Abstract

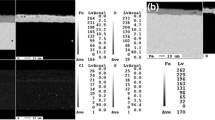

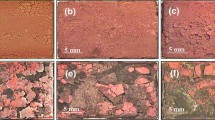

To reveal the high-temperature corrosion mechanism of heating surfaces in the typical flue gas environment in the municipal solid waste incineration (MSWI) system, samples of 310S alloy, a commonly used boiler superheater heating surface material, were deposited with NaCl/50 wt.% K2SO4 and exposed to a typical MSWI flue gas atmosphere of 7% O2 + 600 ppm HCl + 100 ppm SO2 + N2 at 460, 510, 550, and 580 °C for 168 h for corrosion test. The macroscopic morphology, corrosion kinetics, phase composition of corrosion products, and the distribution and content of elements in the corrosion section were analyzed. Our results showed that the NaCl/50 wt. % K2SO4 salt mixture was an extremely corrosive reagent, and its corrosiveness was enhanced with the increase in temperatures. At 460 °C, the salt mixture did not melt, and the corrosion was induced by the reactions between alkali chlorides and alloy, plus the “active oxidation” catalyzed by chlorine. At 510–580 °C, the salt mixtures were completely melted, considerable metal chlorides and some metal sulfides were detected in corrosion products, and the corrosion was controlled by “electrochemical” reactions within the molten salt, coupled with the “active oxidation”. These findings provide new insights into high-temperature corrosion phenomena in MSWI plants.

Similar content being viewed by others

References:

Wienchol P, Szlęk A, Ditaranto M (2020) Waste-to-energy technology integrated with carbon capture—challenges and opportunities. Energy 198:117352. https://doi.org/10.1016/j.energy.2020.117352

Moya D, Aldás C, López G, Kaparaju P (2017) Municipal solid waste as a valuable renewable energy resource: a worldwide opportunity of energy recovery by using waste-to-energy technologies. Energy Procedia 134:286–295. https://doi.org/10.1016/j.egypro.2017.09.618

Dong J, Tang Y, Nzihou A, Chi Y, Weiss-Hortala E, Ni M (2018) Life cycle assessment of pyrolysis, gasification and incineration waste-to-energy technologies: theoretical analysis and case study of commercial plants. Sci Total Environ 626:744–753. https://doi.org/10.1016/j.scitotenv.2018.01.151

Wang Y, Zhang X, Liao W, Wu J, Yang X, Shui W, Deng S, Zhang Y, Lin L, Xiao Y, Yu X, Peng H (2018) Investigating impact of waste reuse on the sustainability of municipal solid waste (MSW) incineration industry using emergy approach: A case study from Sichuan province. China Waste Manage 77:252–267. https://doi.org/10.1016/j.wasman.2018.04.003

Dastjerdi B, Strezov V, Kumar R, Behnia M (2019) An evaluation of the potential of waste to energy technologies for residual solid waste in new South Wales. Australia Renewable and Sustainable Energy Reviews 115:109398. https://doi.org/10.1016/j.rser.2019.109398

Viklund P, Hjörnhede A, Henderson P, Stålenheim A, Pettersson R (2013) Corrosion of superheater materials in a waste-to-energy plant. Fuel Process Technol 105:106–112. https://doi.org/10.1016/j.fuproc.2011.06.017

Otsuka N (2008) A thermodynamic approach on vapor-condensation of corrosive salts from flue gas on boiler tubes in waste incinerators. Corros Sci 50:1627–1636. https://doi.org/10.1016/j.corsci.2008.02.004

Krumm L, Galetz MC (2018) Impact of deposits and their morphology on the active corrosion of iron in chlorine- and sulfur-containing atmospheres in the temperature range of 350–500 °C. Oxid Met 90:365–381. https://doi.org/10.1007/s11085-018-9845-6

Reichelt J, Pfrang-Stotz G, Bergfeldt B, Seifert H, Knapp P (2013) Formation of deposits on the surfaces of superheaters and economisers of MSW incinerator plants. Waste Manage 33:43–51. https://doi.org/10.1016/j.wasman.2012.08.011

Lindberg D, Becidan M, Sørum L (2010) High efficiency waste-to-energy plants—effect of ash deposit chemistry on corrosion at Increased superheater temperatures. Energ Fuel 24:5387–5395. https://doi.org/10.1021/ef100801e

