Abstract

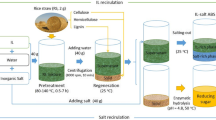

In the present work, mango pit was used to study the feasibility of converting ionic liquid-pretreated biomass into biofuel and activated biochar by using pyrolysis temperature as a key variable. Ionic liquid 1-butyl-3-methylimidazolium chloride ([Bmim]Cl) was used as a green solvent to dissolve mango pit. The impact of [Bmim]Cl on the pyrolysis properties at peak DTG temperature was investigated. Pretreatment with [Bmim]Cl was observed to slightly enhance biochar yield, while somewhat decreasing bio-oil and biogas yields. The yield of hydrogen and methane, as well as the generation of phenolic and alcoholic bio-oils, are increased by [Bmim]Cl pretreatment. [Bmim]Cl pretreatment was determined to promote the formation of pore structure, a greater number of pores were opened, and the BET surface areas increased 24 times. The pyrolysis kinetics were calculated using the DAEM model. The results showed that [Bmim]Cl pretreatment resulted in lower activation energy and a high amount of fraction mass conversion at low temperatures. As a result, the results showed that pyrolysis of [Bmim]Cl-pretreated biomass did not require high temperatures, and that it is possible to convert ionic liquid pretreatment biomass into high-quality biofuel and active biochar by controlling the pyrolysis temperature.

Graphical abstract

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Wildschut J, Smit AT, Reith JH, Huijgen WJ (2013) Ethanol-based organosolv fractionation of wheat straw for the production of lignin and enzymatically digestible cellulose. Bioresour Technol 135:58–66

Paul SK, Chakraborty S (2018) Microwave-assisted ionic liquid-mediated rapid catalytic conversion of non-edible lignocellulosic Sunn hemp fibres to biofuels. Bioresour Technol 253:85–93

Sun X, Atiyeh HK, Li M, Chen Y (2020) Biochar facilitated bioprocessing and biorefinery for productions of biofuel and chemicals: a review. Bioresour Technol 295:122252–122264

Yang X, Kang K, Qiu L, Zhao L, Sun R (2020) Effects of carbonization conditions on the yield and fixed carbon content of biochar from pruned apple tree branches. Renew Energ 146:1691–1699

Ashokkumar V, Chen W-H, AaH A-M, Kumar G, Sathishkumar P, Pandian S, Ani FN, Ngamcharussrivichai C (2019) Bioenergy production and metallic iron (Fe) conversion from Botryococcus sp. cultivated in domestic wastewater: Algal biorefinery concept. Energ Convers Manage 196:1326–1334

Ansari KB, Gaikar VG (2019) Investigating production of hydrocarbon rich bio-oil from grassy biomass using vacuum pyrolysis coupled with online deoxygenation of volatile products over metallic iron. Renew Energ 130:305–318

Barbanera M, Pelosi C, Taddei AR, Cotana F (2018) Optimization of bio-oil production from solid digestate by microwave-assisted liquefaction. Energ Convers Manage 171:1263–1272

Barskov S, Zappi M, Buchireddy P, Dufreche S, Guillory J, Gang D, Hernandez R, Bajpai R, Baudier J, Cooper R, Sharp R (2019) Torrefaction of biomass: a review of production methods for biocoal from cultured and waste lignocellulosic feedstocks. Renew Energ 142:624–642

Badawi MA (2019) Production of biochar from date palm fronds and its effects on soil properties. Mater Res Proceed 11:159–168

Alsewaileh AS, Usman AR, Al-Wabel MI (2019) Effects of pyrolysis temperature on nitrate-nitrogen (NO3(-)-N) and bromate (Br O3(-)) adsorption onto date palm biochar. J Environ Manage 237:289–296

Aceña-Heras S, Novak J, Cayuela ML, Peñalosa JM, Moreno-Jiménez E (2019) Influence of pyrolyzed grape-seeds/sewage sludge blends on the Availability of P Fe, Cu, As and Cd to Maize. Agronomy 9:406–423

Adeniyi AG, Ighalo JO, Onifade DV (2019) Production of bio-char from plantain (musa Paradisiaca) fibers using an updraft biomass gasifier with retort heating. Combust Sci Technol 193:60–74

Awasthi A, Singh G, Dhyani V, Kumar J, Reddy YS, Adarsh VP, Puthiyamadam A, Mullepureddy KK, Sukumaran RK, Ummalyma SB, Sahoo D, Bhaskar T (2019) Co-pyrolysis of phumdi and para grass biomass from Loktak Lake. Bioresour Technol 285:121308–121313

