Abstract

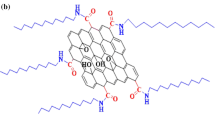

This work presents the influence of functionalised graphene nanoplatelets (f-GnPs) and functionalised glass fibers (f-fiber) on the tensile strength and the fracture toughness of the GFRP composites. The functionalization on the glass fabric and GnPs was performed by using 3-Aminopropyltriethoxysilane (APTS) as a coupling agent and confirmed by Fourier Transform Infrared (FTIR) Spectroscopy. The GnPs (non-functionalised and functionalised) with 0.1 wt% was introduced in the composites in two different ways, (1) dispersing GnPs/f-GnPs in epoxy; (2) depositing GnPs/f-GnPs on the functionalized fiber (f-fiber) surface. The mechanical properties, such as tensile strength and Mode I fracture toughness of the multi-phase composites were investigated. The longitudinal intra-laminar Mode I fracture toughness test was performed on the compact tension (CT) specimens by using the digital image correlation (DIC) technique to perform the fracture control study. The tensile fracture surface morphology of the composites was examined by Scanning Electron Microscope (SEM). The tensile strength of the composites with f-GnPs deposited on the f-Fiber outperformed the unmodified composites with 16% enhancement owing to the strong fiber/matrix interface bonding developed by f-GnPs. The composites with f-GnPs dispersed in the matrix showed an increase in the fracture toughness (KIC) of 76% over the unmodified composites. The effects of the f-GnPs dispersed in the matrix showed good interfacial adhesion, while the composites with f-GnPs deposited on the f-Fibers showed poor fiber/matrix adhesion, as observed in the tensile fractography of the composites.

Similar content being viewed by others

Abbreviations

- GFs:

-

Glass Fibers

- GFRP:

-

Glass fiber reinforced polymer

- UD:

-

Unidirectional fiber

- GnPs:

-

Graphene Nanoplatelets

- f-GnPs:

-

Functionalized Graphene Nanoplatelets

- f-Fiber:

-

Functionalized Fiber

- APTS:

-

3-Aminopropyltriethoxysilane

- wt%:

-

Weight percentage

- Pristine:

-

Neat Fiber and Neat Epoxy

- f-Pristine:

-

f-Fiber and Neat Epoxy

- GE:

-

Neat GnPs in Epoxy

- f-GE:

-

f-GnPs in Epoxy

- GF:

-

Neat GnPs on Fiber

- f-GF:

-

f-GnPs on f-Fiber

- FTIR:

-

Fourier- transform infrared spectroscopy

- SEM:

-

Scanning Electron Microscope

References

Karger-Kocsis, J., Mahmood, H., Pegoretti, A.: Recent advances in fiber/matrix interphase engineering for polymer composites. Prog. Mater Sci. 73, 1–43 (2015). https://doi.org/10.1016/j.pmatsci.2015.02.003

Nagasankar, P., Balasivanandha Prabu, S., Velmurugan, R.: Role of different fiber orientations and thicknesses of the skins and the core on the transverse shear damping of polypropylene honeycomb sandwich structures, Mechanics of Materials. 91, 252–261 (2015). https://doi.org/10.1016/j.mechmat.2015.08.002

Hoffmann, J., Sabban, J., Scharr, G.: Pullout performance of circumferentially notched z-pins in carbon fiber reinforced laminates. Compos. A Appl. Sci. Manuf. 110, 197–202 (2018). https://doi.org/10.1016/j.compositesa.2018.05.002

Yekani Fard, M., Raji, B., Woodward, J., Padilla, M.: Experimental characterization of damage mechanisms of seamless net-shaped circular pre-form and overlapped stitched composite pipes, Polymer Testing. 78, 105934 (2019).https://doi.org/10.1016/j.polymertesting.2019.105934

Dell’Anno, G., Treiber, J.W.G., Partridge, I.K.: Manufacturing of composite parts reinforced through-thickness by tufting. Robotics and Computer-Integrated Manufacturing. 37, 262–272 (2016). https://doi.org/10.1016/j.rcim.2015.04.004

Zhang, P., Zhou, W., Yin, H., Shang, Y.: Progressive damage analysis of three-dimensional braided composites under flexural load by micro-CT and acoustic emission. Compos. Struct. 226, 111196 (2019). https://doi.org/10.1016/j.compstruct.2019.111196

Keszei, S., Matkó, S., Bertalan, G., Anna, P., Marosi, G., Tóth, A.: Progress in interface modifications: from compatibilization to adaptive and smart interphases. Eur. Polymer J. 41, 697–705 (2005). https://doi.org/10.1016/j.eurpolymj.2004.10.039

