Abstract

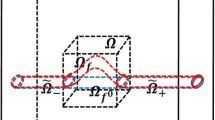

Low volume fraction (~ 3%) chopped fiber reinforced resin matrix composites have both structural toughness and strength. In this work, bisphenol F epoxy resin was used as the matrix, which has low viscosity and high strength, so it is not easy to make fiber agglomeration. The aim of this study is to explore the size effect and the response of directional modulus to the dispersion angle in the homogenization process with low volume fraction (~ 1.24%) chopped fiber reinforced resin based RVE structure. In this work, a novel mesoscale chopped fiber filled resin matrix random field algorithm named spatial direction sensitive Hotelling expansion (SDSHE) is proposed to study the change of composite properties caused by the random distribution of chopped carbon fiber (CCF) unit cells (UCs) in the representative volume element (RVE) structure. Meanwhile, several influencing factors to the size effect in these RVEs structure are also studied. A post-processing scheme of subdomain in RVE structure based on Gauss theorem is proposed for the first time. Namely, the volume integral of the continuously differentiable vector field (displacement, force, et al.) in the subdomain calculated by finite element method is extracted, which is used to calculate the average strain and stress in three-dimensional structure. The results shows that the SDHSE algorithm matches well with low volume fraction chopped carbon fiber reinforced composites, and based on the generated RVEs, the decay length t is 0-21 μm, the average directive modulus also appear respective sensitivities with rotation angles.

Similar content being viewed by others

Data Availability

The authors confirm that the data supporting the findings of this study are available within the article, cited references and its supplementary data.

References

Naili, C., Doghri, I., Kanit, T., Sukiman, M. S., Aissa-Berraies, A., Imad, A.: Short fiber reinforced composites: Unbiased full-field evaluation of various homogenization methods in elasticity. Compos. Sci. Technol. 187, 107942 (2020)

Monfared, V.: Problems in short-fiber composites and analysis of chopped fiber-reinforced materials. New Mater. Civ. Eng. 919–1043 (2020)

Huang, H.B., Huang, Z.M.: Micromechanical prediction of elastic-plastic behavior of a short fiber or particle reinforced composite. Composites Part A: Appl. Sci. Manuf. 134, 105889 (2020)

Yuan, M., Yang, Y., Zhao, H., Wang, Y., Li, R., Zhang, B.: A novel trans-scale method for predicting mode I matrix crack density of composite laminates. Compos. Struct. 235, 111726 (2020)

Tohidi, S.D., Rocha, A.M., Dourado, N., Rezazadeh, M., Quyền, N.T., Zille, A., Hesseler, S., Gries, T., Dencheva, N. V., Denchev. Z.: Influence of transcrystalline layer on finite element mesoscale modeling of polyamide 6 based single polymer laminate composites. Compos. Struct. 232, 111555 (2020)

Qi, S., Shi, P., Yan, C., Imran, A., Liu, D., Zhu, Y., Herrmann, A. S.: Damage model based on gradient property method for simulating the tensile behavior of composite laminates with Variable Angle Tow reinforcement. Struct. 23, 152–163 (2020)

Zhao, J., Su, D.X. Yi, J.M. Cheng, G., Turng, L.S. Osswald, T.: The effect of micromechanics models on mechanical property predictions for short fiber composites. Compos. Struct. 244, 112229 (2020)

Wang, Z., Smith, D.E.: Numerical analysis on viscoelastic creep responses of aligned short fiber reinforced composites. Compos. Struct. 229, 111394 (2019)

Tang, H., Chen, H., Sun, Q., Chen, Z. Yan, W.: Experimental and computational analysis of structureproperty relationship in carbon fiber reinforced polymer composites fabricated by selective laser sintering. Compos. Part B: Eng. 204, 108499 (2021)

Zhong, Y., Liu, P., Pei, Q., Sorkin, V., Louis, A., Commillus, Z., Su, T., Guo, W., Thitsartarn, T., Lin, C., He, Zhang Y.W.: Elastic properties of injection molded short glass fiber reinforced thermoplastic composites. Compos. Struct. 254, 112850 (2020)

