Abstract

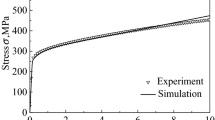

A crystal plasticity model is developed to predict the fatigue crack nucleation of polycrystalline materials, in which the accumulated dislocation dipoles are considered to be the origin of damage. To describe the overall softening behavior under cyclic loading, a slip system-level dislocation density-related damage model is proposed and implemented in the finite element analysis with Voronoi tessellation. The numerical model is applied to calibrate the stress–strain relationship at different cycles before fatigue crack nucleation. The parameters determined from the numerical analysis are substituted into a modified phase transformation model to predict the critical fatigue crack nucleation cycle. Comparing with the experimental results of Sn–3.0Ag–0.5Cu (SAC305) alloy and P91 steel, the proposed method can describe the constitutive behavior and predict the fatigue crack nucleation accurately.

Similar content being viewed by others

References

Shim, D.J., Alderliesten, R.C., Spearing, S.M., et al.: Fatigue crack growth prediction in GLARE hybrid laminates. Compos. Sci. Technol. 63, 1759–1767 (2003)

Wen, K., Xiong, B., Zhang, Y., et al.: Over-aging influenced matrix precipitate characteristics improve fatigue crack propagation in a high Zn-containing Al–Zn–Mg–Cu alloy. Mater. Sci. Eng., A 716, 42–54 (2018)

Naderi, M., Amiri, M., Iyyer, N., et al.: Prediction of fatigue crack nucleation life in polycrystalline AA7075-T651 using energy approach. Fatigue Fract. Eng. M. 39, 167–179 (2016)

Tanaka, K., Mura, T.: A dislocation model for fatigue crack initiation. ASME J. Appl. Mech. 48, 97–103 (1981)

Chan, K.S.: A microstructure-based fatigue-crack-initiation model. Metall. Mater. Trans. A 34, 43–58 (2003)

Li, D.F., Barrett, R.A., O’Donoghue, P.E., et al.: A multi-scale crystal plasticity model for cyclic plasticity and low-cycle fatigue in a precipitate-strengthened steel at elevated temperature. J. Mech. Phys. Solids 101, 44–62 (2017)

Fine, M.E., Bhat, S.P.: A model of fatigue crack nucleation in single crystal iron and copper. Mater. Sci. Eng., A 468, 64–69 (2007)

Yao, Y., Wang, J.D., Keer, L.M.: A phase transformation based method to predict fatigue crack nucleation and propagation in metals and alloys. Acta Mater. 127, 244–251 (2017)

McDowell, D.L., Dunne, F.P.E.: Microstructure–sensitive computational modeling of fatigue crack formation. Int. J. Fatigue 32, 1521–1542 (2010)

Basinski, Z.S., Basinski, S.J.: Fundamental-aspects of low amplitude cyclic deformation in face-centered cubic-crystals. Prog. Mater Sci. 36, 89–148 (1992)

Phan, V.T., Zhang, X., Li, Y., et al.: Microscale modeling of creep deformation and rupture in Nickel-based superalloy IN 617 at high temperature. Mech. Mater. 114, 215–227 (2017)

Sweeney, C.A., Vorster, W., Leen, S.B., et al.: The role of elastic anisotropy, length scale and crystallographic slip in fatigue crack nucleation. J. Mech. Phys. Solids 61, 1224–1240 (2013)

Li, L., Shen, L., Proust, G.: Fatigue crack initiation life prediction for aluminium alloy 7075 using crystal plasticity finite element simulations. Mech. Mater. 81, 84–93 (2015)

Zhang, K.S., Ju, J.W., Li, Z., et al.: Micromechanics based fatigue life prediction of a polycrystalline metal applying crystal plasticity. Mech. Mater. 85, 16–37 (2015)

Chen, B., Jiang, J., Dunne, F.P.E.: Microstructurally-sensitive fatigue crack nucleation in Ni-based single and oligo crystals. J. Mech. Phys. Solids 106, 15–33 (2017)

