Abstract

Low-power IoT sensing applications have proliferated, focusing on self-powered sensors. Accordingly, researchers have investigated serval procedures for the power management of such self-powered sensors. Obesely, minimizing the energy consumed by the sensor is critical to efficient power management. However, another challenge is still considered in harvesting energy effectively. Herein, we provide an attempt to investigate light harvesters that are capable of semi-transparent applications. Six samples were simulated under three light sources while performing a unifacial and bifacial optical injection. The optoelectronic numerical model has shown the utility of perovskite solar cells to harvest the AM1.5G solar spectrum up to 28.63%, with transparency reaching 87%. On the other hand, the bifacial condition boosted the overall cell efficiency to nearly 33% with transparency of 90%, without considering Fresnel glass reflection of 8%. The proposed bifacial cell is a primary light-harvesting source for four IoT sensing applications, including biomedical sensing, underwater harvesting, and IoT sensing in intelligent vehicles and buildings.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Self-powered sensors have demonstrated their significance in various industrial and residential low-power IoT applications [1, 2]. Temperature [3,4,5], humidity [6, 7], gas [8,9,10,11], wearable [5, 12, 13], biomedical [14,15,16], and under-skin [17] self-powered sensors were reported in the literature. One of the main challenges in optimizing the performance of such sensors is the capability of balancing the energy budget [18], on the one hand, minimizing the energy consumption of the sensor as well as its associated interfacing circuit [19], and on the other hand, maximizing the energy harvested with minimum conversion losses [20, 21]. A wide range of energy resources was harvested [22]. These energy resources include but are not limited to thermal energy through using thermoelectric harvesters [23,24,25], kinetic energy that can be harvested using piezoelectric materials [16, 26,27,28,29], and light-harvester through either solar spectrum or artificial lighting [13, 30,31,32].

The term light-harvesting is considered a generic term that can describe the harvesting process due to different light sources, such as solar spectrum (AM1.5G) [33], artificial indoor lighting sources (ex: Light-emitting diodes, LEDs) [34], Xenon lamps [35], Halogen lamps [36], low-intensity light sources (below 0.2 Sun), or diffused lighting [33]. Alternatively, light harvesters can also be classified based on the light sources' spectral energy, i.e., Ultra-violet (UV) harvesters [37], visible harvesters [38], infrared (IR) harvesters [39], and broadband light harvesters [40]. By varying the light source, intensity, or spectrum [30, 34]. These design parameters are on both the material level and device topology level. In addition, another constraint might be added related to the nature of sensing application(s). For example, material toxicity is crucial in biomedical, wearable, or under-skin sensing [41, 42]. Another example is in photovoltaic window applications, utilized in smart buildings and self-charged electric vehicles, where the light harvester’s transparency shows high priority [33, 43]. Moreover, harvesting diffused light is a dominating source in underwater applications [30, 32].

The broadening of the optical source spectral performance impacted the designing parameters for optimum light harvesters. Accordingly, tunable materials attracted researchers to fabricate efficient light harvesters [44]. Among various materials and structures, perovskite solar cells (PSCs) [45,46,47] and dye-sensitized solar cells (DSSCs) [48,49,50] have proven their effectiveness in self-powered sensing. The work in [45] has demonstrated an exciting attempt to capture the indoor broadband spectrum using perovskite-based solar cells for sensing applications. Another attempt was introduced in [47], with the aid of perovskite cells, for RFID seniors. Alternatively, DSSCs have been enrolled for underwater and diffused light-harvesting applications, showing an auspicious performance concerning conventional silicon cells [30, 31, 43, 51, 52]. Besides, both PSCs and DSSCs showed potential in forming bifacial cells, contributing to the light-harvesting performance in many applications [52, 53]. Herein, we merge both PSCs and DSSCs under the term “mesostructured-based Solar Cells” (MSSCs) as both utilize mesoporous [50, 54] TiO2 thin film.

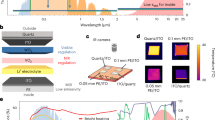

The current study investigates six different MSSCs topologies (see Fig. 1). All structures were modeled and simulated under three lighting sources considering the AM1.5G spectrum as a reference. In addition, the six cells were optically tested under both unifacial and bifacial optical injection. The six harvesters were designed for the transparency-efficiency trade-off, semi-transparent and efficient light harvesters. Finally, two potential sensing applications were introduced with complete power budget management. The work illustrated in this paper is considered an extended version of our previous work in [43].

