Abstract

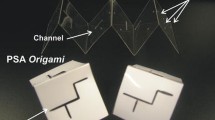

In this paper, we focus on characterizing the limits of xurography, or patterning with a razor blade, of a pressure-sensitive double-sided adhesive. This is a rapid, inexpensive technique to fabricate robust microfluidics devices. Straight, curved and square serpentine as well as zigzag channels of different dimensions are studied. General guidelines are provided to assess feasibility of a particular geometry a priori. The mechanics of the cut are explored with the aim at identifying the bottlenecks that limit the maximum resolution achieved in xurography of adhesive films. A number of advantages and disadvantages of this technique compared to other common fabrication techniques are also provided.

Similar content being viewed by others

References

Ai Y, Beskok A, Gauthier DT et al (2009) Dc Electrokinetic transport of cylindrical cells in straight microchannels. Biomicrofluidics 3:44110. doi:10.1063/1.3267095

Alom Ruiz S, Chen CS (2007) Microcontact printing: a tool to pattern. Soft Matter 3:168. doi:10.1039/b613349e

Atencia J, Cooksey GA, Locascio LE (2012) A robust diffusion-based gradient generator for dynamic cell assays. Lab Chip 12:309. doi:10.1039/c1lc20829b

Bartholomeusz D, Boutté RW, Andrade JD (2005) Xurography: rapid prototyping of microstructures using a cutting plotter. J Microelectromech Syst 14:1364. doi:10.1109/JMEMS.2005.859087

Beebe DJ, Mensing GA, Walker GM (2002) Physics and applications of microfluidics in biology. Annu Rev Biomed Eng 4:261–286. doi:10.1146/annurev.bioeng.4.112601.125916

Bruzewicz D a, Recheses M, Whitesid GM (2008) Low-cost printing of poly(dimethylsiloxane) barriers to define microchannels in paper. Anal Chem 80:3387–3392. doi:10.1021/ac702605a

Carrilho E, Martinez AW, Whitesides GM (2009) Understanding wax printing: a simple micropatterning process for paper-based microfluidics. Anal Chem 81:7091–7095. doi:10.1021/ac901071p

Cho C-H, Cho W, Ahn Y, Hwang S-Y (2007) PDMS–glass serpentine microchannel chip for time domain PCR with bubble suppression in sample injection. J Micromechanics Microengineering 17:1810–1817. doi:10.1088/0960-1317/17/9/009

Choi K, Ng AHC, Fobel R, Wheeler AR (2012) Digital microfluidics. Annu Rev Anal Chem (Palo Alto Calif) 5:413–440. doi:10.1146/annurev-anchem-062011-143028

Cosson S, Aeberli LG, Brandenberg N, Lutolf M (2015) Ultra-rapid prototyping of flexible, multi-layered microfluidic devices via razor writing. Lab Chip 15:72. doi:10.1039/c4lc00848k

Cubaud T, Ho C-M (2004) Transport of bubbles in square microchannels. Phys Fluids 16:4575. doi:10.1063/1.1813871

Do J, Zhang JY, Klapperich CM (2011) Maskless writing of microfluidics: rapid prototyping of 3D microfluidics using scratch on a polymer substrate. Robot Comput integr Manuf 27:245–248. doi:10.1016/j.rcim.2010.06.004

Dong Q, Xia Y, Whitesides GM (1996) Rapid prototyping of complex structures with feature sizes larger than 20 micron. Adv Mater 8:917–919

Duffy DC, McDonald JC, Schueller OJ, Whitesides GM (1998) Rapid prototyping of microfluidic systems in poly(dimethylsiloxane). Anal Chem 70:4974–4984. doi:10.1021/ac980656z

Gorking R, Clime L, Madou M, Kido H (2010) Pneumatic pumping in centrifugal microfluidic platforms. Microfluid Nanofluid 9:541–549. doi:10.1007/s10404-010-0571-x

Greer J, Sundberg SO, Wittwer CT, Gale BK (2007) Comparison of glass etching to xurography prototyping of microfluidic channels for DNA melting analysis. J Micromech Microeng 17:2407–2413. doi:10.1088/0960-1317/17/12/003

Harrison DJ, Manz A, Fan Z et al (1992) Capillary electrophoresis and sample injection systems integrated on a planar glass chip. Anal Chem 64:1926–1932

Jaramillo MDC, Torrents E, Martínez-Duarte R et al (2010) On-line separation of bacterial cells by carbon-electrode dielectrophoresis. Electrophoresis 31:2921–2928. doi:10.1002/elps.201000082

