Abstract

Polythene bags waste valorization has become a consequential environmental issue throughout the world. Single used polythene bags cause a significant problem in the management of this waste because of its arduous degradation process. In this study, single used polythene bags waste was used as a fine aggregate substitute (0, 5, 10, 15 and 20%) in order to evaluate the effect of compaction technique (pre-compression and vibration) during the development of the single used polythene bag waste concrete paver blocks. In the hardened state compressive strength, flexure strength, abrasion resistance, ultrasonic pulse velocity, water permeability, and impact resistance were studied to find the performance of the single used polythene bag waste concrete paver blocks. The test results showed the lower mechanical property (compressive and flexure strength), ultrasonic pulse velocity and water permeability for a single used polythene bag waste concrete paver blocks than the normal concrete paver block without shredded plastic waste. However, single used polythene bag waste concrete paver blocks showed better abrasion resistance and impact resistance. In comparison, the pre-compressed concrete paver blocks showed good performance than the vibrated concrete paver blocks. Therefore, the pre-compression compaction method is recommended for the polythene bags waste paver block development and single used polythene bags' waste content should be limited to 5% to substitute the fine aggregate.

Similar content being viewed by others

References

Jain A, Siddique S, Gupta T et al (2021) Evaluation of concrete containing waste plastic shredded fibers: ductility properties. Struct Concr 22(1):566–575. https://doi.org/10.1002/suco.201900512

Browning S, Beymer-Farris B, Seay JR (2021) Addressing the challenges associated with plastic waste disposal and management in developing countries. Curr Opin Chem Eng 32:100682

Saxena R, Siddique S, Gupta T et al (2018) Impact resistance and energy absorption capacity of concrete containing plastic waste. Constr Build Mater 176:415–421. https://doi.org/10.1016/j.conbuildmat.2018.05.019

Meert J, Izzo A, Atkinson JD (2021) Impact of plastic bag bans on retail return polyethylene film recycling contamination rates and speciation. Waste Manag 135:234–242. https://doi.org/10.1016/j.wasman.2021.08.043

Ayalon O, Goldrath T, Rosenthal G, Grossman M (2009) Reduction of plastic carrier bag use: an analysis of alternatives in Israel. Waste Manag 29(7):2025–2032. https://doi.org/10.1016/j.wasman.2009.02.016

Sharma HB, Vanapalli KR, Cheela VS et al (2020) Challenges, opportunities, and innovations for effective solid waste management during and post COVID-19 pandemic. Resour Conserv Recycl 162:105052. https://doi.org/10.1016/j.resconrec.2020.105052

Agrawal Y, Gupta T, Siddique S, Sharma RK (2021) Potential of dolomite industrial waste as construction material : a review. Innov Infrastruct Solut 6(4):1–15. https://doi.org/10.1007/s41062-021-00570-5

Agrawal Y, Gupta T, Sharma RK (2021) Strength and durability assessment of concrete containing dolomite quarry waste as fine aggregate. J Mater Cycles Waste Manag 24(1):268–286. https://doi.org/10.1007/s10163-021-01318-0

Agrawal Y, Siddique S, Sharma RK, Gupta T (2021) Valorization of granite production dust in development of rich and lean cement mortar. J Mater Cycles Waste Manag 23(2):686–698. https://doi.org/10.1007/s10163-020-01158-4

Agrawal Y, Gupta T, Sharma R et al (2021) A comprehensive review on the performance of structural lightweight aggregate concrete for sustainable construction. Constr Mater 1(1):39–62. https://doi.org/10.3390/constrmater1010003

Gupta T, Siddique S, Sharma RK, Chaudhary S (2019) Behaviour of waste rubber powder and hybrid rubber concrete in aggressive environment. Constr Build Mater 217:283–291. https://doi.org/10.1016/j.conbuildmat.2019.05.080

Gupta T, Chaudhary S, Sharma RK (2014) Assessment of mechanical and durability properties of concrete containing waste rubber tire as fine aggregate. Constr Build Mater 73:562–574. https://doi.org/10.1016/j.conbuildmat.2014.09.102

