Abstract

Photocatalytic membranes reactors have become one of the most efficient technologies to treat polluted waters. However, a major drawback is the unilateral irradiation of the membrane, where only one side of the membrane is exploited. To overcome this issue, we developed a reactor where the membrane can be irradiated on both sides. Polyacrylonitrile membranes containing different amounts of TiO2 nanoparticles up to 60% were first prepared by electrospinning. These membranes were used in a 3D-printed crossflow photocatalytic membrane reactor for the degradation of methylene blue under different combinations of lights. The use of both sides of the photocatalytic membrane significantly enhanced the photocatalytic activity for the decolorization of methylene blue in water. The prepared membranes showed the best decolorization rate for a loading of 60% of TiO2 and the use of dual ultraviolet lights, where the methylene blue solution was completely discolored after 90 min. This is the first report of a such system configuration, and this new irradiation concept is promising for photocatalytic membrane reactions and water cleaning.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Heterogeneous photocatalysis is one of the most promising approaches for organic pollutants treatment and remediation. Making use of a semiconductor material for the photocatalytic oxidation of toxic pollutants has been studied and showed great potential for the degradation of compounds such as pesticides, dyes, chlorinated compounds, phenols or the emergence of nanoplastics (Vaya and Surolia 2020; Allé et al. 2021; Rafiq et al. 2021; Shoneye et al. 2022). Several materials have been investigated as potential semiconductor photocatalysts, including many metal oxides such as TiO2, ZnO, SnO2, Fe2O3 or nitrides/sulfides such as Ta3N5 and CdS (Su et al. 2017; Li et al. 2022; Kaur et al. 2022). Within all these semiconductors, TiO2 is still the most common photocatalyst, due to its relatively high activity, photochemical stability, resistant to pH changes, relatively cheap and commercially available.

Most studies have reported that suspension reactors are more efficient due to the large surface area available and a better mass transfer. However, the main drawback is the requirement for post-treatment separation, recovery processes and recycling of the catalyst, making the system more complex, time consuming and costly. Therefore, treatment using immobilized photocatalyst is now favorable and has gained main attention.

Photocatalytic membrane reactors, which coupled photocatalysts with the membrane separation process, have therefore gained huge interest (Mozia 2010; Argurio et al. 2018; Riaz and Park 2020). Photocatalytic polymer-based membranes have been successfully produced such as polypropylene/TiO2 (Mozia et al. 2008; Molinari et al. 2015), polyvinyl difluoride/TiO2 (Zheng et al. 2021) or polyamide/TiO2 (Lombardi et al. 2011). Electrospinning is an emerging method for the fabrication of membranes with high specific area and porosity (Nasir et al. 2021). Especially, polyacrylonitrile (PAN) may be promising as a template polymer for the immobilization of catalytic materials due to their chemical stability, hydrophobic and flexible nature (Yar et al. 2017). Several authors showed the potential of PAN/TiO2 photocatalytic membranes under both ultraviolet (Yar et al. 2017; Zhu et al. 2019; Blanco et al. 2019) and visible/solar light (Shi et al. 2017; Ademola Bode-Aluko et al. 2021; Zhang et al. 2021).

Though, even if intensive research is currently conducted into solar active photocatalytic systems, the main drawbacks of an everyday utilization of such are (1) the treatment activity depends essentially on the solar irradiance during the daytime and (2) the absence of light during nighttime, where no treatment is carried out. On another side, utilization of only artificial ultraviolet (UV) light lamps is known to consume a large amount of energy and is therefore costly, leaving solar application as an efficient renewable technology for the degradation of pollutants.

The concept studied in this work is meant to alleviate such disadvantages and focus on developing a treatment system which can operate ideally continuously, using solar light when available and UV artificial light when needed, or in combination for enhanced activity. Thus, we developed a simple 3D-printed photocatalytic membrane reactor able to use light on both sides of the membrane. To demonstrate the feasibility of such a system we prepared polyacrylonitrile electrospun membranes containing commercial TiO2 P25 nanoparticles.

