Abstract

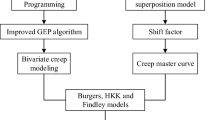

In this article, a new method for establishing creep predictive model using gene expression programming (GEP) is proposed. The three-point bending tests under constant load are carried out to determine time-dependent creep curves of fiber reinforced polymer materials with different lay-up styles, a modeling program is developed to predict creep behavior of composite materials. The creep of fiber is much smaller than that of resin matrix, various fiber layups play a role in constraining the deformation of resin, resulting in differences in creep performance of composites. The mathematical model satisfies the variation law that creep strain monotonically increases with time and tends to be stable. Based on 0 ~ 1000 h experimental data, the creep model is established by GEP, and then utilized to predict creep ranging from 1000 to 2000 h, the predicted values are in good agreement with experimental values. The fitting efficiency and prediction accuracy of GEP model are demonstrated by R2, RMSE, MAE and RRSE metrics. Moreover, taking R2 as a statistical metric, the validity of developed model is verified by comparison with Burgers model, Findley model and HKK model. Creep factor calculated by GEP model is lower than standard specified value, and the relative errors δ of creep deflection are very low, all within about 10%, indicating that GEP model can accurately predict the long-term creep performance of composites.

Similar content being viewed by others

Data Availability

The data used to support the findings of this study are available from the corresponding author upon reasonable request.

References

Demircan, G., Kisa, M., Ozen, M., Aktas, B.: Surface-modified alumina nanoparticles-filled aramid fiber-reinforced epoxy nanocomposites: preparation and mechanical properties. Iran. Polym. J. 29, 253–264 (2020). https://doi.org/10.1007/s13726-020-00790-z

Demircan, G., Kisa, M., Ozen, M., Acikgoz, A.: Quasi-static penetration behavior of glass-fiber-reinforced epoxy nanocomposites. Mech. Compos. Mater. 57(4), 503–516 (2021). https://doi.org/10.1007/s11029-021-09973-y

Ozen, M., Demircan, G., Kisa, M., Acikgoz, A., Ceyhan, G., Isıker, Y.: Thermal properties of surface-modified nano-Al2O3/Kevlar fiber/ epoxy composites. Mater. Chem. Phys. 278, 125689 (2022). https://doi.org/10.1016/j.matchemphys.2021.125689

Berardi, V.P., Perrella, M., Feo, L., Cricrì, G.: Creep behavior of GFRP laminates and their phases: experimental investigation and analytical modeling. Compos. Part B-Eng. 122, 136–144 (2017). https://doi.org/10.1016/j.compositesb.2017.04.015

Jia, Y., Peng, K., Gong, X., Zhang, Z.: Creep and recovery of polypropylene/carbon nanotube composites. Int. J. Plasticity. 27(8), 1239–1251 (2011). https://doi.org/10.1016/j.ijplas.2011.02.004

Rafiee, R., Mazhari, B.: Simulation of the long-term hydrostatic tests on glass fiber reinforced plastic pipes. Compos. Struct. 136, 56–63 (2016). https://doi.org/10.1016/j.compstruct.2015.09.058

Katouzian, M., Vlase, S., Scutaru, M.L.: Finite element method-based simulation creep behavior of viscoelastic carbon-fiber composite. Polymers 13(7), 1017 (2021). https://doi.org/10.3390/polym13071017

Asyraf, M.R.M., Ishak, M.R., Sapuan, S.M., Yidris, N.: Comparison of static and long-term creep behaviors between balau wood and glass fiber reinforced polymer composite for cross-arm application. Fiber. Polym. 22(3), 793–803 (2021). https://doi.org/10.1007/s12221-021-0512-1

Asyraf, M.R.M., Ishak, M.R., Sapuan, S.M., Yidris, N.: Utilization of bracing arms as additional reinforcement in pultruded glass fiber-reinforced polymer composite cross-arms: creep experimental and numerical analyses. Polymers 13(4), 620 (2021). https://doi.org/10.3390/polym13040620

