Abstract

Acid rock drainage (ARD) was successfully neutralized in this study using carpet tiles. Most polyolefin-based carpet tiles contain over 65% of finely ground calcium carbonate (CaCO3) powder by weight in the compound-blended and extruded backing structure; therefore, using them for neutralization is an innovative way to reuse a difficult-to-recycle complex and abundant product. The overall neutralization efficiency potential was calculated at 40% based on the density, purity, and surface images that display the domains of CaCO3 on the tiles. The carpet backing increased the mean of proton activity of AMD collected from a single acidic stream point within the Pinkerton Run tributary near Pittsburgh, PA from 3.3 to 6.1 over the span of four hours in batch-method experiments at CaCO3 loading levels of 0.1 g/L and overall surface area exposure of 229 mm2/mL. Hot acidity levels decreased from 90 to less than 10 mg CaCO3/L, and below detection limits after 20 h of neutralization. The treated and neutralized AMD sample contained 80 mg/L more calcium than the untreated, non-neutralized control, demonstrating the dissolution of CaCO3 from the carpet tile.

Resumen

En este estudio se utilizaron con éxito losetas de moqueta para neutralizar el drenaje ácido de roca (DAR). La mayoría de las losetas de moqueta a base de poliolefina contienen más de un 65% de polvo de carbonato de calcio (CaCO3) finamente molido en peso en la estructura de soporte extruida y mezclada con compuestos; su utilización para la neutralización es una forma innovadora de reutilizar un producto complejo y abundante y que es difícil de reciclar. El potencial de eficiencia de neutralización global es del 40% en base a su densidad, la pureza y las imágenes de superficie que muestran los dominios de CaCO3 en las losetas. El soporte de la moqueta incrementó la media de la actividad protónica del AMD recogido de un único punto de corriente ácida dentro del afluente Pinkerton Run, cerca de Pittsburgh, PA, de 3,3 a 6,1 en el transcurso de cuatro horas en experimentos por lotes con niveles de carga de CaCO3 de 0,1 g/L y una exposición global del área superficial de 229 mm²/mL. Niveles muy elevados de acidez disminuyeron de 90 mg CaCO3/L a menos de 10 mg CaCO3/L, y por debajo de los límites de detección tras 20 horas de neutralización. La muestra de AMD tratada y neutralizada contenía 80 mg/L más de calcio que el control no tratado y no neutralizado, lo que demuestra la disolución del CaCO3 de la loseta de moqueta.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Acid mine drainage (AMD) from coalfields is the single largest source of water contamination in the state of Pennsylvania (PA), with an estimated 11,838 km of contaminated streams (PA Dept of Environmental Protection 2022). The extensive coalfields in the Appalachian region of the eastern United States were first mined in the late 1700s (National Academies of Sciences et al. 2018) and excavated for 200 years before regulations were enacted to alleviate environmental issues. The acidity generated from oxidation of exposed pyrite can create streams void of aquatic and plant life.

Most aquatic animals cannot survive in acidic environments with a pH < 5 (Office of Research and Monitoring 1973). Larvae and eggs from insects, reptiles, and fish also cannot survive in environments with elevated acidity levels, which influences the food chain and local ecosystem. The additional suspended solids create murky water, inhibiting fish spawning and plant growth (U.S. Environmental Protection Agency 2000). Acidic stream runoff that flows through a region frequently encounters rocks that naturally contain metals such as mercury, lead, copper, aluminum, and zinc. This secondary contamination process leads to additional contamination. Plants and animals in these areas bioaccumulate these contaminants, which spreads regionally up and down the food chain.

The Appalachian region is particularly susceptible to the negative consequences of AMD due to shallow groundwater levels and the widespread presence of pyrite (Tewalt et al. 2000). Elements typically encased within the earth are exposed to the environment during the mining process. Pyrite, or iron sulfide (FeS2), produces sulfuric acid when it encounters water and oxygen.

Several parameters affect the intensity level of the AMD, such as the surrounding area’s rock composition and hydrology. Metal ions, such as Fe2+, Fe3+, Al3+, and Mn2+, can produce acidity as they hydrolyze (Hedin 2006), while naturally occurring minerals found in sedimentary strata, such as limestone and calcite, can add alkalinity (Bunt and Ntwampe 2015).