Rawlings, R.D., Matthews. F.L.: Composite Materials Engineering and Science. Woodhead Publishing. (1999)

Tang, H., Chen, Z., Xu, H., Liu, Z., Sun, Q., Zhou G., Yan, W., Han, W., Su, X.: Computational micromechanics model based failure criteria for chopped carbon fiber sheet molding compound composites. Compos Sci Technol. 200, 108400 (2020)

Chen, Z., Tang, H., Shao, Y., Sun, Q., Zhou, G., Li, Y., Xu, H., Zeng, D., Su, X.: Failure of chopped carbon fiber Sheet Molding Compound (SMC) composites under uniaxial tensile loading: Computational prediction and experimental analysis. Composites Part A: Appl. Sci. Manuf. 118, 117–130 (2019)

Tang, H., Chen, Z., Avinesh, O., Guo, H., Meng, Z., Engler-Pinto C., Kang H., Su, X.: Notch insensitivity in fatigue failure of chopped carbon fiber chip-reinforced composites using experimental and computational analysis. Compos. Struct. 244, 112280 (2020)

Naya, F., Herráez, M., Lopes, C.S., González, C., Van der Veen, S., Pons, F.: Computational micromechanics of fiber kinking in unidirectional FRP under different environmental conditions. Compos. Sci. Technol. 144, 26–35 (2017)

Pimenta, S., Gutkin, R., Pinho, S.T., Robinson, P.: A micromechanical model for kink-band formation: Part I — Experimental study and numerical modelling. Compos. Sci. Technol. 69, 948–955 (2009)

Savvas, D., Stefanou, G., Papadopoulos, V., Papadrakakis, M.: Effect of waviness and orientation of carbon nanotubes on random apparent material properties and RVE size of CNT reinforced composites. Compos. Struct. 152, 870–882 (2016)

Hsiao, H.M., Daniel, I.M.: Elastic properties of composites with fiber waviness. Compos. A 27A, 931–941 (1996)

Hill, R.: On constitutive macro-variables for heterogeneous solids at finite strain. Proceedings of the Royal Society of London. A. Math. Phys. Sci. 326, 131–147 (1972)

Ogden R.W.: On the overall moduli of non-linear elastic composite materials. J. Mech. Phys. Solids. 22, 541–553 (1974)

Castaneda, P.P.: Second-order homogenization estimates for nonlinear composites in corporating field fluctuations: I – theory. J. Mech. Phys. Solids. 50, 737–757 (2002)

Castaneda, P.P.: Exact second-order estimates for the effective mechanical properties of nonlinear composite materials. J. Mech. Phys. Solids. 44, 827–862 (1996)

Kouznetsova, M.G.D.G. V.G., Brekelmans, W.A.M.: Multi-scale second-order computational homogenization of multi-phase materials: a nested finite element solution strategy. Comput. Methods Appl. Mech. Eng. 193, 5525–5550 (2004)

Heidari-Rarani, M., Bashandeh-Khodaei-Naeini, K.: Micromechanics based damage model for predicting compression behavior of polymer concretes. Mech. Mater. 117, 126–136 (2018)

Chen, L., Gu, B., Tao, J., Zhou, J.: The average response and isotropy of 3D representative volume elements for random distributed short fibers reinforced elastomer. Compos. Struct. 216, 279–289 (2019)

Caylak, I., Penner, E., Mahnken, R.: Mean-field and full-field homogenization with polymorphic uncertain geometry and material parameters. Comput. Methods Appl. Mech. Eng. 373, 113439 (2021)

Ghaboussi, B.J.: Knowledge-based modeling of material behavior with neural networks. J. Eng. Mech. 117, 132–153 (1991)

Lefik, M., Schrefler, B.A.: Artificial neural network as an incremental non-linear constitutive model for a finite element code. Comput. Methods Appl. Mech. Eng. 192, 3265–3283 (2003)

Jung, S., Ghaboussi, J.: Neural network constitutive model for rate-dependent materials. Comput. Struct. 84, 955–963 (2006)