Agar DA, Kwapinska M, Leahy JJ (2018) Pyrolysis of wastewater sludge and composted organic fines from municipal solid waste: laboratory reactor characterisation and product distribution. Environ Sci Pollut Res Int 25:35874–35882

Bach Q-V, Chen W-H, Eng CF, Wang C-W, Liang K-C, Kuo J-Y (2019) Pyrolysis characteristics and non-isothermal torrefaction kinetics of industrial solid wastes. Fuel 251:118–125

Cheng Y-S, Mutrakulcharoen P, Chuetor S, Cheenkachorn K, Tantayotai P, Panakkal EJ, Sriariyanun M (2020) Recent situation and Progress in biorefining process of lignocellulosic biomass: toward green economy. Appl Sci Eng Prog 13:299–311

Sriariyanun M, Heitz JH, Yasurin P, Asavasanti S, Tantayota P (2019) Itaconic acid: a promising and sustainable platform chemical? Appl Sci Eng Prog 12:75–82

Song L, Li Z, Zhang D, Liu D, Wu P, Li Q (2017) Investigations on co-refining of biomass with vacuum gas oil in the presence of hydro-donor. Energ Convers Manage 148:1225–1232

Sorn V, Chang KL, Phitsuwan P, Ratanakhanokchai K, Dong CD (2019) Effect of microwave-assisted ionic liquid/acidic ionic liquid pretreatment on the morphology, structure, and enhanced delignification of rice straw. Bioresour Technol 293:121929–121936

Lin J, Sun S, Ma R, Fang L, Zhang P, Qu J, Zhang X, Geng H, Huang X (2018) Characteristics and reaction mechanisms of sludge-derived bio-oil produced through microwave pyrolysis at different temperatures. Energ Convers Manage 160:403–410

Reshad AS, Tiwari P, Goud VV (2019) Thermal and co-pyrolysis of rubber seed cake with waste polystyrene for bio-oil production. J Anal Appl Pyrol 139:333–343

Dyer AC, Nahil MA, Williams PT (2022) Biomass:polystyrene co-pyrolysis coupled with metal-modified zeolite catalysis for liquid fuel and chemical production. J Mater Cycles Waste Manage 24:477–490

Lan Z, Chen C, Rezaei Rashti M, Yang H, Zhang D (2018) High pyrolysis temperature biochars reduce nitrogen availability and nitrous oxide emissions from an acid soil. GCB Bioenergy 10:930–945

Yuan P, Wang J, Pan Y, Shen B, Wu C (2019) Review of biochar for the management of contaminated soil: preparation, application and prospect. Sci Total Environ 659:473–490

Dieguez-Alonso A, Anca-Couce A, Fristak V, Moreno-Jimenez E, Bacher M, Bucheli TD, Cimo G, Conte P, Hagemann N, Haller A, Hilber I, Husson O, Kammann CI, Kienzl N, Leifeld J, Rosenau T, Soja G, Schmidt HP (2019) Designing biochar properties through the blending of biomass feedstock with metals: Impact on oxyanions adsorption behavior. Chemosphere 214:743–753

Lebrun M, Miard F, Renouard S, Nandillon R, Scippa GS, Morabito D, Bourgerie S (2018) Effect of Fe-functionalized biochar on toxicity of a technosol contaminated by Pb and As: sorption and phytotoxicity tests. Environ Sci Pollut Res Int 25:33678–33690

Cha JS, Park SH, Jung S-C, Ryu C, Jeon J-K, Shin M-C, Park Y-K (2016) Production and utilization of biochar: a review. J Ind Eng Chem 40:1–15

Zhang T, Walawender W, Fan L, Fan M, Daugaard D, Brown R (2004) Preparation of activated carbon from forest and agricultural residues through CO activation. Chem Eng J 105:53–59

Dou G, Jiang Z (2019) Preparation of sodium humate-modified biochar absorbents for water treatment. ACS Omega 4:16536–16542

Thomas W (1999) Room-temperature ionic liquids solvents for synthesis and catalysis,. Chem Rev 99:2071–2083

Hallett JP, Welton T (2011) Room-temperature ionic liquids: solvents for synthesis and catalysis. 2. Chem Rev 111:3508–3576

Elgharbawy AA, Alam MZ, Moniruzzaman M, Goto M (2016) Ionic liquid pretreatment as emerging approaches for enhanced enzymatic hydrolysis of lignocellulosic biomass. Biochem Eng J 109:252–267

