Abstract

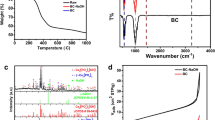

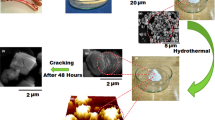

Biodiesel is widely known as a renewable energy that can be directly used as an alternative diesel fuel. This paper emphasizes on the synthesis and characterization of lithium modified calcium oxide (CaO) derived from eggshell and cow bone waste materials. The synthesized catalysts were tested in term of their performance in biodiesel production from dairy waste scum oil (DWSO). The CaO was derived from eggshell and cow bone by calcination at 800 °C and then a mixture of CaO from eggshell and cowbone was combined with lithium via wet impregnation which resulted to four catalysts labeled as eggshell (ES), cow bone (CB), eggshell and cow bone (ESCB) and Lithium modified eggshell and cowbone (Li-ESCB). All catalysts were characterized by Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), Brunauer–Emmett–Teller (BET), Field Emission Scanning electron microscopy (FESEM) with energy dispersive X-ray (EDX) and Thermogravimetric Analysis (TGA) to interpret their morphologic, structural and chemical properties. The Li-ESCB showed better properties than ESCB, especially in BET analysis, where the surface area was 2.59 m2/g. Only in XRD analysis can it show the presence of lithium as it is very low in concentration (1 wt %), whereas EDX analysis cannot be detected. The biodiesel production were performed via microwave assisted transesterification and ES catalyst showed the highest biodiesel production (82%). Even though Li-ESCB appeared as the best properties, the biodiesel was still low due to the inhibition of phosphorus from CB. The utilization of waste materials can contribute to sustainability development, environmentally friendly and cost-effective method.

Similar content being viewed by others

References

Tan YH, Abdullah MO, Kansedo J, Mubarak NM, Chan YS, Nolasco-Hipolito C (2019) Biodiesel production from used cooking oil using green solid catalyst derived from calcined fusion waste chicken and fish bones. Renew Energy 139(696):706. https://doi.org/10.1016/j.renene.2019.02.110

Roschat W, Siritanon T, Yoosuk B, Promarak V (2016) Biodiesel production from palm oil using hydrated lime-derived CaO as a low-cost basic heterogeneous catalyst. Energy Convers Manage 108:459–467. https://doi.org/10.1016/j.enconman.2015.11.036

Srikanth HV, Venkatesh J, Godiganur S, Manne B (2019) Acetone and diethyl ether : improve cold fl ow properties of dairy washed milkscum biodiesel. Renew Energy 130:446–451. https://doi.org/10.1016/j.renene.2018.06.051

Samniang A, Tipachan C, Kajorncheappun-ngam S (2014) Comparison of biodiesel production from crude Jatropha oil and Krating oil by supercritical methanol transesterification. Renew Energy 68:351–355. https://doi.org/10.1016/j.renene.2014.01.039

Kaur M, Ali A (2011) Lithium ion impregnated calcium oxide as nano catalyst for the biodiesel production from karanja and jatropha oils. Renew Energy 36(11):2866–2871. https://doi.org/10.1016/j.renene.2011.04.014

Kavitha V, Geetha V, Jacqueline PJ (2019) Production of biodiesel from dairy waste scum using eggshell waste. Process Saf Environ Prot 125:279–287. https://doi.org/10.1016/j.psep.2019.03.021

Sai BAVSL, Subramaniapillai N, Mohamed K, Sheriffa M, Narayanan A (2020) Optimization of continuous biodiesel production from rubber seed oil ( RSO ) using calcined eggshells as heterogeneous catalyst. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2019.103603

Corro G, Sánchez N, Pal U, Bañuelos F (2016) Biodiesel production from waste frying oil using waste animal bone and solar heat. Waste Manage 47:105–113. https://doi.org/10.1016/j.wasman.2015.02.001

Suwannasom P, Tansupo P, Ruangviriyachai C (2016) A bone-based catalyst for biodiesel production from waste cooking oil, Energy Sources. Recover Util Environ Eff 38(21):3167–3173. https://doi.org/10.1080/15567036.2015.1137998