Several AMD remediation solutions exist to create a net alkaline outcome. Anoxic limestone drains (ALD) use a layer of buried limestone and an impervious liner to intercept subsurface mine water and increase alkalinity (Watzlaf et al. 2000). Successive alkalinity-producing systems (SAPS) are similar to ALDs; they treat acidic water by creating a flow path through a layer of organics to deoxygenate the water and permit sulfate-reduction and limestone dissolution (Kepler and Mccleary 1995). Limestone is also used in alkaline leach beds and open limestone channels to create a long residence time that allows the acidic water to react with the CaCO3 (Larkins 2018).

Carpet is a multi-material product that is a significant component of waste in landfills. Research is needed to create a second use for carpets, thereby extending the product lifecycle. Recycling systems that do not require costly disassembly or other post-use modifications are essential for economic and technically feasible carpet recycling options. This study has explored using waste carpet tiles containing high amounts of CaCO3 as a neutralization substrate for ARD. This novel application of embedded calcium carbonate within carpet tiles can potentially function similarly to current systems using calcium in neutralization treatments and ARD prevention techniques.

Commercial carpet tiles contain a polymeric backing system that contains CaCO3, as an inexpensive filler. Polyolefin-based carpet tile backing systems often contain these fillers at > 65% by weight. For example, a 50 m2 room covered in carpet tiles contains ≈ 75 kg of CaCO3 powder. These fillers increase the product’s weight and create recycling challenges related to multi-material disposal.

Waste carpet tile disposal in landfills is often the result of commercial renovations or demolitions and yields large quantities of single-source waste. An estimated 2.3 billion kg of carpet is discarded annually (U.S. Environmental Protection Agency 2016). Waste carpet comprises over 3% of all materials in domestic landfills, approximately double the amount of waste generated by vehicle tires. Approximately 90% of all discarded carpet waste ends up in U.S. landfills, and ≈ 6%, or over 90 million kg, is burned in cement kilns and municipal incinerators annually (Carpet America Recovery Effort 2015).

Architectural specifications and new legislation regulations have motivated sustainability initiatives that encourage the use of environmentally friendly building materials and an improved circular economy for carpet products (Paben 2021). Healthy and sustainable products are now required for constructing or remodeling government buildings, hospitals, daycare facilities, and office buildings. The flooring industry has experienced a demand for transparency in ingredient disclosure, which has led to an ever-increasing number of building certification expansions. Diverting carpet products from landfills has become essential as more regulations are established and brand owners fulfill their sustainability goals.

Methods

Efficiency Rate

The carpet tiles used in this experiment for neutralization were manufactured using an ExxonMobil propylene elastomer (Vistamaxx™ Performance Polymer) and contained ≈ 70% CaCO3 filler by weight. This study used a common carpet tile with a polyolefin-based backing system (Table 1).

A typical CaCO3-containing carpet, such as Hubercarb® M4 calcium carbonate, was used for the calculations in this study (Huber Corporation 2019). This product has a density of 2.7 g/cm3 (ASTM D153) and consists of 92% CaCO3 purity. Vistamaxx™ Performance Polymer 6502 has a density of 0.865 g/cm3, according to the ExxonMobil product datasheet.

Scanning electron microscope (SEM) images of the carpet tile were obtained at the ExxonMobil Baytown Technology and Engineering Center (BTEC). Images of the substrate’s bottom and the tile’s cross-section were taken. Variable pressure SEM conditions used a backscatter compositional mode of 20 kV, 1000 pA, and 70 Pa N2. These images provide information on a three-dimensional level of the variation and amount of total CaCO3 that can be exposed to ARD.

ENVI Classic 5.6 (32-bit) image processing and analysis software was used to determine approximately how much calcium mineral is exposed on the carpet tile’s surface. Areas were classified by selecting polygon training areas in bright CaCO3 domains and the darker polymeric regions. An unsupervised classification was performed by classifying the filler and polymer regions based on color to determine approximately how much filler was exposed.

It is important to determine the volume percentages of the blend due to the high-density nature of CaCO3 in the polymeric blend compared to the polymer portion. This method will provide a better perspective for determining the degree of CaCO3 on the surface for the reaction rate compared to the blend mixture by weight percentage. The volume percentage of CaCO3 was estimated using the base amount of a 100 g sample at 70% filler by weight (Eqs. 1 and 2).

Volume percentage was estimated using the polymeric portion volume (Eq. 3).

