Abstract

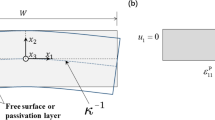

The phenomenological flow theory of higher-order strain gradient plasticity proposed by Fleck and Hutchinson (J. Mech. Phys. Solids, 2001) and then improved by Fleck and Willis (J. Mech. Phys. Solids, 2009) is used to investigate the surface-passivation problem and micro-scale plasticity. An extremum principle is stated for the theory involving one material length scale. To solve the initial boundary value problem, a numerical scheme based on the framework of variational constitutive updates is developed for the strain gradient plasticity theory. The main idea is that, in each incremental time step, the value of the effective plastic strain is obtained through the variation of a functional in regard to effective plastic strain, provided the displacement or deformation gradient. Numerical results for elasto-plastic foils under tension and bending, thin wires under torsion, are given by using the minimum principle and the numerical scheme. Implications for the role of dissipative gradient effect are explored for three non-proportional loading conditions: (1) stretch-passivation problem, (2) bending-passivation problem, and (3) torsion-passivation problem. The results indicate that, within the Fleck–Hutchinson–Willis theory, the dissipative length scale controls the strengthening size effect, i.e. the increase of initial yielding strength, while the surface passivation gives rise to an increase of strain hardening rate.

Graphic abstract

Similar content being viewed by others

References

Fleck, N.A., Muller, G.M., Ashby, M.F., et al.: Strain gradient plasticity: theory and experiment. Acta. Met. Mater. 42, 475–487 (1994)

Liu, D., He, Y., Dunstan, D.J., et al.: Anomalous plasticity in the cyclic torsion of micron scale metallic wires. Phys. Rev. Lett. 110, 244301 (2013)

Dunstan, D.J., Ehrler, B., Bossis, R., et al.: Elastic limit and strain hardening of thin wires in torsion. Phys. Rev. Lett. 103, 155501 (2009)

Liu, D., He, Y., Tang, X., et al.: Size effects in the torsion of microscale copper wires: experiment and analysis. Scripta Mater. 66, 406–409 (2012)

Liu, D., He, Y., Shen, L., et al.: Accounting for the recoverable plasticity and size effect in the cyclic torsion of thin metallic wires using strain gradient plasticity. Mater. Sci. Eng. A-Struct. 647, 84–90 (2015)

Ehrler, B., Hou, X.D., Zhu, T.T., et al.: Grain size and sample size interact to determine strength in a soft metal. Philos. Mag. 88, 3043–3050 (2008)

Stolken, J.S., Evans, A.G.: A microbend test method for measuring the plasticity length scale. Acta Mater. 46, 5109–5115 (1998)

Haque, M.A., Saif, M.T.A.: Strain gradient effect in nanoscale thin films. Acta Mater. 51, 3053–3061 (2003)

Stelmashenko, N., Walls, M., Brown, L., et al.: Microindentations on W and Mo oriented single crystals: an STM study. Acta. Met. Mater. 41, 2855–2865 (1993)

Ma, Q., Clarke, D.R.: Size dependent hardness of silver single crystals. J. Mater. Res. 10, 853–863 (1995)

Ashby, M.F.: The deformation of plastically non-homogeneous materials. Philos. Mag. 21, 399–424 (1970)

Nye, J.F.: Some geometrical relations in dislocated crystals. Acta Metall. 1, 153–162 (1953)

Aifantis, E.C.: On the microstructural origin of certain inelastic models. J. Eng. Mater-T. ASME. 106, 326 (1984)

Fleck, N.A., Hutchinson, J.W.: A reformulation of strain gradient plasticity. J. Mech. Phys. Solids 49, 2245–2271 (2001)

Hutchinson, J.W.: Generalizing J(2) flow theory: fundamental issues in strain gradient plasticity. Acta. Mech. Sinica. 28, 1078–1086 (2012)

Fleck, N.A., Willis, J.R.: A mathematical basis for strain-gradient plasticity theory. Part II: Tensorial plastic multiplier. J. Mech. Phys. Solids. 57, 1045–1057 (2009)

Fleck, N.A., Willis, J.R.: A mathematical basis for strain-gradient plasticity theory-Part I: scalar plastic multiplier. J. Mech. Phys. Solids 57, 161–177 (2009)

Gudmundson, P.: A unified treatment of strain gradient plasticity. J. Mech. Phys. Solids 52, 1379–1406 (2004)

Gudmundson, P., Dahlberg, C.F.O.: Isotropic strain gradient plasticity model based on self-energies of dislocations and the Taylor model for plastic dissipation. Int. J. Plast. 121, 1–20 (2019)