Ma W, Wenga T, Frandsen FJ, Yan B, Chen G (2020) The fate of chlorine during MSW incineration: vaporization, transformation, deposition, corrosion and remedies. Prog Energ Combust 76:100789. https://doi.org/10.1016/j.pecs.2019.100789

Dal Pozzo A, Muratori G, Antonioni G, Cozzani V (2021) Economic and environmental benefits by improved process control strategies in HCl removal from waste-to-energy flue gas. Waste Manage 125:303–315. https://doi.org/10.1016/j.wasman.2021.02.059

Liu X, Duan Y, Chen Q, Long L, Lv G, Huang Q, Jiang X (2022) Study of corrosion kinetic measurement and morphology observation of superheater tube 12cr1mov alloy in simulated mswi flue gas containing varied HCl or SO2 concentrations. ACS Omega 7:23929–23938. https://doi.org/10.1021/acsomega.2c02722

Sadeghimeresht E, Reddy L, Hussain T, Huhtakangas M, Markocsan N, Joshi S (2018) Influence of KCl and HCl on high temperature corrosion of HVAF-sprayed NiCrAlY and NiCrMo coatings. Mater Design 148:17–29. https://doi.org/10.1016/j.matdes.2018.03.048

Enestam S, Bankiewicz D, Tuiremo J, Mäkelä K, Hupa M (2013) Are NaCl and KCl equally corrosive on superheater materials of steam boilers? Fuel 104:294–306. https://doi.org/10.1016/j.fuel.2012.07.020

Asteman H, Spiegel M (2007) Investigation of the HCl (g) attack on pre-oxidized pure Fe, Cr, Ni and commercial 304 steel at 400 °C. Corros Sci 49:3626–3637. https://doi.org/10.1016/j.corsci.2007.03.028

Folkeson N, Johansson LG, Svensson JE (2007) Initial stages of the hcl-induced high-temperature corrosion of alloy 310. J Electrochem Soc 154:C515–C521. https://doi.org/10.1149/1.2754174

Grabke HJ, Reese E, Spiegel M (1995) The effects of chlorides, hydrogen chloride, and sulfur dioxide in the oxidation of steels below deposits. Corros Sci 37:1023–1043. https://doi.org/10.1016/0010-938X(95)00011-8

Zahs A, Spiegel M, Grabke HJ (2000) Chloridation and oxidation of iron, chromium, nickel and their alloys in chloridizing and oxidizing atmospheres at 400–700℃. Corros Sci 42:1093–1122. https://doi.org/10.1016/S0010-938X(99)00142-0

Dal Pozzo A, Lazazzara L, Antonioni G, Cozzani V (2020) Techno-economic performance of HCl and SO2 removal in waste-to-energy plants by furnace direct sorbent injection. J Hazard Mater 394:122518. https://doi.org/10.1016/j.jhazmat.2020.122518

Zhang H, Yu S, Shao L, He P (2019) Estimating source strengths of HCl and SO2 emissions in the flue gas from waste incineration. J Environ Sci 75:370–377. https://doi.org/10.1016/j.jes.2018.05.019

Wenga T, Chen G, Ma W, Yan B (2019) Study on corrosion kinetics of 310H in different simulated MSW combustion environment. The influence of SO2 and H2O on NaCl assisted corrosion. Corros Sci 154:254–267. https://doi.org/10.1016/j.corsci.2019.04.013

Liu X, Chen Q, Long L, Meng X, Lv G, Huang Q, Jiang X (2021) In-situ sampling investigation of deposition and corrosion of convective heating surfaces in a grate type municipal solid waste incineration plant: a case study. Waste Disposal & Sustainable Energy 3:299–308. https://doi.org/10.1007/s42768-021-00087-8

Zhao J, Wei X, Li T, Li H, Bin F (2018) Behavior of alkali metals in fly ash during waste heat recovery for municipal solid waste incineration. Energ Fuel 32:4417–4423. https://doi.org/10.1021/acs.energyfuels.7b03001

Abu Warda N, López AJ, Pedraza F, Utrilla MV (2021) Corrosion behavior of T24, T92, VM12, and AISI 304 steels exposed to KCl-NaCl-K2SO4-Na2SO4 salt mixtures. Mater Corros 72:936–950. https://doi.org/10.1002/maco.202012139