Neutralization Rate

The neutralization reaction is highly dependent on the amount of CaCO3 introduced to the mine water. Carpet tile is produced by extruding the CaCO3 into a sheet and bonding it with latex to create a high-density layer using industrial-scale equipment. Images from the tile surface and a cross-section were taken to estimate the amount of CaCO3 present on the product’s surface.

Samples were obtained at different reaction times to determine if the CaCO3 in the carpet tile backing could function as an acid neutralizer. The Dataset I samples were obtained for initial analysis to investigate our hypothesis: carpet tiles can neutralize AMD. Dataset II was obtained to further challenge the ability to neutralize water with high acidity levels. All samples were obtained at locations near the greater Pittsburgh area (Fig. 1).

Dataset I required sampling from six different streams, resulting in 49 data points with various geochemical characteristics. All samples were collected within the Chartiers watershed in Pittsburgh and had known ARD discharge zones. Data from the Chartiers Greenway project, Water Quality AMD (2009), provided locations for sampling (Chartiers Greenway 2009). The acidic values were medium-to-neutral. Orange flocculates were also collected at the sample point from George’s Run.

Dataset II was aggregated by taking multiple samples on the same day from the Dickson Mine location at Settler’s Cabin Park to reduce geochemical variables. A total of 72 data points were collected to gain statistical insights and establish differences between surface area exposures. A technical report by Hedin Environmental, Assessment of AMD Discharges in the Pinkertons Run Watershed, was referred to for the sample location site (Hedin Environmental 2016).

A handheld high 0.01 accuracy digital pH tester with automatic temperature compensation by Blandstrs digital meter—model X002H44ZT5 was used to gather in-stream data during collection. The 250 mL polypropylene bottles were fully submerged in the ARD water to allow no headspace. Samples were then kept at 40°F to minimize microbial growth.

Pieces of carpet tiles were weighed and cut into varying amounts. Backing weights were calculated based on the overall weights and the ratio of upper-to-backing (Table 1). This weight was then converted into density, ρ, or backing weight per milliliter of ARD sample water for consistency. Density was documented directly in the results for both datasets.

Each pH level reading was recorded after 30 s of slow stirring with the digital meter probe. The cut tile pieces were placed vertically into each jar after the initial reading was obtained. Acidity levels were recorded over time (Table 2). Both datasets used the same batch process, with limited water agitation.

Confirming and Quantifying Acidic Values

All data were collected (121 total data points) and tested using a handheld pH reader; therefore, further methods were used to confirm the accuracy of these findings. A calibrated pH probe at BTEC was used to compare the results of four samples. Hot acidity, a test widely used to determine the true acidity of the acid mine drainage’s complex chemical composition, was used to confirm findings. pH level is not the optimal measurement for acidity when testing ARD. Dissolved acidic metals may lead to “false-neutral” readings on pH probes due to their potential for creating acidity (Means 2021).

The Hot Acidity Standard 2310 method was used by a third-party lab, Eurofins Xenco, for these reasons. This standard method, described in the 18th Edition of Standard Methods for the Examination of Water and Wastewater, uses titration to determine potentiometric acidity. Two specimens were submitted: an untreated control and a sufficiently neutralized sample. Results were presented in acidity levels of mg CaCO3 per liter of ARD water.

Inductively coupled plasma (ICP) testing was completed to gain more information on the geochemical components of the treated and untreated mine water. This test was performed at BTEC using a PerkinElmer optical emission spectrometer—Optima 8300, with detection limits of < 0.2 ppm.

A prediction method to calculate an estimated acidity was conducted using the method described by Hedin Environmental in The Use of Measured and Calculated Acidity Values to Improve the Quality of Mine drainage Datasets (2006). Results from the ICP were used to gather elemental data, as described above. This calculation (Eq. 4) considers the pH level and modifies it appropriately to include acidity produced by common metals.