Experimental

Materials

TiO2 nanoparticles (P25 from EVONIK), polyacrylonitrile (PAN, average Mw 150,000, MERCK), N, N-dimethylformamide (purity higher that 99.8%, MERCK) and methylene blue (Sigma-Aldrich) were used as received. Detailed characterization methods can be found in supplementary material.

Preparation of electrospun membranes

TiO2 nanoparticles are first dispersed in dimethylformamide for 30 min under high mechanical agitation, followed by 15 min in an ultrasound bath. Polyacrylonitrile is then gradually added and stirred until fully dispersed at room temperature. Polyacrylonitrile concentration is kept constant at 7.5%, while TiO2 concentration varies from 10, 30, 40, 50 to 60% (namely PAN-10 to PAN-60). A reference solution of polyacrylonitrile in dimethylformamide containing no TiO2 nanoparticles is also prepared (namely PAN-0).

Polyacrylonitrile-based nanofibers were electrospun using a NS-LAB Nanospider™ laboratory instrument (Elmarco, Czech Republic). The electrospinning substrate was a non-woven polypropylene (PP) antistatic material (Pegatex S, 30 g/m2). The polymer mixture was charged in a carriage reservoir and delivered to the spinning electrode wire at a speed of 100 mm/s. Electrospun fibers were produced at a voltage of 60 kV, at a fixed distance of 20 cm. The electrospun mat on the PP substrate is then dried under the hood for 2 h, cut into 5 × 5 cm pieces and stored between two plastic sheets to keep the membranes flat.

Photocatalytic membrane tests

The homemade reactor and lamps details are described in supplementary material. The photocatalytic membrane reactor system is illustrated in Fig. 1. A methylene blue solution (10 mg/L) is fed to the reactor using a peristaltic pump (80 mL/min) in complete dark for 2 h for a complete equilibrium of adsorption/desorption. The chosen light is turned on, and a 2 mL sample is withdrawn from the feed bottle at any chosen time. The sample is then analyzed using UV–vis spectrophotometry (Agilent, CARY 5000).

Results and discussion

The aim of this study was first to develop and optimize polyacrylonitrile membrane containing TiO2 nanoparticles and then to observe the influence of light combinations on the photocatalytic activity for the degradation of a common dye, methylene blue.

Membrane characterizations

The electrospun mat produced is relatively thin but mechanically strong enough to be cut into smaller membranes for further utilization inside the photocatalytic reactor. The average thickness of the membranes has been measured between 200 and 300 µm with a precision caliper. The surface morphology evolution of the electrospun membranes with the addition of TiO2 nanoparticles was then investigated by electron microscopy. Figure 2a shows scanning electron microscopy (SEM) pictures of electrospun polyacrylonitrile nanofibers (PAN-0) as well as all polyacrylonitrile membranes containing 10, 30, 40, 50 and 60 wt% of TiO2 P25 nanoparticles (PAN-10 to PAN-60). All samples showed randomly distributed nanofibers forming a non-woven fibrous mat characteristic of electrospun membranes. The surface morphology of PAN-0 electrospun membrane is composed of nanofibers with a relatively uniform distribution and size, with an average fiber diameter between 150 and 400 nm. The polymer surface is smooth but does not always form clean nanofibers and a small number of beads were observed. For samples PAN-10 to PAN-60, SEM images show the deposition of TiO2 nanoparticles on the nanofibers. The more the dispersion is loaded with TiO2, the more the nanofibers are covered by these nanoparticles. Between 10 and 40%, we did not observe a significant fiber thickness difference, but nanofibers decorated with an increased number of nanoparticles and larger agglomerates. For samples PAN-50 and PAN-60, we can observe a fiber thickness increase up to 700 nm. It should be noted that above 60% TiO2 loading, the electrospinning proved to be difficult, and the mechanical properties of the membranes were not stable. The sample was very brittle and could not be used for further testing.

