Abstract

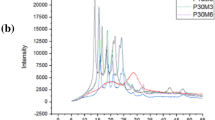

There is an overwhelming interest in composite materials derived from bio-based waste resources, recycled plastic materials and their combinations. The judicious utilization of forest waste (Pine needles) and recycling of plastic waste can certainly help the scientists and engineers in achieving the global goals of sustainable development. In the current research endeavor, five different types of hybrid laminates have been developed using recycled PP with 10 wt% of jute woven fiber and varying concentrations of pine needles (10, 20, and 30 wt%). The mechanism of water absorption in developed composites has been discussed. The developed composites have the potential to significantly reduce the usage of plastic (40%) with a slight compromise in the mechanical performance. However, the modulus values were found to increase. Thermo-gravimetric analysis (TGA) of the developed samples indicates significant and comparable results as compared to recycled PP. Scanning electron microscopy (SEM) established that the failure mechanism is mainly dominated by poor fiber-matrix adhesion and low strength of the pine needles.

Graphical abstract

Similar content being viewed by others

Data availability

The datasets generated and analyzed during the current study are made available from the corresponding author on reasonable request.

References

Kala LD, Subbarao PM (2018) Estimation of pine needle availability in the Central Himalayan state of Uttarakhand, India for use as energy feedstock. Renew Energy 128:9–19. https://doi.org/10.1016/j.renene.2018.05.054

Kumar S, Kumar M, Sheikh MA (2013) Carbon stock variation of Pinus roxburghii Sarg. Forest along altitudes of Garhwal Himalaya, India. Russ J Ecol 44:131–136. https://doi.org/10.1134/S1067413613020136

Murthy KK, Sinha SK, Kaul R, Vaidyanathan S (2019) A fine-scale state-space model to understand drivers of forest fires in the Himalayan foothills. For Ecol Manage 432:902–911. https://doi.org/10.1016/j.foreco.2018.10.009

Singh RD, Gumber S, Tewari P, Singh SP (2016) Nature of forest fires in Uttarakhand: frequency, size and seasonal patterns in relation to pre-monsoonal environment. Curr Sci 111(2):398–403. https://doi.org/10.18520/cs/v111/i2/398-403

Mohan HT, Jayanarayanan K, Mini KM (2021) Recent trends in utilization of plastics waste composites as construction materials. Constr Build Mater 271:121520. https://doi.org/10.1016/j.conbuildmat.2020.121520

Naik TP, Gairola S, Singh I, Sharma AK (2022) Microwave hybrid heating for moulding of Sisal/Jute/HDPE composites. J Nat Fibers 19:13524–13538. https://doi.org/10.1080/15440478.2022.2100553

Belviso C, Montano P, Lettino A, Toschi F, Lambertini VG, Veca AD, Moschetto E, Cavalcante F, Guarnaccio A (2021) Determining the role of the method used to recycle polypropylene waste materials from automotive industry using sepiolite and zeolite fillers. J Mater Cycles Waste Manag 23(3):965–975. https://doi.org/10.1007/s10163-021-01184-w

Rajasekaran D, Maji PK (2021) Recycling of waste PP and crumb rubber together by use of self-healing ionomer as process compatibilizer. J Mater Cycles Waste Manag 23(3):1058–1070. https://doi.org/10.1007/s10163-021-01194-8

El Hajj N, Seif S, Zgheib N (2021) Recycling of poly (propylene)-based car bumpers as carrier resin for short glass fiber composites. J Mater Cycles Waste Manag 23(1):288–300. https://doi.org/10.1007/s10163-020-01128-w

Ignatyev IA, Thielemans W, Vander Beke B (2015) Recycling of polymers: a review. Chemsuschem 7:1579–1593. https://doi.org/10.1002/cssc.201300898

Bledzki AK, Mamun AA, Volk J (2010) Physical, chemical and surface properties of wheat husk, rye husk and soft wood and their polypropylene composites. Compos Part A Appl Sci Manuf 41:480–488. https://doi.org/10.1016/j.compositesa.2009.12.004

Sanjay MR, Madhu P, Jawaid M, Senthamaraikannan P, Senthil S, Pradeep S (2018) Characterization and properties of natural fiber polymer composites: a comprehensive review. J Clean Prod 172:566–581. https://doi.org/10.1016/j.jclepro.2017.10.101

Vinod A, Sanjay MR, Suchart S, Jyotishkumar P (2020) Renewable and sustainable biobased materials: an assessment on biofibers, biofilms, biopolymers and biocomposites. J Clean Prod 258:120978. https://doi.org/10.1016/j.jclepro.2020.120978

