Abstract

Phosphorus (P) recovery and recycling play a crucial role in improving resource efficiency, sustainable nutrient management and moving toward circular economy. Increasing demand for fertilizers, signs of geopolitical constraints, and high discharge of P to waterbodies are the other reasons to pursue the circularity of P. Various research have been carrying out and several processes have been developed for P-recovery from different resources. However, there is still a huge unexplored potential for P-recovery specially in the regional framework from the four main P-rich waste resources: food waste, manure, mining waste, and sewage sludge. This study reviews recovery methods of P from these secondary resources comprehensively. Additionally, it analyzes the Nordic viewpoint of P-cycle by evaluating Nordic reserves, demands, and secondary resources to gain a systematic assessment of how Nordic countries could move toward circular economy of P. Results of this study show that secondary resources of P in Nordic countries have the potential of replacing mineral fertilizer in these countries to a considerable extent. However, to overcome the challenges of P-recovery from studied resources, policymakers and researchers need to take decisions and make innovation along each other to open the new possibilities for Nordic economy.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Today the world is on a trajectory where waste generation is dramatically increasing, and the linear take-make-waste economy is still the dominant practice globally. The trend in global waste generation does not show any significant reduction by 2050 [37] and the transition from the linear economy to circular economy is now a necessity. The world has generated approximately 2 billion tons of waste per year in 2016 and for example 44% of it belongs only to food and greens sector [37]. The other main producer of waste in terms of volume is mining sector where the mining waste is estimated to be 50 times bigger in volume compared to municipal solid waste generated by humankind [6]. Waste management is a major global challenge and circular economy is the ultimate tool that transforms the throwaway economy into a regenerative economy where resources are conserved, waste is minimized, and the environment is protected.

In our earlier research, we evaluated the status of circular economy in Finland, to establish for which material flows circularity needs to be accelerated. Nutrients/fertilizers were identified as one of such critical flows, where there is a need to increase circularity [33]. Humans have altered the natural biocycles of materials through various industrial and agricultural activities. Nutrients are extracted and used to produce food and they are necessary to maintain human life. Phosphorus (P) and Nitrogen (N) are key nutrients for all living organisms. Natural P-cycle (Fig. 1) starts with releasing mineral P from P-reserves by weathering, it follows by uptake by plants and animals and eventually returning to the soil after their death. The natural cycles of P have been disturbed by human activities due to the intense use as fertilizer to increase crop yields and plant production. Today P-cycle has low efficiency due to the loss in every stage of it including P-extraction from natural reserves, producing, and utilizing fertilizers. Nutrient loss can affect our societies in many ways and, in the case of P, the scarcity of it leads to serious consequences.

The demand for P-fertilizer to provide enough food for the growing global population has been predicted to increase by the middle of this century. Trends in the global food systems indicate that dietary preference is going toward consuming more P-intensive animal proteins; as well as, crop production in P-poor soils such as in tropical locations will need to increase [44, 57]. Approximately 24 million tons of P is extracted from mines per year, for food production [64, 65] and only about one fifth of the extracted P actually reaches the ultimate goal of being consumed by human beings [9]. There are significant differences in the estimated lifetime of P-reserves, from hundreds to thousands of years and even if there are enough P-reserves the geopolitical constraints of phosphate rock reserves are already obvious and likely to increase in the future. Therefore, although P might not be physically scarce on a short-term, these reasons make P recycling from secondary resources an inevitable part of the P-cycle [43, 45, 59]. It is worth to mention that in this paper P-reserves refers to the mineral P-deposits and secondary P-resources indicates those waste-based flows that contains P.

Furthermore, P and N cycles are one of the nine planetary boundaries for which the safe limits have been surpassed and pushed beyond the zone of uncertainty. The concept of planetary boundaries was introduced by [56] and later updated by [63]. They define nine indicators, for which humanity needs to operate within safe limits, without putting pressure on the earth’s systems. From the key plant nutrients, it is P that represents the most significant concern for planetary boundaries and sustainability [63]. P-flows to the biosphere and oceans push marine life and aquatic systems across their ecological thresholds. Water bodies enriched by nutrients such as P are at risk of eutrophication. Eutrophication is enrichment of waterbodies with nutrients (P&N) and results in extensive growth of algae and aquatic plants, water quality deterioration and depletion of marine life [7, 36].

These challenges to P acquisition and loss are a clear incentive for improving the P-cycle. A sustainable P-management indicates changes in every stage of the process from mining to downstream processes in order to promote the circular economy of P. The changes which are conducive to the conservation of remaining P include [55]:

-

1.

Improving the efficiency of P-related processes, including improvement in mining and beneficiation process, utilization of mining wastes.

-

2.

Restricting P-use for essential purposes and improving P-efficiency in agriculture.

-

3.

Closing the P-cycle in the economy includes recycling P from secondary resources.

Consequently, the European Union has listed P as one of the critical raw materials since 2014, and sustainable management of P has been one of the European policies since 2013, which is also highlighted in the “Roadmap to Resource-Efficient Europe in 2011 [18, 19, 21]. Therefore, pursuing circular economy which ensures improved material flows and aims to keep the material within the inner circles of economy and with their highest functionalities is a necessity. Circular economy of P reduces reliance on imports and increases national security [12]. More circular P-flows are essential for economies to secure food production and mitigate eutrophication [40]. For example, the EU 28 consumed 1.1 million tons of P fertilizers in 2018 [25] while only 3% of it is produced in the EU [26]. For these reasons, there is a need to investigate the possibilities of each country to pursue circular economy of P and how sustainable P-management benefits natural ecosystem and our society.