The paper is designed in five sections, including the introduction section. The next section demonstrates the optoelectronic model utilized in simulating the targeted six topologies. Followed by a complete illustration for the results extracted from the numerical model, with three sub-sections for: validation, investigating the efficiency-transparency trade-off and optimum bifacial topology characteristics. The integration of the designed bifacial harvester in potential low-power applications is presented in section four, while conclusions are listed in the final section.

2 Optoelectronic simulation model

The optoelectronic model presented in this work is developed with a Solar Cell Capacitance Simulator, abbreviated by "SCAPS," to model our six proposed topologies under various optical injectors [55]. SCAPS is a 1-D drift–diffusion model solver capable of simulating solar cell optoelectronic and semiconductor performance and consists of a stack of layers. SCAPS enables a user-friendly interface to alternate the optical injection conditions, spectrum, and dark J-V characteristics [55]. Moreover, SCAPS facilitates the in-depth analysis of a cell under test by exploring the energy-band diagram [55].

As highlighted earlier, both PSCs and DSSCs are very appropriate for low-power light-harvesting applications due to the flexibility in tuning the material parameters and the relatively low-temperature fabrication process. Accordingly, we have nominated six various structures for detailed investigation in this paper. In the current context, we specify four various perovskite structures for investigation. Generally, the perovskite solar cells can be classified either in the active layer, i.e., organic or inorganic, or based on the lead existence (lead-based and lead-free) [21]. Lead-free solar cells have acquired great attention as they can be compatible with many biomedical, food, and health applications [50, 56]. This biased our study to include two lead-free PSCs, considering only another two lead-based cells for interpretation. Formamidine Tin Iodide (FASnI3) PSCs [56] are chosen as sample #1, cf. Figure 1(a), representing a lead-free organic structure. Another organic but lead-based cell is considered as sample #2, Methylammonium Lead Iodide (CH3NH3PbI3) [57] (see Fig. 1(b)). An inorganic lead-based solar cell (sample #3), Cesium Lead Iodide (CsPbI3) [58] is demonstrated in Fig. 1(c). Finally, a second organic lead-free PSC (sample #4), Methylammonium Tin Iodide (CH3NH3SnI3), is introduced in Fig. 1(d) [59]. Across the four PSCs, the perovskite active layer is sandwiched by an electron transport layer (ETL) and a hole transport layer (HTL). For ETL, mesoporous TiO2 is used. Alternatively, Spiro is utilized in both topologies (a) and (b) as HTL, while Cu-based HTLs are integrated in the other two topologies. Herein, the selection of the appropriate HTL was conducted based on the heterojunction computability with the perovskite layer, as well as the electron affinity matching.

On the other hand, two DSSCs modeled were selected to be investigated. An N719 dye-based cell with a compact TiO2 layer, acting as a blocking layer, is nominated as sample #5; see Fig. 1(e) [60]. The topology demonstrated in sample #5 shows that the mesoporous layer with the dye is treated as an effective medium [31, 43]. Still, conjugated polymer BEHP-co-MEH PPV is used with organic dyes in the DSSC sample #6, cf. Figure 1f [61]. It is worth highlighting that the proposed cells are symmetric in terms of electrodes to ensure bifacial capabilities [53]. Accordingly, transparent conducting oxides (TCOs) were used, mainly FTO except for topology (d), where ZnO was utilized.

Following the objective of the current study, our simulation procedure is based on varying the thickness of the active layer, seeking a trade-off intersection point between the cell average transparency in the visible spectrum and the overall power conversion efficiency (PCE). The active layer thickness is varied from 10 to 5000 nm. Principally, all cells tested are optically injected from the front electrode by a standard AM1.5G (One Sun) spectrum (see Fig. 2). Additionally, we have investigated our cells' performance under high-power LED and Xenon illumination, respectively [62]. The nominated cell with the highest PCE is then treated under bifacial injection. The front contact is illuminated by AM1.5G, while a high-power LED is injected into the counter terminal.

3 Results and discussions

This section illustrates the numerical simulation results presented in this paper. As an initial step, an intermediate validation point is conducted by referring to previous data from the literature. Consequently, the trade-off between transparency and efficiency under unifacial injection is demonstrated for the six samples. Finally, the nominated sample with maximum efficiency-transparency trade-off is tested under bifacial optical sources.

