Abstract

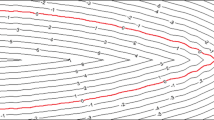

The directional deviation and wrinkling deformation of the fibers need to be strictly controlled within a specific range to guarantee the final formed composite component's quality. This work proposed a novel method for generating an initial path that is proportionally adjustable between the fixed-angle and the geodesic direction to satisfy the fiber directional deviation and wrinkling deformation constraints. The paths under multiple reference lines are better suited to component geometry than paths under a single reference line. In the path offset process, a parallel equidistant offset algorithm considering the design and manufacturing constraints was proposed, which avoids the generation of unqualified paths. Simulation results showed that the proposed path generation methods have better design flexibility and higher path planning efficiency.

Similar content being viewed by others

Data Availability

Some or all data, models, or code generated or used during the study are available from the corresponding author by request.

1. The models in Fig. 15, including the conical part and the variable cross-section C beam.

2. The model of fuselage skin of a certain type of aircraft in Fig. 17, and the planned placement paths and the tow paths.

References

Koricho, E.G., Khomenko, A., Fristedt, T., Haq, M.: Innovative tailored fiber placement technique for enhanced damage resistance in notched composite laminate. Compos. Struct. 120, 378–385 (2015). https://doi.org/10.1016/j.compstruct.2014.10.016

Shirinzadeh, B., Wei Foong, C., Hui Tan, B.: Robotic fibre placement process planning and control. Assem. Autom. 20(4), 313–320 (2000). https://doi.org/10.1108/01445150010353242

Shirinzadeh, B., Alici, G., Foong, C.W., Cassidy, G.: Fabrication process of open surfaces by robotic fibre placement. Robotics and Computer-Integrated Manufacturing 20(1), 17–28 (2004). https://doi.org/10.1016/s0736-5845(03)00050-4

Debout, P., Chanal, H., Duc, E.: Tool path smoothing of a redundant machine: Application to Automated Fiber Placement. Comput. Aided Des. 43(2), 122–132 (2011). https://doi.org/10.1016/j.cad.2010.09.011

Martinec, T., Mlýnek, J., Petrů, M.: Calculation of the robot trajectory for the optimum directional orientation of fibre placement in the manufacture of composite profile frames. Robotics and Computer-Integrated Manufacturing 35, 42–54 (2015). https://doi.org/10.1016/j.rcim.2015.02.004

He, R., Qu, W., Ke, Y.: An improved path discretization method for automated fiber placement. J. Reinf. Plast. Compos. 39(13–14), 545–559 (2020). https://doi.org/10.1177/0731684420915986

Yan, L., Chen, Z.C., Shi, Y., Mo, R.: An accurate approach to roller path generation for robotic fibre placement of free-form surface composites. Robotics and Computer-Integrated Manufacturing 30(3), 277–286 (2014). https://doi.org/10.1016/j.rcim.2013.10.007

Bruyneel, M., Zein, S.: A modified Fast Marching Method for defining fiber placement trajectories over meshes. Compos. Struct. 125, 45–52 (2013). https://doi.org/10.1016/j.compstruc.2013.04.015

Xiaoping, W., Luling, A., Zhang Liyan, Z., Laishui, Z.: Uniform Coverage of Fibres over Open-contoured Freeform Structure Based on Arc-length Parameter. Chinese Journal of Aeronautics. 21, 571–577 (2008). https://doi.org/10.1016/s1000-9361(08)60176-4

Shirinzadeh, B., Cassidy, G., Oetomo, D., Alici, G., Ang, M.H., Jr.: Trajectory generation for open-contoured structures in robotic fibre placement. Robotics and Computer-Integrated Manufacturing 23(4), 380–394 (2007). https://doi.org/10.1016/j.rcim.2006.04.006

Venkatesan, C., Velu, R., Vaheed, N., Raspall, F., Tay, T.-E., Silva, A.: Effect of process parameters on polyamide-6 carbon fibre prepreg laminated by IR-assisted automated fibre placement. The International Journal of Advanced Manufacturing Technology 108(4), 1275–1284 (2020). https://doi.org/10.1007/s00170-020-05230-z

Hassan, N., Thompson, J.E., Batra, R.C., Hulcher, A.B., Song, X., Loos, A.C.: A Heat Transfer Analysis of the Fiber Placement Composite Manufacturing Process. J. Reinf. Plast. Compos. 24(8), 869–888 (2016). https://doi.org/10.1177/0731684405047773

