Abstract

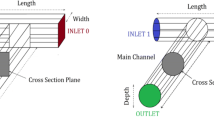

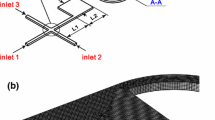

Recent drive for high-throughput microfluidic systems has triggered tremendous research effort to develop efficient, high-throughput microfluidic mixers. In particular, inducing a fluid–fluid collision at high flow rate in microfluidic channel has been suggested as an effective strategy to enhance mixing. However, previous studies using T-shaped microfluidic mixers showed that, in addition to fluid–fluid collision, the confluence angle of fluid stream in microfluidic channel also has a dramatic effect on mixing. This study suggests the possibility to enhance mixing by simply changing the inlet confluence angle of the streams. In this work, we assess the mixing behaviour of microfluidic mixers with variable inlet confluence angle with the Reynolds number (Re) range of 2.83–566. It is shown that the increase in inlet confluence angle enables the reduction of Re required for complete mixing. Simulation results demonstrate that increasing the confluence angle facilitates the interaction of vortices in mixers to induce an enhanced mixing. We further demonstrate that the increased interaction of vortices also prompts the turbulent emulsification where a significant reduction in emulsion size is observed for each mixer with increased inlet confluence angle at same Re.

Similar content being viewed by others

References

Ahmed D, Mao X, Juluri BK, Huang TJ (2009) A fast microfluidic mixer based on acoustically driven sidewall-trapped microbubbles. Microfluid Nanofluid 7:727–731

Ansari MA, Kim KY, Anwar K, Kim SM (2012) Vortex micro T-mixer with non-aligned inputs. Chem Eng J 181–182:846–850

Cheaib F, Kekejian G, Antoun S, Cheikh M, Lakkis I (2016) Microfluidic mixing using pulsating flows. Microfluid Nanofluid 20(5):1–19

Cortes-Quiroz CA, Azarbadegan A, Zangeneh M (2014) Evaluation of flow characteristics that give higher mixing performance in the 3-D T-mixer versus the typical T-mixer. Sens Actuator B Chem 202:1209–1219

Dimotakis PE (2005) Turbulent mixing. Annu Rev Fluid Mech 37:329–356

Dreher S, KockmannN N, Woias P (2009) Characterization of laminar transient flow regimes and mixing in T-shaped micromixers. Heat Transf Eng 30:91–100

Fani A, Camarri S, Salvetti MV (2013) Investigation of the steady engulfment regime in a three-dimensional T-mixer. Phys Fluids 25:064102

Glasgow I, Lieber S, Aubry N (2004) Parameters influencing pulsed flow mixing in microchannels. Anal Chem 76(16):4825–4832

Hardt S, Pennemann H, Schönfeld F (2006) Theoretical and experimental characterization of a low-Reynolds number split-and-recombine mixer. Microfluid Nanofluid 2(3):237–348

Hawkes JJ, Barber RW, Emerson DR, Coakley WT (2004) Continuous cell washing and mixing driven by an ultrasound standing wave within a microfluidic channel. Lab Chip 4:446–452

He B, Burke BJ, Zhang X, Zhang R, Regnier FE (2001) A picoliter-volume mixer for microfluidic analytical systems. Anal Chem 73(9):1942–1947

Hossain S, Kim KY (2015) Mixing performance of a serpentine micromixer with non-aligned inputs. Micromachines 6(7):842–854

Hsieh SS, Lin JW, Chen JH (2013) Mixing efficiency of Y-type micromixers with different angles. Int J Heat Fluid Flow 44:130–139

Judy J, Maynes D, Webb BW (2002) Characterization of frictional pressure drop for liquid flows through microchannels. Int J Heat Mass Transf 45:3477–3489

Kashid M, Renken A, Kiwi-Minsker L (2011) Mixing efficiency and energy consumption for five generic microchannel designs. Chem Eng J 167:436–443

Kim H, Min KI, Inoue K, Im DJ, Kim DP, Yoshida J (2016) Submillisecond organic synthesis: outpacing Fries rearrangement through microfluidic rapid mixing. Science 352(6286):691–694

Kockmann N, Kiefer T, Engler M, Woias P (2006) Convective mixing and chemical reactions in microchannels with high flow rates. Sens Actuator B Chem 117(2):495–508

