Abstract

To evaluate the mass of coarse woody debris (CWD), it is necessary to quantify its density. Drill resistance measurements are introduced as a approach to estimate the density of CWD in different stages of decay. Dead logs of Norway spruce [Picea abies (L.) Karst.] from a Central European mountainous site were used as a test system to compare the new method with conventional predictors of wood density such as fast quantitative field estimates (e.g., knife probe) and classification of decay classes based on a set of qualitative traits and quantitative estimates. The model containing only drill resistance as a predictor explained 65% of the variation in wood density and was markedly better than models containing one or more of several conventional predictors. However, we show that the relationship between drill resistance and gravimetric wood density relationship is sensitive to the decay status. Therefore, the best model combines drill resistance and decay class (adj. R² = 0.732). An additional experiment showed that drill resistance is also sensitive to the moisture state (fresh vs. oven-dry) of the sample. The major potential of the method lies in its non-destructive nature which allows repeated sampling in long-term ecosystem studies or in protected areas where destructive sampling is prohibited. The limitations of the method are discussed and recommendations for applications are given.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Coarse woody debris (CWD) plays an important role in forest ecosystems. It provides substrate and habitat for numerous organisms and is thus essential for the maintenance of biodiversity (Grove 2002; Jonsson et al. 2005; Lonsdale et al. 2008). Furthermore, it may constitute a significant fraction of carbon stocks in natural forest ecosystems (Harmon et al. 1986; Jonsson 2000) and increasing the CWD pool in managed forests can induce a strong albeit transient carbon sink. To project the development of CWD pools at a given input, it is necessary to know the kinetics of CWD decomposition, which during the early stages of decay manifests itself primarily as a reduction in wood density. This reduction results from fragmentation by xylophagous or wood-dwelling insects and from heterotrophic consumption by micro-organisms (Harmon et al. 1986; Speight 1989). A reduction in volume is observed mainly during later stages, when the process of fragmentation has progressed to destabilize the log’s integrity.

So far changes in density of CWD have been mainly quantified with destructive methods (Harmon and Sexton 1996; Naesset 1999a; Yatskov et al. 2003). Usually wood discs are taken at different positions along sample logs in various stages of decay. The discs are dried in the laboratory and the density is calculated as the ratio of dry weight and fresh volume. These data are then used to establish a relationship between the ‘decay class’ assessed in the field and the relative density loss (Naesset 1999b). This method has several disadvantages. (1) Since it is destructive, temporally repeated measurements on the same log are not possible. Standing or hanging logs collapse after sampling and get into contact with the forest floor which usually accelerates the decomposition process. (2) Destructive methods are prohibited in nature reserves, which in Central Europe and many regions of the US represent the only areas where sufficient deadwood can be found. (3) The method is prone to error because it is difficult to cut and transport highly decomposed wood without losing material. (4) The classification according to decay class is only semi-quantitative and includes many descriptive predictors and the relationship between decay class and density is usually weak (Graham and Cromack 1982; Naesset 1999b).

Drill resistance has been used to measure density and concentrations of carbon and nitrogen in CWD of red spruce (Picea rubens Sarg.) and Fraser fir [Abies fraseri (Pursh) Poir.] (Creed et al. 2004). Creed et al. (2004) could show that drill-resistance measurements can be employed within a certain range of CWD density, but nevertheless that they are less precise than displacement or mensuration density determination.

In this paper, we explore drill resistance in combination with fast quantitative field methods as a method for measuring wood densities across a gradient of decay classes in managed spruce forests. We use a resistograph that measures the drill resistance in wood. Drill-resistance measurements are mainly used by arborists or by construction engineers (Rinn 1996; Costello and Quarles 1999; Eckstein and Saß 1994; Niemz et al. 2002) to detect defects either in living trees or in construction timbers. Furthermore, the method has been used to assess wood density in living trees (Isik and Li 2003) and to evaluate annual tree ring characteristics (Wang et al. 2003). The method is based on the drill resistance of a thin drilling needle while it penetrates the wood (Rinn 1996; Rinn et al. 1996).

In this paper, we demonstrate that drill resistance measurements in combination with a coarse classification of decay classes is a suitable method for detecting density loss in CWD of Norway spruce (Picea abies Karst.) and represents an improvement over conventional methods. We also discuss the limitations of this method.