Gurtin, M.E., Anand, L.: A theory of strain-gradient plasticity for isotropic, plastically irrotational materials. Part II: finite deformations. Int. J. Plast. 21, 2297–2318 (2005)

Gurtin, M.E., Anand, L.: A theory of strain-gradient plasticity for isotropic, plastically irrotational materials. Part I: Small deformations. J. Mech. Phys. Solids. 53, 1624–1649 (2005)

Gurtin, M.E.: A gradient theory of small-deformation isotropic plasticity that accounts for the Burgers vector and for dissipation due to plastic spin. J. Mech. Phys. Solids 52, 2545–2568 (2004)

Nix, W.D., Gao, H.J.: Indentation size effects in crystalline materials: a law for strain gradient plasticity. J. Mech. Phys. Solids 46, 411–425 (1998)

Gao, H., Huang, Y., Nix, W.D., et al.: Mechanism-based strain gradient plasticity—I. Theory. J. Mech. Phys. Solids. 47, 1239–1263 (1999)

Kuroda, M., Tvergaard, V.: An alternative treatment of phenomenological higher-order strain-gradient plasticity theory. Int. J. Plast. 26, 507–515 (2010)

Chen, S.H., Wang, T.C.: A new hardening law for strain gradient plasticity. Acta Mater. 48, 3997–4005 (2000)

Voyiadjis, G.Z., Song, Y.: Strain gradient continuum plasticity theories: theoretical, numerical and experimental investigations. Int. J. Plast. 121, 21–75 (2019)

Evans, A.G., Hutchinson, J.W.: A critical assessment of theories of strain gradient plasticity. Acta Mater. 57, 1675–1688 (2009)

Gurtin, M.E., Fried, E., Anand, L.: The mechanics and thermodynamics of continua. Cambridge Univ Press, Cambridge (2009)

Mühlhaus, H.B., Aifantis, E.C.: A variational principle for gradient plasticity. Int. J. Solids Struct. 28, 845–857 (1991)

Gurtin, M.E., Anand, L.: Thermodynamics applied to gradient theories involving the accumulated plastic strain: the theories of Aifantis and Fleck and Hutchinson and their generalization. J. Mech. Phys. Solids 57, 405–421 (2009)

Fleck, N.A., Willis, J.R.: Strain gradient plasticity: energetic or dissipative? Acta. Mech. Sinica. 31, 465–472 (2015)

Gurtin, M.E.: On the plasticity of single crystals: free energy, microforces, plastic-strain gradients. J. Mech. Phys. Solids 48, 989–1036 (2000)

Xiang, Y., Vlassak, J.J.: Bauschinger and size effects in thin-film plasticity. Acta Mater. 54, 5449–5460 (2006)

Anand, L., Gurtin, M.E., Lele, S.P., et al.: A one-dimensional theory of strain-gradient plasticity: formulation, analysis, numerical results. J. Mech. Phys. Solids 53, 1789–1826 (2005)

Fredriksson, P., Gudmundson, P.: Size-dependent yield strength of thin films. Int. J. Plast. 21, 1834–1854 (2005)

Niordson, C.F., Legarth, B.N.: Strain gradient effects on cyclic plasticity. J. Mech. Phys. Solids 58, 542–557 (2010)

Bardella, L.: Size effects in phenomenological strain gradient plasticity constitutively involving the plastic spin. Int. J. Eng. Sci. 48, 550–568 (2010)

Bardella, L., Panteghini, A.: Modelling the torsion of thin metal wires by distortion gradient plasticity. J. Mech. Phys. Solids 78, 467–492 (2015)

Martinez-Paneda, E., Niordson, C.F., Bardella, L.: A finite element framework for distortion gradient plasticity with applications to bending of thin foils. Int. J. Solids Struct. 96, 288–299 (2016)

Hua, F., Liu, D., He, Y.: Modelling the effect of surface passivation within higher-order strain gradient plasticity: the case of wire torsion. Eur. J. Mech. A-Solid. 78, 103855 (2019)

Chiricotto, M., Giacomelli, L., Tomassetti, G.: Dissipative scale effects in strain-gradient plasticity: the case of simple shear. Siam. J. Appl. Math. 76, 688–704 (2016)

Panteghini, A., Bardella, L.: On the role of higher-order conditions in distortion gradient plasticity. J. Mech. Phys. Solids 118, 293–321 (2018)

Niordson, C.F., Hutchinson, J.W.: On lower order strain gradient plasticity theories. Eur. J. Mech. A-Solid. 22, 771–778 (2003)

