Abstract

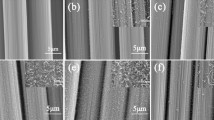

Oxidization treatment has been successfully applied on carbon nanotubes grown carbon fiber (CNTs-CF) to improve the surface activity and the interfacial property of CNTs-CF/epoxy resin (CNTs-CF/EP) composite. The surface element, morphology, and mechanical property of CNTs-CF have been systematically studied by X-ray photoelectron spectrum (XPS), scanning electron microscope (SEM), and single fiber tensile strength tester, respectively. The results indicate that the oxygen content on the CNTs-CF surface has been markedly increased from 2.5% to 19.4% after oxidization treatment, while the tensile strength shows no significant decrease. The CNTs layer on the surface protected the carbon fiber from corrosive oxidization agent, at the cost of collapsing and falling off of itself. Contact angle measurement and shear strength test have been introduced to investigate the interfacial property of CNTs-CF/EP composite. The result shows that the contact angle of resin to fiber has been reduced from ~39° to ~35° after oxidization, while the interfacial shear strength (IFSS) and interlaminar shear strength (ILSS) has been improved by 14.32% and 12.4% compared with untreated CNTs-CF/EP, respectively. A model is proposed to explain the wave-shaped fracture surface phenomenon of the composite. This work could reveal a novel approach to further improve the surface property of carbon fiber after growing carbon nanotubes.

Similar content being viewed by others

Data Availability

The datasets generated and studied during the current work are available form the corresponding author on reasonable request.

References

Peter, M.: Carbon Fibers and Their Composite. CRC Press, Boca Raton (2005)

Das, T.K., Ghosh, P., Das, N.C.: Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: a review. Adv. Compos. Hybrid. Mater. (2019). https://doi.org/10.1007/s42114-018-0072-z

Zheng, H., Zhang, W., Li, B., Zhu, J., Wang, C., Song, G., Ma, L.: Recent advances of interphases in carbon fiber-reinforced polymer composites: A review. Compos. B. Eng. (2022). https://doi.org/10.1016/j.compositesb.2022.109639

Alshammari, B.A., Alsuhybani, M.S., Almushaikeh, A.M., Alotaibi, B.M., Alenad, A.M., Alqahtani, N.B., Alharbi, A.G.: Comprehensive review of the properties and modifications of carbon fiber-reinforced thermoplastic composites. Polymers. 13(15), 2474 (2021). https://doi.org/10.3390/polym13152474

Liu, J., Chen, X., Liang, D., Xie, Q.: Development of pitch-based carbon fibers: a review. Energy. Sources. A. Recovery. Util. Environ. Eff. (2020). https://doi.org/10.1080/15567036.2020.1806952

Xu, B., Wang, X., Lu, Y.: Surface modification of polyacrylonitrile-based carbon fiber and its interaction with imide. Appl. Surf. Sci. 253(5), 2695–2701 (2006). https://doi.org/10.1016/j.apsusc.2006.05.044

Yuan, J.M., Fan, Z.F., Yang, Q.C., Li, W., Wu, Z.J.: Surface modification of carbon fibers by microwave etching for epoxy resin composite. Compos. Sci. Technol. 164, 222–228 (2018). https://doi.org/10.1016/j.compscitech.2018.05.043

Fu, J., Zhang, M., Jin, L., et al.: Enhancing interfacial properties of carbon fibers reinforced epoxy composites via Layer-by-Layer self assembly GO/SiO2 multilayers films on carbon fibers surface. Appl. Surf. Sci. 470, 543–554 (2019). https://doi.org/10.1016/j.apsusc.2018.11.168

He, M., Xu, P., Zhang, Y., Liu, K., Yang, X.: Phthalocyanine nanowires@ GO/carbon fiber composites with enhanced interfacial properties and electromagnetic interference shielding performance. Chem. Eng. J. 388, 124255 (2020). https://doi.org/10.1016/j.cej.2020.124255