Materials and methods

Within the study area “Wetzstein” CWD was collected in zero-thinning areas, where no management activities had taken place for a period of 30–50 years. With an elevation of 792 m a.s.l. the Wetzstein plateau forms the highest ridge in the south-eastern part of the Thuringian mountains of central Germany. The geological substrate is carbonaceous quartzite and the dominating soil type is podzol or podzolic brown soil with a sandy-loamy texture. Average annual precipitation measured at the three nearest climate stations varies between 880 and 1,015 mm. The mean annual temperature averages 5.5°C (6.0°C). The study area is dominated by monospecific (95%) even-aged plantations of Norway spruce with single tree occurrence of mountain ash (Sorbus aucuparia L.), European beech (Fagus sylvatica L.) and silver fir (Abies alba L.).

A total of 44 deadwood logs of Norway spruce were randomly selected to represent the decay classes 1–4 (Table 1) and different positions (standing, hanging, downed). For gravimetric density determination in the laboratory, 10-cm-thick discs were cut with a handsaw from the dead wood logs. From logs longer than 2 m, every meter one sample was taken but at least three samples per tree according to the following scheme: two discs 0.3 m from the base and the top, respectively, and one from the middle. Disc diameter ranged from 4.7 to 19 cm with a mean of 11.3 cm. To avoid fragmentation of strongly decayed wood during cutting and transportation, the discs were either taken at temperatures below 0°C in a frozen state or wrapped with 5-cm-wide Velcro® fastener. The discs were either processed immediately after thawing or stored at −20°C until further processing. In the laboratory, the thickness, circumference and weight of the fresh discs were recorded and the drill-resistance measurements obtained. Afterwards the discs were dried at 70°C (not at 103°C, to avoid changes in C/N ratios in later measurements) to constant weight followed by a second drill-resistance measurement. The gravimetric density (D [gdw cm−3]) of the discs was computed as the ratio of dry mass to fresh volume.

Drill resistance measurements

We used a RESISTOGRAPH® 3450S (RINNTECH, Frank Rinn Engineering and Distribution, Bierhelder Weg 20, 69126 Heidelberg, Germany) to obtain a proxy measurement of dead wood density. The resistograph uses a micro-drilling device equipped with a needle of 3 mm diameter and 45 cm length and an automatically adapted protrusion speed mechanism (Rinn 1996). The resistance to drilling is recorded at a spatial position resolution of 0.01 mm. The data are stored electronically and printed on paper for visual inspection in the field (Fig. 1). One measurement usually takes 2–3 min. The number of consecutive measurements is limited by battery lifetime (30–80 measurements) rather than by data storage capacity (~400 measurements). Every 80–100 measurements, this equals about 10 m of total drilling length, the needle was replaced. The drill resistance was measured for each disc along two perpendicular diameters. The average per disc was used in the statistical analysis.

Examples of RESISTOGRAPH® outputs for decay classes 1, 2, 3, and 4 as denoted by DC 1, DC 2, DC 3, and DC 4, respectively (top to bottom; see Table 1 for decay class details). The original profile length of the four measurements is to the same scale (160 mm). Individual tree rings are visible as jagged pattern that results from the difference in wood densities between early and latewood. Mean drill resistance (R) and wood density (D) for the shown examples: R = 824; D = 0.44 gdw cm−3 for DC 1; R = 456; D = 0.29 gdw cm−3 for DC 2; R = 346; D = 0.26 gdw cm−3 for DC 3 and R = 191; D = 0.18 gdw cm−3 for DC 4

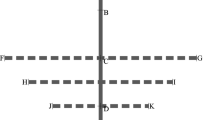

To calculate the average drill resistance per disc, the dead wood was computationally divided into concentrically, 1/100-mm-wide rings (Fig. 2). The average was calculated by weighting each measurement (e.g., R1; Fig. 2) by its respective area (A1). The weighted average was calculated as follows:

where R = mean drill resistance value, R ’ ij = drill resistance value of the ith sector in the jth ring, A ’ j = 1/4 the area of the jth ring, A tot = total disc area of CWD sample and n = number of rings with a threshold ring thickness of 1/100 mm. The software that was developed to perform the calculation is available upon request.

Other predictors of wood density loss

Fast quantitative field methods

Three quantitative variables were measured in the field. A pocket knife with a length, width and thickness of 100, 15 and 1.5 mm, respectively, was stabbed (following the fibre direction) into the samples in the field and the depth of penetration was recorded (knife probe = kp). Despite this method being prone to errors, e.g., the force used to insert the knife into the sample, it is easily applicable and widely used to get an estimate of wood hardness (Norden and Paltto 2001; Rouvinen and Kouki 2002; Heilmann-Clausen and Christensen 2003). Further, the percentage branch (br) and bark loss (ba) was estimated.

