Abstract

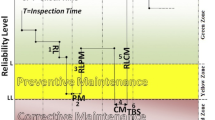

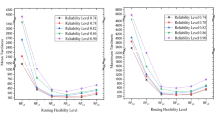

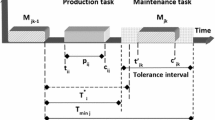

Integrated consideration of production planning and maintenance processes is a real world assumption. Specifically, by improving the monitoring equipment such as various sensors or product-embedded information devices in recent years, joint assessment of these processes is inevitable for enhancing the level of the system optimization. By means of this equipment, managers can benefit from a condition-based maintenance (CBM) for monitoring and managing their system. The chief aim of the paper is to develop a stochastic maintenance problem based on CBM activities engaged with a complex applied production problem called flexible job shop scheduling problem (FJSP). This integrated problem considers two maintenance scenarios in terms of corrective maintenance (CM) and preventive maintenance (PM). The activation of scenario is done by monitoring the degradation condition of the system and comparing the associated value by predetermined PM and CM levels. Moreover, to make it more realistic, the developed problem allows breakdown of the system between inspection intervals. The event time and duration of performing the maintenance activities are also considered stochastic. The developed methodology copes with high stochastic complexity of proposed problem through simulation-based optimization (SBO) approach, which works based on harmony search optimization algorithm. The developed items of SBO are discussed on different generated test problems and assessed through statistical methods and new visualization approach. Numerical example shows that the proposed method is practical for proposed integrated CBM and FJSP problem. It also offers a basis for any implementation of CBM on production problems.

Similar content being viewed by others

References

Aggoune, R. (2004). Minimizing the makespan for the flow shop scheduling problem with availability constraints. European Journal of Operational Research, 153, 534–543.

Ahmad, R., & Kamaruddin, S. H. (2012). An overview of time-based and condition-based maintenance in industrial application. Computers and Industrial Engineering, 63, 135–149.

Ahmadi, E., Zandieh, M., Farrokh, M., & Emami, S. M. (2016). A multi objective optimization approach for flexible job shop scheduling problem under random machine breakdown by evolutionary algorithms. Computers and Operations Research, 73, 56–66.

Allaoui, H., & Artiba, A. (2004). Integrating simulation and optimization to schedule a hybrid flow shop with maintenance constraints. Computers and Industrial Engineering, 47, 431–450.

Allaoui, H., & Artiba, A. (2006). Scheduling two-stage hybrid flow shop with availability constraints. Computers and Operations Research, 33, 1399–1419.

Ben Ali, M., Sassi, M., Gossa, M., & Harrath, Y. (2011). Simultaneous scheduling of production and maintenance tasks in the job shop. International Journal of Production Research, 49, 3891–918.

Ben-Daya, M., Duffuaa, S., & Raouf, A. (2000). Maintenance, modeling and optimization. London: Kluwer Academic.

Berrichi, A., Amodeo, L., Yalaoui, F., Chatelet, E., & Mezghiche, M. (2008). Bi-objective optimization algorithms for joint production and maintenance scheduling: Application to the parallel machine problem. Journal of Intelligent Manufacturing, 20, 389–400.

Bevilacqua, M., & Braglia, M. (2000). The analytic hierarchy process applied to maintenance strategy selection. Reliability Engineering and System Safety, 70, 71–83.

Blanchard, B. S., Verm, D., & Peterson, E. L. (1995). Maintainability: A key to effective and maintenance management. New York, NY: Wiley.

Børresen, C. S. (2011). A framework for cost-benefit analysis on use of condition based maintenance in an IO perspective. Trondheim: Norwegian University of Science and Technology.

Brucker, P., & Schlie, R. (1990). Job-shop scheduling with multipurpose machines. Computing, 45(4), 369–375.

Cassady, C. R., & Kutanoglu, E. (2005). Integrating preventive maintenance planning and production scheduling for a single machine. IEEE Transactions on Reliability, 54, 304–309.

Chen, J. S. (2008). Scheduling of non-resumable jobs and flexible maintenance activities on a single machine to minimize makespan. European Journal of Operational Research, 190, 90–102.

