Abstract

Carbon fibres have exceptional mechanical properties and are used for critical structural applications such as composite pressure vessels and aerospace components. For such high performance applications, reliability-based designs and lifetime assessments require very accurate strength models. Accuracy of the predictions made by composite strength models depend on realistic material properties of constituents, which are used as input. In practice however, fibre strength properties reported by different sources show significant variations. The work described here aims at understanding the influence of measurement uncertainty and sampling randomness on the uncertainty in calculated tensile strength distribution parameters. Tensile strength data for T700 carbon fibres obtained from single fibre testing process has been analysed for uncertainties. A parametric bootstrap method has been used for the evaluation. It has been shown that although both the causes studied of uncertainty are critical, the sampling randomness has a larger influence on the uncertainty of fibre strength, as compared to the uncertainty due to measurement. Choosing an insufficient sample size for analysis can thus result in uncertain or even inaccurate fibre strength properties, which would limit the reliability of composite strength models. The knowledge of the causes and effects of these uncertainties can help in taking appropriate measures for improving the accuracy of results. This would thereby enhance the capability of composite strength models to estimate the behaviour of different composite structures more accurately.

Similar content being viewed by others

References

Zhang, X., Zhao, J., Wang, Z.: Burst pressure prediction and structure reliability analysis of composite overwrapped cylinder. Appl. Composite Materials 25 (6), 1269–1285 (2018). https://doi.org/10.1007/s10443-017-9665-x

Chou, H., Bunsell, A., Mair, G., Thionnet, A.: Effect of the loading rate on ultimate strength of composites. Application: Pressure Vessel Slow Burst Test, Composite Structures 104, 144–153 (2013). https://doi.org/10.1016/j.compstruct.2013.04.003

Overview of the global composites market - at the crossroads, JEC Group (2017)

Bunsell, A.R., Thionnet, A., Chou, H.Y.: Intrinsic safety factors for glass & carbon fibre composite filament wound structures. Applied Composite Materials 21(1), 107–121 (2014). https://doi.org/10.1007/s10443-013-9367-y

Ilankeeran, P., Mohite, P., Kamle, S.: Axial tensile testing of single fibres. Modern Mechanical Engineering (4), 151–156. https://doi.org/10.4236/mme.2012.24020(2012)

Thionnet, A., Chou, H.-Y., Bunsell, A.: Fibre break failure processes in unidirectional composites. part 1: failure and critical damage state induced by increasing tensile loading. Appl. Composite Materials 22(2), 119–140 (2015). https://doi.org/10.1007/s10443-014-9397-0

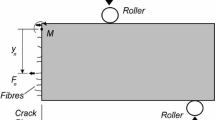

Gamstedt, E.K., Östlund, S.: Fatigue propagation of fibre-bridged cracks in unidirectional polymer-matrix composites. Appl. Composite Materials 8(6), 385–410 (2001). https://doi.org/10.1023/A:1012677604599

Kaddour, A., Hinton, M.: Maturity of 3d failure criteria for fibre-reinforced composites: comparison between theories and experiments: part b of wwfe-ii. Journal of Composite Materials 47 (6-7), 925–966 (2013). https://doi.org/10.1177/0021998313478710

Bunsell, A., Gorbatikh, L., Morton, H., Pimenta, S., Sinclair, I., Spearing, M., Swolfs, Y., Thionnet, A.: Benchmarking of strength models for unidirectional composites under longitudinal tension. Composites Part A: Applied Science and Manufacturing 111, 138–150 (2018). https://doi.org/10.1016/j.compositesa.2018.03.016. http://www.sciencedirect.com/science/article/pii/S1359835X18301180

Chou, H.Y., Thionnet, A., Mouritz, A., Bunsell, A.R.: Stochastic factors controlling the failure of carbon/epoxy composites. J. Materials Sci. 51(1), 311–333 (2016). https://doi.org/10.1007/s10853-015-9390-5

Swolfs, Y., Verpoest, I., Gorbatikh, L.: A review of input data and modelling assumptions in longitudinal strength models for unidirectional fibre-reinforced composites. Composite Structures 150, 153–172 (2016). https://doi.org/10.1016/j.compstruct.2016.05.002