Classification of decay classes

Logs were assigned to four decay classes following the schemes developed by Yatskov et al. (2003). The classification is based on four qualitative categorical or ordinal variables classification (Table 1).

Statistical methods

To compare the performance of the various predictors of wood density D (including the drill resistance), we established five classes of models representing the above mentioned methods and combinations of them. The first class of models represented the fast quantitative field methods where three different variables were available (kp, br and ba). The second and third class were single-predictor models containing the categorial variable ‘decay class’ DC (ranging from 1–4; see above) and the drill resistance R measured in the fresh state (continuous variable) as predictors. The fourth class represents combinations of DC and R and the fifth class combinations of DC and predictors of the first class (kp, br and ba). Depending on the tree size, up to seven samples were taken from the same sample tree. Since the residuals of several samples for a given tree cannot be assumed to be independent, this violates a fundamental assumption of general linear models (Crawley 2002). We therefore use mixed linear models (lme-procedure of S-Plus©, 2002 Insightful Corp.) with the identity of the tree as a random grouping factor. The model selection uses Akaike’s Information Criterion (AIC) (Burnham and Anderson 1998) which reflects a trade-off between model fit and parameter load where the best model has the lowest value. In addition, the adjusted R² according to Neter et al. (1996) is reported.

Each sample piece was probed twice, under field conditions (R moist) and oven dry (70°C, R dry). To analyse whether moisture status affects the drill resistance a paired t test was performed.

Results

Drill resistance R alone explained 65% of the variation in dead wood density (Table 2, model 9). This model was markedly better than any models containing any or several of the conventional predictors. These were either models containing the fast quantitative field methods (Table 2, models 1–7), the subjective classification based on qualitative traits (Table 2, model 8) or combinations of the two predictor classes (Table 2, models 12–18). Model 9 could be further improved by adding the decay class DC as categorical variable (Table 2, model 10) indicating that the relationship between drill resistance and gravimetric wood density is influenced by changes in the wood structure as the log decays. At a given value of drill resistance, the range of predicted gravimetric wood density spans a range of 0.14 gdw cm−3 and differences between consecutive decay classes are about 0.045 gdw cm−3. Within a given decay class the relationships are visibly linear down to densities of 0.1 gdw cm−3 and the variances are homoscedastic (Fig. 3). Allowing the slopes of individual decay classes to vary did not improve the model performance (Table 2, model 11).

Relationship between measured gravimetric wood density D and drill resistance R according to separate decay classes DC 1 (open circle, solid line), DC 2 (open triangle, dotted line), DC 3 (+, chain-dotted line), and DC 4 (×, dashed line). The lines represent the predictions of the best candidate model [model 10 (Table 3)]

A paired t test revealed that moisture influences the drill resistance. Oven-dry CWD has significantly lower drill resistance than fresh material [t [129] = 13.19, P < 0.001, mean difference 108.6 (95% CI: 92.3–124.8) drill resistance units]. The difference between the drill resistances in fresh- and oven-dry state of CWD for the same sample excludes the effect of wood density and should mainly reveal the effect of moisture content on the drill resistance. However, there was no significant linear relationship between the moisture content (%) of fresh CWD and the difference between drill resistance in fresh and oven-dry state (y = −0.006x + 109, R² = 0, P = 0.927).

Discussion

With our analysis, we could show that drill resistance in combination with decay classes provides a useful proxy of the absolute wood density in decaying wood in situ. The resulting predictive model explained approximately 75% of the variance of wood density and was therefore superior to our models relying on conventional predictors.

Next to its potential as proxy for density, the method has several distinct advantages. First of all, it is a non-destructive method. Its main application is in long-term ecosystem studies where destructive sampling of logs should be avoided to minimize the effect of the sampling on the decay process itself and to allow repeated sampling at multiple positions along an entire log. The method can also be used in areas where destructive sampling is legally prohibited. This is important because in many industrialised countries the highest stocks and the highest diversity of coarse woody debris are found in protected nature reserves (Korpel 1997; Jonsson 2000; Wirth et al. 2004; Christensen et al. 2005; Mund and Schulze 2006). Another advantage of the method lies in the additional information provided by the measurement. Because in many tree species early and late wood exhibit vastly different wood densities, tree rings are visible on the 1/100-mm resolution output from which information regarding the age and the ring width pattern can be extracted (Rinn et al. 1996). Furthermore, the method would be useful to study the process of fragmentation and the spatial pattern of decay because the resistograph easily detects small cavities, boreholes of insects, and cracks in the wood.

