Abstract

Burning fossil fuels account for over 75% of global greenhouse gas emissions and over 90% of carbon dioxide emissions, calling for alternative fuels such as hydrogen. Since the hydrogen demand could reach 120 million tons in 2024, efficient and large-scale production methods are required. Here we review electrocatalytic water splitting with a focus on reaction mechanisms, transition metal catalysts, and optimization strategies. We discuss mechanisms of water decomposition and hydrogen evolution. Transition metal catalysts include alloys, sulfides, carbides, nitrides, phosphides, selenides, oxides, hydroxides, and metal-organic frameworks. The reaction can be optimized by modifying the nanostructure or the electronic structure. We observe that transition metal-based electrocatalysts are excellent catalysts due to their abundant sources, low cost, and controllable electronic structures. Concerning optimization, fluorine anion doping at 1 mol/L potassium hydroxide yields an overpotential of 38 mV at a current density of 10 mA/cm2. The electrocatalytic efficiency can also be enhanced by adding metal atoms to the nickel sulfide framework.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Adopting renewable energy sources is essential for achieving sustainable development, as using non-renewable energy sources has resulted in environmental problems and depletion of resources. Hydrogen is a promising alternative to traditional fossil fuels due to its high energy density, clean combustion products, and renewable nature (Osman et al. 2023). Various hydrogen energy sources exist, including reforming traditional fossil fuels, biotechnology, and water electrolysis (Osman et al. 2022; Theerthagiri et al. 2022; Yang et al. 2023a). Water electrolysis for hydrogen production is environmentally friendly and has emerged as the most commonly used method, with alkaline water electrolysis and proton exchange membrane water electrolysis representing the two established technical routes for hydrogen production (Suen et al. 2017). Proton exchange membrane water electrolysis offers favorable conditions for industrialization and large-scale development. However, most catalysts perform poorly under harsh acidic conditions, substantially hindering their widespread adoption (Seh et al. 2017). Compared with proton exchange membrane, alkaline water electrolysis technology uses non-noble metal catalysts that can be used stably under alkaline conditions, effectively reducing the cost of catalytic materials (Rossmeisl et al. 2005; Ursua et al. 2012). However, the current water decomposition technology still faces low energy efficiency and high-cost problems (Roger et al. 2017), despite over 230 years of research.

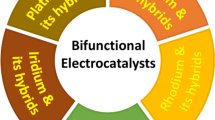

This article offers an overview of the fundamental principle of catalytic hydrogen production through alkaline water electrolysis, summarizes the progress in transition metals as electrocatalytic hydrogen evolution materials, and proposes effective approaches for optimizing electrocatalytic performance to achieve large-scale hydrogen production, as shown in Fig. 1. The findings suggest that optimizing the electrocatalytic performance of these materials is critical for achieving large-scale hydrogen production, and various strategies for achieving this goal have been proposed and studied.

Applications of transition metals as electrocatalysts in hydrolysis reactions and methods for catalyst performance improvement. Transition metal electrocatalysts can catalyze both the hydrogen evolution and oxygen reduction reactions, with some even possessing bifunctional activities. These catalysts can be classified according to the specific transition metal combined with different elements. The properties of each type of catalyst can vary greatly, and the appropriate catalyst can be selected based on the reaction conditions. Moreover, modifying the nanostructure and electronic structure of the catalyst can significantly enhance the catalytic performance

Most electrocatalytic hydrogen evolution reactions still rely on precious metals, and research on transition metal-based hydrogen evolution reactions is in its early stages. However, there is significant potential for developing transition metal-based alkaline hydrogen evolution reactions. This review explores and optimizes transition metal-based electrocatalysts for alkaline hydrogen evolution reactions. It provides an in-depth summary of the characteristics of different transition metal catalysts and their optimization strategies, highlighting the effects of nanostructures and electronic structures on the physical, chemical, and structural properties of transition metal electrocatalysts. From the perspective of rational material design, this review offers simple and low-cost preparation methods for synthesizing electrocatalysts with high activity and catalytic stability, providing new insights for optimizing electrocatalyst design to achieve optimal catalytic reaction performance. This facilitates the development of new high-efficiency transition metal electrocatalysts, addresses the blind spots in electrocatalyst optimization strategies, and identifies research directions for optimizing transition metal electrocatalysts to achieve green and sustainable large-scale industrial hydrogen production.

Reaction mechanism

There is a high amount of hydrogen on the earth, most of which exists in water. Among many hydrogen production methods, electrocatalytic water decomposition provides an effective method for preparing high-purity hydrogen and has been widely used in industry. It converts electrical energy into chemical energy through two processes: hydrogen evolution reaction on the cathode and oxygen evolution reaction on the anode (Wang et al. 2022).

Electrocatalytic water decomposition is crucial for advancing the field of sustainable energy. This section focuses on one of its most important semi-reactions—the hydrogen evolution reaction. Our review specifically looks at the behavior of this reaction under alkaline conditions, which is a key factor in optimizing its efficiency (Wei et al. 2018b).

Electrocatalytic water decomposition

The basic principle of electrocatalytic water decomposition is that water is used as raw material to apply voltage from outside to form a complete electrified circuit. Because the injection breaks the internal balance of water molecules of electric energy, it is cracked, and at the same time, the hydrogen atoms and oxygen atoms are reconstructed, and finally, hydrogen and oxygen are precipitated (Dittmeyer et al. 2015).

As shown in Fig. 2, the water decomposition electrolyzer usually comprises a cathode, anode, electrolyte, and power supply. An external circuit connects the cathode and anode to form a complete conductive loop (Roger et al. 2017). Electrons are transmitted to the cathode by the external circuit, and hydrogen protons on the cathode surface get electrons to generate hydrogen; at the same time, water molecules oxidize on the anode surface to form oxygen (David et al. 2019). In the electrocatalytic water decomposition process, pure water's low ionization degree results in poor electrolyte conductivity and low electric energy utilization efficiency. To address this, acidic or alkaline electrolytes like sodium hydroxide, potassium hydroxide, or sulfuric acid are typically added to pure water to enhance conductivity. The reaction steps of the cathode and anode in different electrolyte systems are also different (Zhang et al. 2019a).

Water decomposition electrolyzer setup. As illustrated, the water decomposition electrolyzer consists of a cathode, anode, electrolyte, and power supply. A fully conductive circuit connects the cathode and anode to an external circuit, which transfers electrons (e−) to the cathode. Hydrogen protons (H+) on the cathode surface obtain these electrons (e−) to produce hydrogen (H2), while water molecules (H2O) oxidize on the anode surface to generate oxygen (O2). H2, O2, e−, and H+ refer to hydrogen, oxygen, electron, and hydrogen ion, respectively. Modified from Ursua et al. (2012)

To increase the conductivity of the solution, acidic or alkaline electrolytes, such as sodium hydroxide, potassium hydroxide, or sulfuric acid, are often added to pure water during electrocatalytic water decomposition. Furthermore, the reaction steps of the cathode and anode vary depending on the type of electrolyte utilized, according to research conducted by Zhang et al. (2019b).

Thermodynamic factors determine the theoretical decomposition voltage Ed of electrolyzed water when the applied reaction conditions are constant. It is generally considered that the thermodynamic decomposition voltage Ed of water is 1.23 V at normal temperature and pressure, which is usually called the reversible equilibrium potential of the electrocatalytic water decomposition process (Roger et al. 2017; Ursua et al. 2012; Zeng and Zhang 2011). The reversible equilibrium potential of 1.23 V is mainly composed of 0 V for the hydrogen evolution reaction and 1.23 V for the oxygen evolution reaction.

Theoretically, the minimum voltage for water cracking at room temperature (25 °C) and 1 standard atmosphere is 1.23 V. However, water electrolysis always needs a voltage higher than 1.23 V because various resistance must be overcome in the reaction process. The part of the voltage exceeding the theoretical value by 1.23 V is overpotential η. Overpotential is the main cause of energy loss in electrolytic water. Finding a suitable catalyst to reduce overpotential η is the most fundamental way to reduce energy consumption (Hou et al. 2019).

The major challenge in electrocatalytic water decomposition to produce hydrogen is to design and synthesize efficient and stable catalysts. In electrocatalytic water decomposition, the main functions of catalysts are (Sultan et al. 2019): to achieve stable charge transfer, provide adsorption sites for reaction intermediate species, and reduce the activation energy of oxidation and reduction of water molecules. The electrocatalyst for hydrogen evolution reaction with excellent activity is a noble metal platinum-based catalyst (Liang et al. 2020). However, this kind of catalyst's high cost and low stability restrict its large-scale industrial application. To obtain an efficient and low-cost electrocatalyst, it is necessary to fully understand the basic principle of hydrogen reaction.