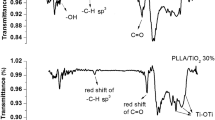

a Scanning electron microscopy picture of a polyacrylonitrile membrane without TiO2 (PAN-0), and membrane containing 10–60% TiO2 loading (PAN-10 to PAN-60) (scale bar 3 µm); b Fourier-transform infrared spectroscopy of a polyacrylonitrile membrane without TiO2 (PAN-0) and with 60% TiO2 loading (PAN-60) and c Thermogravimetric analysis of PAN-0 and PAN-60

Fourier-transform infrared spectroscopy spectra of polyacrylonitrile membranes without TiO2 (PAN-0) and with 60% TiO2 (PAN-60) membranes are shown in Fig. 2b. The characteristic peaks of polyacrylonitrile have been observed especially the stretching vibration peaks of C≡N at 2245, 1624 and 659 cm−1. The other peaks at 2930, 1450, 1369, 1250 and 1232 cm−1 are corresponding to aliphatic C–H vibrations. For the sample PAN-60, a strong wide band at 400–700 cm−1 was observed and corresponds to Ti–O and Ti–O–Ti stretching vibrations of TiO2 nanoparticles present in the electrospun sample.

Thermogravimetric analysis was established to investigate if the electrospinning had been performed homogeneously with conservation of the proportions of TiO2 in the membrane. The comparison of data in Fig. 2c shows a mass change of around 100% for the PAN-0 at temperature higher than 600 °C, as expected and a mass change of around 40% for the PAN-60 membrane. This result shows that 40% of the membrane corresponds to polyacrylonitrile and 60% of the mass remaining was not degraded and corresponds to TiO2. This amount of TiO2 matches the mass introduced into the dispersion and thus confirms that electrospinning was performed homogeneously.

Photocatalytic results

First, direct photolysis (photocatalytic experiment without a membrane) of methylene blue under both UV and solar-simulated light has been carried out. Results showed negligible methylene blue degradation under UV light. Under solar-simulated light, we measured a variation of 11% after 3 h of reaction, which is explained by the photosensitization on methylene blue under visible irradiation (Sáenz-Trevizo et al. 2019).

The influence of the TiO2 content on the photocatalytic activity of the membranes has been investigated. Polyacrylonitrile membranes containing 0, 10, 30, 40, 50 and 60% of TiO2 have therefore been tested under UV and solar-simulated light, separately, and representative results are shown in Fig. 3a and b. (All data curves are in supplementary material Figure S3.) In the absence of TiO2 (PAN-0), under both UV and solar-simulated light, the membrane has no photocatalytic activity. Also, in both irradiation cases, we observed that by increasing the TiO2 loading in the membrane we obtained better photocatalytic activity. The best photocatalytic activity was observed for PAN-60 with a methylene blue decolorization of 95% after 3 h of UV light irradiation and 52% under solar-simulated light. Methylene blue is significantly more discolored under UV exposure than when it is exposed to solar-simulated light. (Fig. 3)

All membranes used for further experiments under dual lights are 60% TiO2 in polyacrylonitrile (PAN-60). The experiments were performed using a homemade crossflow photocatalytic membrane reactor with the particularity of having quartz windows on each side of the reactor. This enables irradiation of the membrane on both sides, either with a similar or a different type of irradiation. In our experiments, we either used UV light, solar-simulated light or more interestingly a combination of these irradiations. Figure 4 shows the photocatalytic activity for PAN-60 under these different irradiations. Results of photocatalytic tests using single irradiation (SOLAR, UV and UV LED) are plotted for comparison. We clearly observed that a combination of irradiation on both sides of the photoreactor has a significant impact on the photocatalytic activity. A combination of solar simulated and UV light (DUAL SOLAR + UV) showed 98% discoloration after 120 min of irradiation. The best activity has been observed for a combination of UV lights (DUAL UV + UV LED), with a complete discoloration of methylene blue after 90 min. In addition, total organic carbon (TOC) analysis has been performed after each photocatalytic test (Fig. 4b). These tests showed that full mineralization is not entirely achieved. Though, we observed a TOC removal much higher when dual lights have been used, proving the superior photocatalytic efficiency of using such a combination of irradiations.