Khatibi M, Khorasheh F, Larimi A (2021) Biodiesel production via transesterification of canola oil in the presence of Na–K doped CaO derived from calcined eggshell. Renew Energy 163:1626–1636. https://doi.org/10.1016/j.renene.2020.10.039

Hsiao MC, Kuo JY, Hsieh SA, Hsieh PH, Hou SS (2020) Optimized conversion of waste cooking oil to biodiesel using modified calcium oxide as catalyst via a microwave heating system. Fuel. https://doi.org/10.1016/j.fuel.2020.117114

Alimova I (2016) Production of Biodiesel through Esterification Catalysed by Ionic Liquids Trabalho realizado sob a orientação de. Instituto Politecnio De Braganca, Portugal

S. Konar, (2012) High Pressure and High Temperature Study on Lithium carbide (Li2C2 ) and Calcium carbide (CaC2 ): An attempt to make a novel polyanionic form of Carbon Arizona state university.

Nair P, Singh B, Upadhyay SN, Sharma YC (2012) Synthesis of biodiesel from low FFA waste frying oil using calcium oxide derived from Mereterix mereterix as a heterogeneous catalyst. J Clean Prod 29–30:82–90. https://doi.org/10.1016/j.jclepro.2012.01.039

Zhang J, Chen S, Yang R, Yan Y (2010) Biodiesel production from vegetable oil using heterogenous acid and alkali catalyst. Fuel 89(10):2939–2944. https://doi.org/10.1016/j.fuel.2010.05.009

Granados ML et al (2007) Biodiesel from sunflower oil by using activated calcium oxide. Appl Catal B Environ 73(3):317–326. https://doi.org/10.1016/j.apcatb.2006.12.017

J. Lamsihar Manalu, B. Soegijono, and D. J. 2015 Indrani Characterization of Hydroxyapatite Derived from Bovine Bone Asian J Appl. Sci., 2321 0893 [Online] www.ajouronline.com.

Correia LM, Cecilia JA, Rodríguez-Castellón E, Cavalcante CL, Vieira RS (2017) Relevance of the physicochemical properties of calcined quail eggshell (CaO) as a catalyst for biodiesel production. J Chem. https://doi.org/10.1155/2017/5679512

Kesić Ž et al (2012) Mechanochemical preparation and characterization of CaO·ZnO used as catalyst for biodiesel synthesis. Appl Catal A Gen 427–428:58–65. https://doi.org/10.1016/j.apcata.2012.03.032

Liu T, Zhu Y, Zhang X, Zhang T, Zhang T, Li X (2010) Synthesis and characterization of calcium hydroxide nanoparticles by hydrogen plasma-metal reaction method. Mater Lett 64(23):2575–2577. https://doi.org/10.1016/j.matlet.2010.08.050

Chingakham C, Tiwary C, Sajith V (2019) Waste animal bone as a novel layered heterogeneous catalyst for the transesterification of biodiesel. Catal Lett 149(4):1100–1110. https://doi.org/10.1007/s10562-019-02696-9

Mondal S et al (2012) Synthesis, characterization and in vitro cytotoxicity assessment of hydroxyapatite from different bioresources for tissue engineering application. Bull Mater Sci 35(4):683–691. https://doi.org/10.1007/s12034-012-0346-y

Boro J, Konwar LJ, Deka D (2014) Transesterification of non edible feedstock with lithium incorporated egg shell derived CaO for biodiesel production. Fuel Process Technol 122:72–78. https://doi.org/10.1016/j.fuproc.2014.01.022

Bhuvaneswari MS, Selvasekarapandian S, Kamishima O, Kawamura J, Hattori T (2005) Vibrational analysis of lithium nickel vanadate. J Power Sources 139(1–2):279–283. https://doi.org/10.1016/j.jpowsour.2004.07.006

Krishnamurthy KN, Sridhara SN, Ananda Kumar CS (2020) Optimization and kinetic study of biodiesel production from Hydnocarpus wightiana oil and dairy waste scum using snail shell CaO nano catalyst. Renew Energy. https://doi.org/10.1016/j.renene.2019.06.161

Habte L, Shiferaw N, Mulatu D, Thenepalli T, Chilakala R, Whan Ahn J (2019) Synthesis of nano-calcium oxide from waste eggshell by sol-gel method. Sustainability. https://doi.org/10.3390/su11113196