3.1 Model validation

In the way toward utilizing our developed optoelectronic model in assessing the trade-off between transparency and efficiency, validation is a must. Accordingly, we used the previously reported data in the literature and our experimental data to evaluate the accuracy of our model. Herein, samples #2, 3, 4, and 5 are chosen for validation concerning [57,58,59] data. For the three samples 2, 3, and 4, AM1.5G is used from the contact with an active layer thickness of 850 nm in sample #2, 700 nm in sample #3, and 600 nm in sample #4. Experimentally, we adopted our previous reported recipe for fabricating DSSCs in [30, 33, 50,51,52,53,54] to fabricate sample #5. In the suggested recipe, TiO2 layers are deposited via screen printing and spin coating, respectively, where the iodine-based electrolyte is used. Characterization is done using our customized LED-based solar simulator, which is associated with the Keithley source/meter 2410 series. Simulated J-V characteristic curves for samples 2, 3, and 4 are plotted in Fig. 3, while the simulated J-V characteristic curve against experimentally fabricated DSSC for sample #5 is demonstrated in Fig. 4. The four main solar cell parameters, open-circuit voltage, short-circuit current, fill factor, and PCE, are listed in Table 1. Generally, the listed data showed an acceptable agreement with the corresponding data from the literature [57,58,59]. However, mismatching is still observed with fluctuations from one sample to another.

Sample #2 indicated an overall mismatching error of 5.37% concerning the PCE [57]. We attribute such deflection to the absence of some parameters related to the electrode [57], for example, work-function, which were assumed in our current model. In [58], the reported PCE is 17.50%, with a 12% gap from our simulated PCE. This can be due to the impact of the defects, i.e., defect-based model to defect-free model. In the investigation of sample #3, we simplify our simulation model to be a defect-free model. This reflects the mismatching between the simulation data and the experimental one in [58]. Alternatively, sample #4 performed the minimum divergence, compared with the data in [59], where the assumption of the electrode work-function can be the justification of such mismatch. The observed errors are in the expected zone, making it reliable to trust the proposed model in further investigations. Experimentally, a perfect matching was observed while comparing sample # 5 with the corresponding simulation results, see Table 1 and Fig. 4. A maximum deflection error of 3% was observed through the four main evaluating parameters, which gives a higher trust for the proposed model.

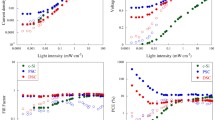

3.2 Transparency against efficiency

This study investigates the trade-off between transparency and efficiency in MSSCs for sensing applications in the introduction section. Following our previous work in [54], the absorbing film in MSSCs is the dominating layer in absorption or scattering mechanisms. Consequently, tuning the thickness of the absorber (active layer) can significantly contribute to the overall cell transparency. We varied the active layer thickness across the proposed six samples from 10 to 500 nm. On the other hand, the efficiency expected degradation is simulated to observe the trade-off between the two conflicting parameters, i.e., the transparency and the efficiency (cf. Fig. 5). Herein, the power conversion efficiency (ζ, abbreviated as PCE) is defined as:

where \({V}_{oc}\) is the open-circuit voltage, \({J}_{sc}\) short-circuit current density, \(FF\) is the fill factor, and \({I}_{s}\) is the optical source intensity per unit area. The current study includes three light sources, as mentioned in Fig. 2. Due to the variation in the dynamic range for the given PCE across the six samples, and as the intersection points in the transparency-efficiency trade-off curves function in the selected range, we chose to normalize the given PCE by:

where \({\upzeta }_{max}\) represents the maximum PCE per cell per light source, and \({t}_{active}\) is the thickness.

The transparency-efficiency trade-off curves shown in Fig. 5 conclude with 18 optimum points, where the transmission curves intersect with the efficiency curves. A complete list for the 18 optimum points is accessible in the Supplementary Material table A.1, associated with the corresponding J-V characteristic curves in figure A.1. By classifying these optimum points, it can be observed that sample #4 performed the best efficiencies among the six samples, regardless of the type of optical injection. On the one hand, sample #4 has shown the highest PCE under AM1.5G optical injection, reaching 29.97%, nearly six times the minimum recorded efficiency under AM1.5G for sample #6 (\(\upzeta\)= 4.86%). On the other hand, the simulated transparency of sample #4 is not considered the maximum reported transparency, but it is only 3% away from the maximum transparency showed by sample #6 (88.44% to 85.59%). Similar behavior is also detected in the other two sources, LED and Xenon lamps. As a result, sample #4 can be nominated as the best sample among those under test in performing semi-transparent light-harvesting capabilities.

