Abstract

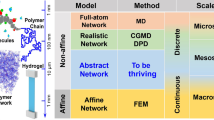

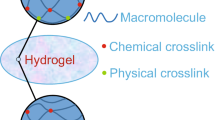

The damage models based on the eight-chain model and the affine full-chain network model are not adequate to describe the damage behaviors in double-network (DN) hydrogels. To overcome this limitation, we propose a combined chain stretch model with new damage flow rules. It is demonstrated that the new proposed micro-chain stretch is a reduced form of the complete representation for the transversely isotropic tensor function. As a result, the damage models based on the eight-chain model and the affine model are incorporated as special cases. The effects of chain affineness and network entangling are simultaneously involved in the new model, while only one of these two effects can be characterized in either the eight-chain model or the affine model. It is further shown that the new model can effectively capture the Mullins features of the DN hydrogels and achieve better agreement with the experimental data than the affine model and the eight-chain model.

Similar content being viewed by others

References

Liu Z, Toh W, Ng TY. Advances in mechanics of soft materials: a review of large deformation behavior of hydrogels. Int J Appl Mech. 2015;7:1530001.

Ullah F, Othman MBH, Javed F, Ahmad Z, Akil HM. Classification, processing and application of hydrogels: a review. Mat Sci Eng: C. 2015;57:414–33.

Lei J, Li Z, Xu S, Liu Z. Recent advances of hydrogel network models for studies on mechanical behaviors. Acta Mech Sin. 2021:1-20.

Eslahi N, Abdorahim M, Simchi A. Smart polymeric hydrogels for cartilage tissue engineering: a review on the chemistry and biological functions. Biomacromol. 2016;17:3441–63.

Ionov L. Biomimetic hydrogel-based actuating systems. Adv Funct Mater. 2013;23:4555–70.

Dong L, Agarwal AK, Beebe DJ, Jang H. Adaptive liquid microlenses activated by stimuli-responsive hydrogels. Nature. 2006;442:551–4.

Gong JP, Katsuyama Y, Kurokawa T, Osada Y. Double-network hydrogels with extremely high mechanical strength. Adv Mater. 2003;15:1155–8.

Mai TT, Matsuda T, Nakajima T, Gong JP. Distinctive characteristics of internal fracture in tough double network hydrogels revealed by various modes of stretching. Macromolecules. 2018;51:5245–57.

Creton C. 50th anniversary perspective: networks and gels: soft but dynamic and tough. Macromolecules. 2017;50:8297–316.

Nakajima T. Generalization of the sacrificial bond principle for gel and elastomer toughening. Polym J. 2017;49:477–85.

Diani J, Fayolle B, Gilormini P. A review on the Mullins effect. Eur Polymer J. 2009;45(3):601–12.

Haque MA, Kurokawa T, Gong JP. Super tough double network hydrogels and their application as biomaterials. Polymer. 2012;53:1805–22.

Liu Y, Zhang H, Zheng Y. A micromechanically based constitutive model for the inelastic and swelling behaviors in double network hydrogels. J Appl Mech. 2016;83(2):021008.

Lu H, Wang X, Shi X, Yu K, Fu YQ. A phenomenological model for dynamic response of double-network hydrogel composite undergoing transient transition. Compos Part B Eng. 2018;151:148–53.

Qi Y, Caillard J, Long R. Fracture toughness of soft materials with rate-independent hysteresis. J Mech Phys Solid. 2018;118:341–64.

Vernerey FJ, Brighenti R, Long R, Shen T. Statistical damage mechanics of polymer networks. Macromolecules. 2018;51:6609–22.

Külcü İD. Characterization of stress softening and self-healing in a double network hydrogel. Results in Physics. 2019;12:1826–33.

Lu T, Wang Z, Tang J, Zhang W, Wang T. A pseudo-elasticity theory to model the strain-softening behavior of tough hydrogels. J Mech Phys Solid. 2020;137:103832.

Xiao R, Mai TT, Urayama K, Gong JP, Qu S. Micromechanical modeling of the multi-axial deformation behavior in double network hydrogels. Int J Plast. 2021;137:102901.