Chen, W. J. (2009). Minimizing number of tardy jobs on a single machine subject to periodic maintenance. Omega, 37, 592–599.

Cheng, T., & Liu, Z. (2003). Approximatability of two-machine no-wait flow shop scheduling with availability constraints. Operation Research Letters, 31, 319–22.

Cho, D. I., & Parlar, M. (1991). A survey of maintenance models for multi-unit systems. European Journal of Operational Research, 51, 1–23.

Choi, C., & Choi, D. S. (2002). A local search algorithm for job shop scheduling problems with alternative operations and sequence-dependent setups. Computers & Industrial Engineering, 42, 43–58. http://www.sciencedirect.com/science/article/pii/S0360835202000025#!.

Chouikhi, H., Khatab, A., & Rezg, N. (2014). A condition-based maintenance policy for a production system under excessive environmental degradation. Journal of Intelligent Manufacturing, 25, 727–737.

Cui, W. W., & Lu, Z. (2017). Minimizing the makespan on a single machine with flexible maintenances and jobs’ release dates. Computers and Operations Research, 80, 11–22.

Dalfard, V. M., & Mohammadi, G. (2012). Two meta-heuristic algorithms for solving multi-objective flexible job-shop scheduling with parallel machine and maintenance constraints. Computers and Mathematics with Applications, 64, 2111–2117.

Dekker, R. Z., Wildeman, R. E. Z., & Van Der Duyn Schouten, F. A. Z. (1997). A review of multi-component maintenance models with economic dependence. Mathematical Methods of Operations Research, 45(3), 411–435.

Demir, Y., & Isleyen, S. K. (2013). Evaluation of mathematical models for flexible job-shop scheduling problems. Applied Mathematical Modelling, 37, 977–988.

Fattahi, P., Jolai, F., & Arkat, J. (2009). Flexible job shop scheduling with overlapping in operations. Applied Mathematical Modeling, 33, 3076–3087.

Frutos, M., Olivera, A. C., & Tohmé, F. (2010). A memetic algorithm based on a NSGAII scheme for the flexible job-shop scheduling problem. Annals of Operations Research, 181, 745–765.

Espinouse, M., Formanowlcz, P., & Penz, B. (2001). Complexity results and approximation algorithms for the two-machine no-wait flow-shop with limited machine availability. Journal of the Operational Research Society, 52, 116–21.

Gao, J., Gen, M., & Sun, L. (2006). Scheduling jobs and maintenance in flexible job shop with a hybrid genetic algorithm. Journal of Intelligent Manufacturing, 17, 493–507.

Gao, J., Gen, M., Sun, L. Y., & Zhao, X. H. (2007). A hybrid of genetic algorithm and bottleneck shifting for multiobjective flexible job shop scheduling problems. Computers & Industrial Engineering, 53(1), 149–162.

Geem, Z. W., Kim, J. H., & Loganathan, G. V. (2001). A new heuristic optimization algorithm: Harmony search. Simulation, 76, 60–68.

Graves, G. H., & Lee, C. Y. (1999). Scheduling maintenance and semi-resumable jobs on a single machine. Naval Research Logistics, 46, 845–863.

Ho, N. B., Tay, J. C. J., & Lai, E. (2007). An effective architecture for learning and evolving flexible job-shop schedules. European Journal of Operational Research, 179, 316–333.

Huang, R. H., & Yu, S. C. (2016). Two-stage multiprocessor flow shop scheduling with deteriorating maintenance in cleaner production. Journal of Cleaner Production, 142, 276–283.

Kacem, I., Chu, C. H., & Souissi, A. (2008). Single-machine scheduling with an availability constraint to minimize the weighted sum of the completion times. Computers & Operations Research, 35(3), 827–844. http://dl.acm.org/citation.cfm?id=1288010&CFID=855574846&CFTOKEN=41745658.

Karimi, H., Rahmati S. H. A., & Zandieh, M. (2012). An efficient knowledge-based algorithm for the flexible job shop scheduling problem. Knowledge-Based Systems, 36, 236–244.

Kim, B. S., & Ozturkoglu, Y. (2015). Scheduling a single machine with multiple preventive maintenance activities and position-based deteriorations using genetic algorithms. International Journal of Advanced Manufacturing,. doi:10.1007/s10845-008-0113-5.