To embrace circular economy of P, several secondary P-resources have been identified and different P-recovery methods has been developed in the EU and other countries such as USA and Japan. Yet, the ultimate solution should be addressed through pioneering technologies and systems that can recover P in a way that is energy efficient and economically viable while ensuring the product is an effective and an environmentally friendly fertilizer [10]. Nevertheless, there are some barriers to tackle such as lack of qualitative and quantitative data and information about secondary resources, regulative obstacles, technology availability, marketing, and financing.

The Nordic countries, including Finland, Sweden and Norway have an open market economy, but each of them has their own distinct characteristics as well. Economic interaction and trades between these three countries is extensive and there are several intra-industry exports and imports among them. Therefore, in this paper the objective is to review the main secondary P-sources in Nordic countries and their potential recovery methods. Evaluating the different aspects of P-management of these countries in parallel gives a valuable outlook of how the Nordics can move toward circular economy of P.

Another notable incentive to embrace circular economy of P for Nordic countries is the Baltic Sea. The Baltic Sea, surrounded by the Nordic countries, is one of the most polluted seas and eutrophication is the biggest problem that put aquatic organisms of this sea at risk [62]. The Baltic Sea is a semi-closed marine area with limited water exchange, and it is surrounded by densely populated countries with heavy industrial and agricultural activities. This lead to the accumulation of P in its basin that endangers marine life and pushes many of the species to the edge of their environmental tolerance [3]. The biggest sources of P-pollution are related to agricultural activities, animal farms, as well as urban and industrial wastewater discharges [28].

To obtain a systematic perspective how each of these countries can achieve a sustainable and circular P-cycle and move toward P-independency and reducing danger of eutrophication of the Baltic Sea, several aspects need to be assessed. For instance, EU/regional regulation, available technologies, P-resources and market demand for renewable fertilizers. In this magnitude, this paper investigates P-reserves, demands, and secondary resources in the mentioned three countries, available technologies and regional criteria that may affect the P-recovery developments.

Methodology

In an attempt to gain a deeper understanding on how to improve the circularity of P in the Nordic countries (Finland, Sweden, and Norway) and protecting Baltic Sea, this study first creates a comprehensive overview of the global P-reserves, secondary P-resources and the different routes and methods which are developed around the world to recover P. Further, the characteristics of Nordic countries and the main secondary P-sources in these countries are investigated. Figure 2 shows the issues of concern that motivate this study; global criticality of P, P being one of the key materials of circular economy and Baltic seas eutrophication. Nordic circularity of P is at the intersection of these three concerns.

The main method used in this study to assess the aspects of recycling P in Nordic countries has been adopted from the sustainable P-recovery framework [11]:

-

Step 1. Identification of key drivers for recovery of P.

-

Step 2. System boundaries definition.

-

Step 3. Identification of quantity and quality of P available from various resources.

-

Step 4. Identification of technologies available to recover P from different sources, suitable for key drivers.

-

Step 5. Examine logistics, identify spatial demand for P relative to the source of recovered P.

-

Step 6. Identification of life cycle costs from economic, energy, and environmental point of view.

-

Step 7. Identification of any synergies and conflicts with other services such as sanitation, energy, and food.

-

Step 8. Identification of key stakeholder and institutional arrangements.

Figure 3 shows the schematic overview of the study and the aspects that has been included to analyze the recovery of P in Nordic countries. The life cycle assessment has not been performed in this study since it needs in depth case-specific analysis which is out of the scope of this paper.

Phosphorus reserves

Phosphorus (P) belongs to the family of macronutrients that are involved in the metabolism or enzyme activation of all organisms. P is a crucial part of DNA and reproduction system, energy supply (ATP), and some structures of human bodies such as bones and teeth [50, 59]. These macronutrients are a non-separable part of food production and life as water and soil, and they cannot be substituted with any other elements. P-reserves (mineral P) are the only non-renewable bio-essential resources in the world and half of the food production system is dependent on them [17].

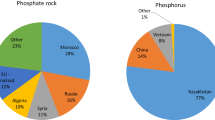

Morocco including occupied Western Sahara is currently the dominant provider of P to the world [8, 65], as can be seen in Fig. 4. Depending on geological assurances and economic feasibility, reserves have dynamic measures. However, phosphate rock reserves remained relatively constant on 65,000–70,000 Million tons from 2011 until 2020 [54, 65]. Although there are substantial deposits in Spain, Belgium, and France [68], the only country that currently exploits mineral phosphate in the EU is Finland. Consequently, 90% of the EU need for phosphate is covered by imports [14, 54, 55].

World phosphate reserves 2000–2020, Data source: [4]

On average, phosphate ores contain around 30% P2O5 and a critical issue is that not all of the P can be extracted from the ore. The amount that could be extracted depends on many factors such as type of the ore, mining method, and mining efficiency [67]. Extraction process in general includes mining the ore, beneficiation and flotation to increase the grade and remove the excessive parts and eventually the chemical process of adding phosphoric and sulfuric acid to separate phosphate component and form P2O5 concentrate [30]. There are four different types of phosphate deposits: igneous, sedimentary, metamorphic, and biogenic and among these, sedimentary and igneous are the most common occurring deposits. Sedimentary phosphate deposits, which accounts for 90% of P-fertilizer production, contain relatively high amount of P but trace elements concentration is also high in this type of rocks. Igneous phosphate deposits which approximately produce 10% of the P-fertilizer has lower amount of trace elements. These trace elements are mainly heavy metals such as cadmium (Cd), lead (Pb), arsenic (As), uranium (U), mercury (Hg), and vanadium (V). They are environmentally relevant due to the fact that they accumulate in the soil and are absorbed by crops to eventually end up in the food chain [66].