Results and Discussion

Efficiency Rates

Specific types of plastic processing can lead to polymeric “skins” that form on the outside of a filled product that contains less filler. This process would skew the amount of CaCO3 on the surface vs. the interior; therefore, visual images of the tile’s bottom surface and a cross-sectional image were captured using SEM. Results from the statistical analysis of the classified images indicate that the surface and cross-sectional areas offer approximately 39% of filler exposure (Fig. 2). These values validate the weight and density calculations from Eqs. 1 through 3. There are slight discrepancies due to the samples’ terrain, resulting in slightly lower values than the actual material. Shadows that inherently exist in the terrain of the CaCO3 domains were difficult to classify as non-polymeric and would increase calcium exposure; however, the SEM results confirmed that the calculated 43% CaCO3 is an accurate value for future reaction calculations and can be used to further determine an approximate value for overall filler exposure on the surface. These results also validate that there is little to no difference between the exposure percentages of CaCO3 on the substrate surface compared to the cross-sectional interior.

The efficiency was determined by taking the surface area exposure percentage (43%) and multiplying it by the purity of the CaCO3, based on supplier specifications in the methods section (92%) (Eq. 5).

CaCO3 can effectively neutralize acidic water with an efficiency of ≈ 40%. Therefore, there is a limitation in reaction rates compared to current neutralization approaches that use unembedded limestone.

Reaction Rate

Dataset I

Dataset I confirmed the proof of concept, with near-neutral ARD-affected streams that had pH levels ranging from 6.0 to 7.5. These streams were all classified as “yellow boy” waterways due to their orange appearance caused by a high degree of iron precipitation. ICP results from the high-turbidity orange flocculate sample collected from George’s Run established that the iron level was 5,680 g/mL.

All nine samples were neutralized using the carpet tile treatments. The amount of CaCO3 required for neutralization was minimal due to the natural near-neutral characteristics of this water. The quantity of carpet tile neutralizer that was used in this study ranged from 0.08 to 0.23 g/mL.

The results from the George’s Run samples, listed in Table 2, exhibit a similar overall trend to the complete dataset. This highly focused dataset illustrates the neutralization trends with less variability due to the multiple geochemical compositions. Table 2 reveals that the inflection point of a pH of 7 was reached after two hours using higher amounts of neutralizer but was extended with the sample that used 0.08 g/mL of the neutralizing agent.

Dataset II

The objective of Dataset II was to further investigate the findings by: using a more acidic stream; exploring different quantities and the surface area exposure of the CaCO3 on the tiles; and verifying the acidity levels using multiple methods. Samples were obtained in very close proximity to the mine's discharge, where the water was highly acidic (pH 3) with very little turbidity and metal precipitates (Hedin Environmental 2016). Aluminum hydroxide precipitate was observed a few hundred feet downstream from the sampling point, later confirmed using ICP (Table 3). All samples were obtained at the same points using the same sampling procedure employed for Dataset I aggregation to gauge repeatability and limit the geochemical differences between streams.

Multiple testing procedures were used to demonstrate and confirm the acidity values for this dataset. The same testing procedure used for Dataset I was repeated. Data points for the pH levels were captured based on residence time for each sample. The graph in Fig. 3 illustrates the results from these pH data points with respect to time.

The carpet tiles’ ability to successfully neutralize highly acidic streams was confirmed. The pH levels were raised from an average initial 3.3–4.1 after two hours of treatment. Using ≈ 0.1 g/mL of total carpet tile backing raised the water to a pH of 6.0, in four hours. Samples with higher CaCO3 volumes or more exposed surface area neutralized the water faster. The residence time for ARD using a 15–30 cm limestone bed in a conventional passive wetlands system was 40 h for water with a pH less than five and 20 h for near-neutral ARD (Metesh et al. 1998). The solution’s efficiency was less than pure limestone; however, the results indicated that neutralization occurred at a rate that is appropriate for use in a remediation system with a sufficient volume of carpet tile backing.

The relationship between CaCO3 exposure and neutralization capability was further explored (Fig. 4). The total surface area of the neutralization tiles placed in each jar, which included the cross-sectional and surface areas, was calculated. The Fig. 4 graph demonstrates an obvious correlation between the degree of neutralization over two hours of exposure and the total amount of carpet tile surface exposure. Surface area was an approximate calculation based on CaCO3 calculations, SEM images, and the sample’s preparation method to gain insight into additional CaCO3 exposure. The total volume of backing placed in the batch is also illustrated in Fig. 4.

The ability to perform this experiment using a laboratory test with an open flow channel was not an option due to the 2020 COVID-19 pandemic; however, batch-style results are common in initial neutralization experiments to determine the functionality of CaCO3. An example of this method is described in the research performed by Sheoran et al. (2012).

