objective, we proposed and empirically tested an integrated model of BAC and SCI, with mediating mechanisms of SAG and SAD and the moderating role of technology uncertainty.

This study was grounded theoretically on the RBV and the dynamic capabilities theories. According to Teece et al. (1997), the dynamic capabilities view implies that firms must have the capabilities to restore and recreate their processes and systems to efficiently manage the fluctuations in their environment, including technological advancements. This is even more important if the firms compete in a global digital market; in order to gain a competitive advantage, data-driven technologies must be harnessed as special resources (George et al., 2014; Janssen et al., 2017). To strengthen the link between BAC and SCI, this research confirmed the intervening mechanisms of two of the most critical resources: the agility and adaptability of such supply chains.

Moreover, researchers have argued that uncertainties in technology can create considerable problems and obstacles to manufacturing industries due to quick changes in product or service specifications and standards; these may result in disruptions across the supply chains (Xiao et al., 2019). However, the majority of the literature looks towards environmental dynamism and ignores the exploration of the boundary effect of technology uncertainty in the BAC and performance link (Mikalef et al., 2019; Vitari & Raguseo, 2020; Wamba, Akter, et al., 2020; Wamba, Dubey, et al., 2020). Thus, our study explicitly fills the gap in the current literature of a comprehensive understanding of technology uncertainty in the BAC-innovation process. Our findings confirm that under the circumstances of high technology uncertainty, BAC leads to the introduction of new and novel ways of introducing better products, services, and relationships across the supply chains. This confirms our hypothesis that, when technology uncertainty is high, BAC can support the identification of new and novel growth prospects for DDI in supply chains.

Thus, the findings of our research resonate with previous researchers upholding the perspective that BAC may assist in improving innovation such as in design driven innovation (Liu et al., 2020), in business models (Ciampi et al., 2021), in product and process innovation (Ghasemaghaei & Calic, 2020), and also in supply chains (Tan et al., 2015), albeit under certain conditions. Even so, the main premise on which our study foundation is built is that to achieve an innovative supply chain, organisations need to invest in acquiring and assimilating complementary organisational capabilities that overcome the ambidexterity in supply chains (Wamba, Akter, et al., 2020; Wamba, Dubey, et al., 2020). Subsequently, the capabilities of supply chain agility and adaptability have been identified as critical factors for firms to leverage the true potential of BAC (Dubey et al., 2019b; Wamba, Akter, et al., 2020; Wamba, Dubey, et al., 2020). While firm performance has been the focus of data science researchers and much attention has been devoted to understanding how BAC translates into higher value creation in recent years, there is now an increased emphasis on exploring the capabilities that increase innovation output and on grasping the knowledge of how firms should equip themselves in order to fully adopt and implement data-driven strategies (Mikalef et al., 2019). Our study takes this exploration one step further and confirms our hypotheses that innovation across the supply chain can also be realised through these dynamic capabilities.

5.1 Implications for theory

Our theoretical model contributes to the theories of RBV and dynamic capabilities to examine the BAC and augments the small but growing body of literature directed at exploring the impact that i4.0 technologies have had on manufacturing firms. Not many researchers have investigated the impact of BAC through such a holistic lens (Dubey et al., 2018; Wamba, Akter, et al., 2020; Wamba, Dubey, et al., 2020); thus, the underlying mechanisms of BAC and DDI still require in depth empirical examination (Correani et al., 2020; Mikalef et al., 2019). This research adds to the domain of OM and supply chain management as it is one of the few studies that establishes a link between BAC and SCI. Researchers have identified the fact that firms who integrate BAC into their supply chains have a higher probability of better organisational performance (Srinivasan & Swink, 2018). However, an in depth study by Ghasemaghaei and Calic (2020) revealed that not all types of data capabilities improve firm innovation performance, challenging the general conviction that “big data is better data” (p. 147). Furthermore, the majority of the existing literature on SCI is centred around case study methodology (Gao et al., 2017). Very few studies have explored the antecedents of innovations in the supply chain and previous researchers have recommended using a survey methodology for future studies (Kabadurmus, 2020). Thus, we extend the existing literature by offering and testing a model that explores how big data capabilities impact the innovation strategies within the supply chains and our study offers empirical insights into how technological capabilities can contribute to innovations in manufacturing firms’ supply chains.