Zheng, L., Wang, Y., Qin, J., Wang, X., Lu, R., Qu, C., Wang, C.: Scalable manufacturing of carbon nanotubes on continuous carbon fibers surface from chemical vapor deposition. Vacuum. 152, 84–90 (2018). https://doi.org/10.1016/j.vacuum.2018.03.011

Yao, Z., Wang, C., Qin, J., Su, S., Wang, Y., Wang, Q., Wei, H.: Interfacial improvement of carbon fiber/epoxy composites using one-step method for grafting carbon nanotubes on the fibers at ultra-low temperatures. Carbon. 164, 133–142 (2020). https://doi.org/10.1016/j.carbon.2020.03.060

Zhao, F., Huang, Y., Liu, L., Bai, Y., Xu, L.: Formation of a carbon fiber/polyhedral oligomeric silsesquioxane/carbon nanotube hybrid reinforcement and its effect on the interfacial properties of carbon fiber/epoxy composites. Carbon. 49(8), 2624–2632 (2011). https://doi.org/10.1016/j.carbon.2011.02.026

Giebel, E., Herrmann, T., Simon, F., Fery, A., Buchmeiser, M.R.: Surface Modification of Carbon Fibers by Free Radical Graft-Polymerization of 2-Hydroxyethyl Methacrylate for High Mechanical Strength Fiber-Matrix Composites. Macromol. Mater. Eng. 302(12), 1700210 (2017). https://doi.org/10.1002/mame.201700210

Stojcevski, F., Hilditch, T.B., Gengenbach, T.R., Henderson, L.C.: Effect of carbon fiber oxidization parameters and sizing deposition levels on the fiber-matrix interfacial shear strength. Compos. A. Appl. Sci. Manuf. 114, 212–224 (2018). https://doi.org/10.1016/j.compositesa.2018.08.022

Li, J., Sun, F.F.: The effect of nitric acid oxidization treatment on the interface of carbon fiber-reinforced thermoplastic polystyrene composite. Polym. Plast. Technol. Eng. 48(7), 711–715 (2009). https://doi.org/10.1080/03602550902824580

Wen, Z., Xu, C., Qian, X., Zhang, Y., Wang, X., Song, S., Zhang, C.: A two-step carbon fiber surface treatment and its effect on the interfacial properties of CF/EP composites: The electrochemical oxidation followed by grafting of silane coupling agent. Appl. Surf. Sci. 486, 546–554 (2019). https://doi.org/10.1016/j.apsusc.2019.04.248

Terrones, M.: Carbon nanotubes: synthesis and properties, electronic devices and other emerging applications. Int. Mater. Rev. 49(6), 325–377 (2004). https://doi.org/10.1179/174328004X5655

Brown, N.M., You, H.X.: A scanning tunnelling microscopy study of PAN-based carbon fibre in air. Surf. Sci. 237(1–3), 273–279 (1990). https://doi.org/10.1016/0039-6028(90)90539-K

Kara, M., Ak, S., Uyaner, M., Gunoz, A., Kepir, Y.: The effect of hydrothermal aging on the low-velocity impact behavior of multi-walled carbon nanotubes reinforced carbon fiber/epoxy composite pipes. Appl. Compos. Mater. 28(5), 1567–1587 (2021). https://doi.org/10.1007/s10443-021-09923-w

Çetin, M.E.: Investigation of carbon nanotube reinforcement to polyurethane adhesive for improving impact performance of carbon fiber composite sandwich panels. Int. J. Adhes. Adhes. 112, 103002 (2022). https://doi.org/10.1016/j.ijadhadh.2021.103002

Çetin, M.E.: The effect of carbon nanotubes modified polyurethane adhesive on the impact behavior of sandwich structures. Polym. Compos. 42(9), 4353–4365 (2021). https://doi.org/10.1002/pc.26153