Secondary phosphorus sources and recovery methods

There are four main secondary P-sources with high potential for P-recovery: livestock manure, sewage sludge, food waste, and mining waste [34, 48, 51, 71]. Table 1 shows the volume of secondary P-sources in Europe. In some studies, landfills have also been mentioned as a source of P and urban mining has been discussed recently as a method for recovery of some valuable substances including P [32, 52, 53]. In this study, landfills are excluded from P sources and recovery methods because there are no clear data about the volume of waste in landfills and the amounts of P they contain. P-concentration in the different sources is the key knowledge for estimating the total available P for recovery. Yet, other factors such as quality are also significant for example, urine P content is low in comparison with other organic waste but since it is sterile and can be applied directly to the land, it does not need any further treatment and extra costs can be avoided. Generally, the lower the P content, the more energy for physical or chemical processes such as dewatering is needed. Moreover, transport of the waste to the recovery plant is also an important factor in terms of distance and fossil fuel use [11].

According to the P-source types, main routes for nutrient recovery include recovery of P from agricultural waste (including livestock manure and crop harvest loss), sewage sludge (sewage sludge and sewage sludge ash), mining waste, and food chain waste. The recovery methods can be also divided into five groups: extractive re-processing, raw usage, biological techniques (composting and anaerobic digestion), thermal treatments (combustion), and chemical treatments. Figure 5 shows available processes for P-recovery from different secondary resource types.

Mining waste including mineral excavation waste (waste rocks), treatment waste (mining tails, waste gravel sand, and clays), and drilling wastes are high volume streams that are side product of mineral beneficiation processes. These types of wastes usually have impact on water quality, environment quality, and human health [61]. Extractive waste may include several critical raw materials in addition to P, therefore a key contribution to circular economy could come from recovery of these elements from mining wastes. Eurostat collects and reports some data in this area such as statistics on extractive waste flows in the EU but there are still huge knowledge and data gaps on these potential resources of P. The potential of P-recovery from mining waste depends on several factors such as volume, concentration of the P, mineralogy, and re-processing technology availability and market demand [2].

Manure which is produced in farming in Europe is mainly applied directly to soil (more than 90%) and the remaining part will go through separation processes or anaerobic digestion [38]. Factors such as livestock sector evolution, availability and lower cost of recovery technologies, and finding alternative methods for disposal path of manure influence the success of P-recovery from manure [5]. There are also some methods such as digestion or composting to increase the amount of P per volume of the applied material (as organic fertilizer) for example AGRIPLUS is a full-scale nutrient recovery plant which produces fertilizer and organic peat replacement for improving efficiency of arable farming in Germany [23]. ManureEcoMine is another project in the Netherland and Spain that is testing technologies of nutrient recovery from manure with combined methods of anaerobic digestion and biological processes [20]. BioEcoSim method uses acidification, solid/liquid separation, and struvite precipitation to address P-recovery from manure in pilot plan assessment [20]. Some other examples are Agro America (VP Hope) operating a plant in Netherland, which uses pyrolysis to produce P-containing biochar, Geninaal which is a full-scale plant in Netherland which produces P-rich fertilizer by flotation and membrane filtration, and, the Hitachi Zosen method in Japan which uses composting followed by a thermal process to recover P in the form of charcoal [22]. If manure is not treated as waste but as a nutrient resource and its management reaches proper efficiency, it would be a double benefit to the environment: less waste and more resources.

Food waste can be used for P-recovery via different techniques such as composting, anaerobic digestion, and incineration. Composting and anaerobic digestion bring back the nutrients in waste to the soil, however, due to the low concentration of nutrients it is classified as soil improvement substrate rather than fertilizer. Despite the large amount of food waste, this stream is very heterogeneous and diluted (concentration is approximately 0.4% on dry matter) and only part of the food chain waste has higher potential for P-recovery, and it is slaughterhouse waste (meat and bone meals). Consequently, there are not many processes developed for P-recovery from food waste chain.

Sewage sludge and different flows of wastewater treatment contain P that can be a potential source of P. In fact, the most studied and invested secondary P-source is sewage sludge. Sewage sludge has been recycled directly to the fields for many years but recently several countries have implemented regulations restricting direct usage due to the potential environmental and health concerns. Thus, several researchers has been studying P-recovery from sewage sludge in the recent years [49]. P can be recovered from sludge, sludge liquor (effluent, digester supernatant), and incineration ash of sewage sludge. The most common processes operating today in Europe are based on struvite (magnesium ammonium phosphate) recovery from dewatering reject streams and sludge liquor [5, 15]. P-recovery plants from sewage sludge are mainly located in Europe (Belgium, Germany, Denmark, Netherland, Italy, and Spain), North America (USA and Canada), and in some parts of Asia (Japan and China). In general, P can be recovered in different points of wastewater treatment plants [16]. The operation of the facilities is based on various recovery methods and a full list of them, and their product has been compiled in Supplementary Appendix 1.

Recovered P from various secondary sources differ not only in amounts, but also in their energy usage and environmental impact. Various P-recovery processes have already been commercialized and working in countries such as Germany, the Netherlands, Denmark, and Japan. In addition to that, several other techniques are in a development phase working on a pilot scale. The most appropriate method of recovery may be different between countries depending on their regulations and legislations, existing infrastructure, amounts of secondary resources and the economic feasibility of the method. Subsequently, there is not “one solution fits all” for P-recovery and the suitable recovery method should be evaluated based on many factors (listed in: the 8 key steps of developing sustainable framework) in every region and country [71]. To address all aspects of P-recovery a comprehensive study is required to highlight more practical issues rather than common issues regarding quantity of the resources or presence of heavy metals. In this essence, in the next sections, P-recovery in the Nordic countries is studied based on their demands, reserves, secondary sources, and geographical features.