In this study, the mean resistance value was used, despite the fact, that the same log can exhibit multiple decay stages (Fig. 1, DC 2). The reason for the use of a mean drill resistance lies first of all in the small diameter (mean 11.3 cm) of the sampled logs. Secondly, this study was aimed to provide a tool for estimating CWD mass at the stand level and not to find different decay patterns inside individual logs.

A limitation of the method is that drill resistance is influenced by a range of wood features other than density. The fact that the categorical variable decay class was significant in the best candidate model illustrated that changes in wood structure and chemical composition that go along with the decay process influences the relationship between drill resistance and density. For example, the decay type, namely brown rot versus white rot fungi, may influence the drill resistance. Brown rot fungi cause the decay of cellulose and leave the brittle lignin, whereas the white rot fungi preferably disintegrate the lignin in the beginning and leave the more ductile cellulose which is either decayed simultaneously with the lignin or later (Weber and Mattheck 2001). Preliminary analyses of studies in our laboratory with wood of various other tree species revealed significant species-specific differences in the relationship between drill resistance and wood density. The lowest detectable drill resistance values with the resistograph are between 100 and 200 which were in this study sufficient to detect the lowest wood densities down to about 0.1 g cm−3 (Fig. 3). In the case of lower wood density, the resistograph would not be able to detect any changes. This could cause problems when adapting this method to highly decayed wood of other tree species where no more drill resistance can be detected but still woody material is left. As shown above, also the moisture state of the wood influences the relationship between drill resistance and density with moist wood (fresh state) exhibiting a higher drill resistance than oven-dry CWD. However, the offset between moist and oven-dry CWD is itself not a function of the moisture content. This is evidenced by the lack of a significant linear relationship between moisture content and the difference between drill resistance in moist (fresh state) and oven-dry state. Therefore, when estimating the wood density with drill resistance measurements, the moisture content of CWD should not to be taken into account. For the application, it is therefore important to calibrate the resistograph for each tree species and decay class separately and to conduct the measurements in samples of comparable moisture status. With these caveats in mind, the drill resistance measurements represents a powerful method in the field of dead wood ecology.

References

Burnham KP, Anderson DA (1998) Model selection and inference—a practical information-theoretic approach. Springer, New York

Christensen M, Hahn K, Mountford EP, Odor P, Standovar T, Rozenbergar D, Diaci J, Wijdeven S, Meyer P, Winter S, Vrska T (2005) Dead wood in European beech (Fagus sylvatica) forest reserves. For Ecol Manag 210:267–282. doi:10.1016/j.foreco.2005.02.032

Costello LR, Quarles SL (1999) Detection of wood decay in blue gum and elm: an evaluation of the Resistograph® and the portable drill. J Arboric 25:311–318

Crawley MJ (2002) Statistical computing—an introduction to data analysis using S-Plus. Wiley, Chichester

Creed IF, Webster KL, Morrison DL (2004) A comparison of techniques for measuring density and concentrations of carbon and nitrogen in coarse woody debris at different stages of decay. Can J For Res Rev Can Rech For 34:744–753. doi:10.1139/x03-212

Eckstein D, Saß U (1994) Bohrwiderstandsmessungen an Laubbäumen und ihre holzanatomische Interpretation. Holz Roh Werkst 52:279–286

Graham RL, Cromack K (1982) Mass, nutrient content, and decay-rate of dead boles in rain forests of Olympic-National-Park. Can J For Res Rev Can Rech For 12:511–521. doi:10.1139/x82-080

Grove SJ (2002) Saproxylic insect ecology and the sustainable management of forests. Annu Rev Ecol Syst 33:1–23. doi:10.1146/annurev.ecolsys.33.010802.150507

Harmon ME, Sexton J (1996) Guidelines for measurements of woody detritus in forest ecosystems. Rep No US LTER Publication No. 20

Harmon ME, Franklin JF, Swanson FJ, Sollins P, Gregory SV, Lattin JD, Anderson NH, Cline SP, Aumen NG, Sedell JR, Lienkaemper GW, Cromack KJ, Cummins KW (1986) Ecology of coarse woody debris in temperate ecosystems. Adv Ecol Res 15:133–302. doi:10.1016/S0065-2504(08)60121-X

