Abstract

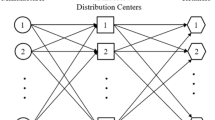

This paper addresses the optimal design of a multiproduct, multi-echelon supply network under uncertainty of demand. The network consists of multiproduct production sites, warehouses and distribution centers and decisions about the selection of facilities and their capacity are taken. Furthermore, information about the flows of products transferred and the safety stock at each distribution center is derived. The lead time of an order to a customer is computed, using the probabilities of overstocking and understocking. All these decisions are incorporated into a single period mixed integer non-linear programming problem (MINLP) which minimizes cost. Linearization techniques for selected highly non-linear terms of the models are explored in order to reduce the computational effort for the solution of the model. Finally, a sensitivity analysis is performed by changing product demand parameters and assessing their effect on the supply chain structure.

Similar content being viewed by others

Abbreviations

- i :

-

Product

- i′:

-

Product out of stock

- i″:

-

Product overstocked

- j :

-

Plant

- m :

-

Warehouse

- k :

-

Distribution center

- l :

-

Customer

- l′:

-

Customer facing stockout

- l″:

-

Customer with satisfied demand

- s :

-

Scenario for stochastic demand

- I :

-

Set for products

- L :

-

Set for customers

- SO :

-

Stockout set

- OVS :

-

Overstocking set

- V :

-

Set for all pairs (i,l)

- NDPS :

-

Number of Normal Distribution parameter scenarios

- α im :

-

Coefficient relating capacity of product i at warehouse m

- β ik :

-

Coefficient relating capacity of product i at warehouse k

- μ il :

-

Mean demand of product i from customer l

- σ il :

-

Standard deviation of product i from customer l

- \(W_{m}^{U}\) :

-

Upper bound of capacity of warehouse m

- \(\mathit{DC}_{k}^{U}\) :

-

Upper bound of capacity of distribution center k

- \(P_{ij}^{U}\) :

-

Upper bound for production capacity of plant j for product i

- \(P_{ij}^{L}\) :

-

Lower bound for production capacity of plant j for product i

- \(Q_{ijm}^{U}\) :

-

Upper bound of flow of product transferred from plant j to warehouse m

- \(Q_{ijm}^{L}\) :

-

Lower bound of flow of product i transferred from plant j to warehouse m

- \(Q_{mk}^{U}\) :

-

Upper bound of total flow of products transferred from warehouse m to distribution center k

- \(Q_{mk}^{L}\) :

-

Lower bound of total flow of products transferred from warehouse m to distribution center k

- \(Q_{kl}^{U}\) :

-

Upper bound of total flow of products transferred from distribution center k to customer l

- \(Q_{kl}^{L}\) :

-

Lower bound of total flow of products transferred from distribution center k to customer l

- T U :

-

Time of delivery of a product in case of a stockout

- \(\mathit{ELT}_{il}^{U}\) :

-

Upper bound of expected lead time of delivering product i to customer l

- T L :

-

Time of delivery of a product in case of service level a

- \(\bar{K}_{ikl}\) :

-

Auxiliary parameter

- \(\bar{Z}_{ikl}\) :

-

Auxiliary parameter

- \(\bar{H}_{ikl}\) :

-

Auxiliary parameter

- n :

-

Number of replenishments

- C(n):

-

Cost function in respect to replenishments (n)

- \(C_{m}^{W}\) :

-

Fixed installation cost of warehouse m

- \(C_{k}^{\mathit{DC}}\) :

-

Fixed installation cost of distribution center k

- \(C_{ij}^{PR}\) :

-

Production cost of product i at production site j

- \(C_{im}^{WH}\) :

-

Handling cost of product i at warehouse m

- \(C_{ik}^{\mathit{DCH}}\) :

-

Handling cost of product i at distribution center k

- F k :

-

Fixed ordering cost of an order made from the supplier to distribution center k

- g k :

-

Fixed transportation cost of an order arriving at distribution center k

- h :