Second, this research sheds light on the significance of the intermediaries in the link between BAC and supply chain capabilities. In the context of the supply chain management domain, this study argues that big data capabilities are crucial for manufacturing firms in creating innovation through the capabilities that reduce supply chain ambidexterity. In this way, it extends the current debate on BAC. We ground our research on the well-established theories of RBV and dynamic capabilities and emphasise that BAC is related to SCI through the intervening mechanisms of supply chain agility and adaptability. Also, technology uncertainty acts as a boundary condition in this relationship. Thus, we establish that BAC necessitates that other capabilities are established and coordinated in order to fully realise innovations in supply chains. The majority of the previous literature focused only on the outcomes of BAC in firms, mainly their performance or competitive advantage (Dubey et al., 2019a, 2019b; Wamba et al., 2017; Wamba, Akter, et al., 2020; Wamba, Dubey, et al., 2020) or on incremental and radical innovation at the firm level (Mikalef et al., 2019). We, however, provide empirical support for innovation in supply chains as an outcome of BAC-enabled dynamic capabilities.

Finally, we test our model in the manufacturing industry of a developing country, i.e., Pakistan. In their review of literature in the field and a bibliometric analysis of current studies on the role of BAC in supply chains, Mishra et al. (2018) found that the majority of the studies in this domain were carried out in advanced economies like the United States, China, the United Kingdom, and Germany. Empirically, our study is one of the few that explicitly investigates the antecedents of innovations within supply chain functions by using the intervening mechanisms of supply chain ambidexterity in this context.

5.2 Implications for practice

This study has highlighted several organisational capabilities that impact the innovation performance of the supply chains of these manufacturers. Huge firms like Amazon, Google, and Alibaba have reaped the benefits of DDI (Akter et al., 2021). Our study stresses that focal manufacturers can innovate their upstream and downstream supply networks by efficiently utilising complementary resources and capabilities. We further argue that this research can be beneficial for manufacturing organisations to augment their big data related decision making competencies that can result in greater supply chain innovation by better responding to supply chain ambidexterity issues. By improving their BAC, organisations may create supply chain capabilities that can help them both reduce their ambidexterity and improve their DDI (Ardito, Scuotto, et al., 2019). This study suggests that supply chain managers belonging to these manufacturing firms must develop a culture of BAC and must also acquire relevant technologies associated with them.

With reference to the performance outcomes at the individual level, our research is useful to data science practitioners and business operations managers alike. Both of these stakeholders can effectively use big data capabilities to cope with supply chain ambidexterity and technology uncertainty. At the firm level, manufacturers can use our theoretical model to devise strategic interventions and informed decision-making processes in order to fully utilise the big data benefits. Through fully utilising big data capabilities, manufacturing supply chains can amplify the rate at which they introduce new products and services, and make sense of multifaceted and fast-paced technological changes. Similarly, they can monitor interactions with their stakeholders (both internal and external) in real time and find room for improvement in operations and processes. For instance, customer involvement through BAC can lead to the customisation of products and services and this individualised product and service provision can lead to improved customer satisfaction.

However, the results of this research also maintain that even a strong BAC itself does not guarantee SCI. It is vital for managers to comprehend and appreciate the significance of understanding the whole process, i.e., how it proceeds from perception to realisation. Although manufacturing firms may develop innovations due to their effective BAC, such firms still need some additional capabilities in order to fully capitalise upon it. In order to fully translate the benefits of BAC, manufacturing firms must strive to cultivate the additional capabilities of both SAG and SAD. By doing so, these firms may overcome a part of the inertia that may obstruct novel ideas to be converted into successful innovations across the supply chains. Thus, managers need to recognise the significance of overcoming the ambidexterity in supply chains and harness the power of technology uncertainty to understand that BAC is one element of creating value from investments in big data analytics.

6 Conclusion, limitations, and future work

The “Age of Data” is presently flourishing where data is continuously being created from multiple sources in a diverse set of industries at an unprecedented rate (Mikalef et al., 2019). This has been accompanied by a massive amount of hype, where companies are struggling to leverage BAC to achieve competitive advantage through value creation (Constantiou & Kallinikos, 2015). Being an integral part of the daily operations of manufacturing firms, big data has a huge role to play in building dynamic capabilities to enhance the DDI (Akter et al., 2021). Furthermore, technological advancements have made supply chains more creative and advanced through the embracing of novel methods and operating routines and these chains are more effective in fulfilling customer needs and demands (Panayides & So, 2005). However, there is a dearth of knowledge available for practitioners as to how to plan and execute their big data projects for new product and process development (Mikalef et al., 2018).