Heilmann-Clausen J, Christensen M (2003) Fungal diversity on decaying beech logs—implications for sustainable forestry. Biodivers Conserv 12:953–973. doi:10.1023/A:1022825809503

Isik F, Li BL (2003) Rapid assessment of wood density of live trees using the resistograph for selection in tree improvement programs. Can J For Res Rev Can Rech For 33:2426–2435. doi:10.1139/x03-176

Jonsson BG (2000) Availability of coarse woody debris in a boreal old-growth Picea abies forest. J Veg Sci 11:51–56. doi:10.2307/3236775

Jonsson BG, Kruys N, Ranius T (2005) Ecology of species living on dead wood—lessons for dead wood management. Silva Fenn 39:289–309

Korpel S (1997) Totholz in Naturwäldern und Konsequenzen für Naturschutz und Forstwirtschaft. Forst Holz 52:619–624

Lonsdale D, Pautasso M, Holdenrieder O (2008) Wood-decaying fungi in the forest: conservation needs and management options. Eur J For Res 127(1):1–22. doi:10.1007/s10342-007-0182-6

Mund M, Schulze ED (2006) Impacts of forest management on the carbon budget of European beech (Fagus sylvatica) forests. Allg Forst Jagdztg 177:47–63

Naesset E (1999a) Decomposition rate constants of Picea abies logs in southeastern Norway. Can J For Res Rev Can Rech For 29:372–381. doi:10.1139/cjfr-29-3-372

Naesset E (1999b) Relationship between relative wood density of Picea abies logs and simple classification systems decayed coarse woody debris. Scand J For Res 14:454–461. doi:10.1080/02827589950154159

Neter J, Kutner MH, Nachtsheim CJ, Wassermann W (1996) Applied linear statistical models, 4th edn. McGraw–Hill, Boston

Niemz P, Bues CT, Herrmann S (2002) Die Eignung von Schallgeschwindigkeit und Bohrwiderstand zur Beurteilung von simulierten Defekten im Fichtenholz. Schweiz Z Forstwesen 153:201–209. doi:10.3188/szf.2002.0201

Norden B, Paltto H (2001) Wood-decay fungi in hazel wood: species richness correlated to stand age and dead wood features. Biol Conserv 101:1–8. doi:10.1016/S0006-3207(01)00049-0

Rinn F (1996) Resistographic visualization of tree-ring density variations. In: Dean JS, Meko DM, Swetnam TW (eds) Tree rings, environment, and humanity, radiocarbon. Department of Geosciences, The University of Arizona, Tucson, pp 871–878

Rinn F, Schweingruber F-H, Schär E (1996) RESISTOGRAPH and X-ray density charts of wood comparative evaluation of drill resistance profiles and X-ray density charts of different wood species. Holzforschung 50:303–311

Rouvinen S, Kouki J (2002) Spatiotemporal availability of dead wood in protected old-growth forests: a case study from boreal forests in eastern Finland. Scand J For Res 17:317–329. doi:10.1080/02827580260138071

Speight MCD (1989) Saproxylic invertebrates and their conservation. Council of Europe, Strasbourg, France

Wang SY, Chiu CM, Lin CJ (2003) Application of the drilling resistance method for annual ring characteristics: evaluation of Taiwania (Taiwania cryptomeribides) trees grown with different thinning and pruning treatments. J Wood Sci 49:116–124. doi:10.1007/s100860300018

Weber K, Mattheck C (2001) Taschenbuch der Holzfäulen im Baum. Forschungszentrum Karlsruhe GmbH, Karlsruhe

Wirth C, Schwalbe G, Tomczyk S, Schulze ED, Schumacher J, Vetter M, Böttcher H, Weber G, Weller G (2004) Dynamik der Kohlenstoffvorräte in den Wäldern Thüringens. Landesanstalt für Wald und Forstwirtschaft, Gotha

Yatskov M, Harmon ME, Krankina ON (2003) A chronosequence of wood decomposition in the boreal forests of Russia. Can J For Res Rev Can Rech For 33:1211–1226. doi:10.1139/x03-033

Acknowledgment

We gratefully acknowledge the help of Manfred Erhardt, Forest Service Thuringia, in providing the permission to take samples.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by T. Seifert.

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Kahl, T., Wirth, C., Mund, M. et al. Using drill resistance to quantify the density in coarse woody debris of Norway spruce. Eur J Forest Res 128, 467–473 (2009). https://doi.org/10.1007/s10342-009-0294-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10342-009-0294-2