Baker, R.T.K., Harris, P.S., Thomas, R.B., Waite, R.J.: Formation of filamentous carbon from iron, cobalt and chromium catalyzed decomposition of acetylene. J. Catal. 30, 86–95 (1973). https://doi.org/10.1016/0021-9517(73)90055-9

Makris, T.D., Giorgi, R., Lisi, N., Pilloni, L., Salernitano, E., De Riccardis, M.F., Carbone, D.: Carbon nanotube growth on PAN-and pitch-based carbon fibres by HFCVD. Fuller. Nanotub. Carbon. Nanostruct. 13(S1), 383–392 (2005). https://doi.org/10.1081/FST-200039380

Wang, W., Xia, Y., Zeng, L., Liang, J., Lei, D., Chen, S., Zhao, H.F.: Synthesis and characterization of carbon nanotubes on carbon microfibers by floating catalysts method. Appl. Surf. Sci. 253, 6807–6810 (2007). https://doi.org/10.1016/j.apsusc.2007.01.129

De Greef, N., Zhang, L., Magrez, A., Forró, L., Locquet, J.P., Verpoest, I., Seo, J.W.: Direct growth of carbon nanotubes on carbon fibers: Effect of the CVD parameters on the degradation of mechanical properties of carbon fibers. Diam. Relat. Mater. 51, 39–48 (2015). https://doi.org/10.1016/j.diamond.2014.11.002

Kumar, M., Ando, Y.: Chemical vapor deposition of carbon nanotubes: a review on growth mechanism and mass production. J. Nanosci. Nanotechnol. 10(6), 3739–3758 (2010). https://doi.org/10.1166/jnn.2010.2939

Pozegic, T.R., Hamerton, I., Anguita, J.V., Tang, W., Ballocchi, P., Jenkins, P., Silva, S.R.P.: Low temperature growth of carbon nanotubes on carbon fibre to create a highly networked fuzzy fibre reinforced composite with superior electrical conductivity. Carbon 74, 319–328 (2014). https://doi.org/10.1016/j.carbon.2014.03.038

Zhu, S., Su, C.H., Lehoczky, S.L., Muntele, I., Ila, D.: Carbon nanotube growth on carbon fibers. Diam. Relat. Mater. 12(10–11), 1825–1828 (2003). https://doi.org/10.1016/S0925-9635(03)00205-X

Fan, W., Wang, Y., Wang, C., Chen, J., Wang, Q., Yuan, Y., Niu, F.: High efficient preparation of carbon nanotube-grafted carbon fibers with the improved tensile strength. Appl. Surf. Sci. 364, 539–551 (2016). https://doi.org/10.1016/j.apsusc.2015.12.189

Qin, J., Wang, C., Lu, R., Su, S., Yao, Z., Zheng, L., Wei, H.: Uniform growth of carbon nanotubes on carbon fiber cloth after surface oxidation treatment to enhance interfacial strength of composites. Compos. Sci. Technol. 195, 108198 (2020). https://doi.org/10.1016/j.compscitech.2020.108198

Qin, J., Wang, C., Wang, Y., Su, S., Yao, Z., Ma, Z., Wei, H.: Preparation carbon nanotube-decorated carbon fibers under low pressure for epoxy-based unidirectional hierarchical composites with enhanced interlaminar shear strength. Polym. Test. 93, 106892 (2021). https://doi.org/10.1016/j.polymertesting.2020.106892

Khan, S., Bedi, H.S., Agnihotri, P.K.: Augmenting mode-II fracture toughness of carbon fiber/epoxy composites through carbon nanotube grafting. Eng. Fract. Mech. 204, 211–220 (2018). https://doi.org/10.1016/j.engfracmech.2018.10.014

Yao, Z., Wang, C., Lu, R., Su, S., Qin, J., Wang, Y., Wang, Q.: Fracture investigation of functionalized carbon nanotubes-grown carbon fiber fabrics/epoxy composites. Compos. Sci. Technol. 195, 108161 (2020). https://doi.org/10.1016/j.compscitech.2020.108161

