Abstract

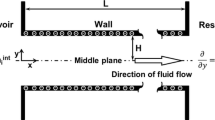

Electrical charges originate at most solid surfaces in contact with aqueous electrolytes which result in the formation of an electrical double layer. If an external electric field is tangentially applied to the double layer, an electroosmotic flow is induced which can be employed for various applications such as microfluidic pumps. Here, highly porous materials are especially suitable since they generate significant flow rates along with high pump pressures. The models which are currently used to describe the electroosmotic flow through porous substrates are based on the so-called parallel capillary flow model. In terms of packed beds of granular materials, these models have the disadvantages of oversimplifying the geometry to tortuous capillaries while neglecting intra- and inter-pore connections, varying pore cross-sectional geometries as well as the influence of the packed bed walls. In the current research, we employ dimensional reasoning (Buckingham \(\Pi\) theorem) to derive a phenomenological model which relates the electroosmotic flow to the averaged parameters of the packed bed as well as to the relevant physicochemical parameters. A comprehensive set of experiments is carried out to infer a semiempirical correlation which can be universally applied to packed beds of arbitrary granular materials. Additionally, we derive a dynamic model of the center-of-mass motion of the fluidic parts of the experimental setup. The model allows for an evaluation of the influence of Joule heating without monitoring the temperature in the bed.

Similar content being viewed by others

References

Ai Y, Yalcin SE, Gu D, Baysal O, Baumgart H, Qian S, Beskok A (2010) A low-voltage nano-porous electroosmotic pump. J Colloid Interface Sci 350(2):465–470

Barz DPJ, Ehrhard P (2005) Model and verification of electrokinetic flow and transport in a micro-electrophoresis device. Lab Chip 5(9):949–958

Barz DPJ, Steen PH (2013) A dynamic model of the electroosmotic droplet switch. Phys Fluids 25(9):097,104

Barz DPJ, Vogel MJ, Steen PH (2009) Determination of the zeta potential of porous substrates by droplet deflection. I. The influence of ionic strength and pH value of an aqueous electrolyte in contact with a borosilicate surface. Langmuir 25(3):1842–1850

Barz DPJ, Zadeh H, Ehrhard P (2011) Measurements and simulations of time-dependent flow fields within an electrokinetic micromixer. J Fluid Mech 676:265–293

Bird RB, Stewart WE, Lightfoot EN (2007) Transport phenomena. Wiley, London

Blake TD, Haynes JM (1969) Kinetics of liquid/liquid displacement. J Colloid Interface Sci 30(3):421–423

Bockelmann H, Heuveline V, Barz DP (2012) Optimization of an electrokinetic mixer for microfluidic applications. Biomicrofluidics 6(2):024,123

Borowsky J, Lu Q, Collins GE (2008a) High pressure electroosmotic pump based on a packed bed planar microchip. Sens Actuators B 131(1):333–339

Borowsky JF, Giordano BC, Lu Q, Terray A, Collins GE (2008b) Electroosmotic flow-based pump for liquid chromatography on a planar microchip. Anal Chem 80(21):8287–8292

Buckingham E (1914) On physically similar systems; illustrations of the use of dimensional equations. Phys Rev IV 4:345–376

Cao Z, Yuan L, Liu YF, Yao S, Yobas L (2012) Microchannel plate electro-osmotic pump. Microfluid Nanofluid 13(2):279–288

Chang C, Yang RR (2007) Electrokinetic mixing in microfluidic systems. Microfluid Nanofluid 3(5):501–525

Cikalo M, Bartle K, Robson M, Myers P, Euerby M (1998) Capillary electrochromatography: tutorial review. Analyst 123(7):87R–102R

Das S, Chanda S, Eijkel J, Tas N, Chakraborty S, Mitra SK (2014) Filling of charged cylindrical capillaries. Phys Rev E 90(4):043,011

de Klerk A (2003) Voidage variation in packed beds at small column to particle diameter ratio. AIChE J 49(8):2022–2029

Delgado A, González-Caballero F, Hunter R, Koopal L, Lyklema J (2007) Measurement and interpretation of electrokinetic phenomena. J Colloid Interface Sci 309(2):194–224

Dias RP, Teixeira JA, Mota MG, Yelshin AI (2004) Particulate binary mixtures: dependence of packing porosity on particle size ratio. Ind Eng Chem Res 43(24):7912–7919

