Abstract

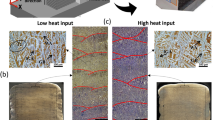

A new fibre metal laminate fabricated with aluminium sheets and unidirectionally arrayed chopped strand (UACS) plies is proposed. The UACS ply is made by cutting parallel slits into a unidirectional carbon fibre prepreg. The UACS/Al laminate may be viewed as aluminium laminate reinforced by highly aligned, discontinuous carbon fibres. The tensile behaviour of UACS/Al laminate, including thermal residual stress and failure progression, is investigated through experiments and numerical simulation. Finite element analysis was used to simulate the onset and propagation of intra-laminar fractures occurring within slits of the UACS plies and delamination along the interfaces. The finite element models feature intra-laminar cohesive elements inserted into the slits and inter-laminar cohesive elements inserted at the interfaces. Good agreement are obtained between experimental results and finite element analysis, and certain limitations of the finite element models are observed and discussed. The combined experimental and numerical studies provide a detailed understanding of the tensile behaviour of UACS/Al laminates.

Similar content being viewed by others

References

Taketa, I., Okabe, T., Matsutani, H., Kitano, A.: Flowability of unidirectionally arrayed chopped strands in compression molding. Compos. Part B 42, 1764–1769 (2011)

Feraboli, P., Peitso, E., Cleveland, T., Stickler, P., Halpin, J.C.: Notched behavior of prepreg-based discontinuous carbon fiof /epoxy systems. Compos. Part A 40, 289–299 (2009)

Feraboli, P., Cleveland, T., Ciccu, M., Stickler, P., Deoto, L.: Defect and damage analysis of advanced discontinuous carbon/epoxy composite materials. Compos. Part A 41, 888–901 (2010)

Taketa, I., Okabe, T., Kitano, A.: A new compression-molding approach using unidirectionally arrayed chopped strands. Compos. Part A 39, 1884–1890 (2008)

Taketa, I., Okabe, T., Kitano, A.: Strength improvement in unidirectional arrayed chopped strands with interlaminar toughening. Compos. Part A 40, 1174–1178 (2009)

Taketa, I., Sato, N., Kitano, A., Nishikawa, M., Okabe, T.: Enhancement of strength and uniformity in unidirectionally arrayed chopped strands with angled slits. Compos. Part A 41, 1639–1646 (2010)

Yashiro, S., Ogi, K.: Fracture behavior in CFRP cross-ply laminates with initially cut fibers. Compos. Part A 40, 938–947 (2009)

Li, H., Wang, W.X., Takao, Y., Matsubara, T.: New designs of unidiretionally arrayed chopped strands by introducing discontinuous angled slits into prepreg. Compos. Part A 45, 127–133 (2013)

Li, H., Wang, W.X., Takao, Y., Matsubara, T.: Multiscale analysis of damage progression in newly designed UACS laminates. Compos. Part A 57, 108–117 (2014)

Asundi, A., Chroi, A.Y.N.: Fiber metal laminates: an advanced material for future aircraft. J. Mater. Process. Technol. 63, 384–394 (1997)

Chen, J.F., Morozov, E.V., Shankar, K.: Progressive failure analysis of perforated aluminium/CFRP fibre metal laminates using a combined elastoplastic damage model and including delamination effects. Compos. Struct. 114, 64–79 (2014)

Lin, C.T., Kao, P.W., Yang, F.S.: Fatigue behaviour of carbon fiber reinforced aluminium laminates. Compt. Rendus Geosci. 22, 135–141 (1991)

Khan, S.U., Alderliesten, R.C., Benedictus, R.: Post-stretching induced stress redistribution in fibre metal laminates for increased fatigue crack growth resistance. Compos. Sci. Technol. 69, 396–405 (2009)

Cortes, P., Cantwell, W.J.: The fracture properties of a fibre-metal laminate based on magnesium alloy. Compos. Part B 37, 163–170 (2006)

Cortes, P., Cantwell, W.J.: The tensile and fatigue properties of carbon fiber-reinforced PEEK-Titanium fiber-metal laminates. J. Reinf. Plast. Compos. 23, 1615–1623 (2004)

Yamaguchi, T., Okabe, T., Yashiro, S.: Fatigue simulation for titanium/CFRP hybrid laminates using cohesive elements. Compos. Sci. Technol. 69, 1968–1973 (2009)

Nakatani, H., Kosaka, T., Osaka, K., Sawda, Y.: Damage characterization of titanium/GFRP hybrid laminates subjected to low-velocity impact. Compos. Part A 42, 772–781 (2011)

Thomas, J.: The A380 program-the big task for Europe’s aerospace industry. Air Space Eur. 3, 35–39 (2001)

Wang, W.X., Takao, Y.: CFRP/Al-FRML Based on Nano-composite Coating and Its Mechanical Properties. In: 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. Honolulu, Hawaii, USA: 2007–2268.

Xue, J., Wang, W.X., Takao, Y., Matsubara, T.: Reduction of thermal residual stress in carbon fiber aluminum laminates using a thermal expansion clamp. Compos. Part A 42, 986–992 (2011)

ABAQUS-Inc. Defining the constitutive response of cohesive elements using atraction–separation description, Abaqus Analysis User’s Manual 6.10. Dassault Systèmes Simulia Corp., USA; 2010

Xue, J.: Tensile strength and thermal residual stress of CARALL and UACS/Al laminates. Ph.D. dissertation. Department of Aeronautics and Astronautics, Kyushu University, Japan. 2012

Turon, A., Camanho, P.P., Costa, J., Renart, J.: Accurate simulation of delamination growth under mixed-mode loading using cohesive elements: Definition of interlaminar strengths and elastic stiffness. Compos. Struct. 92, 1857–1864 (2010)

Chen, J.F., Morozov, E.V., Shankar, K.: Simulating progressive failure of composite laminates including in-ply and delamination damage effects. Compos. Part A 61, 185–200 (2014)

Chen, X., Deng, X.M., Sutton, M.A.:Simulation of stable tearing crack growth events using the cohesive zone model approach. Eng. Fract. Mech. 99, 223–238 (2013)

Acknowledgments

This study was partially supported by Grant-in Aid for Scientific Research (B) (22360052) of Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xue, J., Wang, WX., Zhang, JZ. et al. Experimental and Numerical Study on the Tensile Behaviour of UACS/Al Fibre Metal Laminate. Appl Compos Mater 22, 489–505 (2015). https://doi.org/10.1007/s10443-014-9419-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-014-9419-y