Jiang XN, Zhou ZY, Yao J, et al (1995) Micro-fluid flow in microchannel. In: 8th international conference on solid state sensors actuators eurosensors IX, pp 317–320

Keenan TM, Folch A (2008) Biomolecular gradients in cell culture systems. Lab Chip 8:34–57. doi:10.1039/b711887b

Kido H, Micic M, Smith D et al (2007) A novel, compact disk-like centrifugal microfluidics system for cell lysis and sample homogenization. Colloids Surf B Biointerfaces 58:44–51. doi:10.1016/j.colsurfb.2007.03.015

Martinez-Duarte R, Madou MJ (2011) SU-8 photolithography and its impact on microfluidics. In: Chakraborty S, Mitra S (eds) Microfluidics nanofluidics handbook: fabrication, implementation and applications. CRC Press, Boca Raton, pp 231–268

Martinez-Duarte R, Gorkin RA, Abi-Samra K, Madou MJ (2010) The integration of 3D carbon-electrode dielectrophoresis on a CD-like centrifugal microfluidic platform. Lab Chip 10:1030–1043. doi:10.1039/b925456k

Martinez-Duarte R, Renaud P, Madou MJ (2011) A novel approach to dielectrophoresis using carbon electrodes. Electrophoresis 32:2385–2392. doi:10.1002/elps.201100059

Martinez-Duarte R, Camacho-Alanis F, Renaud P, Ros A (2013) Dielectrophoresis of lambda-DNA using 3D carbon electrodes. Electrophoresis 34:1113–1122. doi:10.1002/elps.201200447

Mernier G, Martinez-Duarte R, Lehal R et al (2012) Very high throughput electrical cell lysis and extraction of intracellular compounds using 3D carbon electrodes in lab-on-a-chip devices. Micromachines 3:574–581. doi:10.3390/mi3030574

Mu X, Zheng W, Sun J et al (2013) Microfluidics for manipulating cells. Small 9:9–21. doi:10.1002/smll.201200996

Munson MS, Yager P (2003) A novel microfluidic mixer based on successive lamination. In: 7th international conference miniaturized chemical and biochemical analysis system. Squaw Valley, California, USA, pp 495–498

Nath P, Maity TS, Petterson F et al (2014) Polymerase chain reaction compatibility of adhesive transfer tape based microfluidic platforms. Microsyst Technol 20:1187–1193. doi:10.1007/s00542-013-1901-1

Pjescic I, Crews N (2012) Genotyping from saliva with a one-step microdevice. Lab Chip 12:2514–2519. doi:10.1039/c2lc00010e

Ren Y, Leung WW-F (2013) Flow and mixing in rotating zigzag microchannel. Chem Eng J 215–216:561–578. doi:10.1016/j.cej.2012.09.136

Rogers JA, Nuzzo RG (2005) Recent progress in soft lithography. Mater Today 8:50–56. doi:10.1016/S1369-7021(05)00702-9

Whitesides GM (2006) The origins and the future of microfluidics. Nature 442:368–373. doi:10.1038/nature05058

Wilding P, Pfahler J, Bau HH et al (1994) Manipulation and flow of biological fluids in straight channels micromachined in silicon. Clin Chem 40:43–47

Woolley AT, Mathies RA (1994) Ultra-high-speed DNA fragment separations using microfabricated capillary array electrophoresis chips. Proc Natl Acad Sci USA 91:11348–11352

Xia Y, Whitesides GM (1998) Soft lithography. Annu Rev Mater Sci 28:153–184

Yi X, Kodzius R, Gong X, Xiao K, Wen W (2010) A simple method of fabricating mask-free microfluidic. pdf. Biomicrofluidics 4:036503. doi:10.1063/1.3487796

Yuen PK, Goral VN (2010) Low-cost rapid prototyping of flexible microfluidic devices using a desktop digital craft cutter. Lab Chip 10:384–387. doi:10.1039/b918089c

Acknowledgments

The authors thank Alicia Werner, Emily Wakefield and Madison Oldham of the Creative Inquiry program of Clemson University for discussion regarding the gradient generator.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Islam, M., Natu, R. & Martinez-Duarte, R. A study on the limits and advantages of using a desktop cutter plotter to fabricate microfluidic networks. Microfluid Nanofluid 19, 973–985 (2015). https://doi.org/10.1007/s10404-015-1626-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-015-1626-9