In summary, electrocatalytic water decomposition is a promising approach for hydrogen production. The process involves the application of an external voltage to water, which results in the decomposition of water molecules into hydrogen and oxygen. However, using acidic or alkaline electrolytes is necessary to improve the conductivity of the solution. The major challenge in electrocatalytic water decomposition is the design and synthesis of efficient and stable catalysts to reduce overpotential and lower energy consumption.

Electrocatalytic hydrogen evolution

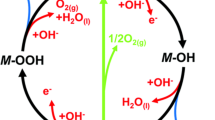

Hydrogen evolution reaction in different electrolyte environments (acidic, neutral, or alkaline) involves three elementary reactions, which are generally accepted by researchers at present (Safizadeh et al. 2015). According to the elementary reaction expressions in different electrolyte environments, it can be seen that the elementary reaction process of it is basically the same regardless of the pH conditions, as shown in Fig. 3.

Hydrogen evolution mechanism under acidic (bottom) and alkaline (top) conditions. Three different reactions occur during electrochemical hydrogen adsorption and desorption. These are the Volmer reaction, the Heyrovsky reaction, and the Tafel reaction. In the Volmer reaction, the catalytic electrode (Mcat) acts as the cathode and adsorbs hydrogen ions (H+) from the electrolyte. It combines with a single electron (e−) to produce the adsorption intermediate state (McatHads). The Heyrovsky reaction, on the other hand, involves the electrochemical hydrogen desorption step. The adsorption intermediate state (McatHads) on the surface of the cathode combines with hydronium ion (H3O+) or water to generate hydrogen, with the participation of e−. During the Tafel reaction, also known as the composite desorption process, there are more adsorption intermediate states (McatHads) on the cathode surface, and two adjacent adsorption intermediate states (McatHads) can easily recombine to generate hydrogen. One notable difference between the Volmer reaction in acidic and alkaline environments is that in the former, hydrogen ion (H+) in hydronium ion (H3O+) are directly adsorbed on the electrode surface. In contrast, in the latter, hydrogen ions (H+) are provided by water. Modified from Wei et al. (2018b)

The Volmer reaction is also known as the electrochemical hydrogen adsorption step; in this process, the surface of the catalytic electrode (Mcat) as the cathode adsorbs hydrogen protons in the electrolyte and combines with a single electron e− to form the adsorption intermediate state (McatHads) (Krstajić et al. 2001). The Heyrovsky reaction is also known as the electrochemical hydrogen desorption step; in this process, the number of adsorption intermediate state (McatHads) on the surface of the cathode is small, and with the participation of electron (e−), adsorption intermediate state (McatHads) is easy to combine with hydronium ion (H3O+) or water to generate hydrogen. Tafel reaction is also known as the composite desorption process; in this process, there are more adsorption intermediate states (McatHads) on the cathode surface, and two adjacent adsorption intermediate states (McatHads) are easy to recombine to generate hydrogen (de Chialvo and Chialvo 1999). The only difference is that during the Volmer reaction, in an acidic environment, the hydrogen protons in hydronium ion (H3O+) are directly adsorbed on the electrode surface; while in an alkaline environment, hydrogen protons are provided by water (Lasia 2019).

Different reaction paths have different reaction energy barriers in the reaction process. In practice, the activity of electrocatalysts in a basic system is usually 2–3 orders of magnitude lower than that in an acidic system (Wang et al. 2017a); this is mainly due to the Volmer reaction in the alkaline reaction process, which requires the initial water dissociation process. The breakage of the hydrogen–oxygen–hydrogen bond in water molecules needs to overcome the high reaction energy barrier, which severely restricts the rate of the whole alkaline catalytic reaction process (Liu et al. 2021c). In the electrocatalysis process, all three reaction steps above may become the reaction rate-determining steps. Usually, the reaction rate and mechanism can be judged by analyzing the Tafel slope of the polarization curve obtained by the electrochemical test. The smaller the value of the Tafel slope obtained by linear fitting means that the smaller the overpotential is needed to provide the same current density, which reflects that the electrocatalyst has better reaction kinetics performance (Guo et al. 2019; Lv et al. 2019).

It is generally considered that the chemisorption and desorption of hydrogen atoms on the catalyst surface are a pair of competitive reactions. If the degree of chemisorption is too strong, it is easy to form hydrogen, but it is not conducive to hydrogen escape. If the chemisorption degree is too weak, it is not conducive to the formation of hydrogen. Generally speaking, the binding ability between hydrogen atoms and active sites in catalysts can be characterized by hydrogen adsorption-free energy ΔGH* (Roldan Cuenya and Behafarid 2015). In the chemisorption process, it is necessary that the active catalytic site can form a strong enough combination with a hydrogen atom to promote the transfer of proton-coupled electrons. In the subsequent chemical desorption process, it is necessary to have a weak bond between the active catalytic site and the hydrogen atom to ensure that the formed hydrogen is easily released from the catalyst surface (He et al. 2017; Lin et al. 2017; Sun et al. 2017). It is generally believed that an ideal electrocatalyst needs a value of ΔGH* approaching 0 electron volt.

In summary, the hydrogen evolution reaction in different electrolyte environments involves three elementary reactions that are essentially the same regardless of the pH conditions. However, the activity of electrocatalysts in a basic system is usually much lower than in an acidic system due to the high energy barrier required for the initial water dissociation process. In addition, the binding ability between hydrogen atoms and active sites in catalysts can be characterized by hydrogen adsorption-free energy. An ideal electrocatalyst needs a value of hydrogen adsorption-free energy ΔGH* approaching 0 eV.

Transition metal-based electrocatalysts for alkaline hydrolysis

The anodic oxygen evolution and cathodic hydrogen evolution reactions, regarded as efficient and environmentally responsible methods to produce hydrogen without polluting the environment, can be improved by creating efficient electrocatalysts (Jian et al. 2018; Liu et al. 2018b). The high cost (Chen et al. 2016), slow kinetics, and scarcity of conventional precious metal-based hydrolysis catalysts are the main barriers to their widespread application (Chen et al. 2021a) because of the high potential difference in the hydrogen precipitation reaction, which results in high energy consumption in the electrolysis of water. Based on this, we will demonstrate in this chapter how these transition metal-based electrocatalysts have advanced recently. This paper reviews the hydrogen precipitation efficiency of different types of electrocatalysts for metals, as shown in Table 1.

Transition metal alloy

By altering the electronic abundance of states at its Fermi energy level, alloying can increase catalytic activity (Rosalbino et al. 2014). Conversely, transition metal alloying can modify the catalyst's electrical structure through doping, strain, and heterostructure, modulating the active metal’s d-band electrical structure to alter the electrocatalytic activity (Xiong et al. 2022). Shi et al. (2020) effectively isolated the intermetallic copper from the nanoporous compound tricobalt molybdate as a multipurpose electrocatalyst to obtain a low Tafel slope (40 mV decade−1) and a current density of − 400 mA−2 cm at overpotentials as low as 96 mV in 1 mol/L potassium hydroxide. Copper, cobalt, and a zeolitic imidazolate framework (ZIF-67) were inserted in a nitrogen-rich mesoporous carbon framework (CuCo@NC) and pre-grown on copper hydroxide nanowires by Kuang et al. (2017). Below 450 °C, copper ions were uniformly contained within ZIF-67 pores. At higher pyrolysis temperatures, the presence of copper-nitrogen bonds further increased the nitrogen content of the ZIF-67 framework, which significantly enhanced the electrocatalytic performance of the hydrogen evolution reaction and oxygen reduction reaction. Su et al. (2017) described an electrocatalyst made of ruthenium and cobalt bimetallic nanoalloys enclosed in a sheet of nitrogen-doped graphene that is both efficient and stable. In addition to being reasonably priced, the ruthenium atom in the platinum group added to the cobalt shell enhances the efficiency of electron transfer from the alloy core to the graphene shell layer, which is helpful for enhancing the carbon-hydrogen bonding and lowering the ΔGH* of hydrogen evolution reaction. Similar efforts have been undertaken to optimize the catalyst arrangement to improve the performance of transition metal catalysts in catalyzing hydrogen precipitation. Nickel-molybdenum alloys (Csernica et al. 2017; Wang et al. 2016a; Zhang et al. 2017), nickel–coper alloys, and iron-cobalt are a few earth-abundant metal alloys that have been designed and claimed to have good hydrogen precipitation yields and stability under alkaline conditions.

In summary, changes in the Fermi energy level resulting from alloying and modifications to the alloy nanostructure and electronic structure achieved through methods such as doping, strain, and heterostructures allow transition metal alloys to function as effective electrocatalysts.