Kuhn W, Grün F. Beziehungen zwischen elastischen Konstanten und Dehnungsdoppelbrechung hochelastischer Stoffe. Kolloid-Zeitschrift. 1942;101:248–71.

Treloar LRG. The Physics of Rubber Elasticity. 3rd ed. Oxford: Clarendon Press; 1975.

Cohen A, Padé A. approximant to the inverse Langevin function. Rheol Acta. 1991;30:270–3.

James HM, Guth E. Theory of elastic properties of rubber. J Chem Phys. 1943;11:455–81.

Flory PJ, Rehner J. Statistical mechanics of cross-linked polymer networks: I. Rubberlike Elast J Chem Phys. 1943;11:512–20.

Arruda EM, Boyce MC. A three-dimensional constitutive model for the large stretch behavior of rubber elastic materials. J Mech Phys Solid. 1993;41:389–412.

Treloar LRG, Riding G. A non-Gaussian theory of rubber in biaxial strain. I. Mechanical properties. Proc. R. Soc. London, Ser. A. 1979; 369:261–280.

Boyce MC, Arruda EM. Constitutive models of rubber elasticity: a review. Rubber Chem Technol. 2000;73:504–23.

Steinmann P, Hossain M, Possart G. Hyperelastic models for rubber-like materials: consistent tangent operators and suitability for Treloar’s data. Arch Appl Mech. 2012;82:1183–217.

Hossain M, Steinmann P. More hyperelastic models for rubber-like materials: consistent tangent operators and comparative study. J Mech Beha Mater. 2013;22:27–50.

Miehe C, Göktepe S, Lulei F. A micro-macro approach to rubber-like materials–part I: the non-affine micro-sphere model of rubber elasticity. J Mech Phys Solid. 2004;52:2617–60.

Zheng QS, Spencer AJM. Tensors which characterize anisotropies. Int J Eng Sci. 1993;31:679–93.

Xiao H. On minimal representations for constitutive equations of anisotropic elastic materials. J Elast. 1996;45:13–32.

Marckmann G, Verron E, Gornet L, Chagnon G, Charrier P, Fort P. A theory of network alteration for the Mullins effect. J Mech Phys Solid. 2002;50:2011–28.

Hossain M, Possart G, Steinmann P. A finite strain framework for the simulation of polymer curing. Part I: Elasticity Comput Mech. 2009;44(5):621–30.

Dal H, Kaliske M. A micro-continuum-mechanical material model for failure of rubber-like materials: application to ageing-induced fracturing. J Mech Phys Solid. 2009;57(8):1340–56.

Bažant P, Oh BH. Efficient numerical integration on the surface of a sphere. ZAMM. 1986;66:37–49.

Itskov M. On the accuracy of numerical integration over the unit sphere applied to full network models. Comput Mech. 2016;57:859–65.

Verron E. Questioning numerical integration methods for microsphere (and microplane) constitutive equations. Mech Mater. 2015;89:216–28.

Mao Y, Talamini B, Anand L. Rupture of polymers by chain scission. Extreme Mech Lett. 2017;13:17–24.

Li B, Bouklas N. A variational phase-field model for brittle fracture in polydisperse elastomer networks. Int J Solids Struct. 2020;182:193–204.

Lei J, Li Z, Xu S, Liu Z. A mesoscopic network mechanics method to reproduce the large deformation and fracture process of cross-linked elastomers. J Mech Phys Solid. 2021;156:04599.

Acknowledgements

This work is supported by the National Natural Science Foundation of China under Grant No. 12022204, the Zhejiang Provincial Natural Science Foundation of China under Grant No. LD22A020001, and the Fundamental Research Funds for the Central Universities, China (Grant No. 2021FZZX001-16).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhan, L., Xiao, R. A Microstructural Damage Model toward Simulating the Mullins Effect in Double-Network Hydrogels. Acta Mech. Solida Sin. 35, 682–693 (2022). https://doi.org/10.1007/s10338-022-00316-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-022-00316-5