-

Working inventory cost

- χ :

-

Days per year for converting daily costs to annual

- alp ik :

-

Unit transportation cost of product i from the supplier to distribution center k

- \(\hat{d}_{ikl}\) :

-

Unit transportation cost of product i shipped from distribution center k to customer l

- P ij :

-

Production capacity of plant j for product i

- Q ijm :

-

Flow of product i transferred from plant j to warehouse m

- Q imk :

-

Flow of product i transferred from warehouse m to distribution center k

- Q ikl :

-

Flow of product i transferred from distribution center k to customer l

- QT il :

-

Total flow of product i delivered to customer l

- \(Q_{il}^{ -}\) :

-

Quantity of product i that is less or equal than the mean demand from customer l

- \(Q_{il}^{ +}\) :

-

Quantity of product i that is greater than the mean demand from customer l

- I ikl :

-

Safety stock of product i at distribution center k for customer l

- \(P_{il}^{1}\) :

-

Probability of having a stockout of product i for customer l

- \(P_{il}^{2}\) :

-

Probability of overstocking of product i for customer l

- za il :

-

Standard normal deviate such that the overstocking of product i for customer l is guaranteed with probability P(z<z a )=a

- ELT il :

-

Expected lead time of delivering product i to customer l

- TC :

-

Total cost

- ELT1 ikl :

-

Auxiliary variable

- ELT2 ikl :

-

Auxiliary variable

- Y m :

-

1 if warehouse m is selected, 0 otherwise

- Y k :

-

1 if distribution center k is selected, 0 otherwise

- X mk :

-

1 if the connection between warehouse m and distribution center k exists, 0 otherwise

- X kl :

-

1 if the connection between distribution center k and customer l exists, 0 otherwise

- ζ il :

-

1 if product i demanded by customer l is out of stock, 0 otherwise

References

Axsäter, S. (1996). Using the deterministic EOQ formula in stochastic inventory control. Management Science, 42(6), 830–834.

Bassett, M., & Gardner, A. (2012). Designing optimal global supply chains at Dow AgroSciences. Annals of Operations Research. doi:10.1007/s10479-010-0802-2.

Baud-Lavigne, B., Agard, B., & Penz, B. (2012). Mutual impacts of product standardization and supply chain design. International Journal of Production Economics, 153(1), 50–60.

Beamon, B. M. (1999). Measuring supply chain performance. International Journal of Operations & Production Management, 19(3), 275–292.

Brook, A., Kendrick, D., & Meeraus, A. (1988). GAMS, a user’s guide. SIGNUM Newsletter, 23, 10–11.

Chaabane, A., Ramudhin, A., & Paquet, M. (2012). Design of sustainable supply chains under the emission trading scheme. International Journal of Production Economics, 135(1), 37–49.

Cachon, G. P., & Fisher, M. (2000). Supply chain inventory management and the value of shared information. Management Science, 46(8), 1032–1048.

Cachon, G. P., & Zipkin, P. H. (1999). Competitive and cooperative inventory policies in a two-stage supply chain. Management Science, 45(7), 936–953.

Charnes, A., & Cooper, W. W. (1963). Deterministic equivalents for optimizing and satisficing under chance constraints. Operations Research, 11(1), 18–39.

Chen, C. L., & Lee, W. C. (2004). Multi-objective optimization of multi-echelon supply chain networks with uncertain product demands and prices. Computers & Chemical Engineering, 28(6–7), 1131–1144.

Chen, C. W., & Fan, Y. (2012). Bioethanol supply chain system planning under supply and demand uncertainties. Transportation Research. Part E, Logistics and Transportation Review, 48(1), 150–164.

Chen, Y., Mockus, L., Orcun, S., & Reklaitis, G. V. (2012). Simulation optimization approach to clinical trial supply chain management with demand scenario forecast. Computers & Chemical Engineering, 40(11), 82–96.

Christopher, M. (2000). The agile supply chain: competing in volatile markets. Industrial Marketing Management, 29(1), 37–44.