Akindoyo JO, Beg MDH, Ghazali S, Akindoyo EO, Jeyaratnam N (2017) Synthesis of hydroxyapatite through ultrasound and calcination techniques IOP Conf. Mater. Sci. Eng, Ser. https://doi.org/10.1088/1757-899X/203/1/012003

Niakan A, Ramesh S, Tan CY, Purbolaksono J, Chandran H, Teng WD (2015) Effect of annealing treatment on the characteristics of bovine bone. J Ceram Process Res 16(2):223–226. https://doi.org/10.36410/jcpr.2015.16.2.223

Nisar J et al (2017) Enhanced biodiesel production from Jatropha oil using calcined waste animal bones as catalyst. Renew Energy 101:111–119. https://doi.org/10.1016/j.renene.2016.08.048

Kumar D, Ali A (2010) Nanocrystalline lithium ion impregnated calcium oxide as heterogeneous catalyst for transesterification of high moisture containing cotton seed oil. Energy Fuels 24(3):2091–2097. https://doi.org/10.1021/ef901318s

Kröger V et al (2007) Effect of phosphorus poisoning on catalytic activity of diesel exhaust gas catalyst components containing oxide and Pt. Top Catal 42–43(1–4):409–413. https://doi.org/10.1007/s11244-007-0215-x

Nabgan W et al (2022) Synthesis and catalytic properties of calcium oxide obtained from organic ash over a titanium nanocatalyst for biodiesel production from dairy scum. Chemosphere. https://doi.org/10.1016/j.chemosphere.2021.133296

Mengistu TG, Reshad AS (2022) Synthesis and characterization of a heterogeneous catalyst from a mixture of waste animal teeth and bone for castor seed oil biodiesel production. Heliyon 8(6):e09724. https://doi.org/10.1016/j.heliyon.2022.e09724

AlSharifi M, Znad H (2019) Development of a lithium based chicken bone (Li-Cb) composite as an efficient catalyst for biodiesel production. Renew Energy 136:856–864. https://doi.org/10.1016/j.renene.2019.01.052

Nazir MH et al (2021) Development of lignin based heterogeneous solid acid catalyst derived from sugarcane bagasse for microwave assisted-transesterification of waste cooking oil. Biomass Bioenergy. https://doi.org/10.1016/j.biombioe.2021.105978

Miao J, Yi X, Su Q, Li H, Chen J, Wang J (2020) Poisoning effects of phosphorus potassium and lead on V2O5-WO3/TiO2 catalysts for selective catalytic reduction with NH3. Catalysts. https://doi.org/10.3390/catal10030345

Thangaraj B, Solomon PR, Muniyandi B, Ranganathan S, Lin L (2019) Catalysis in biodiesel production—a review. Clean Energy 3(1):2–23. https://doi.org/10.1093/ce/zky020

Rizwanul Fattah IM et al (2020) State of the art of catalysts for biodiesel production. Front Energy Res. https://doi.org/10.3389/fenrg.2020.00101

Acknowledgements

We thank and appreciate the Center for Biofuel and Biochemical Research (CBBR), Universiti Teknologi PETRONAS, Higher Institution Centre of Excellence (HiCoE) grant Malaysia, (015MA0-104), Yayasan Universiti Teknologi Petronas (YUTP-FRG) grant (015LC0-331) and International Collaborative Research Fund (015ME0-271) for the support and funding the research on biodiesel production from dairy waste scum.

Funding

Higher Institution Centre of Excellence (HiCoE),015MA0-104,Muhammad Ayoub,Yayasan Universiti Teknologi Petronas (YUTP-FRG),015LC0-331,Muhammad Ayoub,International Collaborative Research Fund,015ME0-271,Muhammad Ayoub

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mohd Johari, S., Ayoub, M., Rashidi, N.A. et al. Syntheses and characterization of lithium modified cao from eggshell and cow bone and its performance in biodiesel production from dairy waste scum oil (DWSO). J Mater Cycles Waste Manag 26, 1394–1402 (2024). https://doi.org/10.1007/s10163-024-01903-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-024-01903-z