Graf, S.F.W., Kaliske, M., Sickert J.U.: Recurrent neural networks for uncertain time-dependent structural behaviour. Comput. Aided. Civ. Inf. Eng. 25, 322-333 (2010), 322–333 (2010)

Martin, C.P., Osborne, J.: Equilibrium in Hotelling’s Model of Spatial Competition. Econometrica Society. 55, 911–922 (1987)

Lusti, H.R., Gusev, A.A.: Finite element predictions for the thermoelastic properties of nanotube reinforced polymers. Model. Simul. Mater. Sci. Eng. 12, S107-S119 (2004)

Mortazavi, B., Baniassadi, M., Bardon, J., Ahzi, S.: Modeling of two-phase random composite materials by finite element, Mori–Tanaka and strong contrast methods. Compos. Part B: Eng. 45, 1117–1125 (2013)

Heidari-Rarani, M., Bashandeh-Khodaei-Naeini, K., Mirkhalaf, S.M.: Micromechanical modeling of the mechanical behavior of unidirectional composites – A comparative study. J. Reinf. Plast. Compos. 37, 1051–1071 (2018)

Li, Y., Li, Y.: Evaluation of elastic properties of fiber reinforced concrete with homogenization theory and finite element simulation. Constr. Build. Mater. 200, 301–309 (2019)

Halpin, J.C., AFFDL: The Halpin-Tsai Equations: A Review. Polym. Eng. Sci. 15, 344–352 (1976)

Liu, Z., Bessa, M.A., Liu, W.K.: Self-consistent clustering analysis: An efficient multi-scale scheme for inelastic heterogeneous materials. Comput. Methods Appl. Mech. Eng. 306, 319–341 (2016)

Logarzo, H.J., Capuano, G., Rimoli. J.J.: Smart constitutive laws: Inelastic homogenization through machine learning. Comput. Methods Appl Mech. Eng. 373, 113482 (2021)

Spahn, J., Andrä, H., Kabel, M., Müller. R.: A multiscale approach for modeling progressive damage of composite materials using fast Fourier transforms. Comput. Methods Appl. Mech. Eng. 268, 871–883 (2014)

Shang, S., Yun, G.J.: Stochastic finite element with material uncertainties: Implementation in a general purpose simulation program. Finite Elem. Anal. Des. 64, 65–78 (2013)

Assami et al.: Improving delamination strength through CNTs reinforcement: Numerical simulation. ECCM-17. (2017)

Anumandla, V., Gibson, R.F.: A comprehensive closed form micromechanics model for estimating the elastic modulus of nanotube-reinforced composites. Composites Part A: Appl. Sci. Manuf. 37, 2178–2185 (2006)

Chamis, C.C.: Simplified composite micromechanics equations for hygral, thermal, and mechanicalproperties, in: NASA (Ed.) NASA Technical Memorandum 83320 Composite Institute, Houston, Texas, (1984)

Jang, D.P. Fazily, P. Yoon, J.W.: Machine learning-based constitutive model for J2- plasticity. International J. Plast. 138, 102919 (2021)

Unal, B.: Divergence Theorems in Semi-Riemannian Geometry. Acta Appl. Math. 40, 173–178 (1995)

Abedin, F., Tahreen, F., Masud, A.K.M.: Effects of Interphase and Matrix Properties on Effective Tensile Elastic Modulus of Carbon Nanotube-Based Composite. J. Mech. Eng. 40, 29–38 (2009)

Trias, D., Costa, J., Turon, A., Hurtado, J.E.: Determination of the critical size of a statistical representative volume element (SRVE) for carbon reinforced polymers. Acta Materialia. 54, 3471–3484 (2006)

Hill, R.: Elastic properties of reinforced solids: some theoretical principles. J . Mech. Phys. Solids. 11, 357–372 (1963)

Harper, L.T., Qian, C., Turner, T.A., Li, S., Warrior, N.A.: Representative volume elements for discontinuous carbon fibre composites – Part 2: Determining the critical size. Compos. Sci. Technol. 72, 204–210 (2012)

Liu, Q., Lomov, S.V., Gorbatikh, L.: The interplay between multiple toughening mechanisms in nanocomposites with spatially distributed and oriented carbon nanotubes as revealed by dual-scale simulations. Carbon. 142, 141–149 (2019)

