Abstract

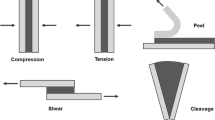

Use of thermoplastic composite material for load bearing components is increasing due to economical processing of complicated shapes in large quantities. Addition of fibre improves the strength and modulus of composites. Although the tribo-behaviour of thermoplastic composites were investigated, the friction and wear mechanisms are not yet fully understood. Friction and wear behaviour of injection unfilled Nylon 66, glass fibre reinforced Nylon 66 and carbon fibre reinforced Nylon 66 is investigated under dry sliding conditions. Tests were conducted at different normal loads and sliding velocities at room temperature. Coefficient of friction, wear loss and heat generation during the wear tests were quantified. Presence of fibre affects coefficient of friction and wear resistance of Nylon 66 matrix composites. The formation and stability of the transfer films affects the wear resistance. The rise in temperature during sliding was also calculated and also measured. The contact temperature rise is influenced by the composition which in turn influences the fibre adhesion and thereby the wear resistance. Glass fibre reinforced Nylon exhibited the lowest wear rate among the materials investigated. Both adhesive and abrasive wear mechanisms were observed in polymer matrix composites.

Similar content being viewed by others

References

Czichos, H., Klaffke, D., Santer, E. and Woydt, M., ‘Advances in Tribology: The Material Point of View’, Wear 190, 1995, 155–161.

Throp, J. M., ‘Friction of Some Commercial Polymer-Based Bearing Materials against Steel’, Tribology International 15, 1982, 69–74.

Watanabe, M. and Yamaguchi, H., ‘The Friction and Wear Properties of Nylon’, Wear 110, 1986, 379–388.

Mens, J. W. M. and de Gee, A. W. J., ‘Friction and Wear Behaviour of 18 Polymers in Contact with Steel in Environments of Air and Water’, Wear 149, 1991, 255–268.

Franklin, S. E., ‘Wear Experiments with Selected Engineering Polymers and Polymer Composites under Dry Sliding Conditions’, Wear 251, 2001, 1591–1598.

Bahadur, S. and Polineni, V. K., ‘Tribological Studies of Glass Fabric-Reinforced Polyamide Composites Filled with CuO and PTFE’, Wear 200, 1996, 95–104.

Palabiyik, M. and Bahadur, S., ‘Mechanical and Triboligical Properties of Polyamide 6 and High Density Polyethyelene polyblends with and without Compalibiliser’, Wear 246, 2000, 149–158.

ASTM D3171, ‘Standard Test Methods for Constituent Content of Composite Materials’, ASTM International, 2002.

Preliminary Product Data of RTP 200, RTP 281, RTP 283, RTP Company Product Data Sheet, RTP Company, USA, 2003.

ASTM G99, ‘Standard Test Method for Wear Testing with a Pin-on-Disc Apparatus’, ASTM International, 2002.

Palabiyik, M. and Bahadur, S., ‘Tribological Studies of Polyamide 6 and High-Density Polyethylene Blend Filled with PTFE and Copper Oxide and Reinforced with Glass Fibres’, Wear 25, 2002, 369–376.

Mclaren, K. G. and Tabor, D., ‘Viscoelastic Properties and Friction of Solids’, Nature 197, 1963, 856–858.

Stachwiak, G. W. and Batcholer, A. W., Engineering Tribology, Butterworth-Heinemann, Boston, 2001.

Holmberg, K. and Wickstrom, C., ‘Friction and Wear Tests of Polymers’, Wear 115, 1987, 95–105.

Sinha, S. K., ‘Wear Failure of Plastics’, in ASM Handbook, Vol. 11, Failure Analysis and Prevention, W. T. Becker and R. J. Shipley (eds), ASM International, OH, 2002, pp. 1020–1027.

Ghosh, D., Basu, H. and Manna, I., ‘Mathematical Modelling of Thermal Profile Generated in the Sample During a Pin-on-Disc Wear Testing Operation’, Scripta Materialia 40, 1999, 417–423.

Bahadur, S., ‘The Development of Transfer Layers and Their Role in Polymer Tribology’, Wear 245, 2000, 92–99.

Zsidai, L., De Baets, P., Samyn, P., Kalacska, G., Van Pateghem, A. P. and Van Parys, F., ‘The Tribological Behaviour of Engineering Plastics During Sliding Friction Investigated with Small-Scale Specimens’, Wear 253, 2002, 673–688.

Reinicke, R., Haupert, F. and Friedrich, K., ‘On Tribological Behaviour of Selected Injection Moulded Thermoplastic Composites’, Composites, Part A 29A, 1998, 763–771.

Unal, H., Mimaroglu, A., Kadioglu, U. and Ekiz, H., ‘Sliding Friction and Wear Behaviour of Polytetrafluroethylene and Its Composites under Dry Conditions’, Materials and Design 25, 2004, 239–245.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Srinath, G., Gnanamoorthy, R. Effect of Short Fibre Reinforcement on the Friction and Wear Behaviour of Nylon 66. Appl Compos Mater 12, 369–383 (2005). https://doi.org/10.1007/s10443-005-5824-6

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s10443-005-5824-6