Abstract

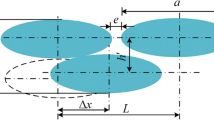

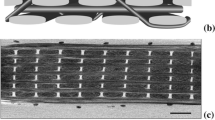

The nesting of layers has great effect on the permeability which is a key parameter in resin transfer molding (RTM). In this paper, two mathematical models were developed to predict the out-of-plane permeability of unidirectional fabrics with minimum and maximum nesting, respectively. For different zones of characteristic yarn arrangement in the unit cell, the local permeability was modeled as a function of geometrical yarn parameters. The global permeability was then modeled as a mixture of permeabilities of different zones with the electrical resistance analogy. The influences of local permeability of each zone on the global value of unit cell were deeply researched. In addition, two different fabrics were tested and a reasonably good agreement was found between the model predictions and experimental results. We also found that the permeability values were two orders of magnitude larger with minimum nesting than with maximum nesting. However, the differences between minimum nesting and maximum nesting decreased with increasing fiber volume fraction.

Similar content being viewed by others

References

Schell, J.S.U., Siegrist, M., Ermanni, P.: Experimental determination of the transversal and longitudinal fibre bundle permeability. Appl. Compos. Mater. 14(2), 117–128 (2007)

Visconti, I.C., Langella, A., Durante, M.: Analysis of transversal permeability for different types of glass fiber reinforcement. Appl. Compos. Mater. 10(2), 119–127 (2003)

Parnas, R.S.: Liquid composite molding. Carl Hanser, Munchen (2000)

Gascons, M., Blanco, N., Mayugo, J.A., Matthys, K.: A strategy to support design processes for fibre reinforced thermoset composite materials. Appl. Compos. Mater. 19(3–4), 297–314 (2012)

Young, W.B.: A Two-layer Model for the Simulation of the VARTM Process with Resin Distribution Layer. Appl. Compos. Mater. 20(6), 1305–1319 (2013)

Turner, D.Z., Hjelmstad, K.D.: Determining the 3D permeability of fibrous media using the Newton method. Compos. Part B 36(8), 609–618 (2005)

Zhou, F., Kuentzer, N., Simacek, P., Advani, S.G., Walsh, S.: Analytic characterization of the permeability of dual-scale fibrous porous media. Compos. Sci. Technol. 66(55), 2795–2803 (2006)

Kuentzer, N., Simacek, P., Advani, S.G., Walsh, S.: Permeability characterization of dual scale fibrous porous media. Compos. Part A 37(11), 2057–2068 (2006)

Amico, S., Lekakou, C.: An experimental study of the permeability and capillary pressure in resin-transfer moulding. Compos. Sci. Technol. 61(13), 1945–1959 (2001)

Han, K.K., Lee, C.W., Rice, B.P.: Measurement of the permeability of fiber performs and applications. Compos. Sci. Technol. 60, 2435–2441 (2000)

Verheus, A.S., Peeters, J.H.A.: The role of reinforcement permeability in resin transfer moulding. Compos. Manuf. 4(1), 33–38 (1993)

Luthy, T., Landert, M., Ermanni, P.: 1d-permeability measurements based on ultrasound and linear direct current resistance monitoring techniques. J. Mater. Process. Manuf. Sci. 10, 25–43 (2001)

Lomov, S.V., Verpoest, I., Peeters, T., Roose, D., Zako, M.: Nesting in textile laminates: geometrical modelling of the laminate. Compos. Sci. Technol. 63(7), 993–1007 (2003)

Hoes, K., Dinescu, D., Vanheule, M., Sol, H., Parnas, R.S., Belov, E.: Statistical distribution of permeability values of different porous materials. In: Proceedings of the 10th European conference on composite materials, Brugge (2002)

Dungan, F.D., Senoguz, M.T., Sastry, A.M., Faillaci, D.A.: Simulations and experiments on low-pressure permeation of fabrics: Part I—3D modeling of unbalanced fabric. J. Compos. Mater. 35(14), 1250–1284 (2001)

Senoguz, M.T., Dungan, F.D., Sastry, A.M., Klamo, J.T.: Simulations and experiments on low-pressure permeation of fabrics: Part II—The variable gap model and prediction of permeability. J. Compos. Mater. 35(14), 1285–1322 (2001)

