Abstract

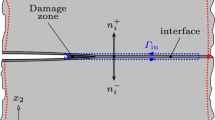

The solution of a half-plane containing a micro-crack and an edge macro-crack under mixed loads is presented based on the distributed dislocation technique. The complete stress field and stress intensity factors are obtained. The finite element model is established to simulate the macro-crack propagation path. The effect of a micro-crack on the macro-crack propagation is analyzed comprehensively. The results show that the shielding effect region is like two ‘petals’ under uniaxial tensile load and rotates with the change in micro-crack angle. For mixed loads, the shielding effect region rotates clockwise with the increasing ratio of applied loads \(\tau ^{\infty }/\sigma ^{\infty }\). It is like two ‘petals’ at \(\tau ^{\infty }/\sigma ^{\infty }\le 2\) and divides into two parts from the macro-crack tip at \(\tau ^{\infty }/\sigma ^{\infty }\ge 5\). The micro-crack has the attraction effect on the macro-crack propagation path. These results are useful for predicting the fracture or fatigue behaviors of materials containing micro-cracks.

Similar content being viewed by others

Abbreviations

- a :

-

Half-length of the micro-crack

- l :

-

Initial macro-crack length

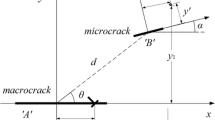

- \(\theta \) :

-

Micro-crack orientation

- \(\alpha \) :

-

Micro-crack angle

- d :

-

Distance between the macro-crack tip and the micro-crack center

- \(\sigma ^{\infty }\) :

-

Uniform tensile load

- \(\tau ^{\infty }\) :

-

Uniform shear load

- \({\tilde{\sigma }}_{ij} \) :

-

Stress components contributed by the applied loads

- \(\bar{{\sigma }}_{ij} \) :

-

Stress components contributed by distributed dislocations

- \(x_{\mathrm{micro}} \) :

-

Horizontal ordinate of the micro-crack center

- \(y_{\mathrm{micro}} \) :

-

Vertical ordinate of the micro-crack center

- \(K_{\mathrm{eff}} \) :

-

Equivalent stress intensity factor

- \(K_{\mathrm{eff}}^\infty \) :

-

Equivalent stress intensity factor for the case without micro-crack

- \(K_{\mathrm{I}}^\infty \) :

-

Mode \(\mathrm{I}\) stress intensity factor for the case without micro-crack

- \(K_{\mathrm{I}} \) :

-

Mode \(\mathrm{I}\) stress intensity factor at the macro-crack tip

- \(K_{\mathrm{I}\mathrm{I}} \) :

-

Mode \(\mathrm{I}\mathrm{I}\) stress intensity factor at the macro-crack tip

- \(b_x , b_y \) :

-

Components of Burgers vector

- \(\mu \) :

-

Shear modulus

- \(\kappa \) :

-

Kolosov constant

- \(G(\xi ,x,y)\) :

-

Dislocation influence function

- \(B(\xi )\) :

-

Dislocation density function

- \(\beta \) :

-

Crack propagation direction

- E :

-

Elasticity modulus

- \(\nu \) :

-

Poisson’s ratio

- \(\sigma _{\mathrm{von}} \) :

-

von Mises stress

- \(\gamma \) :

-

Intersection angle between the micro-crack face and the line composed by the micro-crack center and macro-crack tip

- SIF:

-

Stress intensity factor

- ESIF:

-

Equivalent stress intensity factor

- FE:

-

Finite element

- FEM:

-

Finite element method

- DDT:

-

Distributed dislocation technique

- MCTSC:

-

Maximum circumferential tensile stress criterion

References

Kachanov M. A simple technique of stress analysis in elastic solids with many cracks. Int J Fract. 1985;28:R11–9.

Kachanov M. Elastic solids with many cracks: a simple method of analysis. Int J Solids Struct. 1987;23:23–43.

Chudnovsky A, Dolgopolsky A, Kachanov M. Elastic interaction of a crack with a microcrack array: II. Elastic solution for two crack configurations (piecewise constant and linear approximations). Int J Solids Struct. 1987;23:11–21.

Gong SX, Horii H. General solution to the problem of microcracks near the tip of a main crack. J Mech Phys Solids. 1989;37:27–46.

