Abstract

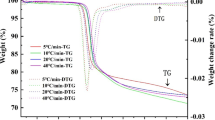

With characteristics of high resources, complex composition, and high toxicity, the treatment and disposal of waste printed circuit boards (WPCBs) have attracted widespread attention, and pyrolysis is regarded as a potential recovery method. In this study, the behaviors, kinetics, and mechanisms of WPCBs pyrolysis were systematically investigated. The pyrolysis process could be divided into three stages: evaporation stage, reaction stage, and stabilization stage. The mass losses of these stages at different heating rates were determined to be < 1%, 10.84–14.11%, and 6.37–8.82%, respectively. Four model-free methods (Friedman, Tang, Starink, and Bosewell) and the distributed activation energy method (DAEM) were used to reveal the pyrolysis kinetics of WPCBs. According to the model-free methods, the apparent activation energy (Eα) decreased with increasing conversion (α) in the range of 0.05–0.25, then increased in the α range of 0.30–0.75, and finally decreased. The Bosewell method possessed the highest fitting degree, and the Eα was calculated as 133.94–204.01 kJ/mol. The components in volatile products were detected using thermogravimetry–mass spectrometry (TG–MS), and the main components were identified as CO2, CH4, H2O, phenol, etc. Based on characteristics of these products, the pyrolysis mechanisms of brominated and non-brominated structures in brominated epoxy resins were expounded.

Similar content being viewed by others

References

Vanessa F, Baldé CP, Kuehr R, Bel G (2020) The Global E-waste Monitor 2020. https://www.researchgate.net/publication/342783104. Accessed 2 July 2020

Kumagai S, Grause G, Kameda T, Yoshioka T (2017) Thermal decomposition of tetrabromobisphenol—a containing printed circuit boards in the presence of calcium hydroxide. J Mater Cycles Waste Manag 19:282–293. https://doi.org/10.1007/s10163-015-0417-4

Pinho S, Ferreira M, Almeida MF (2018) A wet dismantling process for the recycling of computer printed circuit boards. Resour Conserv Recy 132:71–76. https://doi.org/10.1016/j.resconrec.2018.01.022

Dinc N, Tosun A, Esra B, Mustafa O, Burat, (2021) Recovery of valuable metals from WPCB fines by centrifugal gravity separation and froth flotation. J Mater Cycles Waste Manag 24:224–236. https://doi.org/10.1007/s10163-021-01310-8

Guo J, Luo X, Tan S, Ogunseitan OA, Xu Z (2020) Thermal degradation and pollutant emission from waste printed circuit boards mounted with electronic components. J Hazard Mater 382:121038. https://doi.org/10.1016/j.jhazmat.2019.121038

Qin L, Han J, Zhao B, Wang Y, Chen W, Xing F (2018) Thermal degradation of medical plastic waste by in-situ FTIR, TG-MS and TG-GC/MS coupled analyses. J Anal Appl Pyrol 136:132–145. https://doi.org/10.1016/j.jaap.2018.10.012

Li J, Wen J, Guo Y, Guo Y, An N, Liang C, Ge Z (2020) Bioleaching of gold from waste printed circuit boards by alkali-tolerant Pseudomonas fluorescens. Hydrometallurgy 194:105260. https://doi.org/10.1016/j.hydromet.2020.105260

Ma C, Kamo T (2019) Enhanced debromination by Fe particles during the catalytic pyrolysis of non-metallic fractions of printed circuit boards over ZSM-5 and Ni/SiO2–Al2O3 catalyst. J Anal Appl Pyrol 138:170–177. https://doi.org/10.1016/j.jaap.2018.12.021

Qin L, Han J, Zhao B, Chen W, Xing F (2018) The kinetics of typical medical waste pyrolysis based on gaseous evolution behaviour in a micro-fluidised bed reactor. Waste Manag Res 36(11):1073–1082. https://doi.org/10.1177/0734242X18790357

Shen Y (2018) Effect of chemical pretreatment on pyrolysis of non-metallic fraction recycled from waste printed circuit boards. Waste Manage 76:537–543. https://doi.org/10.1016/j.wasman.2018.02.036

Yousef S, Eimontas J, Striugas N, Mohamed A, Abdelnab MA (2022) Prolysis kinetic behavior and TG-FTIR-GC-MS analysis of end-life ultrafiltration polymer nanocomposite membranes. Chem Eng J 428:131181. https://doi.org/10.1016/j.cej.2021.131181

Subagyono RRDJN, Miten PD, Sinaga RH (2022) Pyrolysis of fast growing wood Macaranga gigantea: product characterisation and kinetic study. Fuel 315:123182. https://doi.org/10.1016/j.fuel.2022.123182

Liu W, Xu J, Han J, Jiao F, Qin W, Li Z (2018) Kinetic and mechanism studies on pyrolysis of printed circuit boards in the absence and presence of copper. Acs Sustain Chem Eng 7(2):1879–1889. https://doi.org/10.1021/acssuschemeng.8b03382