Daskin, M. S., Coullard, C. R., & Shen, Z. J. (2002). An inventory-location model: formulation, solution algorithm and computational results. Annals of Operations Research, 110(1–4), 83–106.

Diabat, A., Richard, J. P., & Codrington, C. (2011). A Lagrangian relaxation approach to simultaneous strategic and tactical planning in supply chain design. Annals of Operations Research. doi:10.1007/s10479-011-0915-2.

Duclos, L. K., Vokurka, R. J., & Lummus, R. R. (2003). A conceptual model of supply chain flexibility. Industrial Management & Data Systems, 103(6), 446–456.

Duran, M. A., & Grossmann, I. E. (1986). An outer approximation algorithm for a class of mixed integer nonlinear programs. Mathematical Programming, 36, 307.

Federgruen, A. (1993). Centralized planning models for multi-echelon inventory systems under uncertainty. In S. C. Graves, A. H. G. Rinnooy Kan, & P. H. Zipkin (Eds.), Handbooks in operations research and management science (pp. 133–173). Amsterdam: Elsevier.

Ganeshan, R. (1999). Managing supply chain inventories: a multiple retailer, one warehouse, multiple supplier model. International Journal of Production Economics, 59(1–3), 341–354.

Georgiadis, M. C., Tsiakis, P., Longinidis, P., & Sofioglou, M. K. (2011). Optimal design of supply chain networks under uncertain transient demand variations. Omega, 39(3), 254–272.

Glover, F. (1975). Improved linear integer programming formulations of nonlinear integer problems. Management Science, 22(4), 455–460.

Graves, S. C., & Tomlin, B. T. (2003). Process flexibility in supply chains. Management Science, 49(7), 907–919.

Grossmann, I. E., Viswanathan, J., Vecchietti, A., Raman, R., & Kalvelagen, E. (2002). GAMS/DICOPT: a discrete continuous optimization package. GAMS Development Corporation, Washington, DC.

Gruen, T., & Corsten, D. (2004). Stock outs cause walkouts. Harvard Business Review, 82(5), 26–27.

Handfield, R. B., & Bechtel, C. (2002). The role of trust and relationship structure in improving supply chain responsiveness. Industrial Marketing Management, 31(4), 367–382.

Lee, H. L., Padmanabhan, V., & Whang, S. (1997). Information distortion in a supply chain: the bullwhip effect. Management Science, 43(4), 546–558.

Lee, Y. H., & Kim, S. H. (2002). Production-distribution planning in supply chain considering capacity constraints. Computers & Industrial Engineering, 43(1–2), 169–190.

Liu, S., & Papageorgiou, L. G. (2013). Multiobjective optimisation of production, distribution and capacity planning of global supply chains in the process industry. Omega, 41(2), 369–382.

Lummus, R. R., Vokurka, R. J., & Duclos, L. K. (2005). Delphi study on supply chain flexibility. International Journal of Production Research, 43(13), 2687–2708.

Martin, M. J. C. (1994). Managing innovation and entrepreneurship in technology-based firms. New York: Wiley-Interscience.

Miranda, P. A., & Garrido, R. A. (2004). Incorporating inventory control decisions into a strategic distribution network design model with stochastic demand. Transportation Research. Part E, Logistics and Transportation Review, 40(3), 183–207.

Nagurney, A., Masoumi, A. H., & Yu, M. (2012). Supply chain network operations management of a blood banking system with cost and risk minimization. Computational Management Science, 9(2), 205–231.

Olivares-Benitez, E., González-Velarde, J. L., & Ríos-Mercado, R. Z. (2012). A supply chain design problem with facility location and bi-objective transportation choices. TOP, 20(3), 729–753.

Özekici, S., & Parlar, M. (1999). Inventory models with unreliable suppliers in a random environment. Annals of Operations Research, 91(0), 123–136.

