Abstract

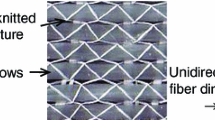

Automation of the preforming process brings up two opposing requirements for the used engineering fabric. On the one hand, the fabric requires a sufficient drapeability, or low shear stiffness, for forming into double-curved geometries; but on the other hand, the fabric requires a high form stability, or high shear stiffness, for automated handling. To meet both requirements tailored non-crimp fabrics (TNCFs) are proposed. While the stitching has little structural influence on the final part, it virtually dictates the TNCFs local capability to shear and drape over a mold during preforming. The shear stiffness of TNCFs is designed by defining the local stitching geometry. NCFs with chain stitch have a comparatively high shear stiffness and NCFs with a stitch angle close to the symmetry stitch angle have a very low shear stiffness. A method to design the component specific local stitching parameters of TNCFs is discussed. For validation of the method, NCFs with designed tailored stitching parameters were manufactured and compared to benchmark NCFs with uniform stitching parameters. The designed TNCFs showed both, generally a high form stability and in locally required zones a good drapeability, in drape experiments over an elongated hemisphere.

Similar content being viewed by others

Change history

03 July 2017

An erratum to this article has been published.

References

Laessig, R., Eisenhut, M., Mathias, A., Schulte, R., Peters, F., Kuehnemann, T., et al.: Series Production of High-Strength Composites: Perspectives for the German Engineering Industry (2012)

Middendorf, P., Metzner, C.: Aerospace applications of non-crimp fabric composites. In: Non-crimp fabric composites: Manufacturing, properties and applications. In: Lomov, S. (ed.) Woodhead Publishing in materials; Oxford and Philadelphia: Woodhead Pub. ISBN 9780857092533 (2011)

Skoeck-Hartmann, B., Gries, T.: Automotive applications of non-crimp fabric composites. In: Lomov, S. (ed.) Non-crimp fabric composites: Manufacturing, properties and applications, Woodhead Publishing in materials; Oxford and Philadelphia: Woodhead Pub. ISBN 9780857092533 (2011)

Beier, U., Fischer, F., Sandler, J.K., Altstädt, V., Weimer, C., Buchs, W.: Mechanical performance of carbon fibre-composites based on stitched preforms. Compos. A: Appl. Sci. Manuf. 38(7), 1655–1663 (2007). doi:10.1016/j.compositesa.2007.02.007

Bibo, G.A., Hogg, P.J., Backhouse, R., Mills, A.: Carbon-fibre non-crimp fabric laminates for cost-effective damage-tolerant structures. Compos. Sci. Technol. 58(1), 129–143 (1998)

Schnabel A, Skoeck-Hartmann B, Hoffmeister C. Characterization of the drapability of non-crimp fabrics. SAMPE 2010, pp. 144. Seatle (2010)

Reinhart, G., Straer, G.: Flexible gripping technology for the automated handling of limp technical textiles in composites industry. Prod. Eng. 5 (2011)

Olofsson, K., Hedlund, E., Joffe, R., Ahlqvist, F.: Automated cutting of fi er materials for tai- lored drapeability. Proceedings of the 5th International Swedish Production Symposium, Linkoping, Sweden (2012)

Huebner, M., Diester, O., Sennewald, C., Gereke, T., Cherif, C.: Simulation if the drapeability of textile semifinished products with gradient-drapeability characteristics by varying the fabric weave. FIBRES and TEXTILES in Eastern Europe. 20, 88–93 (2012)

Falk, E.: The drapability of multi-axial materials and the use of laser-transmission welding. Technical Textiles. 1, E49–E51 (2007)

Molnár, P., Ogale, A., Lahr, R., Mitschang, P.: Influence of drapability by using stitching technology to reduce fabric deformation and shear during thermoforming. Compos. Sci. Technol. 67(15–16), 3386–3393 (2007). doi:10.1016/j.compscitech.2007.03.022

Bilisik, K., Yolacan, G.: Experimental determination of bending behavior of multilayered and multidirectionally-stitched e-glass fabric structures for composites. Text. Res. J. 82, (2012)

Margossian, A., Bel, S., Balvers, J.M., Leutz, D., Freitas, R., Hinterhoelzl, R.: Finite element forming simulation of locally stitched non-crimp fabrics. Compos. A: Appl. Sci. Manuf. 61, 152–162 (2014). doi:10.1016/j.compositesa.2014.02.020

Sennewald, C., Hoffmann, G., Kleicke, R.: Woven semifinished products and weaving techniques. In: Cherif, C. (ed.) Textile Materials for Lightweight Constructions. Berlin, Heidelberg (2016)

Lomov, S.V., Barburski, M., Stoilova, T., Verpoest, I., Akkerman, R., Loendersloot, R., et al.: Carbon composites based on multiaxial multiply stitched preforms. Part 3: biaxial tension, picture frame and compression tests of the preforms. Compos. A: Appl. Sci. Manuf. 36(9), 1188–1206 (2005). doi:10.1016/j.compositesa.2005.01.015

Spencer, D.J.: Knitting technology: A comprehensive handbook and practical guide, 3rd edn. Lancaster, Pa and Cambridge, Eng. Technomic. ISBN 9781855733336 (2001)

Lomov, S.V.: Deformability of textile preforms in the manufacture of non-crimp fabric composites. In: Lomov, S. (ed.) Non-crimp fabric composites: Manufacturing, properties and applications, Woodhead Publishing in materials; Oxford and Philadelphia: Woodhead Pub. ISBN 9780857092533 (2011)

Kong, H., Mouritz, A.P., Paton, R.: Tensile extension properties and deformation mechanisms of multiaxial non-crimp fabrics. Compos. Struct. 66(1–4), 249–259 (2004). doi:10.1016/j.compstruct.2004.04.046

Schnabel, A.S.: Entwicklung von lokal angepassten textilen Halbzeugen fu¨r die Großserienferti- gung von faserversta¨rkten Kunststoffen. Textiltechnik/ Textile Technology; Aachen: Shaker. ISBN 978–3–8440-2023-6 (2013)

Krieger H, Schnabel A, Appel L, Gries T. Experimental setup to validate textile material models for drape simulation. Key Eng. Mater. 554–557:456–64. (2013) doi:10.4028/www.scientific.net/KEM.554-557.456

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article is available at https://doi.org/10.1007/s10443-017-9617-5.

Rights and permissions

About this article

Cite this article

Krieger, H., Gries, T. & Stapleton, S.E. Design of Tailored Non-Crimp Fabrics Based on Stitching Geometry. Appl Compos Mater 25, 113–127 (2018). https://doi.org/10.1007/s10443-017-9603-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-017-9603-y