Harries, K.A., Guo, Q., Cardoso, D.: Creep and creep buckling of pultruded glass-reinforced polymer members. Compos. Struct. 181, 315–324 (2017). https://doi.org/10.1016/j.compstruct.2017.08.098

Ghosh, S.K., Rajesh, P., Srikavya, B., Rathore, D.K., Prusty, R.K., Ray, B.C.: Creep behavior prediction of multi-layer graphene embedded glass fiber/epoxy composites using time-temperature superposition principle. Compos. Part A-Appl. S. 107, 507–518 (2018). https://doi.org/10.1016/j.compositesa.2018.01.030

Yang, Z., Wang, H., Ma, X., Shang, F., Ma, Y., Shao, Z., Hou, D.: Flexural creep tests and long-term mechanical behavior of fiber-reinforced polymeric composite tubes. Compos. Struct. 193, 154–164 (2018). https://doi.org/10.1016/j.compstruct.2018.03.083

Yu, L., Ma, Y.: Loading rate and temperature dependence of flexural behavior in injection-molded glass fiber reinforced polypropylene composites. Compos. Part B-Eng. 161, 285–299 (2019). https://doi.org/10.1016/j.compositesb.2018.10.035

Alwis, K.G.N.C., Burgoyne, C.J.: Time-Temperature superposition to determine the stress-rupture of aramid fibres. Appl. Compos. Mater. 13(4), 249–264 (2006). https://doi.org/10.1007/s10443-006-9017-8

Li, K., Yan, S.L., Pan, W.F., Zhao, G.: Warpage optimization of fiber-reinforced composite injection molding by combining back propagation neural network and genetic algorithm. Int. J. Adv. Manuf. Technol. 90, 963–970 (2017). https://doi.org/10.1007/s00170-016-9409-3

Bautu, E., Bautu, A., Luchian, H.: Symbolic regression on noisy data with genetic and gene expression programming. International Symposium on Symbolic & Numeric Algorithms for Scientific Computing. IEEE Computer Society. 321–324 (2005). https://doi.org/10.1109/SYNASC.2005.70

Zhang, H.R., Hao, J., Lv, Y.G., Zhao, L.: Symbolic regression on noisy data with stepwise genetic programming algorithm. Appl. Mech. Mater. 530(531), 625–628 (2014). https://doi.org/10.4028/www.scientific.net/amm.530-531.625

Yuan, C., Tang, C., Wen, Y., Zuo, J., Peng, J., Hu, J.: Convergency of genetic regression in data mining based on gene expression programming and optimized solution. Int. J. Comput. Appl. 28(4), 359–366 (2006). https://doi.org/10.1080/1206212X.2006.11441822

Kalfat, R., Nazari, A., Al-Mahaidi, R., Sanjayan, J.: Genetic programming in the simulation of FRP-to-concrete patch-anchored joints. Compos. Struct. 138, 305–312 (2016). https://doi.org/10.1016/j.compstruct.2015.12.005

Ebid, A.M., Deifalla, A.: Prediction of shear strength of FRP reinforced beams with and without stirrups using GP technique. Ain. Shams. Eng. J. 12(3), 2493–2510 (2021). https://doi.org/10.1016/j.asej.2021.02.006

Murad, Y., Tarawneh, B., Ashteyat, A.: Prediction model for concrete carbonation depth using gene expression programming. Comput. Concrete. 26(6), 497–504 (2020). https://doi.org/10.12989/cac.2020.26.6.497

Murad, Y., Ashteyat, A., Hunaifat, R.: Predictive model to the bond strength of FRP-to concrete under direct pullout using gene expression programming. J. Civ. Eng. Manage. 25(8), 773–784 (2019). https://doi.org/10.3846/jcem.2019.10798