Confirming and Quantifying Acidity Values Using the Hot Acidity 2310B Standard

A total of 19 control samples containing non-treated ARD from the Dickson mine were tested using the handheld digital pH reader, yielding an average pH of 3.4. The calibrated pH probe from BTEC confirmed this value. The results from samples one through three established that the digital handheld pH probe produced accurate pH results (Table 3).

Hot Acidity Standard 2310 tests on the control sample and sample three generated the expected corresponding findings. The results indicated that the untreated control sample contained 92 mg/L of CaCO3, while the neutralized sample contained less than 10 mg/L of CaCO3, below the detection limit. These results suggest that it requires 92 mg/L of pure CaCO3 per liter of ARD water to neutralize all acid-producing elements, according to the Hot Acidity Standard 2310, which equals ≈ 230 mg of pure carpet tile backing. Only one control and one neutralized sample were analyzed using the hot acidity test method due to project time and budget constraints.

Acidity was calculated based on Eq. 4 and ICP analysis to gather preliminary data before external hot acidity laboratory testing (Table 3). Iron, aluminum, and manganese were present in the samples, contributing to acidity. These preliminary estimates revealed a calculated acidity prediction of 74 mg/L of CaCO3. This discrepancy in calculated results compared to results from the field-proven hot acidity titration method was likely due to sample collection, number of samples tested, and the differences in naturally occurring elements present in the samples. The calculated acidity determined that the sample required a reasonable amount of CaCO3 to sufficiently neutralize the control sample.

Sample three contained 80 mg/L of calcium, more than the untreated control sample. These ICP results suggest that there was a dissolution of calcium in each sample that contained carpet tile backing. These results confirmed a positive correlation between overall alkalinity and the amount of total neutralizer and surface area exposure in each sample.

Additional Considerations

There are some concerns with using carpet tiles to remediate ARD streams, which can be alleviated and controlled with an understanding of the product lifecycle. Fibers may be preserved with stain-resistant treatment chemicals, such as PFAS, and contain other chemicals or substances that were absorbed over the carpet tile’s lifetime, which can lead to additional water contamination. Carpet tile backing materials are comprised of many different materials, including PVC and bitumen, which would likely influence pH; therefore, it is extremely important that this method uses only polyolefin-based backed carpet tiles until additional studies are performed. Carpet tiles containing additional materials and chemicals would shift or offset environmental contamination impacts and potentially compound detrimental effects; therefore, it is extremely important to identify the entire product lifecycle, emphasizing the use phase.

These tiles could be used unmodified for economic reasons or as a shredded product to benefit from higher CaCO3 exposure rates, subject to site requirements. An additional waste post-processing step may include separating the backing from the upper fibers. The higher-value nylons could be recycled into a separate reclamation waste stream designed to handle potential fiber treatments, reducing unintentional microplastic contamination.

A comprehensive lifecycle assessment (LCA) should be conducted to compare current and proposed systems and generate an environmental profile for using carpet tiles to neutralize AMD. An LCA would ensure that the differences would not only shift the overall environmental impact, but also identify areas for improvement in product design and collection or transport. Overall footprint data would also be generated to ensure project progress.

Further research into actual in-field applications should be conducted to explore the most feasible solution, including economic and feasibility studies, to establish which part of the system could use this neutralization tool most effectively. Additional assessments should be completed on reaction rates through flow channels based on target application methods, followed by pilot experiments using ARD-affected streams.

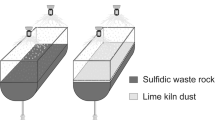

Potential opportunities for applications exist in mine construction, closure, and post-mining remediation. Strategically placing carpet tiles as neutralizers during the backfill resetting process in mine construction presents an opportunity. Active and passive techniques that currently use calcium-based neutralizers to remediate ARD could hypothetically use this waste-to-value product. Examples of potential opportunities for utilization include (limestone) layers in wetlands, limestone drains, ponds, or channels in order to add alkalinity, and remove Fe or Mn.

Conclusion

The hypothesis that there is enough CaCO3 in carpet tiles to successfully neutralize AMD was confirmed. Experimental data established that the volume and surface exposure of the carpet tile backing used for ARD water treatments greatly affects the reaction rate for potential neutralization. The overall efficiency of the treatment potential was evaluated based on the density, purity, and surface images that revealed the domains of CaCO3 present in the tiles. Carpet tile backing functioned well as a neutralizer by increasing the ARD water pH. Successful ARD neutralization using carpet waste creates innovative second-life uses for the multi-layer polymeric floor coverings, allowing for the reuse of discarded construction materials and the development of solutions for two environmental challenges.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article [and/or] its supplementary materials.