Transition metal sulfide

Recent developments have led to earth-abundant transition metal-based nanoscale metal sulfides becoming cost-competitive alternatives to precious metal-based hydrolytic electrocatalysts (Yu and David Lou 2018). Studies have shown that the transition metal sulfide sequences CoxSy, NixSy, FexSy, MoxSy, and WxSy have excellent hydrolytic catalytic activity in alkaline media (Wu et al. 2017). However, many studies have shown that metal sulfides in energy conversion applications have low electronic conductivity and durability (Santhosh Kumar et al. 2022). The performance of these materials can be improved by doping, mixing, strain, phase engineering, heterostructure engineering (Fu et al. 2018; Zhong et al. 2017), and interface engineering (Huang et al. 2016; Li and Zeng 2017). The electronic conductivity can be altered, and the electrocatalytic hydrogen production efficiency can be significantly enhanced (Shen et al. 2015). Therefore, most studies have focused on tuning species and stoichiometry of these materials. The majority have therefore focused on tuning the type and stoichiometry of these materials to obtain the greatest possible hydrogen production efficiency by water electrolysis. Several papers have extensively reviewed the preparation and catalysis of molybdenum(IV) sulfide (Wei et al. 2018b). Therefore, this section focuses on the hydrogen precipitation efficiency of mixed metal sulfide basic hydrogen evolution reaction with other hybrids, transition metal anion doping, and other modification strategies.

Building on the work of Chen et al. (2017), Kou et al. (2018) and He et al. (2019) colleagues recently reported anionic engineering to modulate the electronic structure of transition metal catalysts by substituting sulfur, which is more electronegative than nitrogen. However, the desired catalytic hydrogen precipitation yields were not achieved. Subsequently, by reasonable speculation and experiment, nickel hydroxide nanosheet arrays were synthesized on nickel foam by simple hydrothermal synthesis. Then F–Ni3S2/NF was obtained by hydrothermal sulfidation after doping with fluorine using a gas-phase fluorination reaction on Ni(OH)2/NF, and the synthesis process is shown in Fig. 4a. Technical tests demonstrated that fluorine anion doping at 1 mol/L potassium hydroxide yielding an overpotential of 38 mV at a current density of 10 mA cm−2, even better than Pt/C/NF (50 mV at 10 mA cm−2), a Tafel slope of mV decate−1 and a current exchange density of 3.05 mA cm−2, all of which significantly improved the hydrogen precipitation activity and long-term durability up to 30 h. In addition to anion doping, adding metal atoms to the nickel sulfide framework enhances electrocatalytic efficiency. For instance, Ye et al. (2020) developed 320 mV overpotential, 500 mA cm−2 current density NiFeLa hydroxide modified tungsten-doped nickel sulfide nanoparticles on three-dimensional nickel foam. Tin-doped nickel sulfide nanosheets were also created on nickel (Sn–Ni3S2/NF) using the hydrothermal technique on nickel foam. The voltage needed for the total water splitting was only 1.46 V at a current density of 10 mA cm−2, which was significantly greater than the voltage needed for the nitrogen-doped tri-nickel disulfide framework. To enhance the catalytic efficacy of electrocatalysts, solid elements iron (Zhang et al. 2018a) and manganese can also be used as dopants in addition to tin (Jian et al. 2018).

a The fluorine-doped nickel sulfide nanosheet array synthesis on nickel foam (NF). Nickel hydroxide (Ni(OH)2) is grown on foam nickel by hydrothermal synthesis. Then the required product is obtained by fluorination and sulfuration. b Histograms depicting overpotential and Tafel slope of various electrocatalysts based on cobalt at a current density of 10 mA cm−2 in a potassium hydroxide solution with a concentration of 1 mol/L. N-CoS2/CC refers to nitrogen-doped cobalt disulfide deposited on carbon cloth, NiS–CoS refers to nickel sulfide-cobalt sulfide. Mo–Co9S8@C refers to single-atom molybdenum loaded on Co9S8@C-supported. c Optimized (0 0 1) slabs of cobalt sulfide (top) and nitrogen-cobalt sulfide (bottom). The cobalt atoms in nitrogen-cobalt sulfide are affected by the electronegativity of nitrogen, which weakens the cobalt-hydrogen bond and allows cobalt-hydrogen cleavage and thus accelerates hydrogen precipitation. Co refers to cobalt, S refers to sulfur, and N refers to nitrogen. d Synthetic process for Mo–Co9S8@C. Electron microscope analysis of the Mo–Co9S8@C sample. Mo–SA refers to molybdenum single atom. Figure 4a is modified from He et al. (2019), Fig. 4b is modified from Ma et al. (2018), Wang et al. (2019b), Zhu et al. (2020) and Fig. 4c is modified from Zhu et al. (2020)

Other transition metal sulfide compounds (cobalt, nickel) have recently been considered promising alternatives to precious metal-based compounds for water splitting. For example, transition metal cobalt sulfides have important applications in electrocatalysis, including electronic devices, ion storage, supercapacitors, redox reactions, oxygen precipitation reactions, and hydrogen precipitation reactions. For the hydrogen precipitation reaction of cobalt-based transition metal sulfide, on the one hand, the sulfur atoms are doped into the metal lattice to form a cleavage compound, the distance between metal atoms increases, the d-band gap narrows, and the density of states near the Fermi energy level is enhanced (Wang et al. 2021a). On the other hand, since sulfur and oxygen atoms are in the same main group and have similar physical and chemical properties, cobalt sulfide has good hydrophilicity in an aqueous solution, density of 10 mA cm−2, 1.0-mol potassium hydroxide. Zhu et al. (2020) prepared nitrogen-doped cobalt sulfide nanosheets with a Tafel slope of 60.1 mV decade−1 and an overpotential as low as 112 mV (Fig. 4c). Wang et al. (2019b) used molybdenum atomically dispersed on metal Co9S8 nanosheets as an advanced noble metal-free bifunctional water cracking catalyst Mo–Co9S8@C (Fig. 4d), which also exhibited excellent hydrogen evolution reaction performance in a wide pH range, obtaining an overpotential of 98 mV and a Tafel slope of 34.6 mV decade−1. As shown in Fig. 4b, comparing overpotential and Tafel slope histograms of different cobalt-based electrocatalysts at 1 mol/L potassium hydroxide, current density 10 mA cm−2 in recent years. However, previously reported studies have shown that they still suffer from the defects of active sites and insufficient conductivity.

Along with the doping mentioned above and mixing, interfacial constructs can alter the electrocatalyst by altering the electronic structure, increasing intrinsic activity, and improving electrical conductivity. This alters the catalyst's intrinsic activity and increases the efficiency of hydrogen precipitation (Zhang and Lv 2018). Given these factors, creating hollow/porous nano-rectangles, a regular hollow structure that doubles as a deity by providing an abundance of active surface sites and enabling ion diffusion, is a viable course of action (Guo et al. 2018a, b; Zheng et al. 2020). More importantly, the hollow structure can accommodate large expansion and improve the catalyst's lifetime. However, the design steps of previous hollow structures are tedious and expensive, which are not available for large-scale applications (Ma et al. 2020a). Therefore, a simple method to prepare morphology-controlled hollow structures is urgently needed. Recently, hollow porous squares of cobalt sulfide (CoS2·HNs) were produced with a greater specific surface area using a novel chemical etching-phosphatization/sulfuration technique. The equivalent electrocatalytic activity of selenide hydrolysis and transition metal sulfides has also been documented (Abdel Maksoud et al. 2021; Wang et al. 2021a).

In summary, it is found that sulfur possesses greater electronegativity, but its transition metal compounds possess low electron conduction rates and durability. Based on this, the electronic structure of the catalyst is adjusted to increase the electrical conductivity and the number of catalytic sites of the material, which in turn leads to high-performance catalysis.

Transition metal carbide

Transition metal carbides, also called “quasi-platinum catalysts,” exhibit that it can have a large enough surface area to contact the electrolyte, thus greatly improving the efficiency of hydrogen precipitation. For example, Ma et al. (2018) developed a three-dimensional hybrid/dense NiS–CoS nanorod array with an overpotential of 102 mV at a current exceptional electrocatalytic properties for aqueous decomposition as they possess a d-band electronic structure similar to the noble metal’s platinum. Additionally, they possess high electrical conductivity, high hydrophilicity, good mechanical strength, and good topology, making them highly desirable. On this basis, transition metal carbides have given rise to alternative electrocatalysts for the aqueous decomposition of precious metals. Although these catalysts have demonstrated excellent performance, they do not satisfy the needs of real uses, and it is still difficult to overcome the complicated preparation process and subpar stability. However, modifying the catalysts’ structure and shape can increase surface area and reveal more active sites, increasing electrocatalytic activity. Developing heterostructures, doping, and defect engineering can improve electrocatalytic performance (Chen et al. 2021b). Among them, molybdenum carbide is a promising candidate for electrocatalysis due to its high thermal and chemical stability and surface activity. The electronic structure in the d-band is most similar to that of platinum, the best noble metal electrocatalyst for hydrogen evolution reactions. Researchers have investigated cobalt carbide as an electrocatalyst for hydrogen precipitation reactions (Mir et al. 2023). This section will discuss the alkaline electrocatalytic hydrolysis of transition metal molybdenum carbide.