Dong W, Young-Ho C (2007) A continuous electrical cell lysis device using a low DC voltage for a cell transport and rupture. Sens Actuators B 124(1):84–89

Falahati H, Wong L, Davarpanah L, Garg A, Schmitz P, Barz D (2014) The zeta potential of PMMA in contact with electrolytes of various conditions: theoretical and experimental investigation. ELECTROPHORESIS 35:870–882

Glawdel T, Elbuken C, Lee LE, Ren CL (2009) Microfluidic system with integrated electroosmotic pumps, concentration gradient generator and fish cell line (RTgill-W1)—towards water toxicity testing. Lab Chip 9(22):3243–3250

Gu C, Jia Z, Zhu Z, He C, Wang W, Morgan A, Lu JJ, Liu S (2012) Miniaturized electroosmotic pump capable of generating pressures of more than 1200 bar. Anal Chem 84(21):9609–9614

Heuck FC, Staufer U (2011) Low voltage electroosmotic pump for high density integration into microfabricated fluidic systems. Microfluid Nanofluid 10(6):1317–1332

Hu J, Chao C (2007) A study of the performance of microfabricated electroosmotic pump. Sens Actuators A 135(1):273–282

Hunter R (1981) Zeta potential in colloid science: principles and applications. Academic Press, London

Jacobson SC, Ramsey JM (1997) Electrokinetic focusing in microfabricated channel structures. Anal Chem 69(16):3212–3217

Jahanshahi A, Axisa F, Vanfleteren J (2012) Fabrication of a biocompatible flexible electroosmosis micropump. Microfluid Nanofluid 12(5):771–777

Kang Y, Tan SC, Yang C, Huang X (2007) Electrokinetic pumping using packed microcapillary. Sens Actuators A 133(2):375–382

Kim D, Posner JD, Santiago JG (2008) High flow rate per power electroosmotic pumping using low ion density solvents. Sens Actuators A 141(1):201–212

Kirby B, Hasselbrink E Jr (2004) Zeta potential of microfluidic substrates: 1. Theory, experimental techniques and effects on separations. ELECTROPHORESIS 25(2):187–202

Kwon K, Park CW, Kim D (2012) High-flowrate, compact electroosmotic pumps with porous polymer track-etch membranes. Sens Actuators A 175:108–115

Lazar L, Karger B (2002) Multiple open-channel electroosmotic pumping system for microfluidic sample handling. Anal Chem 74(24):6259–6268

Leese H, Mattia D (2014) Electroosmotic flow in nanoporous membranes in the region of electric double layer overlap. Microfluid Nanofluid 16(4). doi:10.1007/s10404-013-1255-0

Mazur P, Overbeek J (1951) On electro-osmosis and streaming-potentials in diaphragms. II. General quantitative relationship between electro-kinetic effects. Rec Trav Chim 70:83–91

Mehta D, Hawley MC (1969) Wall effect in packed columns. Ind Eng Chem Process Des Dev 8(2):280–282

Niven RK (2002) Physical insight into the Ergun and Wen and Yu equations for fluid flow in packed and fluidised beds. Chem Eng Sci 57(3):527–534

Ouchiyama N, Tanaka T (1981) Porosity of a mass of solid particles having a range of sizes. Ind Eng Chem Fundam 20(1):66–71

Popescu MN, Ralston J, Sedev R (2008) Capillary rise with velocity-dependent dynamic contact angle. Langmuir 24(21):12,710–12,716

Pu Q, Liu S (2004) Microfabricated electroosmotic pump for capillary-based sequential injection analysis. Anal Chim Acta 511(1):105–112

Reichmuth DS, Chirica GS, Kirby BJ (2003) Increasing the performance of high-pressure, high-efficiency electrokinetic micropumps using zwitterionic solute additives. Sens Actuators B 92(1):37–43

Reuss F (1809) Sour un nouvel effet de l’électricité galvanique. Mémoires de la societé impériale des naturalistes de Moscou 2:327–337

Rice C, Whitehead R (1965) Electrokinetic flow in a narrow capillary. J Phys Chem 11:4017–4024

Saini R, Garg A, Barz DP (2014) Streaming potential revisited: the influence of convection on the surface conductivity. Langmuir 30(36):10,950–10,961

