Abstract

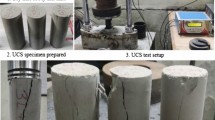

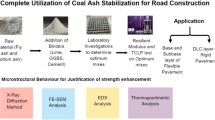

This paper utilizes desulfurization ash (DA), fly ash (FA) and ordinary Portland cement (OPC) to prepare unfired high-strength road-base stones by static pressure forming. The compressive strength after 28 days curing of road-base stones reaches 82.9 MPa for 30% DA, 52.5% FA and 17.5% OPC composition. The XRD, FTIR, and TG prove that the hydration reaction between DA, FA and OPC can produce a large amount of structurally dense C-S-H gels and Ettringite in the road-base stones, and the static pressure forming can increase the contact area between particles, which continuously enhance the cementitious activity of the road-base stones, resulting in such high strength. In addition, the road-base stones utilize 82.5% solid waste, meanwhile save about 49.7 ¥/ton compared to that of using natural materials. Therefore, this work not only provides an ecological and economic way for large-scale utilization of DA and FA in road construction, but also provides a novel approach to guide other industrial solid wastes recycling.

Similar content being viewed by others

References

Hao Y, Wu SM, Pan Y, Li Q, Zhou JZ, Xu YB, Qian GR (2016) Characterization and leaching toxicities of mercury in flue gas desulfurization gypsum from coal-fired power plants in China. Fuel 177:157–163

Zhai M, Guo L, Sun L, Zhang Y, Dong P, Shi WQ (2017) Desulfurization performance of fly ash and CaCO3 compound absorbent. Powder Technol 305:553–561

Wang YF, Zhang YD, Long HM, Qian LX, Luo YF, Wei RF (2021) Low-temperature oxidation behavior and mechanism of semi-dry desulfurization ash from iron ore sintering flue gas. J Iron Steel Res Int 28(9):1075–1081

Takei T, Imazawa N, Miura A, Kumada N, Ogihara K (2013) Conversion of calcium sulfite waste to hydroxyapatite. Powder Technol 237:400–405

Li HX, Zhang H, Li L, Ren Q, Yang XJ, Jiang ZW, Zhang ZL (2019) Utilization of low-quality desulfurized ash from semi-dry flue gas desulfurization by mixing with hemihydrate gypsum. Fuel 255:115783

Xia Y, Yan Y, Hu ZH (2013) Utilization of circulating fluidized bed fly ash in preparing non-autoclaved aerated concrete production. Constr Build Mater 47:1461–1467

Chen XM, Gao JM, Yan Y, Liu YZ (2017) Investigation of expansion properties of cement paste with circulating fluidized bed fly ash. Constr Build Mater 157:1154–1162

Liu BJ, Shi JY, Liang HL, Jiang JY, Yang YX (2020) Synergistic enhancement of mechanical property of the high replacement low-calcium ultrafine fly ash blended cement paste by multiple chemical activators. J Build Eng 32:101520

Sarkar M, Maiti M, Malik MA, Xu SL (2022) Evaluation of the crack-healing performance and durability of bacteria integrated alkali-activated fly ash composites. J Build Eng 54:104642

Tannant DD, Kumar V (2000) Properties of fly ash stabilized haul road construction materials. Int J Surf Min Reclam Environ 14(2):121–135

Liu WF, Wang ZM, Hou HM (2018) Comparative study on legislation of utilization of construction wastes as resources in china and abroad. IOP Conf Ser: Earth Environ Sci 153:062046

Alsheyab MAT, Khedaywi TS, Elayan MS (2013) Laboratory study on solidification/stabilization of unwanted medications using asphalt as a binder. J Mater Cycles Waste Manag 15:129–137

Buzatu T, Talpoş E, Petrescu MI, Ghica VG, Iacob G, Buzatu M (2015) Utilization of granulated lead slag as a structural material in roads constructions. J Mater Cycles Waste Manag 17:707–717

Septiandini E, Widiasanti I, Pamungkas CA, Putri ASS, Mulyono T, Abdul NZP (2021) Compressive strength of pervious concrete paving blocks for pavement with the addition of fly ash. IOP Conf Ser Earth Environ Sci 1098:022046

Jonbi J, Fulazzaky MA (2020) Modeling the water absorption and compressive strength of geopolymer paving block: an empirical approach. Measurement 158:107695

Xu CW, Ni W, Li KQ, Zhang SQ, Xu D (2021) Activation mechanisms of three types of industrial by-product gypsums on steel slag–granulated blast furnace slag-based binders. Constr Build Mater 288:123111

Wei YM, Chai J, Qin Y, Xu ZG, Zhang XW (2019) Performance evaluation of green-concrete pavement material containing selected C&D waste and FA in cold regions. J Mater Cycles Waste Manag 21:1550–1562

Cao CW, Zhang WX, Wang YF (2007) Experimental study on application of high content fly ash concrete to road pavement. J Tongji Univ Nat Sci 35(1):50–55