Despite these benefits, transition metal carbides' generally low conductivity necessitates a highly conductive base. In Vrubel and Hu (2012), first reported the existence of molybdenum carbide as a noble metal-free catalyst active. However, its catalytic activity is low due to the conductivity problem, which requires a reduced catalyst particle size as well as good dispersion and exposure to more active sites to improve the electrocatalytic activity. Fan et al. (2015) suggested that a straightforward thermal treatment of flexible carbon fabric filled with Mo–CTA supramolecular hybrids would develop well-dispersed molybdenum carbide microislands. Tight junctions, high electrical conductivity, and the plentiful catalytic active sites of molybdenum carbide itself were said to be the causes of the molybdenum carbide/carbon fabric composites' outstanding electrocatalytic characteristics. In addition, molybdenum carbide nanoparticles were constructed as nanowires (nanoparticles), which were used as the catalysts for the catalytic activity. In addition, molybdenum carbide nanoparticles have been constructed as nanowires, nanosheets (Xing et al. 2019), nanotubes (Xu et al. 2017), quantum dots (Zhang et al. 2018c), nano-octahedra (Wu et al. 2015), and nanofibers (Liu et al. 2018c). The introduction of molybdenum groups into these various nanostructured carbon materials can increase electrocatalytic activity.

An example is the synthesis of large-size atomically thin heterogeneous nanosheets of molybdenum/molybdenum carbide with abundant nanoscale heterogeneous interfaces through the salt-template method. This involves reducing molybdenum oxide precursors grown on sodium chloride crystals while forming molybdenum/molybdenum carbide-heterogeneous nanosheets in a methane/hydrogen mixture. At the nanoscale, the metal molybdenum and molybdenum carbide are interconnected, resulting in an abundance of molybdenum/molybdenum carbide-heterogeneous interfaces, as illustrated in Fig. 5a. This dual-phase interface achieves high dispersion of nanoparticles and enhanced electrical conductivity. The atomic ratios of three Mo/Mo2C-hetero-nanosheets electrocatalysts were also tested in this research (the atomic ratios of cobalt to cobalt carbide for molybdenum/molybdenum carbide- hetero-nanosheets-650, molybdenum/molybdenum carbide-hetero-nanosheets-700, molybdenum/molybdenum carbide—hetero-nanosheets-750, and 72:28, 61:39, and 89:11, 72:28, and 61:39, respectively, were verified), where the best-performing molybdenum/molybdenum carbide-heterogeneous nanosheets-750 obtained a Tafel slope of 62.86 mV decade−1, a low 10 mA cm−2 of 79 mV, and basic hydrogen evolution reaction activity comparable to 20% platinum/carbon catalyst at high overpotentials, indicating that molybdenum/molybdenum carbide-heterogeneous nanosheets-750 has a lower activation energy and faster reaction kinetics (Xiong et al. 2018).

a Salt-template synthesis of molybdenum/molybdenum carbide atomically thin heterojunction nanosheets. The molybdenum and molybdenum carbide nanoscale interconnections produce a rich molybdenum/molybdenum carbide-heterogeneous interface that provides a biphasic interface consisting of catalytic sites and electron transfer channels. MoO3@NaCl refers to molybdenum trioxide@ sodium chloride, H2 refers to hydrogen, CH4 refers to methane, Mo refers to molybdenum, Mo2C refers to molybdenum carbide, Mo/Mo2C refers to molybdenum/molybdenum carbide-hetero-nanosheets. Modified from Xiong et al. (2018); b cobalt carbide nanoparticle is uniformly embedded in nitrogen-doped chitosan porous carbon microsphere coated with graphene, forming a coating structure as shown in the figure. Mo2C/G–NCS refers to nitrogen-doped porous carbon microspheres, H2 refers to hydrogen, and H2O refers to water. Modified from Wei et al. (2021); c cobalt carbide nitrogen-doped porous carbon nanotubes (Mo2C@2D–NPCs) synthesis steps, Mo@2D–PANI refers to molybdenum/two dimension-polyaniline. Modified from Lu et al. (2017a); d cobalt carbide-schematic diagram of molybdenum carbide dissociation on molybdenum carbide boundary. CoC refers to molybdenum(IV) carbide, Co2C refers to molybdenum carbide, Co refers to cobalt, C refers to Carbon, H2 refers to hydrogen, and H2O refers to water. Modified from Liu et al. (2021c)

Besides developing various new nanostructured molybdenum carbides, there are sophisticated methods to enhance the intrinsic activity of molybdenum carbides, including heteroatomic doping. Lin et al. (2016) have successfully introduced cobalt elements into molybdenum carbide. His colleagues introduced nickel into molybdenum carbide (Chen et al. 2018b), while non-metallic elements doped into molybdenum carbide have been widely reported, phosphorus, nitrogen (Lu et al. 2017a; Wei et al. 2018a), sulfur, and others. However, the molybdenum carbide nanoparticles were homogeneously embedded in graphene-wrapped nitrogen-doped chitosan porous carbon microspheres, forming an encapsulated structure as shown below. Wei et al. (2018a) reported the use of chitosan and ammonium molybdate tetrahydrate as carbon and molybdenum sources, respectively (Fig. 5b). In contrast, Lu et al. (2017a) reported the borrowing of an interfacial strategy to synthesize polyaniline nanosheets with controlled components to achieve Mo2C-embedded nitrogen-doped porous carbon nanosheets (Mo2C@2D–NPCs). The synthesis process is shown in Fig. 5c, with aniline as the monomer, graphene oxide as the two-dimensional template, and Mo4O132− as the molybdenum source, in the toluene to Mo4O132− anchored. Polyaniline(PANI) nanosheets (Mo@2D–PANI) were prepared by in situ polymerization at the interface between toluene and water at room temperature, and in the second stage, Mo@2D-NPCs were obtained by pyrolysis of Mo@2D–PANI at 900 °C under argon (5%) atmosphere for 2 h (Wei et al. 2018a). Both teams used nitrogen doping of the ultra-small size of molybdenum carbide. More vital interaction between the carbon matrix provided a larger exposed active site, and both used graphene structures, significantly improving molybdenum carbide's conductivity problem. Wei et al. (2018a)’s team primarily used doping through porous microsphere structures to increase the contact point between electrolyte and electrode and decrease charge transfer resistance. In contrast, Lu et al. (2017a)’s team reduced the energy barrier for hydrogen precipitation by using a practical interfacial strategy and strong interaction between molybdenum carbide and nitrogen-doped porous carbon nanosheets to improve the hydrogen precipitation yield. However, there are slight differences in the modification strategies both teams use.

According to research by Ang et al. (2015), partial nitrogen doping as an electron-rich dopant lowers the density of the hollow d-band in molybdenum carbide, which diminishes the molybdenum-hydrogen intensity and raises hydrogen evolution reaction activity. The intrinsic activity of electrocatalysts can be successfully increased through reasonably modified element doping.

In addition, nitrogen-doped graphene was added to lessen the contact between transition metal carbide (M = tungsten, vanadium, titanium, and molybdenum) and H* (Wei et al. 2018a). The heterogeneous interfaces of heterostructured catalysts, which can offer multiple functional sites for the complete reaction process, have fascinating synergistic effects. Then Liu et al. (2021c)’s team reported the potential of a hydrogen-universal self-standing molybdenum carbide-molybdenum carbide(II) heterojunction electrode with a multilayer structure that outperformed the noble metal catalyst (platinum) in terms of alkali resistance, achieving an overpotential of 256 mV at a current density of 500 mA cm−2 and a Tafel slope of 59 mV·decade−1. Then comparing each electrode's turnover frequency values, the molybdenum carbide-molybdenum carbide(II)-790 electrode was significantly larger than the other electrodes, indicating that the electrode has excellent activity. In addition, its performance was also tested under acidic conditions, and the molybdenum carbide-molybdenum carbide(II) heterojunction H* adsorption Gibbs free energy was the best (ΔGH* = − 0.13 eV). The water dissociation energy barrier at the molybdenum carbide-molybdenum carbide(II) interface (1.15 eV) was lower than that at the molybdenum carbide (3.33 eV) or molybdenum carbide (1.90 eV) interfaces, further hydrogen evolution reaction indicating that the molybdenum carbide-molybdenum carbide(II) heterojunction has excellent hydrogen evolution reaction activity. Its mechanism is shown in Fig. 5d. The corresponding free energy diagrams were plotted to explain the performance of hydrogen evolution reactions in alkaline solutions.

In summary, transition metal carbides have a d-band electronic structure similar to the noble metal platinum. They are, therefore, ideal electrocatalysts for hydrolysis, but the conductivity and the number of catalytic sites are still lacking.