In our research, we set out to explore how BAC impacts SCI and whether SAD and SAG act as intervening mechanisms in this relation. While the literature has comprehensively explored supply chain agility (Dubey et al., 2019b; Gligor et al., 2015, 2016; Tarafdar & Qrunfleh, 2017), it is mostly silent on the collective influence of agility and adaptability alignment, albeit with a few exceptions (Dubey et al., 2018; Wamba, Akter, et al., 2020; Wamba, Dubey, et al., 2020). Furthermore, the majority of these studies either focused on cost-related performance or else on operational performance (Gupta et al., 2019; Wamba, Akter, et al., 2020; Wamba, Dubey, et al., 2020), competitive advantage (Dubey et al., 2019a), radical and incremental innovation (Mikalef et al., 2019), open innovation (Del Vecchio et al., 2018; Fortunato et al., 2017), or process and product innovation (Saleem et al., 2020) as an outcome. Nevertheless, none of these studies studied SCI as an outcome of BAC.

Thus, in our study, we explored the role of BAC in improving firms’ capabilities in experiencing supply chain ambidexterity and, in turn, on improving the innovation of supply chains under the boundary condition of technology uncertainty. The argument developed in the research model identifies the effect of BAC on SCI by understanding the underlying processes of SAG and SAD. Our model is valuable because, due to the fast pace of technology advancements, many firms are struggling to innovate and they find it hard to use the information extracted from the significant amount of data they already have (Mikalef et al., 2019; Wamba, Akter, et al., 2020; Wamba, Dubey, et al., 2020; Xiao et al., 2019).

In spite of its significance, the current study also encompasses some limitations that can present future research avenues for scholars of DDI. First, this study uses quantitative data collected at a single time frame from a single source, so future researchers can implement a longitudinal or time lagged design in order to examine the proposed model. Second, another opportunity for future researchers might be to test our model by drawing a comparison of underdeveloped and developed economies—or cross cultural ones—in order to fully understand how infrastructure and other institutional aspects impact these relationships. Third, future studies could also explore the relationships of other capabilities of supply chains such as supply chain visibility, flexibility, connectivity, and alignment (Dubey et al., 2018; Wei & Wang, 2010) that could potentially have an impact in this context. Finally, studies can incorporate other stakeholders in the relationship and explore how the BAC of firms belonging to any sector can impact the innovative capabilities of buyers or supplier.

References

Abbasi, A., Sarker, S., & Chiang, R. H. (2016). Big data research in information systems: Toward an inclusive research agenda. Journal of the Association for Information Systems, 17, 3.

Afraz, M. F., Bhatti, S. H., Ferraris, A., & Couturier, J. (2021). The impact of supply chain innovation on competitive advantage in the construction industry: Evidence from a moderated multi-mediation model. Technological Forecasting and Social Change, 162, 120370.

Aiken, L. S., West, S. G., & Reno, R. R. (1991). Multiple regression: Testing and interpreting interactions. Sage.

Akhtar, P., Khan, Z., Tarba, S., & Jayawickrama, U. (2018). The Internet of Things, dynamic data and information processing capabilities, and operational agility. Technological Forecasting and Social Change, 136, 307–316.

Akter, S., & Wamba, S. F. (2016). Big data analytics in E-commerce: A systematic review and agenda for future research. Electronic Markets, 26, 173–194.

Akter, S., Wamba, S. F., Gunasekaran, A., Dubey, R., & Childe, S. J. (2016). How to improve firm performance using big data analytics capability and business strategy alignment? International Journal of Production Economics, 182, 113–131.

Akter, S., Bandara, R., Hani, U., Fosso Wamba, S., Foropon, C., & Papadopoulos, T. (2019). Analytics-based decision-making for service systems: A qualitative study and agenda for future research. International Journal of Information Management, 48, 85–95.

Akter, S., et al. (2021). Algorithmic bias in data-driven innovation in the age of AI. International Journal of Information Management, 60, 102387.

Andriopoulos, C., & Lewis, M. W. (2009). Exploitation-exploration tensions and organizational ambidexterity: Managing paradoxes of innovation. Organization Science, 20, 696–717.

Appio, F. P., Frattini, F., Messeni Petruzzelli, A., & Neirotti, P. (2021). Digital transformation and innovation management: A synthesis of existing research and an agenda for future studies. Journal of Product Innovation Management., 38, 4–20.

Ardagna, C. A., Ceravolo, P., & Damiani, E. (2016). Big data analytics as-a-service: Issues and challenges. In 2016 IEEE International Conference on Big Data (Big Data), 3638–3644.

Ardito, L., Scuotto, V., Del Giudice, M., & Messeni Petruzzelli, A. (2019). A bibliometric analysis of research on Big Data analytics for business and management. Management Decision., 57, 1993–2009.

Ardito, L., Messeni Petruzzelli, A., Panniello, U., & Garavelli, A. C. (2019). Towards Industry 4.0: Mapping digital technologies for supply chain management-marketing integration. Business Process Management Journal., 25, 323–346.

