Abstract

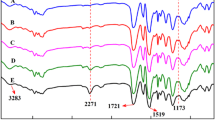

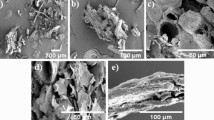

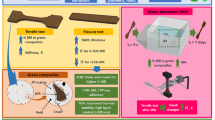

The use of lignocellulosic fibers as fillers in polymer matrices has aroused the interest of the scientific community and industrial sectors. In Brazil, the high macadamia consumption has generated a significant amount of residues that are incorrectly discharged. Thus, the revalorization of macadamia residues (MR) as filler in castor oil-based polyurethane (PU) foams with different particle sizes (28 and 35 mesh) and filler contents (5–20%wt) was evaluated. The MR, neat PU, and their biocomposites were characterized by Spectroscopy Fourier-transform infrared spectroscopy (FTIR), Optical microscopy (OM), Scanning electron microscopy (SEM), apparent density, contact angle, water adsorption experiments, X-Ray diffraction analysis (XRD), Thermogravimetry (TGA), and mechanical tests. The insertion of MR in the PU matrix provided a nucleating effect producing greater density foams and smaller pore sizes compared to neat PU. Specimens of higher MR contents were highlighted. These biocomposites presented a good hydrophobic character, a low water permeation, and a strong interaction between MR/PU, resulting in biocomposites of good thermal stability and compressive strength. Regarding the statistical study, it was observed that the different MR sizes induced the formation of small pores statistically distinct. Besides, the largest particle (28 mesh) provided better mechanical performance. Therefore, MR as filler in PU foams is a sustainable alternative for the development of materials with several applications.

Similar content being viewed by others

References

Rao IP, Armelin MJA, del Mastro NL (2020) Impact of ionizing radiation on cake from Brazilian macadamia nut (Macadamia integrifolia) after oil extraction. Radiat Phys Chem 172:108813. https://doi.org/10.1016/j.radphyschem.2020.108813

Osaili TM, Bani Odeh WAM, Al Ayoubi M et al (2023) Occurrence of aflatoxins in nuts and peanut butter imported to UAE. Heliyon 9:e14530. https://doi.org/10.1016/j.heliyon.2023.e14530

Zhu X (2023) Demand elasticity of import nuts in Korea. Heliyon 9:e13379. https://doi.org/10.1016/j.heliyon.2023.e13379

(2022) International Nut and Dried Fruit Council

Perdoná MJ, Soratto RP (2015) Higher yield and economic benefits are achieved in the macadamia crop by irrigation and intercropping with coffee. Sci Hortic (Amsterdam) 185:59–67. https://doi.org/10.1016/j.scienta.2015.01.007

Piza PLBT, Moriya LM (2014) Cultivo da macadâmia no Brasil. Rev Bras Frutic 36(1). https://doi.org/10.1590/0100-2945-444/13

dos Santos Andrade L, Silva NGS, de Ornellas Cortat LIC, Mulinari DR (2021) Approach in Macadamia integrifolia residue based low-density polyethylene composites on mechanical and thermal performance. J Appl Polym Sci. https://doi.org/10.1002/app.50613

Gustavo Adolfo GF, Wolf-Anno B, Martin R, Christina S (2022) Co-composting of biochar and nitrogen-poor organic residues: nitrogen losses and fate of polycyclic aromatic hydrocarbons. Waste Manag 143:84–94. https://doi.org/10.1016/j.wasman.2022.02.025

Samaksaman U, Pattaraprakorn W, Neramittagapong A, Kanchanatip E (2021) Solid fuel production from macadamia nut shell: effect of hydrothermal carbonization conditions on fuel characteristics. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-021-01330-2

Wechsler A, Zaharia M, Crosky A et al (2013) Macadamia (Macadamia integrifolia) shell and castor (Rícinos communis) oil based sustainable particleboard: a comparison of its properties with conventional wood based particleboard. Mater Des 50:117–123. https://doi.org/10.1016/j.matdes.2013.03.008