Gong SX, Meguid SA. Microdefect interacting with a main crack: a general treatment. Int J Mech Sci. 1992;34:933–45.

Gong SX. On the main crack-microcrack interaction under mode III loading. Eng Fract Mech. 1995;51:753–62.

Tamuzs V, Petrova V. Modified model of macro-microcrack interaction. Theor Appl Fract Mech. 1999;32:111–7.

Soh AK, Yang CH. Numerical modeling of interactions between a macro-crack and a cluster of micro-defects. Eng Fract Mech. 2004;71:193–217.

Alam MM, Barsoum Z, Jonsén P, Kaplan AFH, Häggblad HÅ. Influence of defects on fatigue crack propagation in laser hybrid welded eccentric fillet joint. Eng Fract Mech. 2011;78:2246–58.

Budyn É, Zi G, Moës N, Belytschko T. A method for multiple crack growth in brittle materials without remeshing. Int J Numer Methods Eng. 2004;61:1741–70.

Bouiadjra BB, Benguediab M, Elmeguenni M, Belhouari M, Serier B, Aziz MNA. Analysis of the effect of micro-crack on the plastic strain ahead of main crack in aluminium alloy 2024 T3. Comput Mater Sci. 2008;42:100–6.

Li X, Li X, Yang H, Jiang X. Effect of micro-cracks on plastic zone ahead of the macro-crack tip. J Mater Sci. 2017;52:13490–503.

Hills D, Kelly P, Dai D, Korsunsky A. Solution of crack problems: the distributed dislocation technique, 1996. Dordrecht: Kluwer Academic Publishers; 1996.

Jin X, Keer LM. Solution of multiple edge cracks in an elastic half plane. Int J Fract. 2006;137:121–37.

Jin X. Analysis of some two dimensional problems containing cracks and holes. Northwestern University, 2006.

Zhang J, Qu Z, Huang Q, Xie L, Xiong C. Solution of multiple cracks in a finite plate of an elastic isotropic material with the distributed dislocation method. Acta Mech Solida Sin. 2014;27:276–83.

Li X, Jiang X, Li X, Yang H, Zhang Y. Solution of an inclined crack in a finite plane and a new criterion to predict fatigue crack propagation. Int J Mech Sci. 2016;119:217–23.

Han J-J, Dhanasekar M. Modelling cracks in arbitrarily shaped finite bodies by distribution of dislocation. Int J Solids Struct. 2004;41:399–411.

Erdogan F, Gupta G, Ratwani M. Interaction between a circular inclusion and an arbitrarily oriented crack. J Appl Mech. 1974;41:1007–13.

Xiao Z, Bai J, Maeda R. Electro-elastic stress analysis on piezoelectric inhomogeneity-crack interaction. Int J Solids Struct. 2001;38:1369–94.

Mousavi SM, Paavola J. Analysis of a cracked concrete containing an inclusion with inhomogeneously imperfect interface. Mech Res Commun. 2014;63:1–5.

Tao Y, Fang Q, Zeng X, Liu Y. Influence of dislocation on interaction between a crack and a circular inhomogeneity. Int J Mech Sci. 2014;80:47–53.

Zhang J, Qu Z, Huang Q, Xie L, Xiong C. Interaction between cracks and a circular inclusion in a finite plate with the distributed dislocation method. Arch Appl Mech. 2013;83:861–73.

Erdogan F, Sih G. On the crack extension in plates under plane loading and transverse shear. J Fluids Eng. 1963;85:519–25.

Palaniswamy K, Knauss W. Propagation of a crack under general, in-plane tension. Int J Fract. 1972;8:114–7.

Sih GC. Strain-energy-density factor applied to mixed mode crack problems. Int J Fract. 1974;10:305–21.

Li C. Vector CTD criterion applied to mixed mode fatigue crack growth. Fatigue Fract Eng Mater Struct. 1989;12:59–65.

Khan SMA, Khraisheh MK. A new criterion for mixed mode fracture initiation based on the crack tip plastic core region. Int J Plast. 2004;20:55–84.

Bouchard PO, Bay F, Chastel Y. Numerical modelling of crack propagation: automatic remeshing and comparison of different criteria. Comput Methods Appl Mech Eng. 2003;192:3887–908.