References

Bunt J, Ntwampe I (2015) Chemical reactivity between CaCO3 and Ca(OH)2 in acid mine drainage (AMD) with mixing and shaking techniques during the destabilization-hydrolysis of the AMD. J Chem Eng Mater Sci 6:34–51. https://doi.org/10.5897/JCEMS2015.0217

Carpet America Recovery Effort (2015) CARE 2015 Annual Report

Carpet Tile Compound Study SEM, ExxonMobil Baytown Technology and Engineering Center, BCT201507.0029-40 (2017)

Chartiers Greenway (2009) Water Quality—AMD. http://www.chartiersgreenway.net/water.htm. Accessed 13 Feb 2022

Hedin Environmental (2016) Assessment of AMD Discharges in the Pinkertons Run Watershed (Settler’s Cabin Park)

Hedin RS (2006) The use of measured and calculated acidity values to improve the quality of mine drainage datasets. Mine Water Environ 25:146–152. https://doi.org/10.1007/S10230-006-0126-2

J.M. Huber Corporation (2019) Hubercarb® M4 Calcium Carbonate. Accessed 3 Mar 2022

Kepler DA, Mccleary EC (1995) Successive alkalinity-producing systems (SAPS). West Virginia Surface Mine Drainage Task Force Symp. https://wvmdtaskforce.files.wordpress.com/2015/12/95-kepler.pdf. Accessed 7 Sept 2021

Larkins C (2018) Limestone and steel slag leach beds—mine closure. Geological Survey of Finland GTK. https://mineclosure.gtk.fi/limestone-and-steel-slag-leach-beds/. Accessed 26 Jun 2022

Means B (2021) AML/AMD interests, Office of Surface Mining, Reclamation and Enforcement

Metesh JJ, Jarrell T, Oravetz S (1998) Treating Acid Mine Drainage From Abandoned Mines in Remote Areas. USDA Forest Service Technology and Development Program

National Academies of Sciences, Engineering, and Medicine (2018) Coal Mining in the United States. Monitoring and Sampling Approaches to Assess Underground Coal Mine Dust Exposures. https://doi.org/10.17226/25111

Office of Research and Monitoring (1973) Fish and Food Organisms in Acid Mine Waters of Pennsylvania. EPA - Ecological Research Series R3-73–032:

PA Dept of Environmental Protection (2022) Leading Sources of Stream Impairment. https://storymaps.arcgis.com/stories/b9746eec807f48d99decd3a583eede12. Accessed 28 July 2022

Paben J (2021) EPR proposals for carpet land in four states. In: Resource Recycling. https://resource-recycling.com/plastics/2021/03/03/epr-proposals-for-carpet-land-in-four-states. Accessed 13 Feb 2022

Sheoran AS, Choudhary RP, Sheoran V (2012) Treatment for Acid Mine Drainage Utilizing Dimension Stone Waste. J Environ Sci Technol 119–127

Tewalt SJ, Ruppert LF, Brezinski DK, Wallack RN (2000) A digital resource model of the Upper Pennsylvanian Pittsburgh coal bed. 2000 Resource Assessment of Selected Coal Beds and Zones in the Northern and Central Appalachian Basin Coal Regions. USGS, U.S. Dept of the Interior,

U.S. Environmental Protection Agency (2000) Abandoned Mine Site Characterization and Cleanup Handbook. EPA 910-B-00-001, Washington D.C.

U.S. EPA (2016) Wastes—Resource Conservation—Conservation Tools. Carpet Product Stewardship. U.S. Environmental Protection Agency https://archive.epa.gov/wastes/conserve/tools/stewardship/web/html/carpet.html. Accessed 21 Jan 2022

Watzlaf GR, Schroeder KT, Kairies CL (2000) Long-term performance of anoxic limestone drains. Mine Water Environ 19:98–100

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bram, L., Klemetsrud, B. Calcium Carbonate in Waste Flooring for Neutralization of Acid Rock Drainage. Mine Water Environ 42, 70–77 (2023). https://doi.org/10.1007/s10230-023-00926-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10230-023-00926-6