As indicated earlier in this section, sample #4 performed the best PCE while referring to the six samples under test. Toward justifying such behavior, the J-V characteristic curves and the energy-band diagrams are plotted in Figs. 5 and 6, respectively. The J-V characteristic curves in Fig. 6 indicate a boosted short-circuit current density under the high-power LED and Xenon lamp concerning AM1.5G. This is attributed to the higher light intensity described by the area under the curve in Fig. 2. Moreover, sample #4 still recorded the highest current density among the six samples under AM1.5G; see Table A.1 in the Supplementary Materials. This can be attributed to the energy band gap deflection observed in Fig. 7. Starting from Fig. 7(a), a thermodynamic equilibrium energy-band diagram is simulated. A flat Fermi level is observed with double heterojunctions formed between the perovskite p-doped and the adjacent electron and hole transport layers. After optical injection, see Fig. 7(b), still under zero voltage bias, the quasi-Fermi levels started to appear. The perovskite layer deflection will be adrift for the minority carriers, pushing electrons to the right side and reversely the holes. In Fig. 7(b), this condition reflects the maximum drift current in the cell (short-circuit current). In other words, the larger the drift, the higher the current. While comparing Fig. 7(b) with the energy-band diagram reported for the other five samples (see Supplementary Materials section B, figures B.1 to B.6), the highest band deflection is found in sample #4. This is due to the band-gap arrangement forming the heterojunction between the perovskite material and the electron transport layer (to the left). Finally, the flat band condition is obtained by biasing the cell to the open-circuit point with zero drifting currents (Fig. 7(c).

3.3 Bifacial characteristics

One of the advantages of semi-transparent solar cells is the adaptability for bifacial optical injection. In this context, we adjusted our solar cell samples to be with sympatric transparent conducting oxide electrodes. Using the trade-off curves illustrated in the previous section, the PSC in sample #4 was tested under bifacial conditions. The front contact is injected by AM1.5G, while the counter electrode is inputted through a high-power LED source, with the spectrum in Fig. 2. The simulation results presented in Fig. 8 indicated an overall PCE enhancement from 28.63%, for unifacial injection, to 33.00% for bifacial injection, with enhanced transparency of approximately 3%. Such boosted performance was associated with reducing the active layer thickness from 500 to 1000 nm, as highlighted in Fig. 8. We attributed this active layer thickness reduction to the fact that the bifacial injection is rich on the counter side of the layer with a stream of injected photons, making it possible to reduce the thickness with even higher PCE. It is worth mentioning that all reported transparency in this paper excludes the double reflection from the glass substrates, which should be around 8%. The final proposed bifacial cell with 23.26% PCE can be a potential harvester for many IoT applications, where transparency is considered an added value. Some of these applications are illustrated in the next section.

4 Mesostructured-based solar cells in potential sensing applications

Many low-power applications can operate with the 33% PCE bifacial cell. This section lists potential applications by discussing their proposed energy budget (see Table 2). In biomedical sensing, organic field-effect transistor (OFET) has proven its utility in low-power sensing applications. For example, OFET can detect troponin cord protein in building for heart disease detection [63]. The ultra-low threshold voltage is required for high sensitivity and low energy consumption in such an application. Based on that, our proposed bifacial cell can be utilized to provide the required energy to the sensor with a 4.5 cm2 area. Another exciting field of study is underwater applications, where diffused light dominates. Our previous work in [51] indicated that mesostructured-based cells' performance is much better than conventional Si-based cells under diffused light.

Consequently, the suggested cell showed an acceptable area estimation for temperature sensing of 9.9 cm2, as listed in Table 2. Moreover, integrating semi-transparent windows in electric vehicle technology can be considered a part of the self-charging electric vehicles trend. Herein, we propose enrolling the bifacial cell in the IoT sensors used in car monitoring and communication with the station. Calculations listed in Table 2 show that an area of 15 cm2 is needed per 5 V sensor. Finally, the bifacial cell is integrated into IoT smart building sensors with 27 cm2 for each 9 V sensor. We consider the current brief scanning as a primitive seed to introduce bifacial cells in various industrial IoT sensing applications, where a complete analysis, design, and prototyping are considered a part of future work.