Padrino B, Lara-Serrano M, Morales-delarosa S, Campos-Martin JM, Fierro JLG, Martinez F, Melero JA, Puyol D (2018) Resource recovery potential from lignocellulosic feedstock upon lysis with ionic liquids. Front Bioeng Biotechnol 6:119–131

Moniruzzaman M, Ono T (2013) Separation and characterization of cellulose fibers from cypress wood treated with ionic liquid prior to laccase treatment. Bioresour Technol 127:132–137

Singh JK, Sharma RK, Ghosh P, Kumar A, Khan ML (2018) Imidazolium based ionic liquids: a promising green solvent for water hyacinth biomass deconstruction. Front Chem 6:548

Zhen L, Hang X, Airong X (2014) Selective dissolution for the components of lignocellulose with ionic liquids. J Chem Pharm Res 6:874–879

Fort DA, Remsing RC, Swatloski RP, Moyna P, Moyna G, Rogers RD (2007) Can ionic liquids dissolve wood? processing and analysis of lignocellulosic materials with 1-n-butyl-3-methylimidazolium chloride. Green Chem 9:63–69

P. SR, K. SS, D. HJ, D. RR (2002) Dissolution of Cellose with Ionic Liquids, J Am Chem Soc 124: 4974-4975

Ansari M, Zafar U, Ejaz U, Sohail M, Pirzada A, Aman A (2021) Comparison of composting of chemically pretreated and fermented sugarcane bagasse for zero-waste biorefinery. J Mater Cycles Waste Manage 23:911–921

Mahmood H, Moniruzzaman M, Iqbal T, Yusup S, Rashid M, Raza A (2019) Comparative effect of ionic liquids pretreatment on thermogravimetric kinetics of crude oil palm biomass for possible sustainable exploitation. J Mol Liq 282:88–96

Muhammad N, Omar WN, Man Z, Bustam MA, Rafiq S, Uemura Y (2012) Effect of ionic liquid treatment on pyrolysis products from bamboo. Ind Eng Chem Res 51:2280–2289

Muhammad N, Man Z, Bustam Khalil MA (2011) Ionic liquid—a future solvent for the enhanced uses of wood biomass. Eur J Wood Wood Prod 70:125–133

Dastyar W, Raheem A, Zhao M, Yuan W, Li H, Ting ZJ (2019) Effects of ionic liquid-assisted pretreatment of heavy metal-contaminated biomass on the yield and composition of syngas production using noncatalytic and catalytic pyrolysis and gasification processes. ACS Sustainable Chem Eng 7:18303–18312

Arslanoğlu E, Eren MŞA, Arslanoğlu H, Çiftçi H (2021) Fabrication, characterization, and adsorption applications of low-cost hybride activated carbons from peanut shell-vinasse mixtures by one-step pyrolysis. Biomass Convers Bior 13:2321–2335

Chukwuneke JL, Ewulonu MC, Chukwujike IC, Okolie PC (2019) Physico-chemical analysis of pyrolyzed bio-oil from swietenia macrophylla (mahogany) wood. Heliyon 5:1790–1796

Munir S, Daood SS, Nimmo W, Cunliffe AM, Gibbs BM (2009) Thermal analysis and devolatilization kinetics of cotton stalk, sugar cane bagasse and shea meal under nitrogen and air atmospheres. Bioresour Technol 100:1413–1418

Yu C, Luo Z, Fang M, Liao Y, Wang S, Cen K (2002) An improved kinetic model for cellulose pyrolysis. J Zhejiang Univ (Eng Sci) 36:509–515

Tao W, Zhang P, Yang X, Li H, Liu Y, Pan B (2021) An integrated study on the pyrolysis mecanism of peanut shell based on the kinetic analysis and solid/gas characterization. Bioresour Technol 329:124860–124868

Dou G, Goldfarb JL (2017) In situ upgrading of pyrolysis biofuels by bentonite clay with simultaneous production of heterogeneous adsorbents for water treatment. Fuel 195:273–283

Acknowledgements

The article was made with the support of the National Natural Science Foundation of China (No. 52174213) and the Priority Academic Program Development of Jiangsu Higher Education Institutions.

Author information

Authors and Affiliations

Contributions

GD: conceptualization, methodology, validation, funding acquisition, writing—review and editing. LZ: investigation, data curation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dou, G., Zhang, L. Study of the pyrolysis of ionic liquid [Bmim]Cl-pretreated mango pit at low temperature. J Mater Cycles Waste Manag 25, 2326–2337 (2023). https://doi.org/10.1007/s10163-023-01684-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01684-x