Miller, S.G., Bauer, J.L., Maryanski, M.J., Heimann, P.J., Barlow, J.P., Gosau, J.M., Allred, R.E.: Characterization of epoxy functionalized graphite nanoparticles and the physical properties of epoxy matrix nanocomposites. Compos. Sci. Technol. 70, 1120–1125 (2010). https://doi.org/10.1016/j.compscitech.2010.02.023

Barakat, N.A.M., Khalil, K.A., Kim, H.Y.: Toward facile synthesizing of diamond nanostructures via nanotechnological approach: Lonsdaleite carbon nanofibers by electrospinning. Mater. Res. Bull. 47, 2140–2147 (2012). https://doi.org/10.1016/j.materresbull.2012.06.012

Biswas, M., Sinha Ray, S.: A conducting nanocomposite of poly(N-vinylcarbazole) with buckminsterfullerene, Synthetic Metals. 123, 135–139 (2001). https://doi.org/10.1016/S0379-6779(00)01382-5

Ma, P.C., Siddiqui, N.A., Marom, G., Kim, J.K.: Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. A Appl. Sci. Manuf. 41, 1345–1367 (2010). https://doi.org/10.1016/j.compositesa.2010.07.003

Potts, J.R., Dreyer, D.R., Bielawski, C.W., Ruoff, R.S.: Graphene-based polymer nanocomposites. Polymer 52, 5–25 (2011). https://doi.org/10.1016/j.polymer.2010.11.042

Singh, V., Joung, D., Zhai, L., Das, S., Khondaker, S.I., Seal, S.: Graphene based materials: Past, present and future. Prog. Mater Sci. 56, 1178–1271 (2011). https://doi.org/10.1016/j.pmatsci.2011.03.003

Geim, A.K., Novoselov, K.S.: The rise of graphene. Nat. Mater. 6, 183–191 (2007). https://doi.org/10.1038/nmat1849

Valorosi, F., De Meo, E., Blanco-Varela, T., Martorana, B., Veca, A., Pugno, N., Kinloch, I.A., Anagnostopoulos, G., Galiotis, C., Bertocchi, F., Gomez, J., Treossi, E., Young, R.J., Palermo, V.: Graphene and related materials in hierarchical fiber composites: Production techniques and key industrial benefits. Compos. Sci. Technol. 185, 107848 (2020). https://doi.org/10.1016/j.compscitech.2019.107848

Rafiee, M.A., Rafiee, J., Wang, Z., Song, H., Yu, Z., Koratkar, N.: Enhanced Mechanical Properties of Nanocomposites at Low Graphene Content. ACS Nano 3, 3884–3890 (2009). https://doi.org/10.1021/nn9010472

Mahmood, H., Tripathi, M., Pugno, N., Pegoretti, A.: Enhancement of interfacial adhesion in glass fiber/epoxy composites by electrophoretic deposition of graphene oxide on glass fibers. Compos. Sci. Technol. 126, 149–157 (2016). https://doi.org/10.1016/j.compscitech.2016.02.016

Thomason, J.L.: Glass fibre sizing: A review. Compos. A Appl. Sci. Manuf. 127, 105619 (2019). https://doi.org/10.1016/j.compositesa.2019.105619

Thomason, J.: A review of the analysis and characterisation of polymeric glass fibre sizings. Polym. Testing 85, 106421 (2020). https://doi.org/10.1016/j.polymertesting.2020.106421

Wong, R.: Recent Aspects of Glass Fiber-Resin Interfaces. J. Adhes. 4, 171–179 (1972). https://doi.org/10.1080/00218467208072221

Kuila, T., Bose, S., Mishra, A.K., Khanra, P., Kim, N.H., Lee, J.H.: Chemical functionalization of graphene and its applications. Prog. Mater Sci. 57, 1061–1105 (2012). https://doi.org/10.1016/j.pmatsci.2012.03.002

Saravanan, N., Rajasekar, R., Mahalakshmi, S., Sathishkumar, T., Sasikumar, K., Sahoo, S.: Graphene and modified graphene-based polymer nanocomposites – A review. J. Reinf. Plast. Compos. 33, 1158–1170 (2014). https://doi.org/10.1177/0731684414524847

Ma, J., Meng, Q., Michelmore, A., Kawashima, N., Zaman, I., Bengtsson, C., Kuan, H.C.: Covalently bonded interfaces for polymer/graphene composites. Journal of Materials Chemistry A. 1, 4255–4264 (2013). https://doi.org/10.1039/c3ta01277h