Phosphorus recovery from the Nordic perspective

Similar to other European countries, Nordic countries are mainly dependent on mineral P-imports and the production of mineral fertilizers in these countries is not balanced with their demand. Relying on a single source of P (mineral phosphate rock) makes the food system highly vulnerable to the shocks and stresses to the P market [41]. The three Nordic countries studied in this article; Finland, Sweden and Norway, have their own environmental and societal characteristics including sparse population, long transportation distances, different economic activity/sectors (comparing to central and southern Europe), cold weather and strict regulation of trace elements for recycled fertilizers. These characteristics make them slightly different from countries located in central Europe. Therefore, to facilitate circular economy of P, there is a need to design an appropriate and sustainable P-recovery that is coordinated within the boundaries of these countries. Different studies in the phosphorus recovery context which are reviewed in this article, mainly focused on specific secondary resources of P or recovery method. However, the purpose of this study is a comprehensive assessment of various secondary resources while considering regulation and societal limitation of mentioned countries which at this stage is not demonstrated trough other studies.

Nordic Phosphorus reserves and demand

To boost the installation of P-recovery technologies in each region and to select the most suitable solution, data about P-production, consumption, trades (import and export) are essential. In Norway, phosphate rock, igneous deposits exist in Rogaland, Vestfold, Nordland, and Finnmark. However, due to political and environmental factors, mining these reserves are not possible now. In Sweden, the accumulated mining waste of iron mine in Kiruna contains P which has a high potential for re-extraction. In Finland, according to the Geological Survey of Finland, there are 2360 million tons of phosphate rock reserves located in Siilinjärvi and Sokli with average P content of 4.9 percent and most of these reserves are igneous deposits [29]. Figure 6 shows the locations of the Finnish P-mines, the Swedish Iron mine and the areas of Norway with P-reserve potential.

The Sokli reserve is an apatite-rich carbonatite complex deposit in Savukoski close to the border with Russia and it was discovered in 1967. The phosphate deposits of Sokli have never been mined since it is located in a remote and almost uninhabited area with inadequate transport infrastructure. However, Yara has invested in this site and has been performing research and assessments in it since 2007. Recently, Finnish Minerals Group has acquired the rights of the mining in this site from Yara and will be responsible for future assessments of this project [27]. The Siilinjärvi mine, which is owned by Yara, is the second largest mine in Finland and its most valuable products are apatite, lime, biotite, and various mica products. It is the only operating phosphate mine in Europe and was discovered in 1950 with quarrying beginning in 1979. Up until now, 300 million tons of ore have been mined from two open pit areas of Siilinjärvi, which produce 19.5 million tons of Apatite concentrate used to produce Phosphoric acid and P-fertilizers.

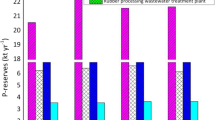

Yara is the P-fertilizer producer in the Nordic countries and is the world’s largest mineral-based fertilizer producer with 30,000 tons of fertilizer production a year. This company was founded in 1905 in Norway and has continued to operate in over 60 countries around the world to this moment. Yara uses 1.8 million tons of Phosphate rocks from Brazil, Morocco, and Finland to produce P-fertilizers [69]. In Sweden and Norway, Yara only has N-fertilizer production sites located in Köping (Sweden), Porsgrunn, and Glömfjord (Norway). Therefore, as can be seen in Fig. 7, Norway and Sweden are highly dependent on P-import. Finland has covered most of the P-fertilizer demands by domestic production from the Siilinjärvi mine, however, the lifetime of these mines is evaluated up to 2035 [70]. Accordingly, for all three countries, P-recovery from secondary resources is the ultimate solution of self-sufficiency in terms of P-fertilizers.

Phosphorus consumption and fertilizer imports (metric tons) of Finland, Sweden and Norway during year 2008–2018 (import data for year 2013 and 2016 is not available for Finland and for year 2016 is not available for Sweden and Norway), *mineral/ inorganic fertilizer consumption in tons of P, **includes mineral/chemical fertilizers which contain phosphate by at least 35% weight, a [58] b [59]

Another issue is the trace elements contamination in phosphate rocks. The remained sedimentary phosphate rock deposits located around the world have high levels of heavy metals such as cadmium, mercury, and other contaminants, which must not enter human food cycles. The cadmium concentration of sedimentary phosphate is usually over 60 mg/kg, whereas the igneous deposits Cadmium concentration can be less than 1 mg/kg [29, 60]. As the majority of Finland’s most significant P-reserves are highly pure, they are very valuable. Yet, based on the mentioned reasons such as the insufficient size of reserves, short lifetime, and remote location, Finland also needs to invest in sustainable P-management alongside Sweden and Norway.

To achieve higher sustainability of the mineral P-cycle in the Nordic countries, several actions have been taken. They include lowering the carbon footprint of P-fertilizer production by Yara, reducing nutrient loss and improving efficiency of fertilizer usage. However, in order to achieve the goal of circular economy of P and closing the P-loop, deeper knowledge on the quantity and quality of the available secondary P-resources is essential.

Nordic secondary resources of Phosphorus

While Finland, Sweden, and Norway have similarities in areas such as population, weather and economic structure; resource flows and available technologies are entirely different t. In the following section, the available P-volumes for each main secondary resources have been studied (Table 2).

Finland: manure is the largest source of secondary P-resources in Finland. Right now, approximately 5% of manures are processed (including separation, composting, and anaerobic digestion), while the remainder is used in agriculture without processing. Distribution of manure production is different within Finland, in some regions (Ostrobothnia, South Ostrobothnia, Satakunta, and Southeast Finland) there is excess of manure production but, in most regions, there is a balance between consumption and production [29, 42]. Regarding sewage sludge, the majority of it is processed by anaerobic digestion or composting or a combination of these two methods. The most common technique used in Finland is simultaneous precipitation, in this method P is separated from wastewater by using iron salt which produces low solubility iron-phosphate. Biowaste (the biodegradable part of MSW) is also processed by the same method as sewage sludge for P-recovery [29, 42]. Finland has one of the lowest population densities in the EU and, in some areas, especially in the northernmost parts of the country, the population density is so low that it is not economically or environmentally viable to invest in P-recovery plants or even transfer the P-containing resources to other places.