Ismail ZZ, AL-Hashmi EA (2008) Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag 28(11):2041–2047. https://doi.org/10.1016/j.wasman.2007.08.023

Panyakapo P, Panyakapo M (2008) Reuse of thermosetting plastic waste for lightweight concrete. Waste Manag 28(9):1581–1588. https://doi.org/10.1016/j.wasman.2007.08.006

Usman M, Javaid A, Panchal S (2015) Feasibility of waste polythene bags in concrete. Int J Eng Trends Technol 23(6):317–1319. https://doi.org/10.14445/22315381/ijett-v23p259

Kumar A, Srivastava V, Kumar R (2014) Effect of waste polythene on compressive strength of concrete. J Acad Ind Res 3(3):152

Marzouk OY, Dheilly RM, Queneudec M (2007) Valorization of post-consumer waste plastic in cementitious concrete composites. Waste Manag 27(2):310–318. https://doi.org/10.1016/j.wasman.2006.03.012

Panda AK, Singh RK, Mishra DK (2010) Thermolysis of waste plastics to liquid fuel. A suitable method for plastic waste management and manufacture of value added products—a world prospective. Renew Sustain Energy Rev 14(1):233–248.

Ghernouti Y, Rabehi B, Safi B, Chaid R (2009) Use of recycled plastic bag waste in concrete. J Int Sci Publ Mater Methods Technol 8:480–487

Batayneh M, Marie I, Asi I (2007) Use of selected waste materials in concrete mixes. Waste Manag 27(12):1870–1876. https://doi.org/10.1016/j.wasman.2006.07.026

Albano C, Camacho N, Hernández M et al (2009) Influence of content and particle size of waste pet bottles on concrete behavior at different w/c ratios. Waste Manag 29(10):2707–2716. https://doi.org/10.1016/j.wasman.2009.05.007

Akinyele JO, Ajede A (2018) The use of granulated plastic waste in structural concrete. African J Sci Technol Innov Dev 10(2):169–175. https://doi.org/10.1080/20421338.2017.1414111

Saikia N, De Brito J (2014) Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle waste as a partial substitution of natural aggregate. Constr Build Mater 52:236–244. https://doi.org/10.1016/j.conbuildmat.2013.11.049

Juki MI, Awang M, Annas MMK et al (2013) Relationship between compressive, splitting tensile and flexural strength of concrete containing granulated waste polyethylene terephthalate (PET) bottles as fine aggregate. Adv Mater Res 795:356–359

Choi YW, Moon DJ, Chung JS, Cho SK (2005) Effects of waste PET bottles aggregate on the properties of concrete. Cem Concr Res 35(4):776–781. https://doi.org/10.1016/j.cemconres.2004.05.014

Galvão JCA, Portella KF, Joukoski A et al (2011) Use of waste polymers in concrete for repair of dam hydraulic surfaces. Constr Build Mater 25(2):1049–1055. https://doi.org/10.1016/j.conbuildmat.2010.06.073

Kou SC, Lee G, Poon CS, Lai WL (2009) Properties of lightweight aggregate concrete prepared with PVC granules derived from scraped PVC pipes. Waste Manag 29(2):621–628. https://doi.org/10.1016/j.wasman.2008.06.014

Safi B, Saidi M, Aboutaleb D, Maallem M (2013) The use of plastic waste as fine aggregate in the self-compacting mortars: effect on physical and mechanical properties. Constr Build Mater 43:436–442. https://doi.org/10.1016/j.conbuildmat.2013.02.049

Mohammed AA, Mohammed II, Mohammed SA (2019) Some properties of concrete with plastic aggregate derived from shredded PVC sheets. Constr Build Mater 201:232–245. https://doi.org/10.1016/j.conbuildmat.2018.12.145

Akçaözoǧlu S, Atiş CD, Akçaözoǧlu K (2010) An investigation on the use of shredded waste PET bottles as aggregate in lightweight concrete. Waste Manag 30(2):285–290. https://doi.org/10.1016/j.wasman.2009.09.033