Fan C, Zhang Y (2018) Adsorption isotherms, kinetics and thermodynamics of nitrate and phosphate in binary systems on a novel adsorbent derived from corn stalks. J Geochemical Explor 188:95–100. https://doi.org/10.1016/j.gexplo.2018.01.020

de Cipriano JP, Zanini NC, Dantas IR, Mulinari DR (2019) Mechanical properties of polypropylene composites reinforced with macadamia nutshell fibers. J Renew Mater 7:1047–1053. https://doi.org/10.32604/jrm.2019.00001

Zanini NC, de Souza AG, Barbosa RFS et al (2021) Eco-friendly composites of polyurethane and sheath palm residues. J Cell Plast. https://doi.org/10.1177/0021955X20987150

Mansuri I, Farzana R, Rajarao R, Sahajwalla V (2018) Carbon dissolution using waste biomass—a sustainable approach for iron-carbon alloy production. Metals (Basel). https://doi.org/10.3390/met8040290

de Oliveira BP, Balieiro LCS, Maia LS et al (2022) Eco-friendly polyurethane foams based on castor polyol reinforced with açaí residues for building insulation. J Mater Cycles Waste Manag 24:553–568. https://doi.org/10.1007/s10163-021-01341-1

Bandeira CF, Da CACA, Montoro SR et al (2022) Thermal behavior evaluation of benzoxazine reinforced with macadamiabiomass composites. J Appl Polym Sci 139:1–20. https://doi.org/10.1002/app.52160

Nanni A, Cancelli U, Montevecchi G et al (2021) Functionalization and use of grape stalks as poly(butylene succinate) (PBS) reinforcing fillers. Waste Manag 126:538–548. https://doi.org/10.1016/j.wasman.2021.03.050

Cortat LO, Zanini NC, Barbosa RFS et al (2021) A sustainable perspective for macadamia nutshell residues revalorization by green composites development. J Polym Environ. https://doi.org/10.1007/s10924-021-02080-y

Maia LS, Zanini NC, Camani PH et al (2022) Coffee husks residues incorporated into polyurethane foam towards greener material for diesel S10 and S500 removal and recovery. Ind Crops Prod 189:115747. https://doi.org/10.1016/j.indcrop.2022.115747

Członka S, Strąkowska A, Kairytė A (2020) Effect of walnut shells and silanized walnut shells on the mechanical and thermal properties of rigid polyurethane foams. Polym Test. https://doi.org/10.1016/j.polymertesting.2020.106534

Sylwia C, Anna S, Kairyte Agnè KA (2020) Nutmeg filler as a natural compound for the production of polyurethane composite foams with antibacterial and anti-aging properties. Polym Test 86:1–13. https://doi.org/10.1016/j.polymertesting.2020.106479

Lei W, Zhou X, Fang C et al (2019) New approach to recycle office waste paper: reinforcement for polyurethane with nano cellulose crystals extracted from waste paper. Waste Manag 95:59–69. https://doi.org/10.1016/j.wasman.2019.06.003

Maia LS, Zanini NC, Claro AM et al (2021) Eco-friendly foams of castor oil based-polyurethane with Artemisia residue fillers for discarded vegetable oil sorption. J Appl Polym Sci. https://doi.org/10.1002/app.51259

Martins L, Zanini N, Pinheiro L, Mulinari D (2021) Valorization of banana peel waste used as filler in castor oil polyurethane foam for vegetal oil sorption. J Nat Fibers 00:1–12. https://doi.org/10.1080/15440478.2021.1958414

Gandara M, Mulinari DR, Monticeli FM et al (2020) Sugarcane bagasse fibers reinforced in polyurethane for sorption of vegetal oil. J Nat Fibers 00:1–12. https://doi.org/10.1080/15440478.2019.1710653

Silva NGS, Cortat LICO, Orlando D, Mulinari DR (2020) Evaluation of rubber powder waste as reinforcement of the polyurethane derived from castor oil. Waste Manag 116:131–139. https://doi.org/10.1016/j.wasman.2020.07.032

Martins LS, Zanini NC, Maia LS et al (2021) Crude oil and S500 diesel removal from seawater by polyurethane composites reinforced with palm fiber residues. Chemosphere 267:129288. https://doi.org/10.1016/j.chemosphere.2020.129288