Sweden: the main secondary resources of Sweden are similar to Finland. Sewage sludge has a higher volume due to double the population compared to Finland. However, only 4% of P in sewage sludge is recycled as a result of strict Swedish regulation on trace element levels in fertilizers [46]. Research indicates that there is a potential of 22–56% substitution of mineral fertilizer if the sewage sludge is used for nutrient recovery [13]. Swedish wastewater treatment plants commonly combine mechanical, biological and chemical treatment in various ways.

A huge potential of P-recovery exists in Sweden from accumulated mining waste; 1,500,000 tons of P. This amount indicates a high possibility for P-recovery in comparison to other flows in Sweden [40]. Mining waste is economically and environmentally relevant for valorization and resource recovery based on many reasons. Massive volumes of easily accessible crushed rocks which could be labelled as low-grade ore is an interesting source of valuable raw material. However, extracting P from this flow might be problematic due to the presence of Arsenic, which is of large concern when it comes to fertilizer and food systems [72]. Two significant projects (LKAB, ReeMAP Project and Grängesberg Apatite Recovery Project) have been started in Sweden to utilize mine tailings either from operating sites or from closed mines to recover P and rare earth elements from apatite ore [24]. The total production of these sites is estimated to be around 63,000 t P/a which is five times more than Sweden’s mineral P fertilizer consumption [24].

Norway: contrary to the other Nordic countries where agriculture is the dominant P-consumer segment of the economy, in Norway, aquaculture and the fishery sector is significant and has similar levels of P-consumption and loss as the agricultural sector of Sweden or Finland. P-recycling in Norway is neither optimized, nor sustainable in any of these three sectors (agriculture, aquaculture and fisheries) and it could be improved in intra and cross-sectoral levels [31]. Norwegian agriculture products are predominantly produced for the domestic market, with a self-sufficiency rate of 45%. On the other hand, aquaculture in Norway is especially significant even on a global scale. [31] claim that with these high volumes of P-secondary resources, Norway is likely to be independent of P-fertilizer import if a proper recovery system was developed.

Lakes and coastal areas are often vulnerable to P-load from fish farming. On one hand, they are small enough to become highly contaminated with even a low amount of P-discharge. On the other hand, they are large enough to be ecologically significant water areas. Fish farming releases large amounts of residual fish feed and excrement into the aquatic environment since there is always an inorganic P supplement in their feed and also there is relatively high concentration of P in meat and bone meals [35, 39]. The two other potential flows in Norway with high volume are animal manure and food waste where the sewage sludge flow is around two thirds of the volume in Finland.

Discussion

Protecting the environment of Nordic countries and especially Baltic Sea marine life requires optimal use of nutrients as a key action, but, at the same time, circular economy of nutrients is a necessity. In a circular economy of P, nutrients are recycled, less virgin phosphate rocks are extracted, and valuable P-resources are not wasted. Countries around the Baltic Sea are at different stages of nutrient recycling, and, in most countries, a holistic strategy of nutrient recycling does not exist. However, some targets have already been set for the relevant waste fractions, and certain country-specific actions have also been addressed. Finland has sat targets for P-recovery from sewage sludge, Sweden aims as reduce organic waste and P-leaching to recipient waters and start P-recovery from mining waste and Norway has invested in promoting more sustainable fisheries.

P-recovery systems should be adapted to the local contexts; therefore, to identify the best solution for the Nordic countries, an assessment should be done to quantify the secondary P-resources and review the established P-recovery technologies. As it was presented in methodology section, the framework sustainable P-recovery consists of different steps which are going to be discussed thoroughly in this section.

The first step is identifying the key drivers for P-recovery and in the second step, the system boundaries should be set. In this study, four main drivers have been identified for P-recovery where three of them are at the EU level and the other one is specific for the Nordic countries. The drivers at the EU level include P-independency, listing P as critical raw material in EU policies, and defining nutrients as a key sector of circular economy. The specific driver for the Nordic countries is protecting the Baltic Sea from eutrophication. The quantities of different secondary resources have been studied in Sect. 4.2 although the quality of these resources has some uncertainties. In Norway, there is a huge potential in aquacultural waste but recycling P from this flow has its own challenges. Fish sludge is accumulated in open cages in Norwegian fjords which makes it less accessible. Moreover, the collected material needs dewatering and desalting before use [4]. Another example is manure, recycling the P-content of manure is crucial in all three countries due to the fact that it has large volume streams (Table 2) and one of the significant efforts to have less nutrient accumulation in the Baltic sea is implementing efficient manure management [1]. The challenge with manure is when the accumulated volume is higher than local demand and spreading it to the nearby fields is not possible. This makes collected manure difficult to utilize since it is logistically not feasible to transfer (Steps 3 and 5). Therefore, considering the geographical distribution of resources is a very significant factor in the Nordic countries where the population is highly dispersed and unevenly distributed which leads to secondary resources being scattered over a large area. Finland and Norway are the second and third most sparsely populated countries in the EU, therefore, another critical factor will rise: transportation distances. The environmental impact from using fossil fuels in the transportation of the secondary P-resources might even overweight the benefits of P-recovery (Steps 3, 4 and 6).

Regarding the technologies available in Nordic countries for P-recovery (Step 4) it is safe to assume that most of the methods (thermal treatment, re-processing with extractive methods, composting, anaerobic digestion, and raw usage) are accessible. Several P-recovery methods are developed and used on industrial scales such as thermal treatment (AshDec in Finland, Ash2Phos and EcoPhos in Sweden), biological treatment (EkoBalans in Sweden and Hias in Norway). In addition, due to the mining resources in all three countries, there is a possibility to develop extractive re-processing methods.