Iqbal, M., Zhao, Q., Zhang, D., Jalal, F.E., Jamal, A.: Evaluation of tensile strength degradation of GFRP rebars in harsh alkaline conditions using non-linear genetic-based models. Mater. Struct. 54(5), 190 (2021). https://doi.org/10.1617/s11527-021-01783-x

Murad, Y., Tarawneh, A., Arar, F., Al-Zu’bi, A., Al-Ghwairi, A., Al-Jaafreh, A., Tarawneh, M.: Flexural strength prediction for concrete beams reinforced with FRP bars using gene expression programming. Struct. 33, 3163–3172 (2021). https://doi.org/10.1016/j.istruc.2021.06.045

Güneyisi, E.M., Nour, A.I.: Axial compression capacity of circular CFST columns transversely strengthened by FRP. Eng. Struct. 191, 417–431 (2019). https://doi.org/10.1016/j.engstruct.2019.04.056

Murad, Y., Hunifat, R., AL-Bodour, W.: Interior reinforced concrete beam-to-column joints subjected to cyclic loading: shear strength prediction using gene expression programming. Case. Stud. Constr. Mat. 13, e00432 (2020). https://doi.org/10.1016/j.cscm.2020.e00432

Murad, Y.: Predictive model for bidirectional shear strength of reinforced concrete columns subjected to biaxial cyclic loading. Eng. Struct. 244, 112781 (2021). https://doi.org/10.1016/j.engstruct.2021.112781

Murad, Y.: Joint shear strength models for exterior RC beam-column connections exposed to biaxial and uniaxial cyclic loading. J. Build. Eng. 30, 101225 (2020). https://doi.org/10.1016/j.jobe.2020.101225

Mansouri, I., Güneyisi, E.M., Mosalam, K.M.: Improved shear strength model for exterior reinforced concrete beam-column joints using gene expression programming. Eng. Struct. 228, 111563 (2021). https://doi.org/10.1016/j.engstruct.2020.111563

Hassani, M., Safi, M., Ardakani, R.R., Daryan, A.S.: Predicting fire resistance of SRC columns through gene expression programming. J. Struct. Fire. Eng. 12(2), 125–140 (2020). https://doi.org/10.1108/JSFE-04-2020-0013

Beheshti Aval, S.B., Ketabdari, H., Asil Gharebaghi, S.: Estimating shear strength of short rectangular reinforced concrete columns using nonlinear regression and gene expression programming. Struct. 12, 13–23 (2017). https://doi.org/10.1016/j.istruc.2017.07.002

Tarawneh, A., Almasabha, G., Alawadi, R., Tarawneh, M.: Innovative and reliable model for shear strength of steel fibers reinforced concrete beams. Struct. 32, 1015–1025 (2021). https://doi.org/10.1016/j.istruc.2021.03.081

Iqbal, M.F., Liu, Q.F., Azim, I., Zhu, X., Yang, J., Javed, M.F., Rauf, M.: Prediction of mechanical properties of green concrete incorporating waste foundry sand based on gene expression programming. J. Hazard. Mater. 384, 121322 (2020). https://doi.org/10.1016/j.jhazmat.2019.121322

Jafari, S., Mahini, S.S.: Lightweight concrete design using gene expression programing. Constr. Build. Mater. 139, 93–100 (2017). https://doi.org/10.1016/j.conbuildmat.2017.01.120

Gholampour, A., Gandomi, A.H., Ozbakkaloglu, T.: New formulations for mechanical properties of recycled aggregate concrete using gene expression programming. Constr. Build. Mater. 130, 122–145 (2017). https://doi.org/10.1016/j.conbuildmat.2016.10.114

Bouziadi, F., Boulekbache, B., Haddi, A., Hamrat, M., Djelal, C.: Finite element modeling of creep behavior of FRP-externally strengthened reinforced concrete beams. Eng. Struct. 204, 109908 (2020). https://doi.org/10.1016/j.engstruct.2019.109908