Qin, J., Wang, C., Yao, Z., Ma, Z., Gao, Q., Wang, Y., Wei, H.: Growing carbon nanotubes on continuous carbon fibers to produce composites with improved interfacial properties: A step towards commercial production and application. Compos. Sci. Technol. 211, 108870 (2021). https://doi.org/10.1016/j.compscitech.2021.108870

Wang, X., Qian, X., Zhang, Y., Wang, X., Song, S., Zhang, C.: Surface oxidation of PAN-based ultrahigh modulus carbon fibers (UHMCFs) and its effect on the properties of UHMCF/EP composites. Carbon. Lett. 31(3), 449–461 (2021). https://doi.org/10.1007/s42823-020-00173-7

Lu, W.B., Wang, C.G., Yuan, H., Hu, X.Y.: Liquid-phase oxidation modification of carbon fiber surface. Adv. Mater. Res. 430, 2008–2012 (2012). https://doi.org/10.4028/www.scientific.net/AMR.430-432.2008

Gulyás, J., Földes, E., Lázár, A., Pukánszky, B.: Electrochemical oxidation of carbon fibres: surface chemistry and adhesion. Compos. A. Appl. Sci. Manuf. 32(3–4), 353–360 (2001). https://doi.org/10.1016/S1359-835X(00)00123-8

Bauer, M., Beratz, S., Ruhland, K., Horn, S., Moosburger-Will, J.: Anodic oxidation of carbon fibers in alkaline and acidic electrolyte: Quantification of surface functional groups by gas-phase derivatization. Appl. Surf. Sci. 506, 144947 (2020). https://doi.org/10.1016/j.apsusc.2019.144947

Sun, Y., Lu, Y., Yang, C.: Stripping mechanism of PAN-based carbon fiber during anodic oxidation in NaOH electrolyte. Appl. Surf. Sci. 486, 128–136 (2019). https://doi.org/10.1016/j.apsusc.2019.05.018

Xing, Y., Deng, S., Feng, S., Wang, Q., Hou, Y.: Selective oxidation of carbon to enhance both tensile strength and interfacial adhesion of carbon fiber. J. Adhes. (2018). https://doi.org/10.1080/00218464.2018.1528152

Li, W., Li, R., Li, C., Zhang, L.: Surface characterization and electrical property of carbon fibers modified by air oxidation. Surf. Interface. Anal. 47(3), 325–330 (2015). https://doi.org/10.1002/sia.5711

Wang, M.W.: Alignment and Surface Modification of Multiwall Carbon Nanotubes Polymeric Composites. Adv. Mater. Res. 881, 872–881 (2014). https://doi.org/10.4028/www.scientific.net/AMR.881-883.872

Wang, S.: Optimum degree of functionalization for carbon nanotubes. Curr. Appl. Phys. 9(5), 1146–1150 (2009). https://doi.org/10.1016/j.cap.2009.01.004

Meena, S., Choudhary, S.: Effects of functionalization of carbon nanotubes on its spin transport properties. Mater. Chem. Phys. 217, 175–181 (2018). https://doi.org/10.1016/j.matchemphys.2018.06.077

Valipour, P., Ghasemi, S.E., Khosravani, M.R., Ganji, D.D.: Theoretical analysis on nonlinear vibration of fluid flow in single-walled carbon nanotube. J. Theor. Appl. Phys. 10(3), 211–218 (2016). https://doi.org/10.1007/s40094-016-0217-9

Bai, Y., Wu, F., Lin, D., Xing, B.: Aqueous stabilization of carbon nanotubes: effects of surface oxidization and solution chemistry. Environ. Sci. Pollut. Res. 21(6), 4358–4365 (2014). https://doi.org/10.1007/s11356-013-2304-7