In the case of demand for recycled fertilizer (Step 5), there are also some challenges such as finding markets for newly developed fertilizers, satisfying the regulations of the Nordic countries (i.e., trace element limit in recovered P). However, many of the recycled fertilizers have made their way to the market already. Therefore, there is a necessity for EU and regional fertilizer regulations renewal and a leveling mechanism to begin the market creation for the recycled fertilizers in these countries [3].

In the Nordic countries, to protect the Baltic Sea, regulations on using recycled fertilizers are stricter compared to the EU level. Hence, the conflict with health and sanitation sector should be investigated carefully (Step 7). For instance, the amount of Cd in the EU regulation is 20–40 (mg kg−1 dry matter) for recovered P-fertilizer from sewage sludge but in Swedish regulation, this amount is 2 and in Finland, this amount is only 1.5 (mg kg−1 dry matter). For Pb, there is also a big difference between EU regulation and national regulation of Nordic countries (750–1200 vs 100 mg kg−1 dry matter) [58]. Regarding synergies with other sectors, the potential usage of mining waste in Sweden for re-processing could be mentioned, which could lead to additional economic benefits for the mining sector. Another beneficial synergy is an integrated system in Norway between agriculture and aquaculture sectors, where the effluents of fisheries could be used for irrigation and fertilization in agriculture. These effluents are rich in P and responsible for eutrophication of aquatic environments and with utilizing them in agriculture, water and fertilizer usage efficiency will be improved and the eutrophication risk will be reduced [47].

Finally, institutional and inter-sectoral arrangements need to be done to support the regional platforms of P-recycling and improve networking between the secondary P-resources supplier and the resource recovery sectors. Furthermore, there is a crucial need to have a strong linkage between different segments of the whole P-recycling chain from research and development to policymakers, business world, and the consumers. For instance, the BioREfine project is a valuable example from Interreg IVB program which put emphasis on developing international networking between different sectors of P-recycling operators including research society, policies, and markets at the EU level [20]. Another example is the InPhos project which considers various aspects of the P-cycle with a holistic approach in the Baltic countries (9 countries including Finland and Sweden) and aims at developing a strategic framework for P-recovery in this region [62]. To connect different sectors of the P-recycling chain to each other and to gain the desired results, it is essential to have similar platforms in the Nordic countries. There might be an opportunity to develop a regional platform among all three countries where one P-recovery facility in a strategically selected region could be used to recover P from the secondary recourse of all three countries in the same geographical area. Here a regional facility could bring an opportunity of P-recovery. This could be a good example of key stakeholders and institutional arrangements, however, in this case, the regulations are a major challenge since when a stream is defined as waste it is difficult to transfer it to other counties.

Figure 8 summarizes the result of this study for the key steps of developing sustainable P-recovery in the Nordic countries. Based on the results of this study, the secondary P-resources of the Nordic countries and existing technologies have the possibility of substitute mineral P-fertilizer. Several challenges exist in moving toward circular economy of P in Nordic countries; however, the transition has to be started at some point and be developed through innovative solution. Furthermore, to design a sustainable P-recovery method for the Nordic countries we recommend LCA studies to establish the overall impacts and benefits of recycling within Nordic boundaries, in particular a strategically located shared facility. While there are individual LCA studies about P-recovery, there is still a research gap regarding a more uniform and comprehensive analysis of recycling systems in a regional context.

Conclusions

The Nordic countries are highly dependent on P-imports and their P-cycle is far from closed-loop. This article reviewed secondary P-sources in the Nordic countries and their recovery technologies. We can conclude that the Nordics have the potential of covering their P-need from secondary sources. However, there are some challenges such as geographical disperse and uneven quantity of secondary sources, and strict regulation of trace elements in recovered fertilizers. Notwithstanding, a shift to circularity of P in the Nordic countries is possible but requires cooperation in the P-chain, from fertilizer producers, through agriculture and food industry to wastewater and waste management facilities. Future research should focus on life cycle analysis and region-specific innovative solutions to bring deeper insights into the development of P-recovery technologies in Nordic countries.

References

Baltic Manure Business Opportunities, Sustainable manure management in the Baltic Sea Region, Baltic Forum for Innovative Technologies for Sustainable Manure Management (2013)

Blengini GA, Mathieux F, Mancini L, Nyberg M, Cavaco Viegas H, Salminen J, Garbarino E, Orveillion G, Saveyn H (2019) Recovery of critical and other raw materials from mining waste and landfills. JRC Sci Policy Rep Eur Comm

Bossier S, Nielsen JR, Almroth-Rosell E, Höglund A, Bastardie F, Neuenfeldt S, Wåhlström I, Christensen A (2021) Integrated ecosystem impacts of climate change and eutrophication on main Baltic fishery resources. Ecol Modell. https://doi.org/10.1016/j.ecolmodel.2021.109609

Brod E, Øgaard AF (2021) Closing global P cycles: the effect of dewatered fish sludge and manure solids as P fertiliser. Waste Manag 135:190–198

Buckwell A, Nadeu E (2016) Nutrient Recovery and Reuse (NRR ) in European agriculture A review of the issues, opportunities, and actions. Brussels

Carmo FF, Lanchotti AO, Kamino LHY (2020) Mining waste challenges: environmental risks of gigatons of mud, dust and sediment in megadiverse regions in Brazil. Sustainability 12:8466

Chowdhury RB, Moore GA, Weatherley AJ, Arora M (2017) Key sustainability challenges for the global phosphorus resource, their implications for global food security, and options for mitigation. J Clean Prod 140:945–963

Cooper J, Lombardi R, Boardman D, Carliell-marquet C (2011) The future distribution and production of global phosphate rock reserves, "Resources. Conserv Recycl 57:78–86

Cordell D, Drangert J-O, White S (2009) The story of phosphorus: global food security and food for thought. Glob Environ Chang 19:292–305