Islam, F., Joannès, S., Bucknell, S., Leray, Y., Bunsell, A., Laiarinandrasana, L.: Improvements in determination of carbon fibre strength distribution using automation and statistical data analysis. In: Proceedings of the Fiber Society’s Spring 2018 Conference, Tokyo (2018)

JCGM 100: Evaluation of measurement data - Guide to the expression of uncertainty in measurement (2010)

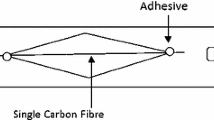

Islam, F., Joannès, S., Laiarinandrasana, L.: Evaluation of critical parameters in tensile strength measurement of single fibres. Journal of Composites Science 3(3). https://doi.org/10.3390/jcs3030069. https://www.mdpi.com/2504-477X/3/3/69

Islam, F., Joannès, S., Bucknell, S., Leray, Y., Bunsell, A., Laiarinandrasana, L.: Towards accurate and efficient single fibre characterization to better assess failure strength distribution. In: Proceedings of the 18th European Conference on Composite Materials (ECCM-2018), Greece, Athens (2018)

Weibull, W.: A statistical distribution function of wide applicability. J. Appl. Mech., 293–297 (1951)

Padgett, W.J., Durham, S.D., Mason, A.M.: Weibull analysis of the strength of carbon fibers using linear and power law models for the length effect. J. Compos. Mater. 29(14), 1873–1884 (1995). https://doi.org/10.1177/002199839502901405

Berger, M.-H., Jeulin, D.: Statistical analysis of the failure stresses of ceramic fibres: dependence of the Weibull parameters on the gauge length, diameter variation and fluctuation of defect density. Journal of Materials Science 38(13), 2913–2923 (2003). https://doi.org/10.1023/A:1024405123420

Yu, W., Yao, J.: Tensile strength and its variation of PAN-based carbon fibers. I. Statistical distribution and volume dependence. J. Appl. Polymer Sci. 101(5), 3175–3182 (2006). https://onlinelibrary.wiley.com/doi/pdf/10.1002/app.23399. https://doi.org/10.1002/app.23399

Yavin, B., Gallis, H.E., Scherf, J., Eitan, A., Wagner, H.D.: Continuous monitoring of the fragmentation phenomenon in single fiber composite materials. Polymer Composites 12(6), 436–446 (1991). https://doi.org/10.1002/pc.750120609

Chi, Z., Chou, T.W., Shen, G.: Determination of single fibre strength distribution from fibre bundle testings. J. Mater. Sci. 19(10), 3319–3324 (1984). https://doi.org/10.1007/BF00549820

Andersons, J., Joffe, R., Hojo, M., Ochiai, S.: Glass fibre strength distribution determined by common experimental methods. Composites Sci. Technol. 62(1), 131–145 (2002). https://doi.org/10.1016/S0266-3538(01)00182-8

Feih, S., Manatpon, K., Mathys, Z., Gibson, A.G., Mouritz, A.P.: Strength degradation of glass fibers at high temperatures. J. Mater. Sci. 44(2), 392–400 (2009). https://doi.org/10.1007/s10853-008-3140-x

Xiao, H., Lu, Y., Wang, M., Qin, X., Zhao, W., Luan, J.: Effect of gamma-irradiation on the mechanical properties of polyacrylonitrile-based carbon fiber. Carbon 52, 427–439 (2013). https://doi.org/10.1016/j.carbon.2012.09.054

Deng, S., Ye, L., Mai, Y.-W., Liu, H.-Y.: Evaluation of fibre tensile strength and fibre/matrix adhesion using single fibre fragmentation tests. Composites Part A: Applied Science and Manufacturing 29 (4), 423–434 (1998). https://doi.org/10.1016/S1359-835X(97)00094-8

Lutz, V., Duchet-Rumeau, J., Godin, N., Smail, F., Lortie, F., Gérard, J.: Ex-PAN carbon fibers vs carbon nanotubes fibers: from conventional epoxy based composites to multiscale composites. European Polymer Journal 106, 9–18 (2018). https://doi.org/10.1016/j.eurpolymj.2018.06.023

Na, W., Lee, G., Sung, M., Han, H.N., Yu, W.-R.: Prediction of the tensile strength of unidirectional carbon fiber composites considering the interfacial shear strength. Composite Structures 168, 92–103 (2017). https://doi.org/10.1016/j.compstruct.2017.02.060