Karlsson S, Jonsson T, Hall J, Svensson J, Liske J (2014) Mitigation of fireside corrosion of stainless steel in power plants: a laboratory study of the influences of SO2 and KCl on initial stages of corrosion. Energ Fuel 28:3102–3109. https://doi.org/10.1021/ef402127h

Karlsson S, Pettersson J, Svensson JE, Johansson LG (2011) KCl-induced high temperature corrosion of the austenitic stainless steel 304L—the influence of SO2. Mater Sci Forum 696:224–229. https://doi.org/10.4028/www.scientific.net/MSF.696.224

Pettersson J, Pettersson C, Folkeson N, Johansson LG, Skog E, Svensson JE (2006) The influence of sulfur additions on the corrosive environments in a waste-fired CFB boiler. Mater Sci Forum 522–523:563–570. https://doi.org/10.4028/www.scientific.net/MSF.522-523.563

Zhai W, Yang B, Zhang S, Ni J, Li S, Li Y (2020) Study on high temperature chlorination corrosion of metallic materials on the waste incineration boilers. IOP Conference Series: Earth and Environmental Science 450:12006. https://doi.org/10.1088/1755-1315/450/1/012006

Li X, Liu Z, Li H, Wang Y, Li B (2013) Investigations on the behavior of laser cladding Ni-Cr-Mo alloy coating on TP347H stainless steel tube in HCl rich environment. Surf Coat Technol 232:627–639. https://doi.org/10.1016/j.surfcoat.2013.06.048

Skrifvars BJ, Backman R, Hupa M, Salmenoja K, Vakkilainen E (2008) Corrosion of superheater steel materials under alkali salt deposits Part 1: The effect of salt deposit composition and temperature. Corros Sci 50:1274–1282. https://doi.org/10.1016/j.corsci.2008.01.010

Bankiewicz D, Enestam S, Yrjas P, Hupa M (2013) Experimental studies of Zn and Pb induced high temperature corrosion of two commercial boiler steels. Fuel Process Technol 105:89–97. https://doi.org/10.1016/j.fuproc.2011.12.017

Ma W, Wenga T, Zhang N, Chen G, Yan B, Zhou Z, Wu X (2017) Full-scale experimental investigation of deposition and corrosion of pre-protector and 3rd superheater in a waste incineration plant. Sci Rep-Uk. https://doi.org/10.1038/s41598-017-17438-3

Verbinnen B, De Greef J, Van Caneghem J (2018) Theory and practice of corrosion related to ashes and deposits in a WtE boiler. Waste Manage 73:307–312. https://doi.org/10.1016/j.wasman.2017.11.031

Lee H, Yi S, Holsen TM, Seo Y, Choi E (2018) Estimation of CO2 emissions from waste incinerators: comparison of three methods. Waste Manage 73:247–255. https://doi.org/10.1016/j.wasman.2017.11.055

Bal M, Siddiqi H, Mukherjee S, Meikap BC (2019) Design of self priming venturi scrubber for the simultaneous abatement of HCl gas and particulate matter from the flue gas. Chem Eng Res Des 150:311–319. https://doi.org/10.1016/j.cherd.2019.08.005

Krumm L, Galetz MC (2017) Chlorine attack of carbon steel between 350 and 500°C and its importance regarding corrosion in waste incineration. Oxid Met 87:757–766. https://doi.org/10.1007/s11085-017-9749-x

Andersson P, Norell M (2005) Field test of superheater corrosion in a CFB waste boiler: Part II—scale formation characteristics. Mater Corros 56:550–560. https://doi.org/10.1002/maco.200403853

Maj I, Kalisz S, Szymajda A, Łaska G, Gołombek K (2021) The influence of cow dung and mixed straw ashes on steel corrosion. Renew Energ 177:1198–1211. https://doi.org/10.1016/j.renene.2021.06.019

Sadeghimeresht E, Reddy L, Hussain T, Markocsan N, Joshi S (2018) Chlorine-induced high temperature corrosion of HVAF-sprayed Ni-based alumina and chromia forming coatings. Corros Sci 132:170–184. https://doi.org/10.1016/j.corsci.2017.12.033

Li YS, Spiegel M, Shimada S (2005) Corrosion behaviour of various model alloys with NaCl-KCl coating. Mater Chem Phys 93:217–223. https://doi.org/10.1016/j.matchemphys.2005.03.015