Transition metal nitride

Transition metal nitrides are interstitial compounds with face-centered cubic, hexagonal dense, and simple cubic arrangements that exhibit the properties of covalent compounds, ionic compounds, and transition metals simultaneously. Nitrogen atoms are embedded into the interstitial positions of metal atoms in these interstitial compounds (Chen et al. 2021b). In addition to their distinctive electronic structure, high stability, high catalytic activity, higher mechanical robustness for corrosion resistance, and improved surface morphology, transition metal nitrides also have numerous other benefits. The behavioral characteristics of noble metals, which are currently promising catalysts across a wide potential hydrogen range, are produced via metal- nitrogen bonding, which induces lattice expansion and band contraction of the metal (Wang et al. 2021c). The catalytic performance of transition metal nitride depends on the catalyst's shape, structure, and size distribution. By nitriding metal precursors such as metals, metal oxides, metal halides, and organometallic precursors in ammonia gas or nitrogen/hydrogen gas mixtures prepared by controlled temperature rise and fall under high-temperature conditions, it is possible to achieve the controlled synthesis of catalyst morphology (Tareen et al. 2019). The controlled temperature increase reaction is the name of this synthesis method. The main factors affecting the performance index of electrocatalysts include the quantity of active catalytic sites, intrinsic activity, conductivity, and the ability to adsorb and desorb reaction intermediates; this is also the direction in which transition metal nitride catalysts are being developed.

Co2N/CoN/Co2Mo3O8 heterostructured catalysts were created on cobalt foam using hydrothermal and nitridation treatment in two stages (Hu et al. 2021). The catalysts' numerous active sites showed extraordinarily high activity and stability in the alkaline hydrogen evolution process. They were equal to the noble metal platinum's catalytic performance at a current density of 100 mA·cm−2 and were made feasible by their nanoporous and multilayer structure. A combination of nickel and molybdenum nitride was used to create homogeneous nickel–molybdenum nitride catalysts on amorphous molybdenum nitride nanorods (Wu et al. 2022a). The layered nanorod-nanoparticle structure, with its wide surface area and multidimensional interfaces/defects, allowed the existence of active sites at current densities of 100 and 1000 mA cm−2, respectively, in 1 mol/L potassium hydroxide. This combination also successfully modulated the boundary electron distribution. In contrast to intact molybdenum nitride nanosheets, which have more active sites on these defects and have better catalytic performance, molybdenum nitride (dr-molybdenum nitride) nanosheets rich in defects have extra edge defects (Xiong et al. 2017).

Using urea as the source of nitrogen, Dai et al. (2022) prepared self-supported Ni3N–Mo2N/NF heterostructures using a hydrothermal method that produced controlled nanowire arrays, attributed to the faster charge transfer rate of the catalyst, exhibiting a more favorable intrinsic electrocatalytic performance, exhibiting an overpotential of only 66 mV under alkaline conditions. Cobalt nitride-vanadium oxynitride (VN1-xOx) nanohybrids were synthesized on carbon cloth using a polyaniline-mediated method. This approach can form a layer of nitrogen-doped carbon, which serves as an electron transfer mediator between the active catalyst and the conducting carrier (Dutta et al. 2019). This results in accelerated processes and increased hydrolysis activity. The nanohybrids showed an overpotential of only 118 mV at a current density of 10 mA cm−2 and maintained long-term stability for up to 100 h. Using the molten salt technique, a series of two-dimensional layered transition metal nitrides (MoN1.2, WN1.5, and Mo0.7W0.3N1.2). As a result of their outstanding electron conductivity and metal-like electronic structure, they showed good electrocatalytic activity (Jin et al. 2021b). These materials have a lower overpotential need than other two-dimensional layered electrocatalysts, just 122 mV at a current density of 10 mA cm−2. On nitrogen-doped carbon carriers, Ni–Mo–O/Ni4Mo@NC nano-interfaces were used using an electrodeposition-calcination-electrodeposition method (Fig. 6b) (Jin et al. 2020). Due to nitrogen's electronegativity, it interacts with the transition metal after being added to carbon carriers and improves the catalyst's electrical conductivity, showing a low overpotential of 61 mV (10 mA cm−2) under alkaline conditions at 1 mol/L potassium hydroxide.

a Fabrication of Cr–Co4N. Cr–Co4N/CC nanorods were synthesized by hydrothermal deposition of Cr–Co(OH)F precursors and annealed at 400 °C under a nitrogen gas atmosphere to obtain the desired products. Cr3+ refers to chromium ions, Co2+ refers to cobalt ions, F− refers to fluoride ions, N2 refers to nitrogen, and Cr-Co4N refers to chromium-tetra cobalt nitride. Modified from Yao et al. (2019); b schematic illustration of the fabrication of Ni–Mo–O/Ni4Mo@NC. The polyaniline was first deposited on carbon cloth and calcined at 800 °C under a nitrogen atmosphere to obtain nitrogen-doped carbon. An electrodeposition step introduced the Ni–Mo–O/Ni4Mo nano-interface. N2 refers to nitrogen, and C refers to carbon. Modified from Jin et al. (2020); c molybdenum phosphide nanoparticles grown in situ on multi-walled carbon nanotubes are used to enhance the hydrogen evolution reaction through a simple path. MWCNTs refer to multi-walled carbon nanotubes, and MoP refers to molybdenum phosphide. Modified from Xiao et al. (2021)

Transition metal nitride possesses superior metallicity, but the unfavorable d-band energy level hinders the catalytic performance of hydrogen precipitation reactions, which can be solved by optimizing the metal abundance. The in situ hybridization of Ni2Fe2N nanoparticles with another metal tri-nickel ferrite electrocatalyst (Hu et al. 2020). Due to the catalyst's improved metallicity, enhanced hydrolytic kinetics, and decreased hydrogen adsorption-free energy, Ni2Fe2N/Ni3Fe nanoparticles demonstrated excellent hydrogen evolution reaction catalytic activity with an overpotential of 74 mV and a low Tafel slope of 53 mV decade−1 at a current density of 10 mA cm−2. The one-pot method (Park et al. 2021) was used to grow Ni2Mo3N with nanostructures on nickel foam. According to density function theory calculations, the nitrogen sites in the four-coordination number Ni2Mo3N have favorable hydrogen adsorption energy (near platinum), and this catalyst has a low overpotential (21.3 mV @ 10 mA cm−2 and 123.8 mV @ 100 mA cm−2) and excellent durability for 24 h. When the electrical mechanism for cobalt nitride is tweaked to get strong hydrogen binding ability (Fig. 6a), the chromium-doped cobalt nitride nanorod arrays on carbon cloth demonstrate a low overpotential of 21 mV (10 mA cm−2 under alkaline conditions at 1 mol/L potassium hydroxide), outperforming platinum/carbon catalysts in terms of performance (Huang et al. 2018; Yao et al. 2019).

In summary, transition metal nitride is a catalyst with a wide range of acid–base applications and possesses the characteristics of good metallicity, but the d-band energy level is not conducive to the catalytic effect, which is the direction to improve the catalytic properties of transition metal nitride.

Transition metal phosphide

Phosphorus has an electronic structure similar to that of metals, and when combined with transition metals in phosphides, it forms metal–metal-like bonds with covalent characteristics. These bonds prevent the achievement of close stacking, resulting in an often asymmetrical structure (Pu et al. 2020). Transition metal phosphides typically form a trigonal prism shape, with phosphorus atoms at the center and metal atoms surrounding them. The metal–metal bonds are spread throughout the catalyst, resulting in good electrical conductivity, which is crucial for high-performing electric catalysts (Carenco et al. 2013). The entry of phosphorus also improves the stability of transition metal carbide and can reduce the degradation of the sample, e.g., molybdenum nitride < molybdenum carbide < molybdenum phosphide for comparison with molybdenum catalysts (Oyama et al. 2009).

As the phosphorus atom enters the catalyst, the transition metal’s d-band center and Fermi energy level change, which affects the metal’s d-orbit width and the electron density in the active site. The catalytic process is supported by adding phosphorus, which also expedites the adsorption and desorption of reactants and reaction intermediates during the reaction (Han et al. 2019a). Combined with Sabatier’s principle, these two elements enable the reaction intermediate to have the best binding energy and catalytic activity. Due to phosphorus's high electronegativity, a tiny electron is transferred from metal to phosphorus. The hydrogen evolution reaction process predominantly uses phosphorus as the active site; hence, adding more phosphorus to the catalyst helps it work better (Zhou and He 2021). To create even more active sites, phosphorus can also induce the emergence of vacancies. Positively charged metal can be a hydride acceptor, and negatively charged phosphorus can be a proton acceptor. Electrons in transition metal phosphide are highly delocalized, in the conductivity of phosphide is weaker than that of metal. However, phosphorus atoms can also accelerate the charge transfer, so transition metal phosphide with a suitable ratio of phosphorus to metal atoms still has good conductivity, especially for compounds with high phosphorus content, and thus exhibits good catalytic properties (Pan et al. 2015). Furthermore, it was discovered that catalysts with a high proportion of unoccupied three-dimensional orbitals had enhanced water-activated oxygenophilic sites and could also modulate the electronic structure for the best hydrogen adsorption. These findings were made using discrete Fourier transform calculations using cobalt phosphide as a model (Men et al. 2020).