Aslam, H., Blome, C., Roscoe, S., & Azhar, T. M. (2018). Dynamic supply chain capabilities: How market sensing, supply chain agility and adaptability affect supply chain ambidexterity. International Journal of Operations & Production Management, 38, 2266–2285.

Awan, U., Bhatti, S. H., Shamim, S., Khan, Z., Akhter, P., & Balta, M. (2021). The role of big data analytics in manufacturing agility and performance: Moderation-mediation analysis of organizational creativity and of the involvement of customers as data analysts. British Journal of Management. https://doi.org/10.1111/1467-8551.12549

Aydiner, A. S., Tatoglu, E., Bayraktar, E., Zaim, S., & Delen, D. (2019). Business analytics and firm performance: The mediating role of business process performance. Journal of Business Research, 96, 228–237.

Barney, J. (1991). Firm resources and sustained competitive advantage. Journal of Management, 17, 99–120.

Barney, J., Wright, M., & Ketchen, D. J., Jr. (2001). The resource-based view of the firm: Ten years after 1991. Journal of Management., 27, 625–641.

Blome, C., Schoenherr, T., & Rexhausen, D. (2013). Antecedents and enablers of supply chain agility and its effect on performance: A dynamic capabilities perspective. International Journal of Production Research, 51, 1295–1318.

Božič, K., & Dimovski, V. (2019). Business intelligence and analytics use, innovation ambidexterity, and firm performance: A dynamic capabilities perspective. The Journal of Strategic Information Systems, 28, 101578.

Bresciani, S., Ferraris, A., Huarng, K. H., & Malhotra, A. (2021). Digital transformation as a springboard for product, process and business model innovation. Journal of Business Research, 128, 204–210.

Bresciani, S., Ciampi, F., Meli, F., & Ferraris, A. (2021). Using big data for co-innovation processes: Mapping the field of data-driven innovation, proposing theoretical developments and providing a research agenda. International Journal of Information Management, 60, 102347.

Carmines, E. G., McIver, J. P., Bohrnstedt, G. W., & Borgatta, E. F. (1981). Social measurement: Current issues. Analyzing Models with Unobserved Variables: Analysis of Covariance Structures, 80, 65–115.

Chatterjee, S., Chaudhuri, R., & Vrontis, D. (2021). Does data-driven culture impact innovation and performance of a firm? An empirical examination. Annals of Operations Research. https://doi.org/10.1007/s10479-020-03887-z

Chen, I. J., & Paulraj, A. (2004). Understanding supply chain management: Critical research and a theoretical framework. International Journal of Production Research, 42, 131–163.

Chen, C. P., & Zhang, C.-Y. (2014). Data-intensive applications, challenges, techniques and technologies: A survey on Big Data. Information Sciences, 275, 314–347.

Chen, H., Chiang, R. H., & Storey, V. C. (2012). Business intelligence and analytics: From big data to big impact. MIS Quarterly, 36, 1165–1188.

Chen, D. Q., Preston, D. S., & Swink, M. (2015). How the use of big data analytics affects value creation in supply chain management. Journal of Management Information Systems, 32, 4–39.

Chin, W. W. (2010). How to write up and report PLS analyses. In Handbook of partial least squares (pp. 655–690). Springer.

Choi, T. M., Wallace, S. W., & Wang, Y. (2017). Big data analytics in operations management. Production and Operations Management, 27, 1868–1883.

Christopher, M., & Holweg, M. (2011). ‘Supply Chain 2.0’: Managing supply chains in the era of turbulence. International Journal of Physical Distribution & Logistics Management, 41, 63–82.

Ciampi, F., Demi, S., Magrini, A., Marzi, G., & Papa, A. (2021). Exploring the impact of big data analytics capabilities on business model innovation: The mediating role entrepreneurial orientation. Journal of Business Research, 123, 1–13.

Conboy, K., Mikalef, P., Dennehy, D., & Krogstie, J. (2020). Using business analytics to enhance dynamic capabilities in operations research: A case analysis and research agenda. European Journal of Operational Research, 281, 656–672.

Constantiou, I. D., & Kallinikos, J. (2015). New games, new rules: Big data and the changing context of strategy. Journal of Information Technology, 30, 44–57.

Correani, A., De Massis, A., Frattini, F., Messeni Petruzzelli, A., & Natalicchio, A. (2020). Implementing a digital strategy: Learning from the experience of three digital transformation projects. California Management Review, 62, 37–56.