Lee CY, Chang CL, Wang YN, Fu FM (2011) Microfluidic mixing: a review. Int J Mol Sci 12(5):3263–3287

Liu RH, Stremler MA, Sharp KV, Olsen MG, Santiago JG, Adrian RJ, Aref H, Beebe DJ (2000) Passive mixing in a three-dimensional serpentine microchannel. J Microelectromech Syst 9(2):190–197

Lupi FR, Gabriele D, Seta L, Baldino N, de Cindio B, Marino R (2015) Rheological investigation of pectin-based emulsion gels for pharmaceutical and cosmetic uses. Rheol Acta 54(1):41–52

Patel AR, Rodriguez Y, Lesaffer A, Dewettinck K (2014) High internal phase emulsion gels (HIPE-gels) prepared using food-grade components. RSC Adv 4:18136–18140

Ryu KS, Shaikh K, Goluch E, Fan Z, Liu C (2004) Micro magnetic stir-bar mixer integrated with parylene microfluidic channels. Lab Chip 4:608–613

Seong GH, Croocks RM (2002) Efficient mixing and reactions within microfluidic channels using microbead-supported catalysts. J Am Chem Soc 124(45):13360–13361

Sia SK, Whitesides GM (2003) Microfluidic devices fabrication in poly (dimethylsiloxane) for biological studies. Electrophoresis 24(21):3563–3576

Siconolfi L, Fani A, Camarri S, Salvetti MV (2016) Effect of geometry modifications on the engulfment in micromixers: numerical simulations and stability analysis. Eur J Mech B Fluid 55:360–366

Stroock AD, Dertinger SK, Ajdari A, Mezić I, Stone HA, Whitesides GM (2002) Chaotic mixer for microchannels. Science 295(5555):647–651

Thomas S, Ameel TA (2010) An experimental investigation of moderate Reynolds number flow in a T-Channel. Exp Fluids 49:1231–1245

van den Brink FTG, Wigger T, Ma L, Odijk M, Olthuis W, Karst U, van der Berg A (2016) Oxidation and adduct formation of xenobiotics in a microfluidic electrochemical cell with boron doped diamond electrodes and an integrated passive gradient rotation mixer. Lab Chip 16:3990–4001

Vankova N, Tcholakova S, Denkov ND, Ivanov IB, Vulchev VD, Danner TJ (2007) Emulsification in turbulent flow 1. Mean and maximum drop diameters in inertial and viscous regimes. Colloid Interface Sci 312:363–380

Wang Y, Zhe J, Chung BTF, Dutta P (2008) A rapid magnetic particle driven micromixer. Microfluid Nanofluid 4(5):375–389

Wong SH, Ward MCL, Wharton CW (2004) Micro T-mixer as a rapid mixing micromixer. Sens Actuator B Chem 100(3):359–379

Yaralioglu GG, Wygant IO, Marentis TC, Khuri-Yakub BT (2004) Ultrasonic mixing in microfluidic channels using integrated transducers. Anal Chem 76(13):3694–3698

You JB, Min KI, Lee B, Kim DP, Im SG (2013) A doubly cross-linked nano-adhesive for the reliable sealing of flexible microfluidic devices. Lab Chip 13:1266–1272

You JB, Kang K, Tran TT, Hwang WR, Kim JM, Im SG (2015) PDMS-based turbulent microfluidic mixer. Lab Chip 15(7):1727–1735

Yuen PK, Li G, Bao Y, Muller UR (2003) Microfluidic devices for fluidic circulation and mixing improve hybridization signal intensity on DNA arrays. Lab Chip 3:46–50

Acknowledgements

This work was supported by Wearable Platform Materials Technology Center (WMC) funded by the National Research Foundation of Korea (NRF) Grant of the Korean Government (MSIP) (No. 2016R1A5A1009926) and by the Center for Advanced Soft-Electronics funded by the Ministry of Science, ICT and Future Planning as Global Frontier Project (CASE-2011-0031638).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

You, J.B., Choi, Y. & Im, S.G. Influence of adjusting the inlet channel confluence angle on mixing behaviour in inertial microfluidic mixers. Microfluid Nanofluid 21, 121 (2017). https://doi.org/10.1007/s10404-017-1958-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-017-1958-8