Cordell D, Neset TSS, Prior T (2012) The phosphorus mass balance: Identifying “hotspots” in the food system as a roadmap to phosphorus security. Curr Opin Biotechnol 23:839–845

Cordell D, Rosemarin A, Schröder JJ, Smit AL (2011) Towards global phosphorus security: a systems framework for phosphorus recovery and reuse options. Chemosphere 84:747–758

Cordell D, White S (2014) Life’s Bottleneck: sustaining the World’s phosphorus for a food secure future. Annu Rev Environ Resour. https://doi.org/10.1146/annurev-environ-010213-113300

Dagerskog L, Olsson O (2020) Swedish sludge management at the crossroads. Stockholm Environment Institute

van Dijk KC, Lesschen JP, Oenema O (2016) Phosphorus flows and balances of the European Union Member States. Sci Total Environ 542:1078–1093

Egle L, Rechberger H, Krampe J, Zessner M (2016) Phosphorus recovery from municipal wastewater: an integrated comparative technological, environmental and economic assessment of P recovery technologies. Sci Total Environ 571:522–542

Egle L, Rechberger H, Zessner M (2015) Overview and description of technologies for recovering phosphorus from municipal wastewater. Resour Conserv Recycl 105:325–346

Erisman JW, Sutton MA, Galloway J, Klimont Z, Winiwarter W (2008) How a century of ammonia synthesis changed the world. Nat Geosci 1:636–639

European Commission (2011) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions Roadmap to a Resource E_cient Europe

European Commission (2013) EC Consultative Communication on the Sustainable Use of Phosphorus

European Commission (2015) Circular approaches to phosphorus: from research to deployment

European Commission (2018) European Commission, Report on Critical Raw Materials and the Circular Economy

European Sustainable Phosphorus platform (2021) ESPP - DPP - NNP phosphorus recovery technology catalogue

European Sustainable Phosphorus Platform (2021) 4th Phosphorus in Europe Research Meeting (PERM)

European Sustainable Phosphorus Platform (2021) New phosphate production planned in Sweden

Eurostat (2020) Agri-environmental indicator - mineral fertiliser consumption

Fertilizer Europe/IFA (2018) Fertlizer Production

Finnish mineral group (2020) Finnish Mineral Group has acquired the rights to the Sokli mining project from Yara Suomi Oy

Fleming-Lehtinen V, Andersen JH, Carstensen J, Łysiak-Pastuszak E, Murray C, Pyhälä M, Laamanen M (2015) Recent developments in assessment methodology reveal that the Baltic Sea eutrophication problem is expanding. Ecol Indic 48:380–388

Geological Finland Survey of Stakeholder (2015) Finland’s phosphorus resources are more important than ever, Geo-Foorumi-GTK

Haldar SK (2018) Mineral processing, In: Miner. Explor., Second, Elsevier, pp. 259–290

Hamilton HA, Brod E, Hanserud OS, Gracey EO, Vestrum MI, Bøen A, Steinhoff FS, Müller DB, Brattebø H (2016) Investigating cross-sectoral synergies through integrated aquaculture, fisheries, and agriculture phosphorus assessments: a case study of Norway. J Ind Ecol 20:867–881

Hitzl M, Corma A, Pomares F, Renz M (2015) The hydrothermal carbonization (HTC) plant as a decentral biorefinery for wet biomass. Catal Today 257:154–159

Hosseinian A, Ylä-Mella J, Pongrácz E (2021) Current status of circular economy research in Finland. Resources. https://doi.org/10.3390/resources10050040

Iwaniec DM, Metson GS, Cordell D (2016) P-FUTURES: towards urban food & water security through collaborative design and impact. Curr Opin Environ Sustain 20:1–7

Jia B, Tang Y, Tian L, Franz L, Alewell C, Huang JH (2015) Impact of fish farming on phosphorus in reservoir sediments. Sci Rep 5:1–11

Kabbe C (2018) Overview of phosphorus recovery from the wastewater stream facilities operating or under construction. Phosphorus Recovery Recycl

Kaza S, Yao L, Bhada-Tata P, Van Woerden F (2018) What a Waste 2.0 Introduction A Global Snapshot of Solid Waste Management to 2050.” Overview booklet

Köninger J, Lugato E, Panagos P, Kochupillai M, Orgiazzi A, Briones MJI (2021) Manure management and soil biodiversity: towards more sustainable food systems in the EU. Agric Syst 194:103251

Li X, Zhang D, Yang TY, Bryden WL (2016) Phosphorus bioavailability: a key aspect for conserving this critical animal feed resource with reference to broiler nutrition. Agriculture. https://doi.org/10.3390/agriculture6020025

Lorick D, Harder R, Svanström M (2021) A circular economy for phosphorus in Sweden-is it possible? Sustainability. https://doi.org/10.3390/su13073733

Lyon C, Cordell D, Jacobs B, Martin-Ortega J, Marshall R, Camargo-Valero MA, Sherry E (2020) Five pillars for stakeholder analyses in sustainability transformations: the global case of phosphorus. Environ Sci Policy 107:80–89

Marttinen S, Venelampi O, Iho A, Koikkalainen K, Lehtonen E, Luostarinen S, Rasa K, Sarvi M, Tampio E, Turtola E, Yli K, Kauppila J, Koskiaho J, Valve H, Lantto R, Oasmaa A (2018) Towards a breakthrough in nutrient recycling Towards a breakthrough in nutrient recycling, State-of-the-art and recommendations for developing policy instruments in Finland

Mayer BK, Baker LA, Boyer TH, Drechsel P, Gifford M, Hanjra MA, Parameswaran P, Stoltzfus J, Westerhoff P, Rittmann BE (2016) Total value of phosphorus recovery. Environ Sci Technol 50:6606–6620

Metson GS, MacDonald GK, Haberman D, Nesme T, Bennett EM (2016) Feeding the corn belt: opportunities for phosphorus recycling in U.S. agriculture. Sci Total Environ 542:1117–1126