Del Vecchio, P., Di Minin, A., Messeni Petruzzelli, A., Panniello, U., & Pirri, S. (2018). Big data for open innovation in SMEs and big corporations: Trends, opportunities, and challenges. Creativity and Innovation Management., 18, 6–22.

Demirkan, H., & Delen, D. (2013). Leveraging the capabilities of service-oriented decision support systems: Potting analytics and big data in cloud. Decision Support Systems, 55, 412–421.

D’Ippolito, B., Messeni Petruzzelli, A., & Panniello, U. (2019). Archetypes of incumbents’ strategic responses to digital innovation. Journal of Intellectual Capital., 20, 662–679.

Duan, Y., Cao, G., & Edwards, J. S. (2020). Understanding the impact of business analytics on innovation. European Journal of Operational Research, 281, 673–686.

Dubey, R., Altay, N., Gunasekaran, A., Blome, C., Papadopoulos, T., & Childe, S. J. (2018). Supply chain agility, adaptability and alignment. International Journal of Operations & Production Management, 38, 129–148.

Dubey, R., Gunasekaran, A., & Childe, S. J. (2019a). Big data analytics capability in supply chain agility. Management Decision, 57, 2092–2112.

Dubey, R., Gunasekaran, A., Childe, S. J., Blome, C., & Papadopoulos, T. (2019b). Big data and predictive analytics and manufacturing performance: Integrating institutional theory, resource-based view and big data culture. British Journal of Management, 30, 341–361.

Dubey, R., Gunasekaran, A., Childe, S. J., Bryde, D. J., Giannakis, M., Foropon, C., Roubaud, D., & Hazen, B. T. (2020). Big data analytics and artificial intelligence pathway to operational performance under the effects of entrepreneurial orientation and environmental dynamism: A study of manufacturing organisations. International Journal of Production Economics, 226, 107599.

Eckstein, D., Goellner, M., Blome, C., & Henke, M. (2015). The performance impact of supply chain agility and supply chain adaptability: The moderating effect of product complexity. International Journal of Production Research, 53, 3028–3046.

Eisenhardt, K. M., & Martin, J. A. (2000). Dynamic capabilities: What are they? Strategic Management Journal, 21, 1105–1121.

Eisenhardt, K. M., Furr, N. R., & Bingham, C. B. (2010). CROSSROADS—microfoundations of performance: Balancing efficiency and flexibility in dynamic environments. Organization Science, 21, 1263–1273.

Elia, S., Giuffrida, M., Mariani, M. M., & Bresciani, S. (2021). Resources and digital export: An RBV perspective on the role of digital technologies and capabilities in cross-border e-commerce. Journal of Business Research., 132, 158–169.

Felin, T., & Powell, T. C. (2016). Designing organizations for dynamic capabilities. California Management Review, 58, 78–96.

Ferraris, A., Mazzoleni, A., Devalle, A., & Couturier, J. (2019). Big data analytics capabilities and knowledge management: Impact on firm performance. Management Decision, 57, 1923–1936.

Fisher, M. L. (1997). What is the right supply chain for your product? Harvard Business Review, 75, 105–117.

Fisher, M., & Raman, A. (2017). Using data and big data in retailing. Production and Operations Management, 27(9), 1665–1669.

Fornell, C., & Larcker, D. F. (1981). Structural Equation Models with Unobservable Variables and Measurement Error: Algebra and Statistics. Sage Publications Sage CA.

Fortunato, A., Gorgoglione, M., Messeni Petruzzelli, A., & Panniello, U. (2017). Leveraging big data for sustaining open innovation: The case of social TV. Information Systems Management., 34, 238–249.

Fynes, B., & Voss, C. (2002). The moderating effect of buyer-supplier relationships on quality practices and performance. International Journal of Operations & Production Management, 22, 589–613.

Gandomi, A., & Haider, M. (2015). Beyond the hype: Big data concepts, meth- ods, and analytics. International Journal of Information Management, 35, 137–144.

Gao, D., Xu, Z., Ruan, Y. Z., & Lu, H. (2017). From a systematic literature review to integrated definition for sustainable supply chain innovation (SSCI). Journal of Cleaner Production, 142, 1518–1538.

George, G., Haas, M. R., & Pentland, A. (2014). Big data and management. Academy of Management Briarcliff Manor.

Ghasemaghaei, M., & Calic, G. (2020). Assessing the impact of big data on firm innovation performance: Big data is not always better data. Journal of Business Research, 108, 147–162.

Gligor, D. M., Esmark, C. L., & Holcomb, M. C. (2015). Performance outcomes of supply chain agility: When should you be agile? Journal of Operations Management, 33, 71–82.