Acknowledgements

This work was supported by the National Natural Science Foundation of China, (No. 51561010). Jiangxi Province Key Research and Development Projects of China (No. 20192BBE50033, 20202BBEL53031, 20161BBH80062), Major Scientific Research Project of Jiangxi Academy of Sciences, China (No. 2020-YZD-2).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix. Related algorithms of this work

Appendix. Related algorithms of this work

Algorithm 1 Space Direction-sensitive Hotelling expansion |

|---|

Input: The RVE length L, Vccf, and Fiber length limits (Llower < Lccf < Lhigher,) |

Output: The position Si and random orientation Rij (x, y, z, δ) of the fibers |

1: Create a cubic matrix with size of L × L × L and oriented along the axes x’, y’ and z’ of the global Cartesian coordinate system of RVE x’ y’ z’; |

2: Set one of matrix corners as the origin of the coordinate system x’ y’ z’; |

3: Generate a given Vccf = vf (or fiber number Nf) of fibers within the UC by algorithm 2; |

4: repeat: |

5: Generate a new candidate fiber i with position Si with (xi, yi, zi) by Eq. (9) and a random length Llower < Li < Lhigher with Weibull distribution by algorithm 2; |

6: for each generated fiber i do: |

7: Assign a random fluctuation < \(\theta_{i}^{rd}(x,y,z,\delta)\)> with Eq. (16) |

8: If the fiber i collides or intersects with the RVE surfaces then: |

9: Create fiber i’s periodic image(s) ip using the method of algorithm 3; |

10: end if |

11: Check for penetration of fiber i with other fibers; |

12: If fiber i without any penetration then: |

13: Create the fiber and record Si and random fluctuation < \(\theta_{i}^{rd}(x,y,z,\delta)\)>; |

14: else If fiber i penetrate with fiber j (i > j) then: |

15: readjustment < \(\theta_{i}^{rd}(x,y,z,\delta)\)> and recheck penetration of fiber i; |

16: If step 12 repeated over 5 times and penetration check failed then: |

17: Delete Si and < \(\theta_{i}^{rd}(x,y,z,\delta)\)> and return to step 5; |

18: until fiber i with no penetration; |

19: end if |

20: end if |

21: Initialize the vf = vcurrent, Fiber number Nf = Ncurrent; |

22: end for |

23: until (vcurrent ≥ Vccf), Record Nf = N, and extract RVE model |

Algorithm 2 Generate a given UC with wavy fiber and interphase |

|---|

Input: Fiber radius dccf and average length with a random length Llower < Li < Lhigher, matrix length Lm/Li ∈ (0,1), crimp amplitude A, crimp period length ω, and radius of interphase di |

Output: stochastic UCs |

1: Initialize the vf = 0 and fiber number Nf = 0; |

2: repeat: |

3:for the fiber number i do: |

4: Generate a candidate wavy fiber i with stochastic by a spatial random field H (x, y, z, δ) with Eq. 9. The length of fiber i submit to Weibull distribution, the waviness, thickness and interphase also generated according to input parameters; |

5: Record the origin of UC coordinates Si with coordinate value (xi, yi, zi); |

6: Create a cubic matrix of UC structure with size of (A + di) × (A + di) × (Li + Lm) and oriented along the axes xi in UC coordinate system. And set the point (xi-Lm/2, yi + (A + di)/2, zi + (A + di)/2) as matrix corners of UC; |

7: Calculate the current Fredholm integral equation according Eq. 10 and 11 get current value of λi, and φi; |

8: Update Eq. 9 with λi, and φi and get spatial random field H (x, y, z, δ) for fiber i + 1 and update current vf = vi, Nf = Ni; |

9: end for |

10: until (vf ≥ Vccf) |

Algorithm 3 Periodic boundary conditions |

|---|

Given a position Sf, length Lf of fiber f and length L of the cubic RVE, periodic images number Np of fiber f depends on the RVE surfaces number Ns that collide or intersect with fiber |

f, and the periodic filling algorithm is given as follows: |

(i) Np = 1 if and only if -Lf/2 < Sf,i < Lf/2 or L-Lf/2 ≤ Sf,i ≤ L + Lf/2 with i ∈ {1,2,3}; |