a Photocatalytic activity of polyacrylonitrile membranes containing 60% TiO2 (PAN-60) using a combination of lights (results are normalized as C/C0 where C0 is the initial concentration at t = 0, and C is the concentration at time t), results of photocatalytic tests using single irradiation (SOLAR, UV and UV LED) are plotted for comparison; and b total organic carbon (TOC) removal results after 180 min

Conclusion

In summary, TiO2/polyacrylonitrile nanofiber membranes were successfully prepared by electrospinning and further used in a photocatalytic membrane reactor using single or dual light irradiations. The results of these preliminary tests showed that a combination of light on each side of the membrane significantly enhances the photocatalytic activity, whereas the combination of dual UV lights showed the best photocatalytic activity.

We believe that the utilization of dual lights provides an effective approach to utilize the full potential of a photocatalytic membrane. The main innovation in such a dual irradiation is to get a system which could be photoactive day and night, thus significantly enhancing the photo-assisted degradation of on-stream pollutants. Also, this can genuinely reduce the energetic consumption of such a system and open the way to independent treatment units, i.e., using solar panels, battery-assisted systems

Data availability

Data are available upon request to the corresponding author.

Code availability

Stl files of the 3D-printed parts are available upon request to the corresponding author.

References

Ademola Bode-Aluko C, Pereao O, Kyaw HH et al (2021) Photocatalytic and antifouling properties of electrospun TiO2 polyacrylonitrile composite nanofibers under visible light. Mater Sci Eng B 264:114913. https://doi.org/10.1016/j.mseb.2020.114913

Allé PH, Garcia-Muñoz P, Adouby K et al (2021) Efficient photocatalytic mineralization of polymethylmethacrylate and polystyrene nanoplastics by TiO2/β-SiC alveolar foams. Environ Chem Lett 19:1803–1808. https://doi.org/10.1007/s10311-020-01099-2

Argurio P, Fontananova E, Molinari R, Drioli E (2018) Photocatalytic membranes in photocatalytic membrane reactors. Processes 6:162. https://doi.org/10.3390/pr6090162

Blanco M, Monteserín C, Angulo A et al (2019) TiO2-doped electrospun nanofibrous membrane for photocatalytic water treatment. Polymers 11:747. https://doi.org/10.3390/polym11050747

Kaur A, Bajaj B, Kaushik A et al (2022) A review on template assisted synthesis of multi-functional metal oxide nanostructures: status and prospects. Mater Sci Eng B 286:116005. https://doi.org/10.1016/j.mseb.2022.116005

Li N, Zhang W, Wang D et al (2022) Synthesis and applications of TiO2-based nanostructures as photocatalytic materials. Chem Asian J. https://doi.org/10.1002/asia.202200822

Lombardi M, Palmero P, Sangermano M, Varesano A (2011) Electrospun polyamide-6 membranes containing titanium dioxide as photocatalyst. Polym Int 60:234–239. https://doi.org/10.1002/pi.2932

Molinari R, Lavorato C, Argurio P (2015) Photocatalytic reduction of acetophenone in membrane reactors under UV and visible light using TiO2 and Pd/TiO2 catalysts. Chem Eng J 274:307–316. https://doi.org/10.1016/j.cej.2015.03.120

Mozia S (2010) Photocatalytic membrane reactors (PMRs) in water and wastewater treatment. A review. Sep Purif Technol 73:71–91. https://doi.org/10.1016/j.seppur.2010.03.021

Mozia S, Morawski AW, Toyoda M, Inagaki M (2008) Effectiveness of photodecomposition of an azo dye on a novel anatase-phase TiO2 and two commercial photocatalysts in a photocatalytic membrane reactor (PMR). Sep Purif Technol 63:386–391. https://doi.org/10.1016/j.seppur.2008.05.029