Dündar H, Ayhan AO. Three-dimensional fracture and fatigue crack propagation analysis in structures with multiple cracks. Comput Struct. 2015;158:259–73.

Ayhan AO. Simulation of three-dimensional fatigue crack propagation using enriched finite elements. Comput Struct. 2011;89:801–12.

Varfolomeev I, Burdack M, Moroz S, Siegele D, Kadau K. Fatigue crack growth rates and paths in two planar specimens under mixed mode loading. Int J Fatigue. 2014;58:12–9.

Liu G, Zhou D, Guo J, Bao Y, Han Z, Lu J. Numerical simulation of fatigue crack propagation interacting with micro-defects using multiscale XFEM. Int J Fatigue. 2018;109:70–82.

Paris PC, Gomez MP, Anderson WE. A rational analytic theory of fatigue. Trend Eng. 1961;13:9–14.

Paris PC, Erdogan FA. Critical analysis of crack propagation laws. J Basic Eng. 1963;85:528–34.

Elber W. The significance of fatigue crack closure. ASTM STP. Damage tolerance in aircraft structures; 1971.

Newman JR. Prediction of fatigue crack growth under variable-amplitude and spectrum loading using a closure model. Design of fatigue and fracture resistant structures. America: ASTM International; 1982.

Walker K. The effect of stress ratio during crack propagation and fatigue for 2024-T3 and 7075-T6 aluminum; 1970.

Alegre JM, Cuesta II. Some aspects about the crack growth FEM simulations under mixed-mode loading. Int J Fatigue. 2010;32:1090–5.

Erdogan F, Gupta GD, Cook T. Numerical solution of singular integral equations. Methods of analysis and solutions of crack problems. Springer; 1973. p. 368–425.

Kaya AC, Erdogan F. On the solution of integral equations with strongly singular kernels. Q Appl Math. 1987;XLV:105–22.

Mi Y, Aliabadi MH. Three-dimensional crack growth simulation using BEM. Comput Struct. 1994;52:871–8.

Mi Y. Three-dimensional analysis of crack growth. Southampton: Computational Mechanics Publications; 1996.

Hosseini-Toudeshky H, Mohammadi B. Mixed-mode numerical and experimental fatigue crack growth analyses of thick aluminium panels repaired with composite patches. Compos Struct. 2009;91:1–8.

Lucht T. Finite element analysis of three dimensional crack growth by the use of a boundary element sub model. Eng Fract Mech. 2009;76:2148–62.

Roux-Langlois C, Gravouil A, Baietto MC, Réthoré J, Mathieu F, Hild F, et al. DIC identification and X-FEM simulation of fatigue crack growth based on the Williams’ series. Int J Solids Struct. 2015;53:38–47.

Mróz KP, Mróz Z. On crack path evolution rules. Eng Fract Mech. 2010;77:1781–807.

Larisa S, Pavel R, Pavel L. A photoelastic study for multiparametric analysis of the near crack tip stress field under mixed mode loading. Procedia Struct Integr. 2016;2:1797–804.

Malíková L, Veselý V, Seitl S. Crack propagation direction in a mixed mode geometry estimated via multi-parameter fracture criteria. Int J Fatigue. 2016;89:99–107.

Smith DJ, Ayatollahi MR, Pavier MJ. The role of T- stress in brittle fracture for linear elastic materials under mixed-mode loading. Fatigue Fract Eng Mater Struct. 2001;24:137–50.

Gupta M, Alderliesten RC, Benedictus R. A review of T-stress and its effects in fracture mechanics. Eng Fract Mech. 2015;134:218–41.

Miranda A, Meggiolaro M, Castro J, Martha L, Bittencourt T. Fatigue life and crack path predictions in generic 2D structural components. Eng Fract Mech. 2003;70:1259–79.

Chudnovsky A, Chaoui K, Moet A. Curvilinear crack layer propagation. J Mater Sci Lett. 1987;6:1033–8.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (11472230) and Doctoral Innovation Fund Program of Southwest Jiaotong University (D-CX201836).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, X., Jiang, X. Effect of a Micro-crack on the Edge Macro-crack Propagation Rate and Path Under Mixed Loads. Acta Mech. Solida Sin. 32, 517–532 (2019). https://doi.org/10.1007/s10338-019-00099-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10338-019-00099-2