Brommesson, R., Ekh, M., Joseph, C.: 3D grain structure modelling of intergranular fracture in forged Haynes 282. Eng. Fract. Mech. 154, 57–71 (2016)

Bhat, S.P., Fine, M.E.: Fatigue crack nucleation in iron and a high strength low alloy steel. Mater. Sci. Eng., A 314, 90–96 (2001)

Döenges, B., Giertler, A., Krupp, U., et al.: Significance of crystallographic misorientation at phase boundaries for fatigue crack initiation in a duplex stainless steel during high and very high cycle fatigue loading. Mater. Sci. Eng., A 589, 146–152 (2014)

Chow, C.L., Wang, J.: An anisotropic theory of elasticity for continuum damage mechanics. Int. J. Fracture 33, 3–16 (1987)

Zhang, W., Jiang, W., Xu, Z., et al.: Fatigue life of a dissimilar welded joint considering the weld residual stress: experimental and finite element simulation. Int. J. Fatigue 109, 182–190 (2018)

Mounounga, T.B., Abdul-Latif, A., Razafindramary, D.: Damage induced anisotropy of polycrystals under complex cyclic loadings. Int. J. Mech. Sci. 53, 271–280 (2011)

Patra, A., McDowell, D.L.: A void nucleation and growth based damage framework to model failure initiation ahead of a sharp notch in irradiated bcc materials. J. Mech. Phys. Solids 74, 111–135 (2015)

Lemaitre, J., Chaboche, J.L.: Mechanics of Solid Materials. Cambridge University Press, Cambridge (1990)

Yao, Y., He, X., Keer, L.M., et al.: A continuum damage mechanics-based unified creep and plasticity model for solder materials. Acta Mater. 83, 160–168 (2015)

Liu, J., Li, J., Dirrasa, G., et al.: A three-dimensional multi-scale polycrystalline plasticity model coupled with damage for pure Ti with harmonic structure design. Int. J. Plast 100, 192–207 (2018)

Kim, J.B., Yoon, J.W.: Necking behavior of AA 6022-T4 based on the crystal plasticity and damage models. Int. J. Plast 73, 3–23 (2015)

Abdul-Latif, A., Saanouni, K.: Damaged anelastic behavior of FCC polycrystalline metals with micromechanical approach. Int. J. Damage Mech 3, 237–259 (1994)

Abdul-Latif, A., Mounounga, B.T.: Damage-induced anisotropy with damage deactivation. Int. J. Damage Mech 18, 177–198 (2009)

Anahid, M., Samal, M.K., Ghosh, S.: Dwell fatigue crack nucleation model based on crystal plasticity finite element simulations of polycrystalline titanium alloys. J. Mech. Phys. Solids 59, 2157–2176 (2011)

Wan, V.V.C., MacLachlan, D.W., Dunne, F.P.E.: A stored energy criterion for fatigue crack nucleation in polycrystals. Int. J. Fatigue 68, 90–102 (2014)

Zhu, Y., Engelhardt, M.D., Pan, Z.: Simulation of ductile fracture initiation in steels using a stress triaxiality–shear stress coupled model. Acta Mech. Sin. (2019). https://doi.org/10.1007/s10409-018-0825-5

Ashton, P.J., Harte, A.M., Leen, S.B.: A strain-gradient, crystal plasticity model for microstructure–sensitive fretting crack initiation in ferritic-pearlitic steel for flexible marine risers. Int. J. Fatigue 111, 81–92 (2018)

Fatemi, A., Socie, D.F.: A critical plane approach to multiaxial fatigue damage including out-of-phase loading. Fatigue Fract. Eng. Mater. Struct. 11, 149–165 (1988)

Manonukul, A., Dunne, F.P.E.: High- and low-cycle fatigue crack initiation using polycrystal plasticity. Proc. R. Soc. Lond. Ser. A Math. Phys. Eng. Sci. 460, 1881–1903 (2004)