Hannawi K, Kamali-Bernard S, Prince W (2010) Physical and mechanical properties of mortars containing PET and P waste aggregates. Waste Manag 30(11):2312–2320. https://doi.org/10.1016/j.wasman.2010.03.028

Silva RV, De Brito J, Saikia N (2013) Influence of curing conditions on the durability-related performance of concrete made with selected plastic waste aggregates. Cem Concr Compos 35(1):23–31. https://doi.org/10.1016/j.cemconcomp.2012.08.017

Ferreira L, De Brito J, Saikia N (2012) Influence of curing conditions on the mechanical performance of concrete containing recycled plastic aggregate. Constr Build Mater 36:196–204. https://doi.org/10.1016/j.conbuildmat.2012.02.098

Nyika J, Dinka M (2022) Recycling plastic waste materials for building and construction materials: a minireview. Mater Today Proc 62:3257–3262. https://doi.org/10.1016/j.matpr.2022.04.226

Haque MS (2019) Sustainable use of plastic brick from waste PET plastic bottle as building block in Rohingya refugee camp: a review. Environ Sci Pollut Res 26(36):36163–36183

BIS:269 (2013) Specification for 43 grade Ordinary Portland Cement. Bureau of Indian Standard, New Delhi, India

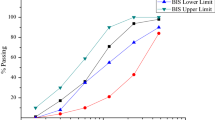

BIS:383 (2016) Coarse and fine aggregate for concrete—Specification. Bureau of Indian Standard, New Delhi, India

BIS:15658 (2006) Precast concrete blocks for paving-specification. Bureau of Indian Standard, New Delhi, India

BIS:10262 (2009) Guidelines for concrete mix design proportioning. Bureau of Indian Standard, New Delhi, India

BIS:456 (2006) Plain and reinforced concrete. Bureau of Indian Standard, New Delhi, India

Gupta T, Sharma RK, Chaudhary S (2015) Impact resistance of concrete containing waste rubber fiber and silica fume. Int J Impact Eng. https://doi.org/10.1016/j.ijimpeng.2015.05.002

Ling TC (2012) Effects of compaction method and rubber content on the properties of concrete paving blocks. Constr Build Mater 28(1):164–175. https://doi.org/10.1016/j.conbuildmat.2011.08.069

Bhogayata AC, Arora NK (2018) Impact strength, permeability and chemical resistance of concrete reinforced with metalized plastic waste fibers. Constr Build Mater 161:254–266. https://doi.org/10.1016/j.conbuildmat.2017.11.135

Gu L, Ozbakkaloglu T (2016) Use of recycled plastics in concrete: a critical review. Waste Manag 51:19–42

Almeshal I, Tayeh BA, Alyousef R et al (2020) Use of recycled plastic as fine aggregate in cementitious composites: a review. Constr Build Mater 253:119146

BIS:1237 (2012) Cement concrete flooring tiles—specification. Bureau of Indian Standard, New Delhi, India

Jain A, Siddique S, Gupta T et al (2019) Fresh, strength, durability and microstructural properties of shredded waste plastic concrete. Iran J Sci Technol Trans Civ Eng 43:455–465. https://doi.org/10.1007/s40996-018-0178-0

Jain A, Siddique S, Gupta T et al (2020) Utilization of shredded waste plastic bags to improve impact and abrasion resistance of concrete. Environ Dev Sustain 22:337–362. https://doi.org/10.1007/s10668-018-0204-1

BIS:516 (2004) Indian standard methods of tests for strength of concrete. Bureau of Indian Standards. New Delhi, India

BIS:13311 (1992) Method of non-destructive testing of concrete, Part 1: Ultrasonic pulse velocity. Bureau of Indian Standard, New Delhi, India

DIN 1048 (1991) EN-testing concr determ depth penetration water under press hardened concr

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Agrawal, Y., Gupta, T. & Sharma, R.K. Effect of compaction technique on single used polythene bag waste concrete paver blocks: mechanical and durability performance. J Mater Cycles Waste Manag 26, 184–196 (2024). https://doi.org/10.1007/s10163-023-01814-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01814-5