Gligor, D. M., Holcomb, M. C., & Feizabadi, J. (2016). An exploration of the strategic antecedents of firm supply chain agility: The role of a firm’s orientations. International Journal of Production Economics, 179, 24–34.

Günther, W. A., Mehrizi, M. H. R., Huysman, M., & Feldberg, F. (2017). Debating big data: A literature review on realizing value from big data. The Journal of Strategic Information Systems, 26, 191–209.

Gupta, S., Drave, V. A., Dwivedi, Y. K., Baabdullah, A. M., & Ismagilova, E. (2019). Achieving superior organizational performance via big data predictive analytics: A dynamic capability view. Industrial Marketing Management, 90, 581–592.

Hahn, G. J. (2020). Industry 4.0: A supply chain innovation perspective. International Journal of Production Research, 58, 1425–1441.

Hair, J. F., Hult, G. T. M., Ringle, C. M., Sarstedt, M., & Thiele, K. O. (2017). Mirror, mirror on the wall: A comparative evaluation of composite-based structural equation modeling methods. Journal of the Academy of Marketing Science, 45, 616–632.

Hazen, B. T., Skipper, J. B., Boone, C. A., & Hill, R. R. (2016). Back in business: Operations research in support of big data analytics for operations and supply chain management. Annals of Operations Research, 270, 201–211.

Hendricks, K. B., & Singhal, V. R. (2005). Association between supply chain glitches and operating performance. Management Science, 51, 695–711.

Henseler, J., Ringle, C. M., & Sarstedt, M. (2015). A new criterion for assessing discriminant validity in variance-based structural equation modeling. Journal of the Academy of Marketing Science, 43, 115–135.

Hitt, M. A., Carnes, C. M., & Xu, K. (2016). A current view of resource based theory in operations management: A response to Bromiley and Rau. Journal of Operations Management, 41, 107–109.

Hu, L., & Bentler, P. M. (1999). Cutoff criteria for fit indexes in covariance structure analysis: Conventional criteria versus new alternatives. Structural Equation Modeling: A Multidisciplinary Journal, 6, 1–55.

Janssen, M., van der Voort, H., & Wahyudi, A. (2017). Factors influencing big data decision-making quality. Journal of Business Research, 70, 338–345.

Johnson, J. S., Friend, S. B., & Lee, H. S. (2017). Big data facilitation, utilization, and monetization: Exploring the 3Vs in a new product development process. Journal of Product Innovation Management, 34, 640–658.

Kabadurmus, F. N. K. (2020). Antecedents to supply chain innovation. The International Journal of Logistics Management, 31, 145–171.

Ketokivi, M. (2016). Point–counterpoint: Resource heterogeneity, performance, and competitive advantage. Journal of Operations Management, 41, 75–76.

Kunc, M., & O’Brien, F. A. (2018). The role of business analytics in supporting strategy processes: Opportunities and limitations. Journal of the Operational Research Society, 70, 974–985.

Kwak, D. W., Seo, Y. J., & Mason, R. (2018). Investigating the relationship between supply chain innovation, risk management capabilities and competitive advantage in global supply chains. International Journal of Operations & Production Management, 38, 2–21.

Lee, H. L. (2004). The triple-A supply chain. Harvard Business Review, 82, 102–113.

Lee, S. M., & Rha, J. S. (2016). Ambidextrous supply chain as a dynamic capability: Building a resilient supply chain. Management Decision, 54, 2–23.

Lee, H. L., So, K. C., & Tang, C. S. (2000). The value of information sharing in a two-level supply chain. Management Science, 46, 626–643.

Liu, Y., Soroka, A., Han, L., Jian, J., & Tang, M. (2020). Cloud-based big data analytics for customer insight-driven design innovation in SMEs. International Journal of Information Management, 51, 102034.

Lu, Y., & Ramamurthy, K. (Ram). (2011). Understanding the link between information technology capability and organizational agility: An empirical examination. MIS Quarterly, 35, 931–954.

Marin-Garcia, J. A., Alfalla-Luque, R., & Machuca, J. A. (2018). A triple-A supply chain measurement model: Validation and analysis. International Journal of Physical Distribution & Logistics Management, 48, 976–994.

McAfee, A., Brynjolfsson, E., Davenport, T. H., Patil, D. J., & Barton, D. (2012). Big data: The management revolution. Harvard Business Review, 90, 60–68.

Mikalef, P., Pappas, I. O., Krogstie, J., & Giannakos, M. (2018). Big data analytics capabilities: A systematic literature review and research agenda. Information Systems and E-Business Management, 16, 547–578.