Zinnecker, V., Stokes-Griffin, C.M., Khudiakova, A., Wolfahrt, M., Compston, P.: A comparative study for shear testing of thermoplastic-based composites and metal-composite hybrids. Composites Part A: Applied Science and Manufacturing. 137, (2020). https://doi.org/10.1016/j.compositesa.2020.105953

Nistal, A., Falzon, B.G., Hawkins, S.C., Chitwan, R., García-Diego, C., Rubio, F.: Enhancing the fracture toughness of hierarchical composites through amino-functionalised carbon nanotube webs. Compos. B Eng. 165, 537–544 (2019). https://doi.org/10.1016/j.compositesb.2019.02.001

Niu, X., Liu, Y., Wu, J., Yang, T.: Curvature-controlled trajectory planning for variable stiffness composite laminates. Composite Structures. 238, (2020). https://doi.org/10.1016/j.compstruct.2020.111986

Oromiehie, E., Prusty, B.G., Compston, P., Rajan, G.: Automated fibre placement based composite structures: Review on the defects, impacts and inspections techniques. Composite Structures. 224, (2019). https://doi.org/10.1016/j.compstruct.2019.110987

Woigk, W., Hallett, S.R., Jones, M.I., Kuhtz, M., Hornig, A., Gude, M.: Experimental investigation of the effect of defects in Automated Fibre Placement produced composite laminates. Compos. Struct. 201, 1004–1017 (2018). https://doi.org/10.1016/j.compstruct.2018.06.078

Zhang, P., Sun, R., Huang, T.: A geometric method for computation of geodesic on parametric surfaces. Computer Aided Geometric Design 38, 24–37 (2015). https://doi.org/10.1016/j.cagd.2015.08.001

Peng Hao, D.L.: Yu Wang, Xuanxiu Liu, Bo Wang, Gang Li, Shaowei Feng: Design of manufacturable fiber path for variable-stiffness panels based on lamination parameters. Compos. Struct. 219, 158–169 (2019). https://doi.org/10.1016/j.compstruct.2019.03.075

Thomas, M.A., Hallett, S.R., Weaver, P.M.: Design considerations for variable stiffness, doubly curved composite plates. Composite Structures. 244, (2020). https://doi.org/10.1016/j.compstruct.2020.112170

Zhang, L., Wang, X., Pei, J., Nian, C.: Adaptive Path Planning of Fiber Placement Based on Improved Method of Mesh Dynamic Representation. Appl. Compos. Mater. 26(3), 785–803 (2019). https://doi.org/10.1007/s10443-018-9751-8

Pei, J., Wang, X., Pei, J., Yang, Y.: Path Planning Based on Ply Orientation Information for Automatic Fiber Placement on Mesh Surface. Appl. Compos. Mater. 25(6), 1477–1490 (2018). https://doi.org/10.1007/s10443-018-9678-0

Wang Peiyuan, L.Y.: Wang xianfeng, and xiao Jun: Research on fiber placement trajectory design algorithm for the free-form surface with given ply orientation information. Polym. Polym. Compos. 19, 203–208 (2011)

Gonzalez Lozano, G., Tiwari, A., Turner, C.: A design algorithm to model fibre paths for manufacturing of structurally optimised composite laminates. Compos. Struct. 204, 882–895 (2018). https://doi.org/10.1016/j.compstruct.2018.07.088

Funding

The author(s) disclosed receipt of the following financial support for the research: This research was supported by the National Natural Science Foundation of China [Grant Number 51975520] and Zhejiang Provincial Natural Science Foundation of China [Grant Number LQ20E050019].

Author information

Authors and Affiliations

Contributions

Weiwei Qu: Conceptualization, Project administration, Writing-Review & Editing, Visualization. Ruming He: Methodology, Software, Validation, Formal analysis, Investigation, Data curation, Writing- Original draft. Qing Wang: Writing-Review & Editing. Liang Cheng: Writing-Review & Editing, Funding acquisition. Di Yang: Writing-Review & Editing. Jiaxin Gao: Validation, Formal analysis, Investigation. Han Wang: Writing-Review & Editing. Qian Yang: Validation, Formal analysis, Investigation. Yinglin Ke: Resources, Supervision, Funding acquisition.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Qu, W., He, R., Wang, Q. et al. Algorithms for Constructing Initial and Offset Path of Automated Fiber Placement for Complex Double-Curved Surfaces. Appl Compos Mater 28, 855–875 (2021). https://doi.org/10.1007/s10443-021-09901-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-021-09901-2