Huang, Y.: A user-material subroutine incorporating single crystal plasticity in the ABAQUS finite element program. [Ph.D Thesis] Harvard University, Cambridge (1991)

Hu, P., Liu, Y., Zhu, Y., et al.: Crystal plasticity extended models based on thermal mechanism and damage functions: application to multiscale modeling of aluminum alloy tensile behavior. Int. J. Plast 86, 1–25 (2016)

Kalidindi, S.R., Bronkhorst, C.A., Anand, L.: Crystallographic texture evolution in bulk deformation processing of FCC metals. J. Mech. Phys. Solids 40, 537–569 (1992)

Beyerlein, I.J., Tomé, C.N.: A dislocation-based constitutive law for pure Zr including temperature effects. Int. J. Plast 24, 867–895 (2008)

Capolungo, L., Beyerlein, I.J., Tomé, C.N.: Slip-assisted twin growth in hexagonal close-packed metals. Scr. Mater. 60, 32–35 (2009)

Madec, R., Devincre, B., Kubin, L., et al.: The role of collinear interaction in dislocation-induced hardening. Science 301, 1879–1882 (2003)

Zecevic, M., Knezevic, M.: A dislocation density based elasto-plastic self-consistent model for the prediction of cyclic deformation: application to AA6022-T4. Int. J. Plast 72, 200–217 (2015)

Kitayama, K., Tomé, C.N., Rauch, E.F., et al.: A crystallographic dislocation model for describing hardening of polycrystals during strain path changes: application to low carbon steels. Int. J. Plast 46, 54–69 (2013)

Mecking, H., Kocks, U.F.: Kinetics of flow and strain-hardening. Acta Metall. 29, 1865–1875 (1981)

Jeong, Y., Barlat, F., Tomé, C.N., et al.: A comparative study between micro- and macro-mechanical constitutive models developed for complex loading scenarios. Int. J. Plast 93, 212–228 (2017)

Bonora, N.: A nonlinear CDM model for ductile failure. Eng. Fract. Mech. 58, 11–28 (1997)

Lin, B., Zhao, L.G., Tong, J., et al.: Crystal plasticity modeling of cyclic deformation for a polycrystalline nickel-based superalloy at high temperature. Mater. Sci. Eng., A 527, 3581–3587 (2010)

Mura, T., Nakasone, Y.: A theory of fatigue crack initiation in solids. J. Appl. Mech. 57, 1–6 (1990)

Liu, L., Yao, Y., Zeng, T., et al.: A dislocation density based micromechanical constitutive model for Sn–Ag–Cu solder alloys. Mater. Res. Express 4, 106506 (2017)

Zhou, B., Bieler, T.R., Lee, T.K., et al.: Methodology for analyzing slip behavior in ball grid array lead-free solder joints after simple shear. J. Electron. Mater. 38, 2702–2711 (2009)

Brar, N.S., Tyson, W.R.: Elastic and plastic anisotropy of white tin. Can. J. Phys. 50, 2257–2264 (1972)

Wen, W., Borodachenkova, M., Tomé, C.N., et al.: Mechanical behavior of low carbon steel subjected to strain path changes: experiments and modeling. Acta Mater. 111, 305–314 (2016)

Mura, T.: Micromechanics of Defects in Solids. Springer, Amsterdam (1982)

Acknowledgements

The work was supported by the National Natural Science Foundations of China (Grants 11572249, 11772257 and 11602196), and Y. Yao acknowledges the Alexander von Humboldt Foundation for supporting his stay at the Max-Planck-Institut für Eisenforschung.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, L., Wang, J., Zeng, T. et al. Crystal plasticity model to predict fatigue crack nucleation based on the phase transformation theory. Acta Mech. Sin. 35, 1033–1043 (2019). https://doi.org/10.1007/s10409-019-00876-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-019-00876-9