Kubiak, W., Blażewicz, J., Formanowicz, P., Breit, J., & Schmidt, G. (2002). Two-machine flow shops with limited machine availability. European Journal of Operational Research, 136(3), 528–540.

Lee, C. Y. (1999). Two-machine flow shop scheduling with availability constraints. European Journal of Operational Research, 114, 420–429.

Lee, C. Y., & Chen, Z. L. (2000). Scheduling of jobs and maintenance activities on parallel machines. Naval Research Logistics, 47, 145–165.

Li, J. Q., & Pan, Q. K. (2012). Chemical-reaction optimization for flexible job-shop scheduling problems with maintenance activity. Applied Soft Computing, 12, 2896–2912.

Li, J. Q., Pan, Q. K., & Fatih, Tasgetiren M. (2014). A discrete artificial bee colony algorithm for the multi-objective flexible job-shop scheduling problem with maintenance activitie. Applied Mathematical Modelling, 38, 1111–1132.

Liao, C. J., & Chen, W. J. (2003). Single-machine scheduling with periodic maintenance and non-resumable jobs. Computers and Operations Research, 30, 1335–1347.

Liao, L. W., & Sheen, G. J. (2008). Parallel machine scheduling with machine availability and eligibility constraints. European Journal of Operational Research, 184, 458–467.

Liao, C. J., Shyur, D. L., & Lin, C. H. (2005). Makespan minimization for two parallel machines with an availability constraint. European Journal of Operational Research, 160, 445–456.

Lin, C. H., & Liao, C. J. (2007). Makespan minimization for two parallel machines with an unavailable period on each machine. International Journal of Advanced Manufacturing, 33, 1024–1030.

Lin, L., & Jia-zhen, H. (2009). Multi-objective flexible job-shop scheduling problem in steel tubes production. Systems Engineering—Theory & Practice, 29(8), 117–126.

Lin, Y. K., Huang, D. H., & Lin, J. S. (2016). Reliability evaluation of a multistate flexible flow shop with stochastic capacity for multiple types of jobs. Journal of Manufacturing Systems, 41, 287–298.

Low, C., Ji, M., Hsu, C. J., & Su, C. T. (2010). Minimizing the makespan in a single machine scheduling problems with flexible and periodic maintenance. Applied Mathematical Modelling, 34, 334–42.

Mati, Y. (2010). Minimizing the makespan in the non-preemptive job-shop scheduling with limited machine availability. Computers and Industrial Engineering, 59, 537–43.

Mauguiere, P. H., Billaut, J. C., & Bouquard, J. L. (2005). New single machine and job shop scheduling problems with availability constraints. Journal of Scheduling, 8(3), 211–31.

Mellouli, R., Sadfi, C., Chu, C., & Kacem, I. (2009). Identical parallel machine scheduling under availability constraints to minimize the sum of completion times. European Journal of Operational Research, 197, 1150–1165.

Mobley, R. K. (2002). An introduction to predictive maintenance (2nd ed.). New York: Elsevier Science.

Mokhtari, H., & Dadgar, M. (2015). Scheduling optimization of a stochastic flexible job-shop system with time-varying machine failure rate. Computers and Operations Research, 61, 31–45.

Moradi, E., Fatemi Ghomi, S. M. T., & Zandieh, M. (2011). Bi-objective optimization research on integrated fixed time interval preventive maintenance and production for scheduling flexible job-shop problem. Expert Systems with Applications, 38, 7169–78.

Naderi, B., Zandieh, M., & Fatemi Ghomi, S. M. T. (2009). Scheduling sequence-dependent setup time job shops with preventive maintenance. International Journal of Advanced Manufacturing Technology, 43, 170–181.

Ozturkoglu, Y., & Bulfin, R. L. (2011). A unique integer mathematical model for scheduling deteriorating jobs with rate-modifying-activities on a single machine. International Journal of Advanced Manufacturing, 57, 753–762.

Pan, E., Liao, W., & Xi, L. (2010). Single machine-based production scheduling model integrated preventive maintenance planning. International Journal of Advanced Manufacturing Technology, 50, 365–375.