Lee SH, Wang S (2006) Biodegradable polymers/bamboo fiber biocomposite with bio-based coupling agent. Compos Part A Appl Sci Manuf 37:80–91. https://doi.org/10.1016/j.compositesa.2005.04.015

Huang X, Netravali A (2009) Biodegradable green composites made using bamboo micro/nano-fibrils and chemically modified soy protein resin. Compos Sci Technol 69:1009–1015. https://doi.org/10.1016/j.compositesa.2005.04.015

Akil HM, Omar MF, Mazuki AAM, Safiee S, Ishak ZAM, Abu Bakar A (2011) Kenaf fiber reinforced composites: a review. Mater Des 32(89):4107–21. https://doi.org/10.1016/j.matdes.2011.04.008

Pickering KL, Beckermann GW, Alam SN, Foreman NJ (2007) Optimising industrial hemp fibre for composites. Compos Part A Appl Sci Manuf 38:461–468. https://doi.org/10.1016/j.compositesa.2006.02.020

Lahouioui M, Ben Arfi R, Fois M, Ibos L, Ghorbal A (2020) Investigation of fiber surface treatment effect on thermal, mechanical and acoustical properties of date palm fiber-reinforced cementitious composites. Waste Biomass Valori 11:4441–4455. https://doi.org/10.1007/s12649-019-00745-3

Dinesh S, Kumaran P, Mohanamurugan S, Vijay R, Singaravelu DL, Vinod A et al (2020) Influence of wood dust fillers on the mechanical, thermal, water absorption and biodegradation characteristics of jute fiber epoxy composites. J Polym Res 27:1–13. https://doi.org/10.1007/s10965-019-1975-2

Jenish I, Veeramalai Chinnasamy SG, Basavarajappa S, Indran S, Divya D, Liu Y et al (2022) Tribo-Mechanical characterization of carbonized coconut shell micro particle reinforced with Cissus quadrangularis stem fiber/epoxy novel composite for structural application. J Nat Fibers 19:2963–79. https://doi.org/10.1080/15440478.2020.1838988

Shravanabelagola Nagaraja Setty VK, Goud G, Peramanahalli Chikkegowda S, Mavinkere Rangappa S, Siengchin S (2022) Characterization of chemically treated Limonia Acidissima (Wood Apple) shell powder: physicochemical, thermal, and morphological properties. J Nat Fibers 19:4093–104. https://doi.org/10.1080/15440478.2020.1853925

Shravanabelagola Nagaraja Setty VK, Govardhan G, Mavinkere Rangappa S, Siengchin S (2021) Raw and chemically treated bio-waste filled (Limonia acidissima shell powder) vinyl ester composites: physical, mechanical, moisture absorption properties, and microstructure analysis. J Vinyl Addit Technol 27:97–107. https://doi.org/10.1002/vnl.21787

Mihai M, Ton-That MT (2018) Valorization of triticale straw biomass as reinforcement in proficient polypropylene biocomposites. Waste Biomass Valor 9:1971–83. https://doi.org/10.1007/s12649-017-9959-0

Lourençon TV, Santilli BV, Magalhães WLE, Muniz GIB (2020) Thermal stabilization of wood/polypropylene composites through addition of unmodified, low-cost Kraft Lignin. Waste Biomass Valor 11:1555–63. https://doi.org/10.1007/s12649-018-0484-6

Nguyen DM, Nhung VT, Le Do TC, Ha-Thuc CN, Perre P (2022) Effective synergistic effect of treatment and modification on spent coffee grounds for sustainable biobased composites. Waste Biomass Valor 13:1339–1348. https://doi.org/10.1007/s12649-021-01566-z

Ramesh M, Deepa C, Kumar LR, Sanjay MR, Siengchin S (2022) Life-cycle and environmental impact assessments on processing of plant fibres and its bio-composites: a critical review. J Ind Text 51:5518S-5542S. https://doi.org/10.1177/1528083720924730

Jagadeesh P, Puttegowda M, Thyavihalli Girijappa YG, Rangappa SM, Siengchin S (2022) Effect of natural filler materials on fiber reinforced hybrid polymer composites: an overview. J Nat Fibers 19(11):4132–47. https://doi.org/10.1080/15440478.2020.1854145

Vinay SS, Sanjay MR, Siengchin S, Venkatesh CV (2021) Effect of Al2O3 nanofillers in basalt/epoxy composites: mechanical and tribological properties. Polym Compos 42:1727–40. https://doi.org/10.1002/pc.25927