Siva, R., Valarmathi, T.N., Palanikumar, K., Samrot, A.V.: Study on a Novel natural cellulosic fiber from Kigelia africana fruit: Characterization and analysis. Carbohyd. Polym. 244, 116494 (2020). https://doi.org/10.1016/j.carbpol.2020.116494

Selvan, M.T.G.A., Binoj, J.S., Moses, J.T.E.J., Sai, N.P., Siengchin, S., Sanjay, M.R., Liu, Y.: Extraction and characterization of natural cellulosic fiber from fragrant screw pine prop roots as potential reinforcement for polymer composites. Polym. Compos. 43(1), 320–329 (2022). https://doi.org/10.1002/pc.26376

Liu, J., Bai, Y., Tian, Y., Huang, X., Wang, C., Liang, J.: Effect of the process of electrochemical modification on the surface structure and properties of PAN-based carbon fibers. Acta. Mater. Compos. Sin. 29(2), 16–25 (2012). https://doi.org/10.13801/j.cnki.fhclxb.2012.02.008

Fairley, N., Fernandez, V., Richard-Plouet, M.J., et al.: Systematic and collaborative approach to problem solving using X-ray photoelectron spectroscopy. Appl. Surf. Sci. Adv. 5, 100112 (2021). https://doi.org/10.1016/j.apsadv.2021.100112

Hinterreiter, A.P., Duchoslav, J., Kehrer, M., Truglas, T., Lumetzberger, A., Unterweger, C., Stifter, D.: Determination of the surface chemistry of ozone-treated carbon fibers by highly consistent evaluation of X-ray photoelectron spectra. Carbon 146, 97–105 (2019). https://doi.org/10.1016/j.carbon.2019.01.081

Kettle, A.P., Beck, A.J., O’toole, L., Jones, F.R., Short, R.D.: Plasma polymerisation for molecular engineering of carbon-fibre surfaces for optimised composites. Compos. Sci. Technol. 57(8), 1023–1032 (1997). https://doi.org/10.1016/S0266-3538(96)00162-5

Xu, X., Huang, S., Hu, Y., Lu, J., Yang, Z.: Continuous synthesis of carbon nanotubes using a metal-free catalyst by CVD. Mater. Chem. Phys. 133(1), 95–102 (2012). https://doi.org/10.1016/j.matchemphys.2011.12.059

Kim, K.J., Yu, W.R., Youk, J.H., Lee, J.: Degradation and healing mechanisms of carbon fibers during the catalytic growth of carbon nanotubes on their surfaces. ACS. Appl. Mater. Interfaces. 4(4), 2250–2258 (2012). https://doi.org/10.1021/am3002499

Naito, K., Yang, J.M., Inoue, Y., Fukuda, H.: The effect of surface modification with carbon nanotubes upon the tensile strength and Weibull modulus of carbon fibers. J. Mater. Sci. 47(23), 8044–8051 (2012). https://doi.org/10.1007/s10853-012-6694-6

Bamane, S.S., Gaikwad, P.S., Radue, M.S., Gowtham, S., Odegard, G.M.: Wetting Simulations of High-Performance Polymer Resins on Carbon Surfaces as a Function of Temperature Using Molecular Dynamics. Polymers 13(13), 2162 (2021). https://doi.org/10.3390/polym13132162

Lee, J., Kessler, S.S., Wardle, B.L.: Void-Free Layered Polymeric Architectures via Capillary-Action of Nanoporous Films. Adv. Mater. Interfaces. 7(4), 1901427 (2020). https://doi.org/10.1002/admi.201901427

Funding

This paper has no known competing financial interest or personal relationships that could have appeared to influence the reported work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, C., Chen, G., Wang, Q. et al. Improving Surface Property of Carbon Nanotube Grown Carbon Fiber by Oxidization Post-treatment. Appl Compos Mater 29, 1695–1713 (2022). https://doi.org/10.1007/s10443-022-10032-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-022-10032-5