Mew MC (2016) Phosphate rock costs, prices and resources interaction. Sci Total Environ 542:1008–1012

Mininni G, Blanch AR, Lucena F, Berselli S (2015) EU policy on sewage sludge utilization and perspectives on new approaches of sludge management. Environ Sci Pollut Res 22:7361–7374

Mustapha A, El Bakali M (2021) Phosphorus waste production in fish farming a potential for reuse in integrated aquaculture agriculture. Int J Environ Agric Res 7:05–13

Nättorp A (2015) European Sustainable Phosphorus Platform (ESPP)

Nättorp A, Kabbe C, Matsubae K, Ohtake H (2019) Phosphorus Recycling in Europe and Japan. In: Ohtake H, Tsuneda S (eds) Phosphorus Recovery and Recycling. Springer, Singapore, pp 29–45

Oelkers EH, Valsami-Jones E (2008) Phosphate mineral reactivity and global sustainability. Elements 4:83–87

Ohtake H, Tsuneda S. Phosphorus recycling in Europe and Japan. In: Phosphorus Recovery and Recycling 4th ed., Springer, n.d

Oliveira V, Labrincha J, Dias-Ferreira C (2018) Extraction of phosphorus and struvite production from the anaerobically digested organic fraction of municipal solid waste. J Environ Chem Eng 6:2837–2845

Oliver-Tomas B, Hitzl M, Owsianiak M, Renz M (2019) Evaluation of hydrothermal carbonization in urban mining for the recovery of phosphorus from the organic fraction of municipal solid waste. Resour Conserv Recycl 147:111–118

Orris BGJ, Chernoff CB (2002) Data set of World phosphate mines, deposits, and occurrences — Part B. Location and Mineral Economic Data

Reijnders L (2014) Phosphorus resources, their depletion and conservation, a review. Resour Conserv Recycl 93:32–49

Rockström J, Steffen W, Noone K, Persson Å, Chapin FS, Lambin ELF, Marten TM, Folke SC, Schellnhuber HJ, Nykvist B, de Wit CA, Hughes T, van der Leeuw S, Rodhe H, Sörlin S, Costanza PSKR, Svedin U, Falkenmark M, Karlberg L, Corell RW, Fabry VJ, Hansen J, Walker B, Liverman D, Richardson K, Crutzen P, Foley JA (2009) A safe operating space for humanity. Nature 461:472–475

Roy ED (2016) Phosphorus recovery and recycling with ecological engineering: a review. Ecol Eng Ecol Eng 98:213–227

Sarvi M, Ylivainio K, Turtola E (2017) Report on compliance of recycled product with present EU fertilizer regulations

Scholz RW, Wellmer FW (2018) Although there is no physical short-term scarcity of phosphorus, its resource efficiency should be improved. J Ind Ecol 00:1–6

Schröder A, Cordell JJ, Smit D, Rosemarin AL (2010) Sustainable use of phosphorus

Singh S, Sukla LB, Goyal SK (2020) Mine waste & circular economy. Mater Today Proc 30:332–339

Smol M, Preisner M, Bianchini A, Rossi J, Hermann L, Schaaf T, Kruopiene J, Pamakštys K, Klavins M, Ozola-Davidane R, Kalnina D, Strade E, Voronova V, Pachel K, Yang X, Steenari BM, Svanström M (2020) Strategies for sustainable and circular management of phosphorus in the Baltic sea region: the holistic approach of the InPhos project. Sustain. https://doi.org/10.3390/su12062567

Steffen W, Richardson K, Rockstrom J, Cornell SE, Fetzer I, Bennett EM, Biggs R, Carpenter SR, de Vries W, de Wit CA, Folke C, Gerten D, Heinke J, Mace GM, Persson LM, Ramanathan V, Reyers B, Sorlin S (2015) Planetary boundaries: guiding human development on a changing planet. Science (80-) 347:1259855

U.S Geological Survey (USGS) (2018) Phosphate rock statistics and information

U.S Geological Survey (USGS) (2021) Phosphate rock statistics and information

Verbeeck M, Salaets P, Smolders E (2020) Trace element concentrations in mineral phosphate fertilizers used in Europe: a balanced survey. Sci Total Environ 712:136419

Van Vuuren DP, Bouwman AF, Beusen AHW (2010) Phosphorus demand for the 1970–2100 period: a scenario analysis of resource depletion. Glob Environ Chang 20:428–439

Walan P, Davidsson S, Johansson S, Höök M (2014) Resources, conservation and recycling phosphate rock production and depletion: regional disaggregated modeling and global implications. Resour Conserv Recycl 93:178–187

YARA (2019) Crop Nutrition Company for the Future

Yara Suomi (2015) The Silinjärvi mine

Zhou K (2017) Phosphorus recovery from wastewater and sludge: Concept for different regional conditions vorgelegt von, Technischen Universität Berlin

Metaller och mineral i gruvavfall (2019)

Acknowledgements

The authors acknowledge the funding of the Academy of Finland provided for the TRANSCIRC project (nro 310407).

Funding

Open Access funding provided by University of Oulu including Oulu University Hospital.

Author information

Authors and Affiliations

Contributions

AH: conceptualization, methodology, writing—original draft, formal analysis, writing: review and editing. AP: conceptualization, methodology, writing: review and editing, supervision. JYM: conceptualization, methodology, writing: review and editing, supervision. EP: conceptualization, methodology, writing: review and editing, supervision, project administration and funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hosseinian, A., Pettersson, A., Ylä-Mella, J. et al. Phosphorus recovery methods from secondary resources, assessment of overall benefits and barriers with focus on the Nordic countries. J Mater Cycles Waste Manag 25, 3104–3116 (2023). https://doi.org/10.1007/s10163-023-01747-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01747-z