5 Conclusion

The current study demonstrated an attempt to simulate the transparency-efficiency trade-off curves in six different samples of solar cells. Four selected six samples are perovskite-type, and the remaining two are DSSCs. The study was extended to include both unifacial and bifacial solar cells. The model was validated using three intermediate validation points from the literature. A boosted bifacial solar cell was reached with a PCE of 33%, capable of integrating into semi-transparent photovoltaic windows applications. The cell was simulated under front injection of AM1.5G and counter injection using a high-power LED source. The simulation model showed around 5% enhancement due to the bifacial injection while referring to the unifacial injection as a reference cell.

References

Dong, B., Shi, Q., Yang, Y., Wen, F., Zhang, Z., & Lee, C. (2021). Technology evolution from self-powered sensors to AIoT enabled smart homes. Nano Energy, 79, 105414.

Wu, Z., Cheng, T., & Wang, Z. L. (2020). Self-powered sensors and systems based on nanogenerators. Sensors, 20(10), 2925.

Sultana, A., Alam, M. M., Middya, T. R., & Mandal, D. (2018). A pyroelectric generator as a self-powered temperature sensor for sustainable thermal energy harvesting from waste heat and human body heat. Applied Energy, 221, 299.

Huang, L., Chen, J., Yu, Z., & Tang, D. (2020). Self-powered temperature sensor with seebeck effect transduction for photothermal–thermoelectric coupled immunoassay. Analytical Chemistry, 92(3), 2809.

Feng, R., Tang, F., Zhang, N., & Wang, X. (2019). Flexible, high-power density, wearable thermoelectric nanogenerator and self-powered temperature sensor. ACS Applied Materials & Interfaces, 11(42), 38616.

Jang, J., Kang, K., Raeis-Hosseini, N., et al. (2020). Self-powered humidity sensor using chitosan-based plasmonic metal–hydrogel–metal filters. Advanced Optical Materials, 8(9), 1901932.

Ejehi, F., Mohammadpour, R., Asadian, E., Sasanpour, P., Fardindoost, S., & Akhavan, O. (2020). Graphene oxide papers in nanogenerators for self-powered humidity sensing by finger tapping. Scientific Reports, 10(1), 1.

Song, Z., Ye, W., Chen, Z., et al. (2021). Wireless self-powered high-performance integrated nanostructured-gas-sensor network for future smart homes. ACS Nano, 15(4), 7659.

Niu, Y., Zeng, J., Liu, X., et al. (2021). A Photovoltaic self-powered gas sensor based on all-dry transferred MoS2/GaSe heterojunction for ppb-level NO2 sensing at room temperature. Advanced Science, 8(14), 2100472.

Liu, X.-L., Zhao, Y., Wang, W.-J., et al. (2020). Photovoltaic self-powered gas sensing: A review. IEEE Sensors Journal, 21(5), 5628.

Kim, Y., Lee, S., Song, J. G., et al. (2020). 2D transition metal dichalcogenide heterostructures for p-and n-type photovoltaic self-powered gas sensor. Advanced Functional Materials, 30(43), 2003360.

Salauddin, M., Rana, S. S., Rahman, M. T., et al. (2022). Fabric-assisted MXene/silicone nanocomposite-based triboelectric nanogenerators for self-powered sensors and wearable electronics. Advanced Functional Materials, 32(5), 2107143.

Zhao, J., Xu, Z., Law, M.-K., et al. (2021). Simulation of crystalline silicon photovoltaic cells for wearable applications. IEEE Access, 9, 20868.

Zhang, Y., Gao, X., Wu, Y., et al. (2021) ExplorationWiley Online Library.

Yan, C., Deng, W., Jin, L., et al. (2018). Epidermis-inspired ultrathin 3D cellular sensor array for self-powered biomedical monitoring. ACS Applied Materials & Interfaces, 10(48), 41070.

Mishra, H. K., Gupta, V., Roy, K., Babu, A., Kumar, A., & Mandal, D. (2022). Revisiting of δ− PVDF nanoparticles via phase separation with giant piezoelectric response for the realization of self-powered biomedical sensors. Nano Energy, 95, 107052.

Dai, X., Huang, L. B., Du, Y., et al. (2020). Self-healing, flexible, and tailorable triboelectric nanogenerators for self-powered sensors based on thermal effect of infrared radiation. Advanced Functional Materials, 30(16), 1910723.

Park, J., Bhat, G., Nk, A., Geyik, C. S., Ogras, U. Y., & Lee, H. G. (2020). Energy per operation optimization for energy-harvesting wearable IoT devices. Sensors, 20(3), 764.