Xiao et al. (2018) utilized hydrothermal phosphorylation to synthesize dibasic cobalt phosphide nanowire arrays with bound transition metal vanadium. This catalyst was deposited on a three-dimensional conductive and pliable carbon fabric with a large surface area. The incorporation of vanadium into the cobalt-phosphorus lattice increased the lattice constant, resulting in a stronger electronic interaction between vanadium and cobalt-phosphorus. This interaction also increased the electron density in the cobalt phosphide, leading to an improvement in its conductivity. The catalyst exhibited an ultra-low overpotential of 123 mV at a current density of 10 mA cm−2 in 1 mol/L potassium hydroxide. Using precipitation reaction and in situ phosphorylation, cobalt phosphide nanosheet arrays were made on Ti3C2MXene by Yan et al. (2020). These arrays had a heterogeneous structure with cobalt phosphide nanosheets distributed vertically on the material. This structure created a hierarchical porous structure with a significant surface area and high conductivity. In order to produce a current density of 10 mA cm−2, there must be enough active sites for catalytic processes, and the charge transfer rate must be increased at 1.0 mol/L potassium hydroxide with an overpotential of 102 mV.

A porous nanostructure with a larger surface area was made by introducing transition metals (molybdenum and cobalt) to the original tungsten phosphide, exposing more active sites. More notably, after cobalt doping, the water dissociation and hydrogen production steps were adjusted, greatly increasing the catalyst's reaction (Guo et al. 2019). Since they have a larger area of exposed active sites and a high surface porosity, hollow nanoparticles are an effective technique to boost the catalytic capacity of hydrogen evolution reactions. Due to their structural characteristics, metal–organic frameworks are suitable precursors for producing hollow nanoparticles. Luo et al. (2022) used metal–organic frameworks as models to make hollow cobalt–ferrum–phosphorus/cerium oxide hexagonal rods. Due to the synergistic effect and the influence of the oxygen vacancies at the interface on the electrical structure, a current density of 10 mA cm−2 in alkaline media may be reached at an overpotential of just 69.7 mV, allowing the catalyst hydrogen adsorption-free energy to be tuned.

Often seen on multi-walled carbon nanotubes, the smaller pore-like defects are effective locations for forming active materials (Fig. 6c) (Xiao et al. 2021). At a distance of 10 mA cm−2, overpotentials of 109 mV and 155 mV were observed in acidic and basic solutions, respectively, with mild Tafel slopes of 56.5 mV decade−1 and 56.8 mV decade−1.

In conclusion, the catalytic performance of the transition metal catalysts is significantly enhanced by the addition of phosphorus, which can be attributed to the introduction of phosphorus to create more vacancies and enhance the conductivity of the catalysts. The modification of the nanostructure and electronic structure further enhances the catalytic performance.

Transition metal selenide

Transition metals can react with elements in the sulfur group, resulting in the formation of compounds. Similarly, transition metal selenides have structures comparable to the corresponding sulfides, but they exhibit better electrical conductivity due to the stronger metallic properties of selenium (Zeng and Li 2015). IVB–VIIB group transition metals interact with cesium to form a lamellar structure. The VIII group is a non-lamellar structure; the lamellar structure has very strong chemical, thermodynamic and mechanical properties, and others (Peng et al. 2020). Diverse anisotropy, metal selenide is a typical layered structure, similar to sulfide, with three common phases: 1T (triangular), 2H (hexagonal), and 3R (rhombic). Among these phases, 1T has good metallicity, and all the basal sites can be used as active catalytic sites, making it an effective catalyst for the hydrogen evolution reaction. As the non-layered structure makes it easier for active oxygen sites to generate via surface oxidation, non-layered transition metal selenide are employed more frequently for catalytic oxygen evolution reaction procedures (Lu et al. 2017b; Peng et al. 2020; Wilson et al. 2001).

Transition metal selenides are gradually filled with non-bonded d-bands from IVB–VIIB and group VIII elements, and the electronic structure is changed. Catalysts with monolayer structures are direct band gap semiconductors with better conductivity. Developing layered transition metal selenide with single or multiple layers can enhance the hydrogen evolution reaction process. Two-dimensional NiWSe nanosheets were synthesized (Zhao et al. 2018). The introduction of tungsten promoted the formation of two-dimensional nanosheets, which exhibited an overpotential of 162 mV in alkaline media, relying on the layered structure and the synergistic electronic effect between layers. After being plasma-treated, Mo–Ni–Co trimetallic selenide nanorod arrangements were constructed on top of nickel–cobalt foams (Wang et al. 2020b), the molybdenum–nickel–cobalt trimetallic selenide nanorod arrays showed a low overpotential of 38 mV and were catalytically stable for more than 100 h as a result of the cumulative effects of the different metals and the interconversion between the mixed phases of molybdenum selenide 1T–2H.

The amount of electrochemically active sites and the surface shape of the catalysts are key components in the catalytic process. Uncovering more transition metal selenide edge planes is crucial because they have more favorable catalytic activity. When exfoliated into lamellar nanosheets, palladium and selenium in palladium diselenide reveal more active sites and have high catalytic characteristics for the hydrogen evolution reaction process. Exfoliated palladium diselenide nanosheets also have a low overpotential of 138 mV at 10 mA cm−2 and a Tafel slope of 100 mV decade−1. Planar coordination of palladium diselenide was developed as a basic catalytic hydrogen evolution reaction (Lin et al. 2021). An in situ-induced growth technique was developed by altering nanocrystalline ferrous selenide on two-dimensional ultrathin Ti3C2TxMXene sheets to create zero-dimensional to two-dimensional heterostructures (Hao et al. 2022) (Fig. 7a), which led to the high exposed surface area, strong electronic coupling properties, and high conductivity, resulting in a competitive onset potential of 89 mV, a favorable Tc, and improved selenium nanocrystal characteristics. On a conductive substrate, transition metal selenides can be produced to lower contact impedance and boost the catalyst's ability to react with hydrogen (Yang et al. 2020b). Molybdenum selenide nanosheets and nickel selenide microislands were produced on nickel foam in a single hydrothermal stage. This method produced 10 mA cm−2 and a very low Tafel slope of 85.7 mV decade−1 while significantly lowering the resistance at the electrocatalyst/substrate interface, speeding up the charge and mass transfer rate of hydrolysis, and exposing more active sites. In their research, Song et al. (2020b) successfully created a ternary phase based on nickel–iron selenide on a stainless steel pad. This phase includes selenium, which is capable of forming strong covalent bonds with the metal surface, leading to increased resistivity and improved charge transfer stability. The researchers found that a low potential of just 260 mV at 75 °C was sufficient to drive a high current density of 1000 mA cm−2.

a Synthetic steps of the FeSe2/Ti3C2Txhybrid. Ti3C2Tx nanospheres were obtained by etching, then by attaching nanoscale selenium seeds to the two-dimensional surface using hydrazine hydrate. Finally, ferrous selenide nanoparticles were attached to Ti3C2Tx by a solvothermal procedure with the help of polyvinyl pyrrolidone. Fe3+ refers to iron ions, N2H4·H2O refers to hydrazine hydrate, and Se refers to selenium. Modified from Hao et al. ( 2022); b schematic illustration for synthesizing boron-doped Ni–Co–P hollow nanoprisms. Ni–Co refers to nickel–cobalt, Ni–Co–B refers to nickel–cobalt–boron, and Ni–Co–B–P refers to nickel–cobalt–boron–phosphorus. Modified from Liu et al. (2021b); c graphical diagram of the preparation of Co–MOF–74 and MoSx/Co–MOF–74 composites. C refers to carbon, O refers to oxygen, H refers to hydrogen, Co(NO3)2·6H2O refers to cobalt nitrate hexahydrate, and N2H4·H2O refers to hydrazine hydrate. Modified from Do et al. (2021)

In summary, selenium and sulfur are in the same leading group; thus, the corresponding transition metal compounds are similar to transition metal sulfides and often exist in a sheet-like structure, which also facilitates the preparation of nanosheets, increasing the specific surface area, exposing more catalytic sites and enhancing the performance of catalysts.

Transition metal oxide

Metal oxides are helpful in various contexts due to their cheap cost and diverse chemical makeup (Abdel Maksoud et al. 2020). The most notable properties of metal oxides are their composition and structure variety and capacity to dynamically rearrange the crystal structure and quantity of electrons. Metal oxides, however, have a limited role in hydrogen evolution reaction processes because of their weak electrical conductivity, inadequate hydrogen adsorption, and low activity.