Matveev, M., Long, A., Jones, I.: Modelling of textile composites with fibre strength variability. Composites Science and Technology 105, 44–50 (2014). https://doi.org/10.1016/j.compscitech.2014.09.012

Zhang, T., Qi, L., Li, S., Chao, X., Tian, W., Zhou, J. : Evaluation of the effect of PyC coating thickness on the mechanical properties of T700 carbon fiber tows. Applied Surface Science 463, 310–321 (2019). https://doi.org/10.1016/j.apsusc.2018.08.195

Zhou, Y., Wang, Y., Xia, Y., Jeelani, S.: Tensile behavior of carbon fiber bundles at different strain rates. Materials Letters 64(3), 246–248 (2010). https://doi.org/10.1016/j.matlet.2009.10.045

Standard test method for tensile strength and Young’s modulus of fibers, ASTM Standards ASTM C1557 - 14

Bunsell, A.R., Hearle, J.W.S.: A mechanism of fatigue failure in nylon fibres. J. Mater. Sci. 6(10), 1303–1311 (1971). https://doi.org/10.1007/BF00552044

Marcellan, A., Bunsell, A., Laiarinandrasana, L., Piques, L.: A multi-scale analysis of the microstructure and the tensile mechanical behaviour of polyamide 66 fibre. Polymer 47(1), 367–378 (2006). https://doi.org/10.1016/j.polymer.2005.10.093

Wollbrett-Blitz, J., Joannès, S., Bruant, R., Le Clerc, C., Romero De La Osa, M., Bunsell, A., Marcellan, A.: Multiaxial mechanical behavior of aramid fibers and identification of skin/core structure from single fiber transverse compression testing. J. Polym. Sci., Part B: Polym. Phys. 54(3), 374–384 (2016). https://doi.org/10.1002/polb.23763

Jauzein, V., Bunsell, A.: Bio-composite aspects of silk: the sericin sheath acting as a matrix. Journal of Materials Science 47(7), 3082–3088 (2012). https://doi.org/10.1007/s10853-011-6141-0

Ramirez, J.M.H., Bunsell, A.R., Colomban, P.: Microstructural mechanisms governing the fatigue failure of polyamide 66 fibres. Journal of Materials Science 41 (22), 7261–7271 (2006). https://doi.org/10.1007/s10853-006-0421-0

Le Clerc, C., Monasse, B., Bunsell, A.R.: Influence of temperature on fracture initiation in pet and pa66 fibres under cyclic loading. Journal of Materials Science 42 (22), 9276–9283 (2007). https://doi.org/10.1007/s10853-007-1864-7

VanderPlas, J.: Frequentism and Bayesianism: a python-driven primer. In: Proceedings of the 13th Python in Science Conference (SCIPY 2014) (2014)

Symynck, J., Bal, F.D.: Monte-carlo pivotal confidence bounds for Weibull analysis, with implementations in R. In: Proceedings of the XVIth International Scientific Conference Tehnomus, Stefan cel Mare University of Suceava - ROMANIA (2011)

Abernethy, R.B.: The new weibull handbook (2008)

Zinck, P., Mäder, E., Gerard, J.F.: Role of silane coupling agent and polymeric film former for tailoring glass fiber sizings from tensile strength measurements. Journal of Materials Science 36(21), 5245–5252 (2001). https://doi.org/10.1023/A:1012410315601

Thomason, J.: On the application of Weibull analysis to experimentally determined single fibre strength distributions. Composites Sci. Technol. 77, 74–80 (2013). https://doi.org/10.1016/j.compscitech.2013.01.009

Acknowledgements

The research leading to these results has been done within the framework of the FiBreMoD project and has received funding from the European Union’s Horizon 2020 research and innovation programme under the Marie Sklodowska-Curie grant agreement No 722626.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Joannès, S., Islam, F. & Laiarinandrasana, L. Uncertainty in Fibre Strength Characterisation Due to Uncertainty in Measurement and Sampling Randomness. Appl Compos Mater 27, 165–184 (2020). https://doi.org/10.1007/s10443-020-09803-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-020-09803-9