Fleck, N.A., Hutchinson, J.W., Willis, J.R.: Strain gradient plasticity under non-proportional loading. Proc. R. Soc. A-Math. Phys. 470, 20140267 (2014)

Hutchinson, J.W.: Plasticity at the micron scale. Int. J. Solids Struct. 37, 225–238 (2000)

Shen, Y.L., Suresh, S., He, M.Y., et al.: Stress evolution in passivated thin films of Cu on silica substrates. J. Mater. Res. 13, 1928–1937 (1998)

Voyiadjis, G.Z., Song, Y.: Effect of passivation on higher order gradient plasticity models for non-proportional loading: energetic and dissipative gradient components. Philos. Mag. 97, 318–345 (2017)

Fredriksson, P., Gudmundson, P.: Modelling of the interface between a thin film and a substrate within a strain gradient plasticity framework. J. Mech. Phys. Solids 55, 939–955 (2007)

Aifantis, E.C.: The physics of plastic deformation. Int. J. Plast. 3, 211–247 (1987)

Smyshlyaev, V.P., Fleck, N.A.: The role of strain gradients in the grain size effect for polycrystals. J. Mech. Phys. Solids 44, 465–495 (1996)

Zhang, X., Aifantis, K.: Interpreting the internal length scale in strain gradient plasticity. Rev. Adv. Mater. Sci. 41, 72–83 (2015)

Liu, D., Dunstan, D.J.: Material length scale of strain gradient plasticity: a physical interpretation. Int. J. Plast. 98, 156–174 (2017)

Idiart, M.I., Deshpande, V.S., Fleck, N.A., et al.: Size effects in the bending of thin foils. Int. J. Eng. Sci. 47, 1251–1264 (2009)

Qiao, L.: Variational constitutive updates for strain gradient isotropic plasticity. Massachusetts Institute of Technology, Cambridge (2009)

Idiart, M.I., Fleck, N.A.: Size effects in the torsion of thin metal wires. Model. Simul. Mater. Sci. 18, 015009 (2010)

Fleck, N.A., Hutchinson, J.W., Willis, J.R.: Guidelines for constructing strain gradient plasticity theories. J. Appl. Mech. 82, 071002 (2015)

Moreau, P., Raulic, M., P’ng, K.M.Y., et al.: Measurement of the size effect in the yield strength of nickel foils. Philos. Mag. Lett. 85, 339–343 (2005)

Motz, C., Schoberl, T., Pippan, R.: Mechanical properties of micro-sized copper bending beams machined by the focused ion beam technique. Acta Mater. 53, 4269–4279 (2005)

Liu, D., Zhang, X., Li, Y., et al.: Critical thickness phenomenon in single-crystalline wires under torsion. Acta Mater. 150, 213–223 (2018)

Guo, S., He, Y., Lei, J., et al.: Individual strain gradient effect on torsional strength of electropolished microscale copper wires. Scripta Mater. 130, 124–127 (2017)

Danas, K., Deshpande, V.S., Fleck, N.A.: Size effects in the conical indentation of an elasto-plastic solid. J. Mech. Phys. Solids 60, 1605–1625 (2012)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grants 11702103 and 11972168), the Young Elite Scientist Sponsorship Program by CAST (Grant 2016QNRC001), and the Fundamental Research Funds for the Central Universities (Grant HUST 2018KFYYXJJ008).

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Three material length scales can be introduced to the Fleck–Hutchinson–Willis theory as seen in Eq. (10). We restrict attention to the simplest model, containing a single material length scale. Following Danas et al. [62], we introduce a particular choice for the relative magnitude of the length scales \(\ell_{I}\) by allowing

With this choice, one can write the length scales \(\ell_{I}\) in terms of a single length scale \(\ell\).

For the cases of foil tension and bending, the generalized effective plastic strain rate Eq. (10) is written as

where the second material length parameter \(\ell_{2}\) does not enter the expression. By (44), Eq. (45) is reduced to be

In Eq. (22), the coefficients read

For the case of wire torsion, the generalized effective plastic strain rate Eq. (10) is expressed as

with

where \(\ell_{3}\) is not involved in the expression. By (44), Eq. (48) is reduced to be

In Eq. (22), the coefficients become

Rights and permissions

About this article

Cite this article

Hua, F., Liu, D. On dissipative gradient effect in higher-order strain gradient plasticity: the modelling of surface passivation. Acta Mech. Sin. 36, 840–854 (2020). https://doi.org/10.1007/s10409-020-00965-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-020-00965-0