Georgakilas, V., Otyepka, M., Bourlinos, A.B., Chandra, V., Kim, N., Kemp, K.C., Hobza, P., Zboril, R., Kim, K.S.: Functionalization of Graphene: Covalent and Non-Covalent Approaches. Derivatives and Applications, Chemical Reviews. 112, 6156–6214 (2012). https://doi.org/10.1021/cr3000412

Chen, J., Zhao, D., Jin, X., Wang, C., Wang, D., Ge, H.: Modifying glass fibers with graphene oxide: Towards high-performance polymer composites. Compos. Sci. Technol. 97, 41–45 (2014). https://doi.org/10.1016/j.compscitech.2014.03.023

Domun, N., Hadavinia, H., Zhang, T., Liaghat, G., Vahid, S., Spacie, C., Paton, K.R., Sainsbury, T.: Improving the fracture toughness properties of epoxy using graphene nanoplatelets at low filler content. Nanocomposites. 3, 85–96 (2017). https://doi.org/10.1080/20550324.2017.1365414

Yang, H., Li, F., Shan, C., Han, D., Zhang, Q., Niu, L., Ivaska, A.: Covalent functionalization of chemically converted graphene sheets via silane and its reinforcement. J. Mater. Chem. 19, 4632–4638 (2009). https://doi.org/10.1039/b901421g

Kuilla, T., Bhadra, S., Yao, D., Kim, N.H., Bose, S., Lee, J.H.: Recent advances in graphene based polymer composites. Progress in Polymer Science (Oxford). 35, 1350–1375 (2010). https://doi.org/10.1016/j.progpolymsci.2010.07.005

Seretis, G.V., Theodorakopoulos, I.D., Manolakos, D.E., Provatidis, C.G.: Effect of sonication on the mechanical response of graphene nanoplatelets/glass fabric/epoxy laminated nanocomposites. Compos. B Eng. 147, 33–41 (2018). https://doi.org/10.1016/j.compositesb.2018.04.034

ASTM.: Standard Test Method for Plane-Strain Fracture Toughness of Metallic Materials 1, ASTM Standard E399–90. 90, 1–31 (1997). https://doi.org/10.1520/E0399-90R97

Vigneshwaran, G.V., Prabu, S.B., Paskaramoorthy, R.: Effect of Graphene Addition on Crack Propagation Resistance in Glass Fibre Reinforced Polymer Matrix Composite, in: MSEC2018–6563 (Ed.), Volume 2: Materials; Joint MSEC-NAMRC-Manufacturing USA, American Society of Mechanical Engineers, College Station, Texas, USA, 2018: pp. 1–7. https://doi.org/10.1115/MSEC2018-6563

Gao, Y., Sun, W., Yang, W., Li, Q.: Palladium nanoparticles supported on amine-functionalized glass fiber mat for fixed-bed reactors on the effective removal of hexavalent chromium by catalytic reduction. J. Mater. Sci. Technol. 34, 961–968 (2018). https://doi.org/10.1016/j.jmst.2017.05.013

Yadav, S.K., Cho, J.W.: Functionalized graphene nanoplatelets for enhanced mechanical and thermal properties of polyurethane nanocomposites. Appl. Surf. Sci. 266, 360–367 (2013). https://doi.org/10.1016/j.apsusc.2012.12.028

Ojha, M., Penumakala, P.K., Marrivada, G.V., Chaganti, P.K., Gupta, A.K.: Processing of glass fiber pultruded composites using graphene nanoplatelets modified epoxy matrix. Materials Today: Proceedings. 18, 3298–3304 (2019). https://doi.org/10.1016/j.matpr.2019.07.237

Priya, I.I.M., Vinayagam, B.K.: Enhancement of bi-axial glass fibre reinforced polymer composite with graphene platelet nanopowder modifies epoxy resin. Adv. Mech. Eng. 10, 1–10 (2018). https://doi.org/10.1177/1687814018793261

Rafiee, M., Nitzsche, F., Laliberte, J., Thibault, J., Labrosse, M.R.: Simultaneous reinforcement of matrix and fibers for enhancement of mechanical properties of graphene-modified laminated composites. Polym. Compos. 40, E1732–E1745 (2019). https://doi.org/10.1002/pc.25137

Ahmadi-Moghadam, B., Sharafimasooleh, M., Shadlou, S., Taheri, F.: Effect of functionalization of graphene nanoplatelets on the mechanical response of graphene/epoxy composites, Materials & Design (1980–2015). 66, 142–149 (2015). https://doi.org/10.1016/j.matdes.2014.10.047