(ii) Np = 3 if and only if (-Lf/2 < Sf,i < Lf/2 or L-Lf/2 ≤ Sf,i ≤ L + Lf/2) and (-Lf/2 < Sf,j < Lf/2 or L-Lf/2 ≤ Sf,j ≤ L + Lf/2) with i ∈ {1,2}, j ∈ {2,3} and i ≠ j; |

(iii) Np = 7 if and only if (-Lf/2 < Sf,i < Lf/2 or L-Lf/2 ≤ Sf,i ≤ L + Lf/2) and (-Lf/2 < Sf,j < Lf/2 or L-Lf/2 ≤ Sf,j ≤ L + Lf/2) and (-Lf/2 < Sf,k < Lf/2 or L-Lf/2 ≤ Sf,k ≤ L + Lf/2) with i = 1, j = 2, and k = 3 |

The position Sf,p of the periodic images of the fiber f are determined by equation: Sf,p = Sf-vf,p with p ∈ {1,2,…,Np} |

Where vf,p is shifted vector of the periodic image p regarding the fiber f. The components of vector vf,p takes the value of {-L,0,L}. Denote the vectors V1 = (-L,0,0), V2 = (0,-L,0), V3 = (0,0,-L), V4 = (L,0,0), V5 = (0,L,0), V6 = (0,0,L), and the components of the vector vf,p can be determined as: |

(i) For the case of Np = 1 |

(1) if and only if -Lf/2 < Sf,i ≤ Lf/2: vf,p=1 = Vi with i ∈ {1,2,3}; |

(2) if and only if L-Lf/2 ≤ Sf,i < L + Lf/2:vf,p=1 = Vi+3 with i ∈ {1,2,3} |

(ii) For the case of Np = 3 |

(1) if and only if -Lf/2 < Sf,i ≤ Lf/2 and -Lf/2 < Sf,j ≤ Lf/2:vf,p=1 = Vi,vf,p=2 = Vj and vf,p=3 = Vi + Vj with i ∈ {1,2}, j ∈ {2,3} and i ≠ j; |

(2) if and only if L-Lf/2 ≤ Sf,i < L + Lf/2 and -Lf/2 < Sf,j ≤ Lf/2:vf,p=1 = Vi+3,vf,p=2 = Vj and vf,p=3 = Vi+3 + Vj with i ∈ {1,2}, j ∈ {2,3} and i ≠ j; |

(3) if and only if -Lf/2 < Sf,i ≤ Lf/2 and L-Lf/2 ≤ Sf,j < L + Lf/2:vf,p=1 = Vi,vf,p=2 = Vj+3 and vf,p=3 = Vi + Vj+3 with i ∈ {1,2}, j ∈ {2,3} and i ≠ j; |

(4) if and only if L-Lf/2 ≤ Sf,i < L + Lf/2 and L-Lf/2 ≤ Sf,j < L + Lf/2:vf,p=1 = Vi+3 and vf,p=2 = Vj+3 and vf,p=3 = Vi+3 + Vj+3 with i ∈ {1,2}, j ∈ {2,3} and i ≠ j |

(iii) For the case of Np = 7 |

(1) if and only if -Lf/2 < Sf,i ≤ Lf/2 and -Lf/2 < Sf,j ≤ Lf/2 and -Lf/2 < Sf,k ≤ Lf/2:vf,p=1 = Vi,vf,p=2 = Vj, vf,p=3 = Vk, vf,p=4 = Vi + Vj, vf,p=5 = Vi + Vk, vf,p=6 = Vj + Vk and vf,p=7 = Vi + Vj + Vk with i = 1, j = 2 and k = 3; |