The existence of gaps modifies the electrocatalysts’ electrical structure properties, which can be used to boost the catalyst’s efficiency. Molybdenum oxides are typically found as α-MoO3 flakes, and by exfoliating the flakes, Datta et al. (2017) created two-dimensional nanosheets. The two-dimensional structure makes it easier for exposed atoms to spill from the surface and create vacancy defects. The development of vacancies results in less surface atomic coordination, increasing the number of surface vacancies. The creation of vacancies causes a drop in the number of surface atomic coordination sites and an increase in the number of active sites, which causes the two-dimensional-MoO3−x nanosheets to exhibit an overpotential 142 mV value at a typical current density of 10 mA cm−2. Existing oxygen gaps might be filled with sulfur rather than being created to generate active sites with better electron transport capacities. The catalyst has a low overpotential of 61 mV at a current density of 10 mA cm−2. It can maintain long-term stability of up to 60 h at 1000 mA cm−2 in a 1.0 mol/L potassium hydroxide medium. This is because sulfur adsorbs hydrogen to form SH*, which enhances the hydrogen evolution process and improves the catalytic activity (Jin et al. 2021a).

It was discovered that metal and oxide synergy enhanced hydrogen evolution reaction efficacy. A heterogeneous nickel/ nickel oxide structure was created using in situ Raman spectroscopy. It was shown that the surface β-Ni(OH)2 correlated with the hydrogen evolution reaction activity of nickel/nickel oxide nanosheets. However, after maintaining a high cathodic electric potential for 2000s, the species β-Ni(OH)2 disappeared (Faid et al. 2020). In order to achieve high hydrogen evolution reaction catalysis efficacy, the hydroxide species must be maintained. Developing many nickel oxide worm-like structures on nickel nanosheets increased the efficiency of oxide/metal heterojunctions (Jin et al. 2021a), resulting in heterostructures with oxygen-rich gaps and hydroxyl compounds. Nickel/nickel oxide-cp considerably reduced the 10 mA cm−2 overpotential by 124 mV. Cobalt–MOF was calcined and grown on nickel foam, and molybdenum disulfide nanosheets were hydrothermally produced on the surface to produce Co3O4/MoS2 heterostructures. Tafel slope driving potential at 10 mA cm−2 is 98 mV decade−1 (Faid et al. 2020; Muthurasu et al. 2019).

A photosensitive WS2/ZnO (WZO) nano-heterojunction is constructed to improve frontal catalyst stability (Pataniya et al. 2021). The material can maintain hydrogen evolution reaction activity constant for 25 h of chronoamperometry and 2000 cycles of cyclic voltammetry. Copper impurities were doped into cobalt(III) oxide nanowire precursors to obtain Co3O4–CuO nanocomposites. This resulted in reduced hydrogen adsorption, improved conductivity, and hydrogen evolution reaction catalysts exhibiting a low Tafel slope of 65 mV decade−1 (Tahira et al. 2019). In order to modify the material's electrical structure and fill it with oxygen gaps, sulfur was infused into cobalt oxide nanosheets (Geng et al. 2019). As a consequence, the material's hydrogen evolution reaction performance was enhanced. A controlled microporous CoMo network was used to build a MoO2@CoMo heterostructure, and the catalyst's optimum overpotential for hydrogen precipitation at – 50 mA cm−2 was just 76 mV (Han et al. 2020).

In conclusion, oxides have compositional diversity, and the presence of oxygen facilitates the construction of oxygen vacancies and enhances catalytic performance. In contrast, the preparation of oxides is relatively simple, and it becomes easy to construct heterojunctions of oxide composition as well as specific structures, which is beneficial to hydrogen production.

Transition metal hydroxide

Nickel, cobalt, and ferrum-based hydroxides are commonly used to catalyze hydrogen evolution reaction processes, and these pristine hydroxides possess different crystalline forms, including layered mono-hydroxides and dihydroxides having the structure of bruckite-type hydroxide magnesium hydroxide, which are compounds consisting of octahedral metal ions surrounded by hydroxide ions (Evans and Slade 2006). The nickel and cobalt hydroxides are typical hydromagnesite-type hydroxides that exhibit good hydrogen evolution reaction properties in alkali, and nickel hydroxide exhibits a higher overpotential margin than cobalt hydroxide. Nickel hydroxide comprises many Ni(OH)2−x layers, between which anions and water molecules can be inserted. Inserting water molecules increases the interlayer spacing and decreases the interaction between neighboring layers. Nickel can also be substituted to form Ni(OH)2-type hydroxides, such as NiFe-layered double hydroxide and NiCo-layered double hydroxide (Hall et al. 2015; Xu et al. 2018; Yu et al. 2018).

The pristine TM(OH)2 does not exhibit weak adsorption to hydrogen. Therefore, a poor hydrogen evolution reaction in active materials shows good hydrogen evolution reaction ability when TM(OH)2 modifies other metallic materials. Yuan et al. (2022) connected metal hydroxides and organic backbones using aromatic carboxylates to construct mutually cross-linked two-dimensional sheet structures, and adjacent stacks can be linked by π–π interaction determining stability. NiCo–B–P was produced using in situ phosphorylation, taking advantage of the structural and doping properties (Liu et al. 2021b), the material possesses more active sites and high activity, and NiCo2–B–PHNPs exhibited excellent hydrogen evolution reaction performance of 10 mA cm−2 at an overpotential of 78 mV. NiCo–Co nanoprisms were used as templates and then used NaBH4 for heat treatment to form NiCo-layered double hydroxide with boron doping (Fig. 7b). The hierarchical heterogeneous structure was created by coupling NiCo-layered double hydroxide nanosheets with NiCo2S4 nanorods on carbon cloth (Liu et al. 2021d). The hierarchical coupling structure improved the stability of the structure and increased electrical conductivity, the nanorods provided more active sites, the structure improved electrocatalytic performance in alkaline electrolytes, and the structure only needed an overpotential of 219 mV to reach a high current density of 50 mA cm−2 for the hydrogen evolution reaction.

NiCo-layered double hydroxide nanosheets loaded on nickel foams were induced to amorphized by Yang et al. (2020c) using a B-doping strategy. This amorphous material's locally disordered structure is rich in oxygen vacancies, exposing more atoms in the unsaturated coordination plane and enabling the material to maintain excellent catalytic activity in 1.0 mol/L potassium hydroxide for at least 72 h. The substance works well as an electrocatalyst for hydrogen evolution reactions. In order to create catalysts with increased basic hydrogen evolution reaction activity, three-dimensional hydroxides (nickel, cobalt, iron, manganese) were grown on two-dimensional sulfide nanosheets (Zhu et al. 2018). At 128 mV at 10 mA cm−2 in 1 mol/L potassium hydroxide, the MoS2/Co(OH)2 hybrid catalyst achieved an exceptionally low overpotential. The formation of a varied surface, which speeds up the process of breaking up the water and lowers the kinetic energy barrier, accounts for the improvement. Dong et al. (2021) also created three-dimensional heterogeneous electrocatalysts made of CoNi, CoNi LDH, and 1T–2H phase molybdenum disulfide using electrodeposition and in situ reduction. Due to the formation of CoNi(CN) alloy on the surface of the double hydroxide and the phase shift of molybdenum sulfide from the 2H phase to the 1T phase, this unique three-dimensional catalyst may decrease the kinetic energy barrier for water activation and boost the effectiveness of the hydrogen evolution process.

In conclusion, the presence of hydroxide in hydroxide makes it water-friendly. It facilitates the generation of intermediates. It is usually present in a lamellar structure, which gives it strong catalytic properties under alkaline conditions, further enhanced by self-supporting and heterogeneous structures.

Transition metal-based-metal organic framework

Metal–organic frameworks (MOF) compounds are porous compounds in which metal ions (clusters) are interconnected through molecular interactions between organic ligands (Yang et al. 2020c). This gives metal–organic frameworks very good crystallinity, porosity, electrical conductivity, and controllable active site characteristics, which are important in promoting electron transfer and mass transfer rate (Wang et al. 2019a). The electronic coupling at the connection interface between organic ligands and metals in metal–organic frameworks greatly affects the hydrogen evolution reaction process. Changing the electronic coupling by changing different organic ligands and metal connections is possible. These superior features make metal–organic frameworks excellent electrocatalysts for hydrogen precipitation (Hua et al. 2019; Xia et al. 2015). Liquid phase diffusion, solvothermal, microwave, and layering methods can prepare metal–organic frameworks electrocatalysts.

According to Hua et al. (2019), a meso-Cu–BTC metal–organic backbone was developed, which exhibits an electrochemical hydrogen precipitation reaction in 1-mol sodium hydroxide solution with a low Tafel slope of 33.41 mV decade−1 and long-term durability. The pristine metal–organic framework also has a porous structure that aids in mass and electron transfer. This device possesses 25 mV to start potential, a low Tafel slope of 33.41 mV decade−1, a large current density, and long-term durability. A bimetallic metal–organic framework (CuRu–MOF) was made to aid hydrogen precipitation because bimetallic nodes expose additional active areas. As a result, they achieved a 25 mA cm−2 current density at a 22.7 mV overpotential (Qiu et al. 2019).