Ganapathy T, Sathiskumar R, Sanjay MR, Senthamaraikannan P, Saravanakumar SS, Parameswaranpillai J et al (2021) Effect of graphene powder on banyan aerial root fibers reinforced epoxy composites. J Nat Fibers 18:1029–36. https://doi.org/10.1080/15440478.2019.1675219

Ganesan K, Kailasanathan C, Sanjay MR, Senthamaraikannan P, Saravanakumar SS (2020) A new assessment on mechanical properties of jute fiber mat with egg shell powder/nanoclay-reinforced polyester matrix composites. J Nat Fibers 17:482–90. https://doi.org/10.1080/15440478.2018.1500340

Abhishek S, Sanjay MR, George R, Siengchin S, Parameswaranpillai J, Pruncu CI (2018) Development of new hybrid Phoenix pusilla /carbon/fish bone filler reinforced polymer composites. J Chin Adv Mater Soc 6:553–60. https://doi.org/10.1080/22243682.2018.1522599

Mengual A, Juárez D, Balart R, Ferrándiz S (2017) Mechanical characterization of composite materials based on pine needle residues processed by thermocompression. Procedia Manuf 13:315–320. https://doi.org/10.1016/j.promfg.2017.09.081

Thakur VK, Singha AS, Thakur MK (2013) Fabrication and physico-chemical properties of high-performance pine needles/green polymer composites. Int J Polym Mater Polym Biomater 62:226–230. https://doi.org/10.1080/00914037.2011.641694

Singha AS, Thakur VK (2008) Mechanical, morphological and thermal properties of pine needle-reinforced polymer composites. Int J Polym Mater Polym Biomater 58:21–31. https://doi.org/10.1080/00914030802461857

Alzebdeh KI, Nassar MMA, Arunachalam R (2019) Effect of fabrication parameters on strength of natural fiber polypropylene composites: statistical assessment. Meas J Int Meas Confed 146:195–207. https://doi.org/10.1016/j.measurement.2019.06.012

Sinha P, Mathur S, Sharma P, Kumar V (2018) Potential of pine needles for PLA-based composites. Polym Compos 39:1339–1349. https://doi.org/10.1002/pc.24074

Naldony P, Flores-Sahagun THS, Satyanarayana KG (2016) Effect of the type of fiber (coconut, eucalyptus, or pine) and compatibilizer on the properties of extruded composites of recycled high density polyethylene. J Compos Mater 50:45–56. https://doi.org/10.1177/0021998315570141

Malkapuram R, Kumar V, Negi YS (2010) Novel treated pine needle fiber reinforced polypropylene composites and their characterization. J Reinf Plast Compos 29:2343–55. https://doi.org/10.1177/0731684409348969

Asghar MA, Imad A, Nawab Y, Hussain M, Saouab A (2021) Effect of yarn singeing and commingling on the mechanical properties of jute/polypropylene composites. Polym Compos 42:828–841. https://doi.org/10.1002/pc.25868

Kumar R, Rakesh PK, Sreehari D (2023) Investigation on physico-chemical, mechanical and thermal properties of extracted novel Pinus roxburghii fiber. J Nat Fibers. https://doi.org/10.1080/15440478.2022.2157924

Bledzki AK, Mamun AA, Volk J (2010) Physical, chemical and surface properties of wheat husk, rye husk and soft wood and their polypropylene composites. Compos Part A Appl Sci Manuf 41:480–8

Sekar S, Suresh Kumar S, Vigneshwaran S, Velmurugan G (2020) Evaluation of mechanical and water absorption behaviour of natural fiber-reinforced hybrid biocomposites. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1788487

Arju SN, Afsar A, Khan MA, Das DK (2015) Effects of jute fabric structures on the performance of jute-reinforced polypropylene composites. J Reinf Plast Compos 34:1306–14. https://doi.org/10.1177/0731684415589360

Saw SK, Akhtar K, Yadav N, Singh AK (2014) Hybrid composites made from jute/coir fibers: water absorption, thickness swelling, density, morphology, and mechanical properties. J Nat Fibers 11:39–53. https://doi.org/10.1080/15440478.2013.825067

Zhang K, Liang W, Wang F, Wang Z (2021) Effect of water absorption on the mechanical properties of bamboo/glass-reinforced polybenzoxazine hybrid composite. Polym Polym Compos 29:3–14. https://doi.org/10.1177/0967391120903664