(2) if and only if L-Lf/2 ≤ Sf,i < L + Lf/2 and -Lf/2 < Sf,j ≤ Lf/2 and -Lf/2 < Sf,k ≤ Lf/2:vf,p=1 = Vi+3,vf,p=2 = Vj, vf,p=3 = Vk, vf,p=4 = Vi+3 + Vj, vf,p=5 = Vi+3 + Vk, vf,p=6 = Vj + Vk and vf,p=7 = Vi+3 + Vj + Vk with i = 1, j = 2 and k = 3; |

(3) if and only if -Lf/2 < Sf,i ≤ Lf/2 and L-Lf/2 ≤ Sf,j < L + Lf/2 and -Lf/2 < Sf,k ≤ Lf/2:vf,p=1 = Vi,vf,p=2 = Vj+3, vf,p=3 = Vk, vf,p=4 = Vi + Vj+3, vf,p=5 = Vi + Vk, vf,p=6 = Vj+3 + Vk and vf,p=7 = Vi + Vj+3 + Vk with i = 1, j = 2 and k = 3; |

(4) if and only if -Lf/2 < Sf,i ≤ Lf/2 and -Lf/2 < Sf,j ≤ Lf/2 and L-Lf/2 ≤ Sf,k < L + Lf/2:vf,p=1 = Vi,vf,p=2 = Vj, vf,p=3 = Vk+3, vf,p=4 = Vi + Vj, vf,p=5 = Vi + Vk+3, vf,p=6 = Vj + Vk+3 and vf,p=7 = Vi + Vj + Vk+3 with i = 1, j = 2 and k = 3; |

(5) if and only if L-Lf/2 ≤ Sf,i < L + Lf/2 and L-Lf/2 ≤ Sf,j < L + Lf/2 and -Lf/2 < Sf,k ≤ Lf/2:vf,p=1 = Vi+3, vf,p=2 = Vj+3, vf,p=3 = Vk, vf,p=4 = Vi+3 + Vj+3, vf,p=5 = Vi+3 + Vk, vf,p=6 = Vj+3 + Vk and vf,p=7 = Vi+3 + Vj+3 + Vk with i = 1, j = 2 and k = 3; |

(6) if and only if L-Lf/2 ≤ Sf,i < L + Lf/2 and -Lf/2 < Sf,j ≤ Lf/2 and L-Lf/2 ≤ Sf,k < L + Lf/2:vf,p=1 = Vi+3,vf,p=2 = Vj, vf,p=3 = Vk+3, vf,p=4 = Vi+3 + Vj, vf,p=5 = Vi+3 + Vk+3, vf,p=6 = Vj + Vk+3 and vf,p=7 = Vi+3 + Vj + Vk+3 with i = 1, j = 2 and k = 3; |

(7) if and only if -Lf/2 < Sf,i ≤ Lf/2 and L-Lf/2 ≤ Sf,j < L + Lf/2 and L-Lf/2 ≤ Sf,k < L + Lf/2:vf,p=1 = Vi,vf,p=2 = Vj+3, vf,p=3 = Vk+3, vf,p=4 = Vi + Vj+3, vf,p=5 = Vi + Vk+3, vf,p=6 = Vj+3 + Vk+3 and vf,p=7 = Vi + Vj+3 + Vk+3 with i = 1, j = 2 and k = 3; |

(8) if and only if L-Lf/2 ≤ Sf,i < L + Lf/2 and L-Lf/2 ≤ Sf,j < L + Lf/2 and L-Lf/2 ≤ Sf,k < L + Lf/2:vf,p=1 = Vi+3, vf,p=2 = Vj+3, vf,p=3 = Vk+3, vf,p=4 = Vi+3 + Vj+3, vf,p=5 = Vi+3 + Vk+3, vf,p=6 = Vj+3 + Vk+3 and vf,p=7 = Vi+3 + Vj+3 + Vk+3 with i = 1, j = 2 and k = 3 |

Rights and permissions

About this article

Cite this article

Liu, J., Fu, Y., Chen, Y. et al. A Novel Algorithm in Stochastic Chopped Carbon Fiber Composite Structure-A Study of RVE Size Effect and Homogenization Response of Directional Modulus. Appl Compos Mater 29, 565–595 (2022). https://doi.org/10.1007/s10443-021-09947-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-021-09947-2