Liu, Y., Zhao, J.-Q., Sun, W.-J., et al. (2018). A facile photo-cross-linking method for polymer gate dielectrics and their applications in fully solution processed low voltage organic field-effect transistors on plastic substrate. Chinese Journal of Polymer Science, 36(8), 918.

Najafi, M., Di Giacomo, F., Zhang, D., et al. (2018). Highly efficient and stable flexible perovskite solar cells with metal oxides nanoparticle charge extraction layers. Small (Weinheim an der Bergstrasse, Germany), 14(12), 1702775.

Kim, J. Y., Lee, J.-W., Jung, H. S., Shin, H., & Park, N.-G. (2020). High-efficiency perovskite solar cells. Chemical Reviews, 120(15), 7867.

Gholikhani, M., Roshani, H., Dessouky, S., & Papagiannakis, A. (2020). A critical review of roadway energy harvesting technologies. Applied Energy, 261, 114388.

Sanad, M. F., Shaker, A., Abdellatif, S. O., Ghali, H. A. (2019) 2019 International Conference on Innovative Trends in Computer Engineering (ITCE).

Sanad, M. F., Abdellatif, S. O., Ghali, H. A. (2019). Enhancing the performance of photovoltaic operating under harsh conditions using carbon-nanotube thermoelectric harvesters. Journal of Materials Science: Materials in Electronics, 1.

Sanad, M. F., Shalan, A. E., Abdellatif, S. O., Serea, E. S. A., Adly, M. S., & Ahsan, M. (2020). Thermoelectric energy harvesters: A review of recent developments in materials and devices for different potential applications. Topics in Current Chemistry, 378(6), 1.

Sezer, N., & Koç, M. (2021). A comprehensive review on the state-of-the-art of piezoelectric energy harvesting. Nano Energy, 80, 105567.

Lee, S., & Youn, B. D. (2011). A new piezoelectric energy harvesting design concept: Multimodal energy harvesting skin. IEEE Transactions on Ultrasonics, Ferroelectrics, and Frequency Control, 58(3), 629.

Covaci, C., & Gontean, A. (2020). Piezoelectric energy harvesting solutions: A review. Sensors, 20(12), 3512.

Cao, X., Xiong, Y., Sun, J., Zhu, X., Sun, Q., & Wang, Z. L. (2021). Piezoelectric nanogenerators derived self-powered sensors for multifunctional applications and artificial intelligence. Advanced Functional Materials, 31(33), 2102983.

Hatem, T., Ismail, Z., Elmahgary, M. G., Ghannam, R., Ahmed, M. A., & Abdellatif, S. O. (2021). Optimization of organic meso-superstructured solar cells for underwater IoT 2 self-powered sensors. IEEE Transactions on Electron Devices, 68(10), 5319.

Al-Saban, O., Abdellatif, S. O. (2021) 2021 International Telecommunications Conference (ITC-Egypt) IEEE.

Abdellatif, M. M., Maher, S. M., & Ghazal, M. (2020). Implementation of a low cost, solar charged RF modem for underwater wireless sensor networks. International Journal on Smart Sensing and Intelligent Systems, 13(1), 1.

Abdellatif, S. O., Josten, S., Khalil, A. S., Erni, D., & Marlow, F. (2020). Transparency and diffused light efficiency of dye-sensitized solar cells: Tuning and a new figure of merit. IEEE Journal of Photovoltaics, 10(2), 522.

Mahran, A. M., Abdellatif, S. O. (2021) 2021 International Telecommunications Conference (ITC-Egypt) IEEE,

Zhang, N., Chen, K.-K., Guo, S., et al. (2019). Sensitizing Ru (II) polyimine redox center with strong light-harvesting coumarin antennas to mimic energy flow of biological model for efficient hydrogen evolution. Applied Catalysis B: Environmental, 253, 105.

Park, S. Y., Labanti, C., Luke, J., Chin, Y. C., & Kim, J. S. (2022). Organic bilayer photovoltaics for efficient indoor light harvesting. Advanced Energy Materials, 12(3), 2103237.

Volkov, I. L., Reveguk, Z. V., Serdobintsev, P. Y., Ramazanov, R. R., & Kononov, A. I. (2018). DNA as UV light–harvesting antenna. Nucleic acids research, 46(7), 3543.

