Abstract

Computer simulation is used to investigate sample transport phenomena of cross microfluidic chips. In this study, Kirchhoff circuit theory is employed to calculate the electric field strength and approximate electroosmotic flow. It is apparent from the results that both the simulation and the theoretical data show similar trends in the electroosmosis of cross microchips. The main target in this study is to summarize the optimal controlling parameter values for avoiding sample leakage in the transport process. The effects of the applied voltage ratio, the geometry ratio and the zeta potential were simulated using a computational fluid dynamics and multiphysics solver software package (CFD-ACE+). Under our designed conditions, two major conclusions were reached: (1) for high-voltage ratios, the sample leakage can be avoided as the geometry ratio is large enough at 0.5 or greater, and (2) for small geometries, maintaining a smaller voltage ratio, 0.3 or less, is essential for avoiding sample leakage. The key is to govern the sample velocity in the upstream faster than that in the downstream. Although real experimental conditions can be further fine tuned under microscopy monitoring, these conclusions are helpful to design the proper channel geometry and set up suitable voltage parameters to avoid sample leakages in one cross-channel chip.

Similar content being viewed by others

References

Ermakov S, Jacobson S, Ramsey J (1998) Anal Chem 70:4494–4504. doi:10.1021/ac980551w

Manz A, Fettinger JC, Verpoorte E, Harrison DJ, Leid H, Widmer AM (1990) Tech. Digest MME 90. Berlin, pp 127–132

Ross D, Johnson TJ, Locascio LE (2001) Anal Chem 73:2509–2515. doi:10.1021/ac001509f

Devasenathipathy S, Santiago JG (2002) Anal Chem 74:3704–3713. doi:10.1021/ac011243s

Patankar NA, Hu HH (1998) Anal Chem 70:1870–1881. doi:10.1021/ac970846u

Arulanandam S, Li D (2000) J Colloid Surf A: Physicochem Eng Asp 161:89–102. doi:10.1016/S0927-7757(99)00328-3

Mala GM, Yang C, Li D (1998) J Colloid Surf A: Physicochem Eng Asp 135:109–116. doi:10.1016/S0927-7757(97)00215-X

Yang C, Li D (1998) J Colloid Surf A: Physicochem Eng Asp 143:339–353. doi:10.1016/S0927-7757(98)00259-3

Jacobson SC, Culbertson CT, Daler JE, Ramsey JM (1998) Anal Chem 70:3476–3480. doi:10.1021/ac980349t

Sinton D, Li D (2003) J Colloid Surf A: Physicochem Eng Asp 222:273–283. doi:10.1016/S0927-7757(03)00233-4

Arulanandam S, Li D (2000) J Colloid Interface Sci 225:421–428. doi:10.1006/jcis.2000.6783

Sinton D, Canseco CE, Ren L, Li D (2002) J Colloid Interface Sci 254:184–189. doi:10.1006/jcis.2002.8584

Sinton D, Ren L, Li D (2003) J Colloid Interface Sci 266:448–456. doi:10.1016/S0021-9797(03)00630-1

Sinton D, Ren L, Li D (2003) J Colloid Interface Sci 260:431–439. doi:10.1016/S0021-9797(02)00181-9

Hu Y, Werner C, Li D (2004) J Colloid Interface Sci 280:527–536. doi:10.1016/j.jcis.2004.08.011

Wang X, Wu J, Li D (2006) J Colloid Interface Sci 293:483–488. doi:10.1006/j. jcis.2005.06.080

Jin Y, Luo GA (2003) Electrophoresis 24:1242–1252. doi:10.1002/elps.200390160

Tsai CH, Yang RJ, Ta CH, Fu LM (2005) Electrophoresis 26:674–686. doi:10.1002/elps.200410032

Seiler K, Fan HZ, Fiurl K, Harrison DJ (1994) Anal Chem 66:3485–3491. doi:10.1021/ac00092a029

Ren CL, Li D (2006) J Colloid Interface Sci 294:482–491. doi:10.1016/j.jcis.2005.07.051

Ren L, Li D (2002) J Colloid Interface Sci 254:384–395. doi:10.1006/jcis.2002.8645

Xuan X, Li D (2005) J Colloid Interface Sci 289:291–303. doi:10.1016/j. jcis.2005.03.069

Jacobson SC, Ramsey JM (1997) Anal Chem 69:3212–3217. doi:10.1021/ac961093z

Zhang CX, Manz A (2001) Anal Chem 73:2656–2662. doi:10.1021/ac010138f

Ren CL, Li D (2004) Anal Chim Acta 518:59–68. doi:10.1016/j.aca.2004.05.018

Patankar SV (1980) Numerical heat transfer and fluid flow in series in computational methods in mechanics and thermal sciences. Mc-Graw–Hill, Toronto

Acknowledgments

This study was supported from National Science Council, Taiwan (NSC), National Chung Cheng University, and National Formosa University.

Author information

Authors and Affiliations

Corresponding author

Appendix: The Kirchhoff Theory Model

Appendix: The Kirchhoff Theory Model

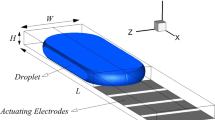

In the cross-channel conduits in Fig. 1, the electric current in each channel follows the relationship

where I 1 is the current in the upper port of the vertical channel, I 2 is the current in both side channels, and I 3 is the current in the lower port of the vertical channel.

In a channel, the electric resistance (R *) is proportional to the channel length L and inversely proportional to the cross-sectional area (A) of channel. In Eq. 7, the constant ρ is the inverse of the bulk liquid conductivity κ.

The above equation can be rearranged to solve for the electrical potential of the downstream after the intersection. The cross biochip requires four electrodes to control the potential in the separation process. To calculate the potential at the cross part (V cross),

where L 1 is 0.5 mm, L 2 is 0.4 mm (left and right), L 3 is 1.5 mm and R is the channel cross-sectional area ratio A2/A1. When channel depth is not changed, the electric resistance of each channel is dependent on the channel width.

For an infinite rectangular channel, the Helmholtz–Smolouchowski equation was obtained as follows:

In Eq. 5, μ eo is the electroosmotic mobility

where ε is the electric permittivity of the solution, η is the viscosity, and ζ is the zeta potential.

In Eq. 12 under the same zeta potential the electroosmotic mobility (μ eo) is constant. However, Eq. 10 indicates that the electric field strength changes when the cross-sectional area varies in different channel width ratios. Therefore, according to Eq. 11 the electroosmotic flow velocity (V s) changes when the channel width ratio varies.

Rights and permissions

About this article

Cite this article

Yang, MH., Wang, SC. & Cheng, JC. The Optimal Control of Geometry and Voltage Parameters on Electrokinetic Transport to Avoid Sample Leakage in Microfluidic Chips. Chromatographia 73, 567–577 (2011). https://doi.org/10.1007/s10337-011-1933-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-011-1933-6