Liu SM, Zhu MM, Ding XX, Ren ZG, Zhao SB, Zhao MS, Dang JT (2021) High-durability concrete with supplementary cementitious admixtures used in corrosive environments. Crystals 11(2):196

Xu F, Zhou MK, Chen JP (2012) Research on the mechanical performance of the road base materials with steel slag sand. Appl Mech Mater 174–177:676–680

Qian GP, Zhong YX, Li X, Peng HZ, Su J, Huang ZC (2022) Experimental study on road performance of high content phosphogypsum in the lime fly-ash mixture. Front Mater 9:935113

Wang CQ, Tan KF, Xu XX, Wang PX (2014) Effect of activators, admixtures and temperature on the early hydration performance of desulfurization ash. Constr Build Mater 70:322–331

Shen WG, Zhou MK, Zhao QL, Jiang ZQ, Zhou HY (2002) Manufacture of steel slag fly-ash road base material. J Wuhan Univ Technol 24(5):15–18

Li J, Dang XT, Zhang JW, Yi P, Li YM (2023) Mechanical properties of fly ash-slag based geopolymer for repair of road subgrade diseases. Polymers 15(2):309

Shen Z, Dong X, Zong L (2011) The experimental research on pavement performance of the fly ash blended with solidified agent JNS-1. J Wuhan Univ Technol 33(12):22–27

Antiohos S, Tsimas S (2004) Activation of fly ash cementitious systems in the presence of quicklime. Cem Concr Res 34(5):769–779

Zhao ZG, Qu XL, Li JH (2021) Microstructure and properties of fly ash/cement-based pastes activated with MgO and CaO under hydrothermal conditions. Cem Concr Compos 114:103739

Ho HJ, Iizuka A, Shibata E (2021) Chemical recycling and use of various types of concrete waste: a review. J Clean Prod 284:124785

Duan SY, Liao HQ, Cheng FQ, Song HP, Yang HQ (2018) Investigation into the synergistic effects in hydrated gelling systems containing fly ash, desulfurization gypsum and steel slag. Constr Build Mater 187:1113–1120

Duan SY, Liao HQ, Ma ZB, Cheng FQ, Fang L, Gao HY, Yang HQ (2018) The relevance of ultrafine fly ash properties and mechanical properties in its fly ash-cement gelation blocks via static pressure forming. Constr Build Mater 186:1064–1071

Zhang P, Wittmann FH, Lura P, Müller HS, Han SB, Zhao TJ (2018) Application of neutron imaging to investigate fundamental aspects of durability of cement-based materials: a review. Cem Concr Res 108:152–166

Gao XJ, Zhang JY, Su Y (2019) Influence of vibration-induced segregation on mechanical property and chloride ion permeability of concrete with variable rheological performance. Constr Build Mater 194:32–41

Ghosh SN, Handoo SK (1980) Infrared and Raman spectral studies in cement and concrete (review). Cem Concr Res 10(6):771–782

Hughes TL, Methven CM, Jones TGJ, Pelham SE, Fletcher P, Hall C (1995) Determining cement composition by Fourier transform infrared spectroscopy. Adv Cem Based Mater 2(3):91–104

Wu M, Zhang YS, Jia YT, She W, Liu GJ, Yang ZQ, Zhang Y, Zhang WT, Sun W (2019) Effects of sodium sulfate on the hydration and properties of lime-based low carbon cementitious materials. J Clean Prod 220:677–687

Wang SP, Peng XQ, Tang LP, Zeng L, Lan C (2014) Influence of inorganic admixtures on the 11Å-tobermorite formation prepared from steel slags: XRD and FTIR analysis. Constr Build Mater 60:42–47

Monteagudo SM, Moragues A, Gálvez JC, Casati MJ, Reyes E (2014) The degree of hydration assessment of blended cement pastes by differential thermal and thermogravimetric analysis. Morphological evolution of the solid phases. Thermochim Acta 592:37–51

Maitra S, Bose S, Bandyopadhyay N, Roychoudhury A (2005) Dehydration kinetics of calcium aluminate cement hydrate under non-isothermal conditions. Ceram Int 31(3):371–374

Wang JX, Lyu XJ, Wang LY, Cao XQ, Liu QL, Zang HY (2018) Influence of the combination of calcium oxide and sodium carbonate on the hydration reactivity of alkali-activated slag binders. J Clean Prod 171:622–629

Acknowledgements

This work was supported by the National Natural Science Foundation of China (U21A20321, 51972019) and National Key Research and Development Plan of China (2020YFB0606205).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, H., Hu, G., Zhang, L. et al. Large-scale utilization of desulfurization ash and fly ash for unfired production of high-strength road-base stones. J Mater Cycles Waste Manag 25, 2222–2231 (2023). https://doi.org/10.1007/s10163-023-01677-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01677-w