Matsubara, S., & Tamiaki, H. (2020). Supramolecular chlorophyll aggregates inspired from specific light-harvesting antenna “chlorosome”: Static nanostructure, dynamic construction process, and versatile application. Journal of Photochemistry and Photobiology C: Photochemistry Reviews, 45, 100385.

Fu, Y., Lu, T., Xu, Y., et al. (2018). Theoretical screening and design of SM315-based porphyrin dyes for highly efficient dye-sensitized solar cells with near-IR light harvesting. Dyes and Pigments, 155, 292.

Yang, X.-G., Qin, J.-H., Huang, Y.-D., Zhai, Z.-M., Ma, L.-F., & Yan, D. (2020). Highly enhanced UV-vis-NIR light harvesting and photoelectric conversion of a pyrene MOF by encapsulation of the D–π–A cyanine dye. Journal of Materials Chemistry C, 8(48), 17169.

Zhu, C., Chen, Z., Gao, S., et al. (2019). Recent advances in non-toxic quantum dots and their biomedical applications. Progress in Natural Science: Materials International, 29(6), 628.

Storck, J. L., Dotter, M., Adabra, S., Surjawidjaja, M., Brockhagen, B., & Grothe, T. (2020). Long-term stability improvement of non-toxic dye-sensitized solar cells via poly (ethylene oxide) gel electrolytes for future textile-based solar cells. Polymers, 12(12), 3035.

Mahran, A. M., Abdellatif, S. O. (2021) 2021 International Conference on Microelectronics (ICM) IEEE,

Xu, Z., Peng, S., Wang, Y. Y., Zhang, J. K., Lazar, A. I., & Guo, D. S. (2016). Broad-spectrum tunable photoluminescent nanomaterials constructed from a modular light-harvesting platform based on macrocyclic amphiphiles. Advanced Materials, 28(35), 7666.

Mathews, I., Kantareddy, S. N. R., Sun, S., et al. (2019). Self-powered sensors enabled by wide-bandgap perovskite indoor photovoltaic cells. Advanced Functional Materials, 29(42), 1904072.

Ippili, S., Jella, V., Thomas, A. M., & Yoon, S.-G. (2021). The recent progress on halide perovskite-based self-powered sensors enabled by piezoelectric and triboelectric effects. Nanoenergy Advances, 1(1), 3.

Kantareddy, S. N. R., Mathews, I., Sun, S., et al. (2019). Perovskite PV-powered RFID: Enabling low-cost self-powered IoT sensors. IEEE Sensors Journal, 20(1), 471.

Han, J., Fan, F., Xu, C., et al. (2010). ZnO nanotube-based dye-sensitized solar cell and its application in self-powered devices. Nanotechnology, 21(40), 405203.

Aslam, A., Mehmood, U., Arshad, M. H., et al. (2020). Dye-sensitized solar cells (DSSCs) as a potential photovoltaic technology for the self-powered internet of things (IoTs) applications. Solar Energy, 207, 874.

Hatem, T., Elmahgary, M. G., Ghannam, R., Ahmed, M. A., & Abdellatif, S. O. (2021). Boosting dye-sensitized solar cell efficiency using AgVO3-doped TiO2 active layer. Journal of Materials Science: Materials in Electronics, 32(20), 25318. https://doi.org/10.1007/s10854-021-06990-4

Abdellatif, S. O., Josten, S., Khalil, A. S. G., Erni, D., & Marlow, F. (2020). Transparency and diffused light efficiency of dye-sensitized solar cells: Tuning and a new figure of merit. IEEE Journal of Photovoltaics. https://doi.org/10.1109/JPHOTOV.2020.2965399

Hassan, M. M., Ismail, Z. S., Hashem, E. M., Ghannam, R., & Abdellatif, S. O. (2021). Investigating the tradeoff between transparency and efficiency in semitransparent bifacial mesosuperstructured solar cells for millimeter-scale applications. IEEE Journal of Photovoltaics. https://doi.org/10.1109/JPHOTOV.2021.3086443

Abdellatif, S. O., Fathi, A., Abdullah, K., Hassan, M. M., & Khalifa, Z. (2022). Investigating the variation in the optical properties of TiO2 thin-film utilized in bifacial solar cells using machine learning algorithm. Journal of Photonics for Energy, 12(2), 022202.

Abdellatif, S., Sharifi, P., Kirah, K., et al. (2018). Refractive index and scattering of porous TiO2 films. Microporous and Mesoporous Materials, 264, 84.