Scales N, Tait R (2006) Modeling electroosmotic and pressure-driven flows in porous microfluidic devices: zeta potential and porosity changes near the channel walls. J Chem Phys 125:094714-1–094714-12

Scales P, Grieser F, Healy T (1992) Electrokinetics of the silica-solution interface: a flat plate streaming potential study. Langmuir 8:965–974

Shin W, Lee JM, Nagarale RK, Shin SJ, Heller A (2011) A miniature, nongassing electroosmotic pump operating at 0.5 V. J Am Chem Soc 133(8):2374–2377

Simal-Gándara J (2004) The place of capillary electrochromatography among separation techniques—a review. Crit Rev Anal Chem 34(2):85–94. doi:10.1080/10408340490475867

Smoluchowski MV (1903) Contribution à la théorie de l’endosmose électrique et de quelques phenoménes corrélatifs. Bull Int Acad Sci Crac 8:182–200

Tang G, Yang C, Chai J, Gong H (2004) Joule heating effect on electroosmotic flow and mass species transport in a microcapillary. Int J Heat Mass Transf 47:215–227

Tripp J, Svec F, Fréchet J, Zeng S, Mikkelsen J, Santiago J (2004) High-pressure electroosmotic pumps based on porous polymer monoliths. Sens Actuators B 99(1):66–73

Vallano PT, Remcho VT (2000) Modeling interparticle and intraparticle (perfusive) electroosmotic flow in capillary electrochromatography. Anal Chem 72:4255–4265

van den Bosch SE, Heemstra S, Kraak JC, Poppe H (1996) Experiences with packed capillary electrochromatography at ambient pressure. J Chromatogr A 755(2):165–177

Waghmare PR, Mitra SK (2010) Modeling of combined electroosmotic and capillary flow in microchannels. Anal Chim Acta 663(2):117–126

Wang C, Wang L, Zhu X, Wang Y, Xue J (2012) Low-voltage electroosmotic pumps fabricated from track-etched polymer membranes. Lab Chip 12(9):1710–1716

Wang P, Chen Z, Chang HC (2006) A new electro-osmotic pump based on silica monoliths. Sens Actuators B 113(1):500–509

Wang X, Cheng C, Wang S, Liu S (2009) Electro osmotic pumps and their applications in microfluidic systems. Microfluid Nanofluid 6:145–162

Waters L, Jacobson S, Kroutchinina N, Khandurina J, Foote R, Ramsey J (1998) Microchip device for cell lysis, multiplex PCR amplification, and electrophoretic sizing. Anal Chem 70(1):158–162

Xuan X (2008) Joule heating in electrokinetic flow. ELECTROPHORESIS 29(1):33–43

Yao S, Santiago J (2003) Porous glass electroosmotic pumps: theory. J Colloid Interface Sci 268:133–142

Yao S, Hertzog D, Zeng S, Mikkelesen J Jr, Santiago J (2003) Porous glass electroosmotic pumps: design and experiments. J Colloid Interface Sci 268:143–153

Zeng S, Chen C, Mikkelsen J, Santiago J (2001) Fabrication and characterization of electroosmotic micropumps. Sens Actuators B 79:107–114

Zeng S, Chen CH, Santiago JG, Chen JR, Zare RN, Tripp JA, Frantisek S, Fréchet JM (2002) Electroosmotic flow pumps with polymer frits. Sens Actuators B 82(2–3):209–212

Acknowledgments

The Natural Sciences and Engineering Research Council of Canada (NSERC) and DuPont Canada are gratefully acknowledge for providing financial support to this project.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Table 1 lists the conditions used to perform the experiments in this work. In detail, we used 9 packed beds, 3 pH values, 5 electric field strengths, and up to 4 ionic strengths. All in all, we perform 342 measurements to cover the widest possible range of the dimensionless groups given in Eq. (6).

Table 2 lists the groups of particle mixtures used for the interpretation of the packed bed parameters where \(\delta = \frac{d}{\rm D}\) is the ratio of small to large particle diameter and \(v_d\) is the volume fraction of the small particles.

Rights and permissions

About this article

Cite this article

Saini, R., Kenny, M. & Barz, D.P.J. Electroosmotic flow through packed beds of granular materials. Microfluid Nanofluid 19, 693–708 (2015). https://doi.org/10.1007/s10404-015-1594-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-015-1594-0