Anand, A., Banerjee, P., Sahoo, D., Rathore, D.K., Prusty, R.K., Ray, B.C.: Effects of temperature and load on the creep performance of CNT reinforced laminated glass fiber/epoxy composites. Int. J. Mech. Sci. 150, 539–547 (2019). https://doi.org/10.1016/j.ijmecsci.2018.09.048

Berardi, V.P., Perrella, M., Armentani, E., Cricrì, G.: Experimental investigation and numerical modeling of creep response of glass fiber reinforced polymer composites. Fatigue. Fract. Eng. M. 44(4), 1085–1095 (2021). https://doi.org/10.1111/ffe.13415

Koza, J.R.: Genetic programming as a means for programming computers by natural selection. Stat. Comput. 4(2), 87–112 (1994). https://doi.org/10.1007/BF00175355

Ferreira, C.: Gene expression programming: a new adaptive algorithm for solving problems. Complex. Syst. 13(2), 87–129 (2001). https://doi.org/10.48550/arXiv.cs/0102027

Zhong, J.H., Ong, Y.S., Cai, W.T.: Self-learning gene expression programming. Ieee. T. Evolut. Comput. 20(1), 65–80 (2016). https://doi.org/10.1109/TEVC.2015.2424410

Gao, Y.F., Yin, D.S.: A full-stage creep model for rocks based on the variable-order fractional calculus. Appl. Math. Model. 95(1), 435–446 (2021). https://doi.org/10.1016/j.apm.2021.02.020

Milad, A., Hussein, S.H., Khekan, A.R., Rashid, M., Al-Msari, H., Tran, T.H.: Development of ensemble machine learning approaches for designing fiber-reinforced polymer composite strain prediction model. Eng. Comput. 38, 3625–3637 (2022). https://doi.org/10.1007/s00366-021-01398-4

Sokairge, H., Elgabbas, F., Rashad, A., Elshafie, H.: Long-term creep behavior of basalt fiber reinforced polymer bars. Constr. Build. Mater. 260, 120437 (2020). https://doi.org/10.1016/j.conbuildmat.2020.120437

Liang, N., Zhu, S.R., Chen, J.Z., Fang, X.: Long-term behavior of GFRP pipes: optimizing the distribution of failure points during testing. Polym. Test. 48, 7–11 (2015). https://doi.org/10.1016/j.polymertesting.2015.08.011

Benmokrane, B., Brown, Vicki L., Mohamed, K., Nanni, A., Rossini, M., Shield, C.: Creep-rupture limit for GFRP bars subjected to sustained loads. J. Compos. Constr. 23(6), 06019001 (2019). https://doi.org/10.1061/(ASCE)CC.1943-5614.0000971

Farooq, M., Banthia, N.: FRP fibre-cementitious matrix interfacial bond under time-dependent loading. Mater. Struct. 52, 109 (2019). https://doi.org/10.1617/s11527-019-1409-y

Li, M., Zhang, H., Li, S., Zhu, W., Ke, Y.: Machine learning and materials informatics approaches for predicting transverse mechanical properties of unidirectional CFRP composites with microvoids. Mater. Design. 224, 111340 (2022). https://doi.org/10.1016/j.matdes.2022.111340

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 11902232).

Author information

Authors and Affiliations

Contributions

Hua Tan: Conceptualization; Formal analysis; Investigation; Methodology; Software; Visualization; Writing-original draft; Writing-review & editing. Sirong Zhu: Conceptualization; Supervision; Resources; Validation. Shilin Yan: Data curation; Methodology; Supervision; Project administration. Pin Wen: Validation; Funding acquisition. All authors have read and agreed to the submitted version of the manuscript.

Corresponding author

Ethics declarations

Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tan, H., Zhu, S., Yan, S. et al. Predictive Model for Creep Behavior of Composite Materials Using Gene Expression Programming. Appl Compos Mater 30, 1003–1030 (2023). https://doi.org/10.1007/s10443-023-10109-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-023-10109-9