Pham, H., & Wang, H. (1996). Imperfect maintenance. European Journal of Operational Research, 14, 425–438.

Pinedo, M., & Chao, X. (1999). Operations Scheduling with Applications in Manufacturing and Services. Irwin/McGraw-Hill. https://www.google.com/search?tbo=p&tbm=bks&q=inauthor:%22Xiuli+Chao%22.

Rahmati, S. H. A., & Zandieh, M. (2011). A new biogeography-based optimization (BBO) algorithm for the flexible job shop scheduling problem. International Journal of Advance Manufacturing Technology, 58, 1115–1129.

Ruiz, R., Garcia-Diaz, J. C., & Maroto, C. (2007). Considering scheduling and preventive maintenance in the flow shop sequencing problem. Computers and Operations Research, 34(11), 3314–30.

Safari, E., & Sadjadi, S. J. (2009). A hybrid method for flow shops scheduling with condition-based maintenance constraint and machines breakdown. Expert Systems with Applications, 38, 2020–2029.

Safari, E., Sadjadi, S. J., & Shahanaghi, K. (2010). Scheduling flow shops with condition-based maintenance constraint to minimize expected makespan. The International Journal of Advanced Manufacturing Technology, 46, 757–767.

Saidi-Mehrabad, M., & Fattahi, P. (2006). Flexible job shop scheduling with tabu search algorithms. International Journal of Advanced Manufacturing, 32, 563–570.

Sbihi, M., & Varnier, C. (2008). Single machine scheduling with periodic and flexible periodic maintenance to minimize maximum tardiness. Computers & Industrial Engineering, 55, 830–840.

Schmidt, G. (2000). Scheduling with limited machine availability. European Journal of Operational Research, 121, 1–15.

Shin, J. H., & Jun, H. B. (2015). On condition based maintenance policy. Journal of the Computational Design and Engineering, 2, 119–127.

Sortrakul, N., Nachtmann, H. L., & Cassady, C. R. (2005). Genetic algorithms for integrated preventive maintenance planning and production scheduling for a single machine. Computers in Industry, 56, 161–168.

Wang, H. (2002). A survey of maintenance policies of deteriorating systems. European Journal of Operational Research, 139, 469–489.

Wang, S., & Yu, J. (2010). An effective heuristic for flexible job-shop scheduling problem with maintenance activities. Computers and Industrial Engineering, 59, 436–447.

Xing, L. N., & Chen, Y. W. (2010). A knowledge-based ant colony optimization for flexible job shop scheduling problems. Applied Soft Computing, 10(3), 888–896.

Ying, K. C., Lu, C. C., & Chen, J. C. (2016). Exact algorithms for single-machine scheduling problems with a variable maintenance. Computers and Industrial Engineering, 98, 427–433.

Zhang, C. Y., Rao, Y. Q., Li, P. G., & Shao, X. Y. (2007). Bilevel genetic algorithm for the flexible job-shop scheduling problem. Jixie Gongcheng Xuebao/Chinese. Journal of Mechanical Engineering, 43(4), 119–124. In Chinese.

Zhou, X., Lu, Z., & Xi, L. (2012). Preventive maintenance optimization for multi-component system under changing job shop schedule. Reliability Engineering and System Safety, 101, 14–20.

Zribi, N., & Borne, P. (2005). Hybrid Genetic algorithm for the flexible job shop problem under maintenance constraints. Advances in Natural Computation, 3612, 259–268.

Zribi, N., Kamel, E., & Borne, P. (2008). Minimizing the makespan for the MPM job-shop with availability constraints. International Journal of Production Economics, 112, 151–160.

Author information

Authors and Affiliations

Corresponding author

Additional information

The authors contributed equally to the paper and the authors’ order is based on the requirement of the first author’s academic program.

Appendix

Rights and permissions

About this article

Cite this article

Rahmati, S.H.A., Ahmadi, A. & Govindan, K. A novel integrated condition-based maintenance and stochastic flexible job shop scheduling problem: simulation-based optimization approach. Ann Oper Res 269, 583–621 (2018). https://doi.org/10.1007/s10479-017-2594-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-017-2594-0