Hoes, K., Dinescu, D., Sol, H., Parnas, R., Lomov, S.V.: Study of nesting induced scatter of permeability values in layered reinforcement fabrics. Compos. Part A 35(12), 1407–1418 (2004)

Endruweit, A., McGregor, P., Long, A.C., Johnson, M.S.: Influence of the fabric architecture on the variations in experimentally determined in-plane permeability values. Compos. Sci. Technol. 66(11–12), 1778–1792 (2006)

Endruweit, A., Long, A.C.: A model for the in-plane permeability of triaxially braided reinforcements. Compos. Part A 42(2), 165–172 (2011)

Grujicic, M., Chittajallu, K.M., Walsh, S.: Effect of shear. Compaction and nesting on permeability of the orthogonal plain-weave fabric performs. Mater. Chem. Phys. 86(2), 358–369 (2004)

Grujicic, M., Chittajallu, K.M., Walsh, S.: Lattice boltzmann method based computation of the permeability of the orthogonal plain-weave fabric performs. J. Mater. Sci. 41(23), 7989–8000 (2006)

Lekakou, C., Edwards, S., Bell, G., Amico, S.C.: Computer modelling for the prediction of the in-plane permeability of non-crimp stitch bonded fabrics. Compos. Part A 37(6), 820–825 (2006)

Jinlian, H., Yi, L., Xueming, S.: Study on void formation in multi-layer woven fabrics. Compos. Part A 35(5), 595 (2004)

Pillai, K.M.: Modeling the unsaturated flow in liquid composite molding processes: a review and some thoughts. J. Compos. Mater. 38(23), 2097–2118 (2004)

Fang, L.C., Jiang, J.J., Wang, J.B., Deng, C.: Non-uniform capillary model for unidirectional fiber bundles considering pore size distribution. J. Reinf. Plast. Compos. (2014). doi:10.1177/0731684414533739

Tran, T., Comas-Cardona, S., Abriak, N.E., Binetruy, C.: Unified microporomechanical approach for mechanical behavior and permeability of misaligned unidirectional fiber reinforcement. Compos. Sci. Technol. 70(9), 1410–1418 (2010)

Song, Y.S., Heider, D., Youn, J.R.: Statistical characteristics of out-of-plane permeability for plain-woven structure. Poly. Compos. 30(10), 1465–1472 (2009)

Breiling, B.K., Adams, D.O.: Effects of layer nesting on compression-loaded 2-D woven textile composites. J. Compos. Mater. 30(15), 1710–1728 (1996)

Shady, E., Gowayed, Y.: Interlaminar shear stress distribution between nested layers of plain weave composites. Poly. Compos. 31(11), 1838–1845 (2010)

Lomov, S., Verpoest, I., Peeters, T., Roose, D., Zako, M.: Nesting in textile laminates: geometrical modelling of the laminate. Compos. Sci. Technol. 63(7), 993–1007 (2002)

Ni, J., Zhao, Y., Lee, L.J., Nakamura, S.: Analysis of two-regional flow in liquid composite molding. Polym. Compos. 18(2), 254–269 (1997)

Gebart, B.R.: Permeability of unidirectional reinforcements for RTM. J. Compos. Mater. 26(8), 1100–1133 (1992)

Merhi, D., Michaud, V., Kämpfer, L., Vuilliomenet, P., Månson, J.A.E.: Transverse permeability of chopped fibre bundle beds. Compos. Part A 38(3), 739–746 (2007)

Chen, B., Chou, T.-W.: Compaction of woven-fabric performs: nesting and multi-layer deformation. Compos. Sci. Technol. 60(12–13), 2223–223 (2000)

Acknowledgments

This work was funded by NPU Foundation for Fundamental Research (JC20110254).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fang, L., Jiang, J., Wang, J. et al. Effect of Nesting on the Out-of-Plane Permeability of Unidirectional Fabrics in Resin Transfer Molding. Appl Compos Mater 22, 231–249 (2015). https://doi.org/10.1007/s10443-014-9403-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-014-9403-6