Mikalef, P., Boura, M., Lekakos, G., & Krogstie, J. (2019). Big data analytics and firm performance: Findings from a mixed-method approach. Journal of Business Research, 98, 261–276.

Mikalef, P., Krogstie, J., Pappas, I. O., & Pavlou, P. (2020). Exploring the relationship between big data analytics capability and competitive performance: The mediating roles of dynamic and operational capabilities. Information & Management, 57, 103169.

Mishra, D., Gunasekaran, A., Papadopoulos, T., & Childe, S. J. (2018). Big Data and supply chain management: A review and bibliometric analysis. Annals of Operations Research, 270, 313–336.

Nambisan, S., Lyytinen, K., Majchrzak, A., & Song, M. (2017). Digital Innovation Management: Reinventing innovation management research in a digital world. MIS Quarterly, 41, 223–238.

Oh, J., & Rhee, S.-K. (2008). The influence of supplier capabilities and technology uncertainty on manufacturer-supplier collaboration. International Journal of Operations & Production Management, 28, 490–517.

Ojha, R., Ghadge, A., Tiwari, M. K., & Bititci, U. S. (2018). Bayesian network modelling for supply chain risk propagation. International Journal of Production Research, 56, 5795–5819.

Pan, G., Pan, S. L., & Lim, C. Y. (2015). Examining how firms leverage IT to achieve firm productivity: RBV and dynamic capabilities perspectives. Information & Management, 52, 401–412.

Panayides, P. M., & So, M. (2005). Logistics service provider–client relationships. Transportation Research Part E: Logistics and Transportation Review, 41, 179–200.

Pezeshkan, A., Fainshmidt, S., Nair, A., Frazier, M. L., & Markowski, E. (2016). An empirical assessment of the dynamic capabilities–performance relationship. Journal of Business Research, 69, 2950–2956.

Porter, M. E., & Heppelmann, J. E. (2014). How smart, connected products are transforming competition. Harvard Business Review, 92, 64–88.

Preacher, K. J., & Hayes, A. F. (2004). SPSS and SAS procedures for estimating indirect effects in simple mediation models. Behavior Research Methods, Instruments, & Computers, 36, 717–731.

Roger, E. M. (2003). Diffusion of Innovations (5th ed.). Free Press.

Saleem, H., Li, Y., Ali, Z., Ayyoub, M., Wang, Y., & Mehreen, A. (2020). Big data use and its outcomes in supply chain context: The roles of information sharing and technological innovation. Journal of Enterprise Information Management, 34, 1121–1143.

Sanders, N. R., & Ganeshan, R. (2015). Big data in supply chain management. Production & Operations Management, 24, 1028–1029.

Schilke, O., Hu, S., & Helfat, C. E. (2018). Quo vadis, dynamic capabilities? A content-analytic review of the current state of knowledge and recommendations for future research. Academy of Management Annals, 12, 390–439.

Schreyögg, G., & Kliesch-Eberl, M. (2007). How dynamic can organizational capabilities be? Towards a dual process model of capability dynamization. Strategic Management Journal, 28, 913–933.

Seo, Y.-J., Dinwoodie, J., & Kwak, D.-W. (2014). The impact of innovativeness on supply chain performance: Is supply chain integration a missing link? Supply Chain Management: An International Journal, 19, 733–746.

Shamim, S., Cang, S., Yu, H., & Li, Y. (2017). Examining the feasibilities of industry 4.0 for the hospitality sector with the lens of management practice. Energies, 10, 499.

Shamim, S., Zeng, J., Shariq, S. M., & Khan, Z. (2019). Role of big data management in enhancing big data decision-making capability and quality among Chinese firms: A dynamic capabilities view. Information & Management, 56, 103135.

Sousa, R., & Voss, C. A. (2008). Contingency research in operations management practices. Journal of Operations Management, 26, 697–713.

Srinivasan, R., & Swink, M. (2018). An investigation of visibility and flexibility as complements to supply chain analytics: An organizational information processing theory perspective. Production and Operations Management, 27, 1849–1867.

Stock, G. N., & Tatikonda, M. V. (2008). The joint influence of technology uncertainty and interorganizational interaction on external technology integration success. Journal of Operations Management, 26, 65–80.

Sultana, S., Akter, S., Kyriazis, E., & Wamba, S. F. (2021). Architecting and developing big data-driven innovation (DDI) in the digital economy. Journal of Global Information Management (JGIM), 29, 165–187.

Sultana, S., Akter, S., & Kyriazis, E. (2022). How data-driven innovation capability is shaping the future of market agility and competitive performance? Technological Forecasting and Social Change, 174, 121260.