Gama N, Godinho B, Barros-Timmons A, Ferreira A (2022) PU/lignocellulosic composites produced from recycled raw materials. J Polym Environ 30:194–205. https://doi.org/10.1007/s10924-021-02191-6

Cheng Y, Xu Z, Chen S et al (2021) The influence of closed pore ratio on sound absorption of plant-based polyurethane foam using control unit model. Appl Acoust 180:108083. https://doi.org/10.1016/j.apacoust.2021.108083

Maia LS, Zanini NC, de Souza AG et al (2022) Effective oil spill cleaned up with environmentally friendly foams filled with eucalyptus charcoal residue. Iran Polym J (English Ed) 31:383–398. https://doi.org/10.1007/s13726-021-00997-8

Costa ILM, Monticeli FM, Mulinari DR (2020) Polyurethane foam reinforced with fibers pineaplle crown biocomposites for sorption of vegetable oil. Fibers Polym 21:1832–1840. https://doi.org/10.1007/s12221-020-9979-4

Martins LS, Silva NGS, Claro AM et al (2021) Insight on açaí seed biomass economy and waste cooking oil: Eco-sorbent castor oil-based. J Environ Manage 293:112803. https://doi.org/10.1016/j.jenvman.2021.112803

Costa ILM, Martins LS, Maia LS, Mulinari DR (2021) Impact of the Jatoba shell residue amount on polyurethane foams based on castor polyol. J Mater Cycles Waste Manag 23:1431–1444. https://doi.org/10.1007/s10163-021-01224-5

Vieira Amorim F, José Ribeiro Padilha R, Maria Vinhas G et al (2021) Development of hydrophobic polyurethane/castor oil biocomposites with agroindustrial residues for sorption of oils and organic solvents. J Colloid Interface Sci 581:442–454. https://doi.org/10.1016/j.jcis.2020.07.091

Song X, He W, Qin H, Yang S (2020) Fused deposition modeling of poly (lactic acid)/macadamia composites—thermal. Mech Mater (Basel) 13:258

Martins LS, Silva NGS, Claro AM et al (2021) Insight on açai seed biomass economy and waste cooking oil: eco-sorbent castor oil-based. J Environ Manag 293:112803. https://doi.org/10.1016/j.jenvman.2021.112803

Jabber LJY, Grumo JC, Alguno AC et al (2021) Influence of cellulose fibers extracted from pineapple (Ananas comosus) leaf to the mechanical properties of rigid polyurethane foam. Mater Today Proc 46:1735–1739. https://doi.org/10.1016/j.matpr.2020.07.566

Martins LS, Monticelli FM, Mulinari DR (2020) Influence of the granulometry and fiber content of palm residues on the diesel S-10 oil sorption in polyurethane /palm fiber biocomposites. Results Mater 8:100143. https://doi.org/10.1016/j.rinma.2020.100143

Sair S, Oushabi A, Kammouni A et al (2018) Mechanical and thermal conductivity properties of hemp fiber reinforced polyurethane composites. Case Stud Constr Mater 8:203–212. https://doi.org/10.1016/j.cscm.2018.02.001

Tiuc AE, Nemeş O, Vermeşan H, Toma AC (2019) New sound absorbent composite materials based on sawdust and polyurethane foam. Compos Part B Eng 165:120–130. https://doi.org/10.1016/j.compositesb.2018.11.103

Zanini NC, Barbosa RFS, de Souza AG et al (2021) Revaluation of Australian palm residues in polypropylene composites: statistical influence of fiber treatment. J Compos Mater 55:813–826. https://doi.org/10.1177/0021998320960534

Mustapha AN, Zhang Y, Zhang Z et al (2021) Taguchi and ANOVA analysis for the optimization of the microencapsulation of a volatile phase change material. J Mater Res Technol 11:667–680. https://doi.org/10.1016/j.jmrt.2021.01.025

Sabu M, Ruban YJV, Ginil MS (2020) Effect of organoclay on contact angle, thermal and mechanical properties of filled epoxy composites. Mater Today Proc 41:549–556. https://doi.org/10.1016/j.matpr.2020.05.248