Yao Z, Xiong J, Yu S, Su W, Wu W, Tang J, Wu D (2020) Kinetic study on the slow pyrolysis of nonmetal fraction of waste printed circuit boards (NMF-WPCBs). Waste Manag Res 38(8):903–910. https://doi.org/10.1177/0734242X19896630

Zhu J, Chen X, Yao Z (2019) Directional concentration of bromine from nonmetallic particles of crushed waste printed circuit boards by vacuum-gasification-condensation. J Clean Prod 231:462–467. https://doi.org/10.1016/j.jclepro.2019.05.169

Joseph HF, Leo AW (1966) A quick, direct method for the determination of activation energy from thermogravimetric data. Express Polym Lett 4:323–328

Zhang J, Chen T, Wu J (2014) Multi-Gaussian-DAEM-reaction model for thermal decompositions of cellulose, hemicellulose and lignin: comparison of N2 and CO2 atmosphere. Bioresource Technol 166:87–95. https://doi.org/10.1016/j.biortech.2014.05.030

Tang W, Liu Y, Zhang H, Wang C (2003) New approximate formula for Arrhenius temperature integral. Thermochim Acta 408(1–2):39–43. https://doi.org/10.1016/S0040-6031(03)00310-1

Starink MJ (2003) The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta 404(1–2):163–176. https://doi.org/10.1016/S0040-6031(03)00144-8

Ali G, Nisar J, Iqbal M, Shah A, Abbas M (2020) Thermo-catalytic decomposition of polystyrene waste: comparative analysis using different kinetic models. Waste Manag Res 38(2):202–212. https://doi.org/10.1177/0734242X19865339

Ashraf A, Sattar H, Munir S (2019) A comparative applicability study of model-fitting and model-free kinetic analysis approaches to non-isothermal pyrolysis of coal and agricultural residues. Fuel 240:326–333. https://doi.org/10.1016/j.fuel.2018.11.149

Tian Y, Perré P (2021) Multiple-distribution DAEM modelling of spruce pyrolysis: an investigation of the best trade-off regarding the number and shape of distributions. Energ Convers Manage 229:113756. https://doi.org/10.1016/j.enconman.2020.113756

Qin L, Xu Z, Zhao B, Zou C, Chen W, Han J (2022) Kinetic study on high-temperature gasification of medical plastic waste coupled with hydrogen-rich syngas production catalyzed by steel-converter ash. J Energy Inst 102:14–21. https://doi.org/10.1016/j.joei.2022.02.005

Vyazovkin S, Burnham AK, Criado JM (2011) ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta 520(1–2):1–19. https://doi.org/10.1016/j.tca.2011.03.034

Vyazovkin S, Wight CA (1998) Isothermal and non-isothermal kinetics of thermally stimulated reactions of solids. Int Rev Phys Chem 17(3):407–433. https://doi.org/10.1080/014423598230108

Bosewell PG (1980) On the calculation of activation energies using a modified Kissinger method. J Therm Analcalorim 18:353–358. https://doi.org/10.1007/BF02055820

Miura K, Maki T (1998) A simple method for estimating f(E) and k0(E) in the distributed activation energy model. Energy Fuels 12:864–869. https://doi.org/10.1021/ef970212q

Please CP, McGuinness MJ, McElwain DLS (2003) Approximations to the distributed activation energy model for the pyrolysis of coal. Combust Flame 133(1–2):107–117. https://doi.org/10.1016/S0010-2180(02)00554-0

Quan C, Li A, Gao N (2009) Thermogravimetric analysis and kinetic study on large particles of printed circuit board wastes. Waste Manag 29(8):2353–2360. https://doi.org/10.1016/j.wasman.2009.03.020

Wang G, Li W, Li B, Chen H (2008) TG study on pyrolysis of biomass and its three components under syngas. Fuel 87(4–5):552–558. https://doi.org/10.1016/j.fuel.2007.02.032

Wolf M, Riess M, Heitmann D, Schreiner M, Thoms H, Vierlr O (2000) Application of a purge and trap TDS-GC/MS procedure for the determination of emissions from flame retarded polymers. Chemosphere 41:693–699. https://doi.org/10.1016/S0045-6535(99)00459-2

Gao R, Liu B, Zhan L, Guo J, Zhang J, Xu Z (2021) Catalytic effect and mechanism of coexisting copper on conversion of organics during pyrolysis of waste printed circuit boards. J Hazard Mater 403:123465. https://doi.org/10.1016/j.jhazmat.2020.123465

Federica B, Katia M, Luigi P, Cozzani V (2005) Thermal degradation and decomposition products of electronic boards containing BFRs. Ind Eng Chem Res 44:4186–4199