Pan TJ, Zeng CL, Niu Y (2007) Corrosion of three commercial steels under ZnCl2 –KCl deposits in a reducing atmosphere containing HCl and H2S at 400–500°C. Oxid Met 67:107–127. https://doi.org/10.1007/s11085-006-9047-5

Meißner TM, Montero X, Fähsing D, Galetz MC (2020) Cr diffusion coatings on a ferritic-martensitic steel for corrosion protection in KCl-rich biomass co-firing environments. Corros Sci 164:108343. https://doi.org/10.1016/j.corsci.2019.108343

Ahila S, Iyer SR, Radhakrishnan VM (1993) Melting point determination of the K2SO4-NaCl system. J Mater Sci Lett 12:1733–1734. https://doi.org/10.1007/BF00517594

Tholence F, Norell M (2002) AES characterization of oxide grains formed on ductile cast irons in exhaust environments. Surf Interface Anal 34:535–539. https://doi.org/10.1002/sia.1355

Li YS, Niu Y, Spiegel M (2007) High temperature interaction of Al/Si-modified Fe-Cr alloys with KCl. Corros Sci 49:1799–1815. https://doi.org/10.1016/j.corsci.2006.10.019

Tsaur C, Rock JC, Wang C, Su Y (2005) The hot corrosion of 310 stainless steel with pre-coated NaCl/Na2SO4 mixtures at 750°C. Mater Chem Phys 89:445–453. https://doi.org/10.1016/j.matchemphys.2004.10.002

Aye KK, Zhang J, Young DJ (2020) Effect of hydrogen chloride on corrosion behaviour of Fe-Cr alloys in wet CO2 gas at 650°C. Oxid Met 94:51–80. https://doi.org/10.1007/s11085-020-09978-3

Nimmervoll M, Schmid A, Mori G, Hönig S, Haubner R (2021) Surface sulphide formation on high-temperature corrosion resistant alloys in a H2S-HCl-CO2 mixed atmosphere. Corros Sci 181:109241. https://doi.org/10.1016/j.corsci.2021.109241

Uusitalo MA, Vuoristo PMJ, Mäntylä TA (2004) High temperature corrosion of coatings and boiler steels below chlorine-containing salt deposits. Corros Sci 46:1311–1331. https://doi.org/10.1016/j.corsci.2003.09.026

Robelin C, Chartrand P, Pelton AD (2004) Thermodynamic evaluation and optimization of the (NaCl+KCl+MgCl2+CaCl2+MnCl2+FeCl2+CoCl2+NiCl2) system. J Chem Thermodyn 36:809–828. https://doi.org/10.1016/j.jct.2004.05.005

Spiegel M (1999) Salt melt induced corrosion of metallic materials in waste incineration plants. Mater Corros 50:373–393. https://doi.org/10.1002/(SICI)1521-4176(199907)50:7%3c373::AID-MACO373%3e3.0.CO;2-T

Yang X, Peng X, Wang F (2007) Hot corrosion of a novel electrodeposited Ni–6Cr–7Al nanocomposite under molten (0.9Na,0.1K)2SO4 at 900°C. Scripta Mater 56:891–894. https://doi.org/10.1016/j.scriptamat.2007.01.035

Zhang S, Li H, Jiang Z, Zhang B, Li Z, Wu J, Feng H, Zhu H, Duan F (2020) Chloride- and sulphate-induced hot corrosion mechanism of super austenitic stainless steel S31254 under dry gas environment. Corros Sci 163:108295. https://doi.org/10.1016/j.corsci.2019.108295

Acknowledgements

This study was supported by the National Key Research and Development Program of China [Grant No. 2018YFC1901302], and the Innovative Research Groups of the National Natural Science Foundation of China [Grant No. 51621005].

Funding

National Key Research and Development Program of China, 2018YFC1901302, Innovative Research Group Project of the National Natural Science Foundation of China, 51621005, Xuguang Jiang

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, X., Duan, Y., Zheng, L. et al. High-temperature corrosion mechanism analysis of 310S alloy in typical MSWI flue gas environment at 460–580 °C. J Mater Cycles Waste Manag 26, 197–212 (2024). https://doi.org/10.1007/s10163-023-01812-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01812-7