Nasir AM, Awang N, Jaafar J et al (2021) Recent progress on fabrication and application of electrospun nanofibrous photocatalytic membranes for wastewater treatment: a review. J Water Process Eng 40:101878. https://doi.org/10.1016/j.jwpe.2020.101878

Rafiq A, Ikram M, Ali S et al (2021) Photocatalytic degradation of dyes using semiconductor photocatalysts to clean industrial water pollution. J Ind Eng Chem 97:111–128. https://doi.org/10.1016/j.jiec.2021.02.017

Riaz S, Park S-J (2020) An overview of TiO2-based photocatalytic membrane reactors for water and wastewater treatments. J Ind Eng Chem 84:23–41. https://doi.org/10.1016/j.jiec.2019.12.021

Sáenz-Trevizo A, Pizá-Ruiz P, Chávez-Flores D et al (2019) On the discoloration of methylene blue by visible light. J Fluoresc 29:15–25. https://doi.org/10.1007/s10895-018-2304-6

Shi Y, Yang D, Li Y et al (2017) Fabrication of PAN@TiO2/Ag nanofibrous membrane with high visible light response and satisfactory recyclability for dye photocatalytic degradation. Appl Surf Sci 426:622–629. https://doi.org/10.1016/j.apsusc.2017.06.302

Shoneye A, Sen Chang J, Chong MN, Tang J (2022) Recent progress in photocatalytic degradation of chlorinated phenols and reduction of heavy metal ions in water by TiO2-based catalysts. Int Mater Rev 67:47–64. https://doi.org/10.1080/09506608.2021.1891368

Su J, Wei Y, Vayssieres L (2017) Stability and performance of sulfide-, nitride-, and phosphide-based electrodes for photocatalytic solar water splitting. J Phys Chem Lett 8:5228–5238. https://doi.org/10.1021/acs.jpclett.7b00772

Vaya D, Surolia PK (2020) Semiconductor based photocatalytic degradation of pesticides: an overview. Environ Technol Innov 20:101128. https://doi.org/10.1016/j.eti.2020.101128

Yar A, Haspulat B, Üstün T et al (2017) Electrospun TiO2/ZnO/PAN hybrid nanofiber membranes with efficient photocatalytic activity. RSC Adv 7:29806–29814. https://doi.org/10.1039/C7RA03699J

Zhang X, Fu K, Su Z (2021) Fabrication of 3D MoS2-TiO2@PAN electro-spun membrane for efficient and recyclable photocatalytic degradation of organic dyes. Mater Sci Eng B 269:115179. https://doi.org/10.1016/j.mseb.2021.115179

Zheng X, Liu Y, Liu X et al (2021) A novel PVDF-TiO2@g-C3N4 composite electrospun fiber for efficient photocatalytic degradation of tetracycline under visible light irradiation. Ecotoxicol Environ Saf 210:111866. https://doi.org/10.1016/j.ecoenv.2020.111866

Zhu Z, Zhang Y, Zhang Y et al (2019) Preparation of PAN@TiO2 nanofibers for fruit packaging materials with efficient photocatalytic degradation of ethylene. Materials 12:896. https://doi.org/10.3390/ma12060896

Funding

Open access funding provided by SINTEF. The authors gratefully acknowledge the support from the Technology Agency of the Czech Republic and the Research Council of Norway through the project METAMORPH (EEA project TO01000329).

Author information

Authors and Affiliations

Contributions

MG was involved in conceptualization, methodology, investigation, writing—original draft, review and editing, supervision, funding acquisition. EO contributed to methodology and investigation.

Corresponding author

Ethics declarations

Conflicts of interest

The authors have no conflicts of interest to disclose.

Consent for publication

All authors have approved the contents of this paper.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Grandcolas, M., Oudin, E. Enhanced photocatalytic activity of electrospun TiO2/polyacrylonitrile membranes in a crossflow reactor using dual lights. Environ Chem Lett 21, 633–638 (2023). https://doi.org/10.1007/s10311-022-01553-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10311-022-01553-3