Akil HM, Santulli C, Sarasini F, Tirillò J, Valente T (2014) Environmental effects on the mechanical behaviour of pultruded jute/glass fibre-reinforced polyester hybrid composites. Compos Sci Technol 94:62–70. https://doi.org/10.1016/j.compscitech.2014.01.017

Chatterjee A, Kumar S, Singh H (2020) Tensile strength and thermal behaviour of jute fibre reinforced polypropylene laminate composite. Compos Commun 22:100483. https://doi.org/10.1016/j.coco.2020.100483

Reddy KO, Maheswari CU, Dhlamini MS, Mothudi BM, Kommula VP, Zhang J et al (2018) Extraction and characterization of cellulose single fibers from native African Napier grass. Carbohydr Polym 188:85–91. https://doi.org/10.1016/j.carbpol.2018.01.110

Margoto OH, Do Prado KDS, Mergulhão RC, Moris VADS, de Paiva JMF (2020) Mechanical and thermal characterization of jute fabric-reinforced polypropylene composites: effect of maleic anhydride. J Nat Fibers. https://doi.org/10.1080/15440478.2020.1788489

Zhao X, Li K, Wang Y, Tekinalp H, Larsen G, Rasmussen D et al (2020) High-strength Polylactic Acid (PLA) biocomposites reinforced by epoxy-modified pine fibers. ACS Sustain Chem Eng 8:13236–13247. https://doi.org/10.1021/acssuschemeng.0c03463

Aridi NAM, Sapuan SM, Zainudin ES, AL-Oqla FM (2016) Mechanical and morphological properties of injection-molded rice husk polypropylene composites. Int J Polym Anal Charact 21:305–13. https://doi.org/10.1080/1023666X.2016.1148316

Chuayjuljit S, Ketthongmongkol S (2013) Properties and morphology of injection- and compression-molded thermoplastic polyurethane/polypropylene-graft-maleic anhydride/wollastonite composites. J Thermoplast Compos Mater 26:923–35. https://doi.org/10.1177/0892705711431104

Komal UK, Lila MK, Singh I (2020) PLA/banana fiber based sustainable biocomposites: a manufacturing perspective. Compos Part B 180:107535. https://doi.org/10.1016/j.compositesb.2019.107535

Lila MK, Singhal A, Banwait SS, Singh I (2018) A recyclability study of bagasse fiber reinforced polypropylene composites. Polym Degrad Stab 152:272–279. https://doi.org/10.1016/j.polymdegradstab.2018.05.001

Jiang G, Wang C, Liu Z, Zhai Y, Zhang Y, Jiang J et al (2015) Characterization of polypropylene/hydrogenated styrene-isoprene-styrene block copolymer blends and fabrication of micro-pyramids via micro hot embossing of blend thin-films. RSC Adv 5:92212–92221. https://doi.org/10.1039/C5RA17934C

El Achaby M, Arrakhiz F-E, Vaudreuil S, el Kacem QA, Bousmina M, Fassi-Fehri O (2012) Mechanical, thermal, and rheological properties of graphene-based polypropylene nanocomposites prepared by melt mixing. Polym Compos 33:733–744. https://doi.org/10.1002/pc.22198

Poletto M, Ornaghi H, Zattera A (2014) Native cellulose: structure, characterization and thermal properties. Materials (Basel) 7:6105–6119. https://doi.org/10.3390/ma7096105

Dhaundiyal A, Gangwar J (2015) Kinetics of the thermal decomposition of pine needles. Acta Univ Sapientiae, Agric Environ 7:5–22. https://doi.org/10.1515/ausae-2015-0001

Acknowledgements

The author, Sandeep Gairola, gratefully acknowledge the National Mission on Himalayan Studies (NMHS), an initiative of the Ministry of Environment, Forest & Climate Change (MoEF&CC) Government of India, for providing fellowship for the PhD work under project grant no. NMH-1336-DMC.

Author information

Authors and Affiliations

Contributions

SG: conceptualization, methodology, investigation, validation, writing—original draft. TPN: experimentation, investigation. SS: resources, review & editing, supervision. IS: resources, formal analysis, review & editing, supervision, project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Research involving human participants and/or animals

This research does not involve any human participants and/or animals their data or biological material.

Informed consent

This research does not involve any human participant’s data.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gairola, S., Naik, T.P., Sinha, S. et al. Waste biomass and recycled polypropylene based jute hybrid composites for non-structural applications. J Mater Cycles Waste Manag 25, 2063–2076 (2023). https://doi.org/10.1007/s10163-023-01653-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01653-4