Drzal, L.T., Madhukar, M.: Fibre-matrix adhesion and its relationship to composite mechanical properties. J. Mater. Sci. 28, 569–610 (1993). https://doi.org/10.1007/BF01151234

Borrego, L.P., Costa, J.D.M., Ferreira, J.A.M., Silva, H.: Fatigue behaviour of glass fibre reinforced epoxy composites enhanced with nanoparticles. Compos. B Eng. 62, 65–72 (2014). https://doi.org/10.1016/j.compositesb.2014.02.016

Ahmadi-Moghadam, B., Taheri, F.: Influence of graphene nanoplatelets on modes I, II and III interlaminar fracture toughness of fiber-reinforced polymer composites. Eng. Fract. Mech. 143, 97–107 (2015). https://doi.org/10.1016/j.engfracmech.2015.06.026

Rokbi, M., Osmani, H., Benseddiq, N., Imad, A.: On experimental investigation of failure process of woven-fabric composites. Compos. Sci. Technol. 71, 1375–1384 (2011). https://doi.org/10.1016/j.compscitech.2011.05.003

Kim, J.-K., Mai, Y.: High strength, high fracture toughness fibre composites with interface control—A review. Compos. Sci. Technol. 41, 333–378 (1991). https://doi.org/10.1016/0266-3538(91)90072-W

Khanna, S.K., Shukla, A.: Energy absorption mechanisms during dynamic fracturing of fibre-reinforced composites. J. Mater. Sci. 28, 3722–3730 (1993). https://doi.org/10.1007/BF00353170

Alexopoulos, N.D., Paragkamian, Z., Poulin, P., Kourkoulis, S.K.: Fracture related mechanical properties of low and high graphene reinforcement of epoxy nanocomposites. Compos. Sci. Technol. 150, 194–204 (2017). https://doi.org/10.1016/j.compscitech.2017.07.030

Domun, N., Paton, K.R., Blackman, B.R.K., Kaboglu, C., Vahid, S., Zhang, T., Dear, J.P., Kinloch, A.J., Hadavinia, H.: On the extent of fracture toughness transfer from 1D/2D nanomodified epoxy matrices to glass fibre composites. J. Mater. Sci. 55, 4717–4733 (2020). https://doi.org/10.1007/s10853-019-04340-8

Menbari, S., Ashori, A., Rahmani, H., Bahrami, R.: Viscoelastic response and interlaminar delamination resistance of epoxy/glass fiber/functionalized graphene oxide multi-scale composites. Polym. Testing 54, 186–195 (2016). https://doi.org/10.1016/j.polymertesting.2016.07.016

Zaheer, U., Khurram, A.A., Subhani, T.: A treatise on multiscale glass fiber epoxy matrix composites containing graphene nanoplatelets. Advanced Composites and Hybrid Materials. 1, 705–721 (2018). https://doi.org/10.1007/s42114-018-0057-y

Li, Z., Wang, R., Young, R.J., Deng, L., Yang, F., Hao, L., Jiao, W., Liu, W.: Control of the functionality of graphene oxide for its application in epoxy nanocomposites. Polymer 54, 6437–6446 (2013). https://doi.org/10.1016/j.polymer.2013.09.054

Jiang, T., Kuila, T., Kim, N.H., Ku, B.-C., Lee, J.H.: Enhanced mechanical properties of silanized silica nanoparticle attached graphene oxide/epoxy composites. Compos. Sci. Technol. 79, 115–125 (2013). https://doi.org/10.1016/j.compscitech.2013.02.018

Chatterjee, S., Wang, J.W.W., Kuo, W.S.S., Tai, N.H.H., Salzmann, C., Li, W.L.L., Hollertz, R., Nüesch, F.A.A., Chu, B.T.T.T.T.: Mechanical reinforcement and thermal conductivity in expanded graphene nanoplatelets reinforced epoxy composites, Chemical Physics Letters. 531, 6–10 (2012) . https://doi.org/10.1016/j.cplett.2012.02.006

Wang, X., Xing, W., Zhang, P., Song, L., Yang, H., Hu, Y.: Covalent functionalization of graphene with organosilane and its use as a reinforcement in epoxy composites. Compos. Sci. Technol. 72, 737–743 (2012). https://doi.org/10.1016/j.compscitech.2012.01.027

Author information

Authors and Affiliations

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Veerakumar, V.G.S., Shanmugavel, B.P. & Harish, S. On the Influence of the Functionalization of Graphene Nanoplatelets and Glass Fiber on the Mechanical Properties of GFRP Composites. Appl Compos Mater 28, 1127–1152 (2021). https://doi.org/10.1007/s10443-021-09908-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-021-09908-9