Ye Z, Yang F, Lin W, Sun S (2018) Improvement of pyrolysis oil obtained from co-pyrolysis of WPCBs and compound additive during two stage pyrolysis. J Anal Appl Pyrol 135:415–421. https://doi.org/10.1016/j.jaap.2018.06.011

Barontini F, Cozzani V (2006) Formation of hydrogen bromide and organobrominated compounds in the thermal degradation of electronic boards. J Anal Appl Pyrol 77(1):41–55. https://doi.org/10.1016/j.jaap.2006.01.003

Chen Y, Yang J, Zhang Y, Kang L (2018) Kinetic simulation and prediction of pyrolysis process for non-metallic fraction of waste printed circuit boards by discrete distributed activation energy model compared with isoconversional method. Environ Sci Pollut Res Int 25(4):3636–3646. https://doi.org/10.1007/s11356-017-0763-y

Zabeti M, Nguyen TS, Lefferts L (2012) In situ catalytic pyrolysis of lignocellulose using alkali-modified amorphous silica alumina. Bioresour Technol 118:374–381. https://doi.org/10.1016/j.biortech.2012.05.034

Reinehr TO, Ohara MA, de Oliveira S (2020) Study of pyrolysis kinetic of green corn husk. J Therm Anal Calorm 143(4):3181–3192. https://doi.org/10.1007/s10973-020-10345-2

Miao W, Li X, Wang Y, Lv Y (2019) Pyrolysis characteristics of oil-field sludge and the comparison of kinetic analysis with two representative methods. J Petrol Sci Eng 182:106309. https://doi.org/10.1016/j.petrol.2019.106309

Kim YM, Kim S, Lee JY, Park YK (2013) Pyrolysis reaction pathways of waste epoxy-printed circuit board. Environ Eng Sci 30(11):706–712. https://doi.org/10.1089/ees.2013.0166

Liu H, Ahmad MS (2020) A hybrid kinetic and optimization approach for biomass pyrolysis: the hybrid scheme of the isoconversional methods, DAEM, and a parallel-reaction mechanism. Energ Convers Manage 208:112531. https://doi.org/10.1016/j.enconman.2020.112531

Undri A, Rosi L, Frediani M (2014) Efficient disposal of waste polyolefins through microwave assisted pyrolysis. Fuel 116:662–671. https://doi.org/10.1016/j.fuel.2013.08.037

Gao R, Xu Z (2019) Pyrolysis and utilization of nonmetal materials in waste printed circuit boards: debromination pyrolysis, temperature-controlled condensation, and synthesis of oil-based resin. J Hazard Mater 364:1–10. https://doi.org/10.1016/j.jhazmat.2018.09.096

Neto IFF, Soares H (2021) Simple and near-zero-waste processing for recycling gold at a high purity level from waste printed circuit boards. Waste Manage 135:90–97. https://doi.org/10.1016/j.wasman.2021.08.025

Xiong J, Yu S, Wu D, Lu X, Tang J, Wu W, Yao Z (2020) Pyrolysis treatment of nonmetal fraction of waste printed circuit boards: focusing on the fate of bromine. Waste Manag Res 38(11):1251–1258. https://doi.org/10.1177/0734242X19894621

Han Y, Yi X, Wang R (2020) Copper extraction from waste printed circuit boards by glycine. Sep Purif Technol 253:117463. https://doi.org/10.1016/j.seppur.2020.117463

Yu S, Su W, Wu D, Yao Z, Liu J, Tang J, Wu W (2019) Thermal treatment of flame retardant plastics: a case study on a waste TV plastic shell sample. Sci Total Environ 675:651–657. https://doi.org/10.1016/j.scitotenv.2019.04.264

Meng L, Guo L, Guo Z (2019) Separation of metals from metal-rich particles of crushed waste printed circuit boards by low-pressure filtration. Waste Manag 84:227–234. https://doi.org/10.1016/j.wasman.2018.11.046

Erust C, Akcil A, Tuncuk A, Panda S (2020) Intensified acidophilic bioleaching of multi-metals from waste printed circuit boards (WPCBs) of spent mobile phones. J Chem Technol Blot 95(8):2272–2285. https://doi.org/10.1002/jctb.6417

Luda MP, Balabanovich AI, Camino G (2002) Thermal decomposition of fire retardant brominated epoxy resins. J Anal Appl Pyrol 65:25–40. https://doi.org/10.1016/j.polymdegradstab.2007.02.004

Acknowledgements

This work was supported financially by the Science and Technology Research Project of Education Department of Hubei Province (Q20201706).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, Q., Wang, H., Liu, J. et al. Nonisothermal pyrolysis kinetics of waste printed circuit boards and product characterization using TG–MS. J Mater Cycles Waste Manag 24, 2151–2161 (2022). https://doi.org/10.1007/s10163-022-01464-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-022-01464-z