The coupling of organic ligands also impacts metal–organic frameworks' active region and activity. The conjugated ligand hexaiminohexaazatrinaphthalene (HAHATN) was used (Huang et al. 2020), which led to the creation of an additional (Metal-Nitrogen) metal center with a narrow band gap that is conducive to electron transfer and mass transport. Ni3(HAHATN)2 nanosheets displayed a tiny overpotential of 115 mV at 10 mA cm−2 with a Tafel slope (45.6 mV decade−1). Pore engineering can be used to modify the catalytic performance of catalysts. The pores of the metal–organic framework influence the absorption and release of gases as well as the uptake of active compounds. [Co6(oba)5(OH)2(H2O)2(DMF)]4n−2DMF was used in the air at a pyrolysis temperature of 100–700 °C as a way to obtain additional pores (Bagheri et al. 2021). At 300 °C, MOF with micro- and mesopores was obtained, effectively improving the catalytic activity.

A two-dimensional to three-dimensional flower-like metal–organic framework material {Co(BIPA)(5-OH-bdc)(DMF)}n was developed and then obtained Co-MOF-8001 by calcination with an onset potential (0.12 V) and an Ej = 10 value (0.193 V) with no decay in catalytic performance over 20 h of cycling (Pan et al. 2019b). Primitive metal–organic frameworks often need to be compounded with other materials to achieve better catalytic performance because of their poor electrical conductivity. Amorphous molybdenum sulfide was combined with cobalt-based metal–organic frameworks (cobalt-MOF-74) to alter molybdenum sulfide using a solvothermal process (Do et al. 2021). The best performance of 40% MoSx with a low onset potential of – 147 mV and a Tafel slope of 68 mV decade−1 is achieved when Co-MOF-74 interacts with molybdenum sulfide to form CoMoS species, reducing the hydrogen adsorption energy. Co-MOF-74 also provides a porous framework, which results in a significant increase in the amount of surface activity of the obtained material (Fig. 7c). A cobalt-based porphyrin-like metal–organic framework was grown on carbon nanotubes (Micheroni et al. 2018), which has a covalent linkage between the metal–organic framework and carbon nanotubes, thus enhancing the electrical conductivity and the hydrogen evolution reaction conversion number (TON) and conversion frequency (TOF) of the Hf12–CoDBP/CNT heterojunction, and this material has become the most active cobalt-based electrocatalyst.

In conclusion, metal–organic frameworks have a naturally microscopic porous structure that allows the catalyst to fully engage with the substrate. On this basis, the catalytic performance is further enhanced by changing the composition of the catalyst and compounding with other materials.

Optimization strategies

The number of active sites, which is the primary determinant of catalytic efficacy for electrocatalytic processes, decides how effective the process will be (Nai et al. 2017). Nanomaterials can have a larger specific surface area and therefore have more active sites; as a result, nanostructures are good candidates for electrocatalysts (Cao et al. 2020). Optimization of nanostructures can improve the dispersion of metal atoms on the catalyst surface, increase the contact area between the catalyst and the substrate, and decrease the cost of the electrocatalyst (Hu et al. 2018).

The electronic bonding between the atomic orbitals on the electrocatalyst and the ions/molecules deposited on the surface is thought to be the cause of chemisorption on catalysts, according to the Newns–Anderson hypothesis (Jin et al. 2022). Consequently, the orbitals are split into two different states, the bonding state and the antibonding state. The relationship between the electronic configuration and electrocatalytic performance has been a hot topic of study, and the electronic structure is crucial (Ouyang et al. 2020). The main elements that control the electron transfer in electrocatalytic reactions are the concentration of charge carriers, the density of states, the energy band structure of the Fermi energy level, and the charge distribution of metal ions. Valence and spin states are frequently included in the electronic structure.

Nanostructure optimization

Core–shell nanostructures

Materials consisting of internal core and external shell components are called core–shell nanostructures. However, it is important to note that core–shell structures are not restricted to the typical spherical particles often associated with this term (Chaudhuri and Paria 2012). A shell structure can be applied to the exterior of a range of other nanostructures, such as one-dimensional nanowires, two-dimensional nanosheets, and even three-dimensional framework structures. The shells provide the active substance within with dependable protection, permitting full exposure of the catalytic sites and enabling the catalyst to attain long-term stability (Chaudhuri and Paria 2012; Royer et al. 2022). The catalyst's electronic and chemical structure may be changed thanks to the strong connection between the core and shell, which also increases the reaction's intrinsic activity and binding energy of the intermediate. The various material compositions of the core and shell components enable the core and shell to work together synergistically to address the fundamental phases of the hydrogen precipitation process (Liu et al. 2015). The interaction between the core and the shell will also cause a lattice mismatch in the shell layer compared to the bulk material, allowing for compression or stretching of the aggregate structure and resulting in a strain effect, further described in the following section.

Influenced by core–shell nanostructures, the synthesis of core–shell structures can be attributed to two main categories, top-down and bottom-up (Hunt and Roman-Leshkov 2018). Top-down refers to the use of various external controls (micromachining techniques, mechanical stress) to achieve a reduction in the size of the material. Bottom-up refers to using the chemical properties of molecules or atoms to self-assemble to form the corresponding structure. These include chemical, vapor deposition, and colloidal aggregation methods (Wei et al. 2011). Reaction conditions (temperature, reaction duration, precursor concentration) can be used to control the core–shell structure’s size, morphology, and structural features. Bottom-up preparation of core–shell structures exists mainly by one-pot methods (precursors such as metals as well as organic ligands are added together to a specific solvent and synthesized by certain means without separation of intermediates) (Chen et al. 2015), in situ synthesis, self-assembly (precursor molecules or nanoparticles spontaneously form an ordered spatial structure through interactions), and self-templating methods (Gao et al. 2014; Zou et al. 2018).

Due to the substantial impact of the shape and molecular structure of the active site at the core–shell junction in adjusting the activity and selectivity of hydrogen evolution reaction, synergistic catalysis between cores and shells is crucial in hydrogen precipitation. On tungsten sulfide core–shell heterostructure (FWS2) particles, core–shell heterostructures were created with complete tungsten sulfide shells and half-tungsten sulfide shells (Zhang et al. 2020). The heterostructures were found to have an unusually increased electron density at the interface, revealing the number of lone pairs of electrons in the active sulfur site. (Zhou et al. 2021b) developed a ternary metal phosphide using an iron-cobalt Prussian blue analog as the central material and a nickel–cobalt Prussian blue analog as the exterior material. This ternary metal phosphide demonstrated an impressive voltage performance of 1.69 V and an overpotential of just 215 mV when tested at a current density of 10 mA cm−2. A core–shell tripartite metal carbide (max phase) structure was created with a Co/Ni-MAX phase at its center (Li et al. 2023b). The Ta2CoC@Ta2CTx core–shell structure exhibits exceptional hydrogen evolution catalytic activity, surpassing the catalytic activity of most individual MAX phase and MXenes catalysts. The catalyst's outer shell is composed of MXenes, and it displays an overpotential of 239 mV when operating at a current density of 10 mA cm−2.

As the central component of the initial cubic configuration of ferrous phosphide\cobalt phosphide\penta-nickel phosphide-reduced graphene oxide, the MOF–FeCo Prussian blue analog with a porous structure was chosen. This catalyst has a surplus of active sites and good electrical conductivity, requiring a cell voltage of just 1.56 V to produce a current density of 10 mA cm−2. Fe–Co2P@Fe–NC demonstrated the best catalytic performance, which was attributed to the synergistic effect between the core–shells, and the carbon shells' textual stability gave the catalyst's durability. M-Co2P@MNC core–shell structures were constructed using secondary metal (iron, nickel, molybdenum, aluminum, manganese) doping (Lv et al. 2021).

Fusing one-dimensional nickel sulfide nanorods with two-dimensional molybdenum sulfide flakes produces cobalt-doped NiS@MoS2 core–shell nanorods. These nanorods display an overpotential of 139.9 mV when operating at a current density of 50 mA−2 cm. This combination of nickel sulfide nanorods and molybdenum sulfide flakes improves the contact between the catalyst and the electrolyte, leading to an accelerated charge rate similar to other catalysts. This catalyst has long-term endurance and requires a low cell potential of just 1.44 V at a current density of 10 mA−2 cm (Gao et al. 2021). In a separate study, stacked nanosheets of layered double hydroxides were used to encase one-dimensional nanorods of CoNiP, resulting in a highly efficient catalyst. The catalyst exhibited excellent performance, requiring only a low cell potential of 1.44 V (Zhou et al. 2018a).

In conclusion, the presence of the core–shell structure allows a synergistic interaction between the core and shell materials to enhance the catalytic properties of the catalyst. Changing the morphological characteristics of the core–shell structure can further improve the catalytic ability.

Mesoporous structure