Tan, K. H., Zhan, Y., Ji, G., Ye, F., & Chang, C. (2015). Harvesting big data to enhance supply chain innovation capabilities: An analytic infrastructure based on deduction graph. International Journal of Production Economics, 165, 223–233.

Tan, K. H., Ji, G., Lim, C. P., & Tseng, M.-L. (2017). Using big data to make better decisions in the digital economy. International Journal of Production Research, 55, 4998–5000.

Tarafdar, M., & Qrunfleh, S. (2017). Agile supply chain strategy and supply chain performance: Complementary roles of supply chain practices and information systems capability for agility. International Journal of Production Research, 55, 925–938.

Teece, D. J. (2012). Dynamic capabilities: Routines versus entrepreneurial action. Journal of Management Studies, 49, 1395–1401.

Teece, D. J. (2014). The foundations of enterprise performance: Dynamic and ordinary capabilities in an (economic) theory of firms. Academy of Management Perspectives., 28, 328–352.

Teece, D. J., Pisano, G., & Shuen, A. (1997). Dynamic capabilities and strategic management. Strategic Management Journal, 18, 509–533.

Van Alstyne, M. W., Parker, G. G., & Choudary, S. P. (2016). Pipelines, platforms, and the new rules of strategy. Harvard Business Review, 94, 54–62.

Vendrell-Herrero, F., Bustinza, O. F., Parry, G., & Georgantzis, N. (2016). Servitization, digitization and supply chain interdependency. Industrial Marketing Management, 60, 69–81.

Vitari, C., & Raguseo, E. (2020). Big data analytics business value and firm performance: Linking with environmental context. International Journal of Production Research, 58, 5456–5476.

Wagner, S. M. (2008). Innovation management in the German transportation industry. Journal of Business Logistics, 29, 215–231.

Waller, M. A., & Fawcett, S. E. (2013). Data science, predictive analytics, and big data: A revolution that will transform supply chain design and management. Journal of Business Logistics, 34, 77–84.

Wamba, F. S., & Akter, S. (2019). Understanding supply chain analytics capabilities and agility for data-rich environments. International Journal of Operations & Production Management, 39, 887–912.

Wamba, S. F., Gunasekaran, A., Akter, S., Ren, S. J., Dubey, R., & Childe, S. J. (2017). Big data analytics and firm performance: Effects of dynamic capabilities. Journal of Business Research, 70, 356–365.

Wamba, S. F., Akter, S., & Guthrie, C. (2020). Making big data analytics perform: The mediating effect of big data analytics dependent organizational agility. Systemes D’information Management, 25, 7–31.

Wamba, S. F., Dubey, R., Gunasekaran, A., & Akter, S. (2020). The performance effects of big data analytics and supply chain ambidexterity: The moderating effect of environmental dynamism. International Journal of Production Economics, 222, 107498.

Wang, G., Gunasekaran, A., Ngai, E. W., & Papadopoulos, T. (2016). Big data analytics in logistics and supply chain management: Certain investigations for research and applications. International Journal of Production Economics, 176, 98–110.

Wei, H.-L., & Wang, E. T. (2010). The strategic value of supply chain visibility: Increasing the ability to reconfigure. European Journal of Information Systems, 19, 238–249.

Whitten, G. D., Green, K. W., & Zelbst, P. J. (2012). Triple-A supply chain performance. International Journal of Operations & Production Management, 32, 28–48.

Winter, S. G. (2003). Understanding dynamic capabilities. Strategic Management Journal, 24, 991–995.

Wu, L. Y. (2010). Applicability of the resource-based and dynamic-capability views under environmental volatility. Journal of Business Research, 63, 27–31.

Xiao, C., Petkova, B., Molleman, E., & van der Vaart, T. (2019). Technology uncertainty in supply chains and supplier involvement: The role of resource dependence. Supply Chain Management: An International Journal, 24, 697–709.

Zahra, S. A., Sapienza, H. J., & Davidsson, P. (2006). Entrepreneurship and dynamic capabilities: A review, model and research agenda. Journal of Management Studies, 43, 917–955.

Zeng, J., & Glaister, K. W. (2018). Value creation from big data: Looking inside the black box. Strategic Organization, 16, 105–140.

Zhan, Y., & Tan, K. H. (2020). An analytic infrastructure for harvesting big data to enhance supply chain performance. European Journal of Operational Research, 281, 559–574.

Zhou, H., & Benton, W. C., Jr. (2007). Supply chain practice and information sharing. Journal of Operations Management, 25, 1348–1365.

Funding

Open access funding provided by Università degli Studi di Torino within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article