Burgelman, M., Decock, K., Niemegeers, A., Verschraegen, J., Degrave, S. (2016). SCAPS manual. February.

Kumar, M., Raj, A., Kumar, A., & Anshul, A. (2020). An optimized lead-free formamidinium Sn-based perovskite solar cell design for high power conversion efficiency by SCAPS simulation. Optical Materials, 108, 110213.

Kumar, M., Kumar, A., Raj, A., Sati, P. C., Sahni, M., & Anshul, A. (2020). Organic-inorganic perovskite-based solar cell designs for high conversion efficiency: A comparative study by SCAPS simulation. Materials Today: Proceedings, 49, 3081–3087.

Lin, L., Jiang, L., Li, P., et al. (2020). Simulated development and optimized performance of CsPbI3 based all-inorganic perovskite solar cells. Solar Energy, 198, 454.

Mandadapu, U., Vedanayakam, S. V., Thyagarajan, K., Reddy, M. R., & Babu, B. (2017). Design and simulation of high efficiency tin halide perovskite solar cell. International Journal of Renewable Energy Research, 7(4), 1603.

Jahantigh, F., & Safikhani, M. J. (2019). The effect of HTM on the performance of solid-state dye-sanitized solar cells (SDSSCs): A SCAPS-1D simulation study. Applied Physics A, 125(4), 276.

Rondan-Gómez, V., Ayala-Mató, F., Seuret-Jiménez, D., et al. (2020). New architecture in dye sensitized solar cells: A SCAPS-1D simulation study. Optical and Quantum Electronics, 52(6), 1.

Hassan, M. M., Sahbel, A., Abdellatif, S. O., Kirah, K. A., Ghali, H. A. (2020) New Concepts in solar and thermal radiation conversion III. In: International Society for Optics and Photonics

Chang, S.-M., Palanisamy, S., Wu, T.-H., et al. (2020). Utilization of silicon nanowire field-effect transistors for the detection of a cardiac biomarker, cardiac troponin I and their applications involving animal models. Scientific Reports, 10(1), 1.

Hatem, T., Ismail, Z., Elmahgary, M. G., Ghannam, R., Ahmed, M. A., & Abdellatif, S. O. (2021). Optimization of organic meso-superstructured solar cells for underwater IoT2 self-powered sensors. IEEE Transactions on Electron Devices. https://doi.org/10.1109/TED.2021.3101780

Nasser, S., Alashram, A., Hani, A., et al. (2019) Proceedings of the 2019 8th International Conference on Software and Information Engineering

Mohammadi, F., & Rashidzadeh, R. (2021). An overview of IoT-enabled monitoring and control systems for electric vehicles. IEEE Instrumentation & Measurement Magazine, 24(3), 91.

Ahmed, M. O., Madkor, A. K., Makeen, P., Betelmal, S. E., Hassan, M. M., Abdelsamee, M. M., Ayman, A., El-Adly, M. H., Nessim, A., & Abdullatif, S. O. (2021). Optimizing the artificial lighting in a smart and green glass building-integrated semi-transparent photovoltaics: A multifaceted case study in Egypt. WSEAS Transactions on Environment and Development, 17, 118. https://doi.org/10.37394/232015.2021.17.12

Acknowledgements

The authors would like to acknowledge the support and contribution of the STDF in this work. As part of the STDF Project entitled, "Mesostructured Based Solar Cells for Smart Building Applications," Project ID#33502. Also, this work is supported by the Information Technology Academia Collaboration (ITAC) initiative under the Information Technology Industry Development Agency (ITIDA) [GP2021.R16.65].

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The authors would like to acknowledge the support and contribution of the STDF in this work. As part of the STDF Project ID#33502. Also, this work is supported by the Information Technology Academia Collaboration (ITAC) initiative under the Information Technology Industry Development Agency (ITIDA) [GP2021.R16.65].

Author information

Authors and Affiliations

Contributions

All authors have contributed equally.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable for that section.

Ethical approval

Not applicable for that section.

Consent to participate

All authors confirm their participation in this paper.

Consent for publication

All authors accept the publication rules applied by the journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mahran, A.M., Abdellatif, S.O. Transparency against efficiency in uni/bifacial mesostructured-based solar cells for self-powered sensing applications. Analog Integr Circ Sig Process 114, 217–227 (2023). https://doi.org/10.1007/s10470-022-02114-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10470-022-02114-y