Amri MR, Guan CT, Osman Al-Edrus SS et al (2021) Effect of cellulose nanofibrils on the properties of jatropha oil-basedwaterborne polyurethane nanocomposite film. Polymers (Basel) 13:1–14. https://doi.org/10.3390/polym13091460

Zhu R, Wang X, Yang J et al (2017) Influence of hard segments on the thermal, phase-separated morphology, mechanical, and biological properties of polycarbonate urethanes. Appl Sci. https://doi.org/10.3390/APP7030306

Sair S, Mansouri S, Tanane O et al (2019) Alfa fiber-polyurethane composite as a thermal and acoustic insulation material for building applications. SN Appl Sci 1:1–13. https://doi.org/10.1007/s42452-019-0685-z

Jamaluddin JF, Firouzi A, Islam MR, Yahaya ANA (2020) Effects of luffa and glass fibers in polyurethane-based ternary sandwich composites for building materials. SN Appl Sci 2:1–10. https://doi.org/10.1007/s42452-020-3037-0

Morifi E, Chimuka L, Richards H et al (2022) Modified Macadamia nutshell nanocomposite for selective removal of hexavalent chromium from wastewater. S Afr J Chem Eng 42:176–187. https://doi.org/10.1016/j.sajce.2022.09.001

Prasad PS, Gomathi T, Sudha PN et al (2022) Biosilica/silk fibroin/polyurethane biocomposite for toxic heavy metals removal from aqueous streams. Environ Technol Innov 28:102741. https://doi.org/10.1016/j.eti.2022.102741

Dzulkifli MH, Majid RA, Yahya MY (2022) Reclaimed rockwool fibers for thermally stable palm oil-based polyurethane foam. J Mater Cycles Waste Manag 24:2416–2425. https://doi.org/10.1007/s10163-022-01488-5

Rizwan M, Zia KM, Javaid MA et al (2021) Synthesis and molecular characterization of chitosan/alginate blends based polyurethanes biocomposites. Int J Biol Macromol 180:324–331. https://doi.org/10.1016/j.ijbiomac.2021.03.064

Ferreira FLQ, Lopes MC, Lopes APM et al (2019) Evaluation of the dispersion of carbon nanotubes in an elastomeric polyurethane and fatigue test. Polimeros 29:1–7. https://doi.org/10.1590/0104-1428.02718

Moghim MH, Keshavarz M, Zebarjad SM (2019) Effect of SiO2 nanoparticles on compression behavior of flexible polyurethane foam. Polym Bull 76:227–239. https://doi.org/10.1007/s00289-018-2384-0

Mustafov SD, Sen F, Seydibeyoglu MO (2020) Preparation and characterization of diatomite and hydroxyapatite reinforced porous polyurethane foam biocomposites. Sci Rep 10:1–9. https://doi.org/10.1038/s41598-020-70421-3

de Avila DR, Magalhães WLE, Petzhold CL, Amico SC (2018) Forest-based resources as fillers in biobased polyurethane foams. J Appl Polym Sci 135:1–7. https://doi.org/10.1002/app.45684

He H, Zhang T, Yang Y (2021) A facile way to modify carbon fibers and its effect on mechanical properties of epoxy composites. J Mater Res Technol 10:164–174. https://doi.org/10.1016/j.jmrt.2020.12.007

Dinesh S, Elanchezhian C, Devaraju A et al (2020) Comparative study of mechanical and morphological analysis of NaOH treated and untreated banana fiber reinforced with epoxy hybrid composite. Mater Today Proc 39:861–867. https://doi.org/10.1016/j.matpr.2020.10.652

Acknowledgements

This research was funded by Fundação Carlos Chagas de Amparo à Pesquisa do Estado do Rio de Janeiro—FAPERJ (E-26/210.368/2018 and E-26/210.450/2021).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maia, L.S., Balieiro, L.C.S., Teixeira, E.J.O. et al. Revalorization of Macadamia nutshell residue as a filler in eco-friendly castor polyol-based polyurethane foam. J Mater Cycles Waste Manag 25, 2295–2311 (2023). https://doi.org/10.1007/s10163-023-01693-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01693-w