Abstract

The probabilistic control volume method has great prospects in correlating the effects of specimen size, notch and loading type on fatigue life or fatigue strength. In this work, the effects of notch size and loading type on fatigue life are investigated by using the probabilistic control volume method. Rotating bending and axial loading fatigue tests are at first performed on the hourglass specimen, circumferential V-notch specimen and V-notch plate specimen of 30CrMnSiA steel. Experimental results indicate that the notch reduces the fatigue strength of specimens in terms of nominal stress amplitude while in terms of local stress amplitude, the notch specimen could endure higher fatigue strength. Then, the probabilistic control volume method is used to evaluate the effects of notch size and loading type on fatigue life. It is shown that the probabilistic control volume method correlates well the effects of notch size and loading type on fatigue life, even for the local stress of the notch root exceeding the yield stress of the material.

Similar content being viewed by others

References

Akiniwa Y, Miyamoto N, Tsuru H, Tanaka K. Notch effect on fatigue strength reduction of bearing steel in the very high cycle regime. Int J Fatigue. 2006;28:1555–65.

Hertel O, Vormwald M. Statistical and geometrical size effects in notched members based on weakest-link and short-crack modelling. Eng Fract Mech. 2012;95:72–83.

Wang R, Li D, Hu D, Meng F, Liu H, Ma Q. A combined critical distance and highly-stressed-volume model to evaluate the statistical size effect of the stress concentrator on low cycle fatigue of TA19 plate. Int J Fatigue. 2017;95:8–17.

Leitner M, Vormwald M, Remes H. Statistical size effect on multiaxial fatigue strength of notched steel components. Int J Fatigue. 2017;104:322–33.

Murakami Y, Yokoyama NN, Nagata J. Mechanism of fatigue failure in ultralong life regime. Fatigue Fract Eng Mater Struct. 2002;25:735–46.

Nakajima M, Tokaji K, Itoga H, Shimizu T. Effect of loading condition on very high cycle fatigue behavior in a high strength steel. Int J Fatigue. 2010;32:475–80.

Haritos GK, Nicholas T, Lanning DB. Notch size effects in HCF behavior of Ti-6Al-4V. Int J Fatigue. 1999;21:643–52.

Lei Z, Xie J, Sun C, Hong Y. Effect of loading condition on very-high-cycle fatigue behavior and dominant variable analysis. Sci China Phys Mech Astron. 2014;57:74–82.

Owolabi G, Okeyoyin O, Bamiduro O, Olasumboye A, Whitworth H. The effects of notch size and material microstructure on the notch sensitivity factor for notched components. Eng Fract Mech. 2015;145:181–96.

Hu Y, Sun C, Xie J, Hong Y. Effects of loading frequency and loading type on high-cycle and very-high-cycle fatigue of a high-strength steel. Materials. 2018;11:1456.

Neuber H. Theory of notch stresses: principles for exact calculation of strength with reference to structural form and material. 2nd ed. Berlin: Springer; 1958.

Peterson RE. Notch sensitivity. In: Sines G, Waisman JL, editors. Metal fatigue. New York: McGraw Hill; 1959. p. 293–306.

Kuguel RA. A relation between theoretical stress concentration factor and fatigue notch factor deduced from the concept of highly stressed volume. ASTM Proc. 1961;61:732–48.

Taylor D. Geometrical effects in fatigue: a unifying theoretical model. Int J Fatigue. 1999;21:413–20.

Susmel L. The theory of critical distances: a review of its applications in fatigue. Eng Fract Mech. 2008;75:1706–24.

Wang J, Yang X. HCF strength estimation of notched Ti-6Al-4V specimens considering the critical distance size effect. Int J Fatigue. 2012;40:97–104.

Naik RA, Lanning DB, Nicholas T, Kallmeyer AR. A critical plane gradient approach for the prediction of notched HCF life. Int J Fatigue. 2005;27:481–92.

Gallo P, Berto F, Lazzarin P. High temperature fatigue tests of notched specimens made of titanium Grade 2. Theor Appl Fract Mech. 2015;76:27–34.

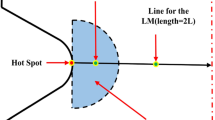

Sun C, Song Q. A method for evaluating the effects of specimen geometry and loading condition on fatigue life of metallic materials. Mater Res Express. 2019;6:046536.

Sun C, Song Q. A method for predicting the effects of specimen geometry and loading condition on fatigue strength. Metals. 2018;8:811.

Sun C, Zhang X, Liu X, Hong Y. Effects of specimen size on fatigue life of metallic materials in high-cycle and very-high-cycle fatigue regimes. Fatigue Fract Eng Mater Struct. 2016;39:770–9.

Acknowledgements

The authors would like to acknowledge the support from the Innovation Program (237099000000170004), the National Natural Science Foundation of China (91860112) and the Strategic Priority Research Program of the Chinese Academy of Sciences (XDB22020200).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, C., Hu, Z., Sun, C. et al. Probabilistic Control Volume Method for Evaluating the Effects of Notch Size and Loading Type on Fatigue Life. Acta Mech. Solida Sin. 33, 141–149 (2020). https://doi.org/10.1007/s10338-019-00126-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-019-00126-2