Pan, F., & Nagi, R. (2010). Robust supply chain design under uncertain demand in agile manufacturing. Computers & Operations Research, 37(4), 668–683.

Petkov, S. B., & Maranas, C. D. (1998). Design of single-product campaign batch plants under demand uncertainty. AIChE Journal, 44(4), 896–911.

Prater, E., Biehl, M., & Smith, M. A. (2001). International supply chain agility—tradeoffs between flexibility and uncertainty. International Journal of Operations & Production Management, 21(5/6), 823–839.

Ramezani, M., Bashiri, M., & Tavakkoli-Moghaddam, R. (2013). A new multi-objective stochastic model for a forward/reverse logistic network design with responsiveness and quality level. Applied Mathematical Modeling, 37(1–2), 328–344.

Schmitt, A. J., & Singh, M. (2012). A quantitative analysis of disruption risk in a multi-echelon supply chain. International Journal of Production Economics, 139(1), 22–32.

Shen, Z. J. M., Coullard, C., & Daskin, M. S. (2003). A joint location-inventory model. Transportation Science, 37(1), 40–55.

Tsiakis, P., & Papageorgiou, L. G. (2008). Optimal production allocation and distribution supply chain networks. International Journal of Production Economics, 111(2), 468–483.

Tsiakis, P., Shah, N., & Pantelides, C. C. (2001). Design of multi-echelon supply chain networks under demand uncertainty. Industrial & Engineering Chemistry Research, 40(16), 3585–3604.

Uskonen, J., & Tenhiälä, A. (2012). The price of responsiveness: cost analysis of change orders in make-to-order manufacturing. International Journal of Production Economics, 135(1), 420–429.

Xanthopoulos, A., Vlachos, D., & Iakovou, E. (2012). Optimal newsvendor policies for dual-sourcing supply chains: a disruption risk management framework. Computers & Operations Research, 39(2), 350–357.

You, F., & Grossmann, I. E. (2008a). Mixed-integer nonlinear programming models and algorithms for large-scale supply chain design with stochastic inventory management. Industrial & Engineering Chemistry Research, 47(20), 7802–7817.

You, F., & Grossmann, I. E. (2008b). Design of responsive supply chains under demand uncertainty. Computers & Chemical Engineering, 32(12), 3090–3111.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Proposition

The total, ordering, transportation, working inventory and replenishment cost is presented with the following term:

Proof

Due to the normally distributed demand, the handling cost of the inventory kept at a distribution center is represented by a (Q, r) policy, while orders can be expressed with the EOQ model. Transportation, inventory and working costs are given by the following mathematical type (Shen et al. 2003):

The first term refers to the standard total ordering cost per year (Fn), the second term refers to the annual transportation cost \(( g + \mathit{alp} \cdot \frac{D}{n} ) \cdot n\) and the third term refers to the annual inventory cost (\(h \cdot \frac{D}{2 \cdot n}\)). If a cost function is considered with respect to n (number of replenishments), the following function:

Setting the first derivative of the cost function equal to zero (C′(n)=0) in order to obtain a minimum for this function, the following equation occurs:

In order to obtain the critical point, the above equation is solved with respect to n. This yields the following:

The second derivative of cost function is:

In order to test whether n ∗ is the minimum of cost function, it is substituted in the second derivative. The following derives from the substitution:

Based on second order derivative theorem for univariate functions, n ∗ is the minimum of cost function C(n) whereas substituting n ∗, the minimum cost is obtained by the following:

In term (A.7), corresponding to the minimum cost of C(n), demand is further analyzed by the product of annual mean demand of product i from customer l with the binary variable X kl which refers to the connection of distribution center k with customer l. Thus, the total ordering, transportation, working inventory and replenishment cost after applying indices, the following desired term is formulated:

□

Rights and permissions

About this article

Cite this article

Petridis, K. Optimal design of multi-echelon supply chain networks under normally distributed demand. Ann Oper Res 227, 63–91 (2015). https://doi.org/10.1007/s10479-013-1420-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10479-013-1420-6