Abstract

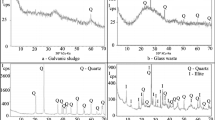

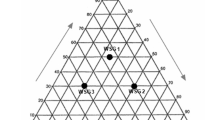

Glass waste from an industrial wastewater treatment plant (WTP) was studied to recycle the material in ceramic materials. A white kaolinitic clay was used replacing the waste in percentages of 0–30%, producing 115 × 25 × 10 mm specimens pressed with 20 MPa burned in the 850–1050 °C range. Burned specimens were evaluated for plasticity, dry mass density, water absorption, firing shrinkage, flexural strength, optical microscopy and scanning electron microscopy. It was found that the application of the glass waste aided the properties such as water absorption and tensile strength and despite increasing the linear shrinkage, it did not damage this property excessively, except for the application of the waste at a firing temperature of 1050 °C. The properties obtained with the use of glass are attributed to the higher liquid-phase formation promoted by the waste due to the chemical and mineralogical composition of the waste, which presents alkaline compounds. The results proved the viability of recycling the wastewater from WTP glass in ceramic materials, promoting an environmentally correct disposal of the waste. The application of 30% of burnt waste at 850 °C, for example, provides a burn shrinkage of about 2%, 17% water absorption and 7 MPa tensile strength, which enables the values established by technical standards to be met application for both tiles and ceramic bricks.

Similar content being viewed by others

References

Smiri M, Elarbaoui S, Missaoui T, Ben Dekhil A (2015) Micropollutants in sewage sludge: elemental composition and heavy metals uptake by phaseolus vulgaris and vicia faba seedlings. Arab J Sci Eng 40:1837–1847. https://doi.org/10.1007/s13369-015-1639-4

Girondi Delaqua GC, Marvila MT, Souza D, Sanchez Rodriguez RJ, Colorado HA, Fontes Vieira CM (2020) Evaluation of the application of macrophyte biomass salvinia auriculata aublet in red ceramics. J Env Manage 275:111253. https://doi.org/10.1016/j.jenvman.2020.111253

Zhou Z, Tang Y, Dong J, Chi Y, Ni M, Li N, Zhang Y (2018) Environmental performance evolution of municipal solid waste management by life cycle assessment in Hangzhou China. J Env Manage 227:23–33. https://doi.org/10.1016/j.jenvman.2018.08.083

de Azevedo ARG, Alexandre J, de Xavier GC, Pedroti LG (2018) Recycling paper industry effluent sludge for use in mortars: a sustainability perspective. J Clean Prod. https://doi.org/10.1016/j.jclepro.2018.05.011

Marvila MT, Azevedo ARG, Alexandre J, Colorado H, Pereira Antunes ML, Vieira CMF (2020) Circular economy in cementitious ceramics: replacement of hydrated lime with a stoichiometric balanced combination of clay and marble waste. Int J Appl Ceram Technol. https://doi.org/10.1111/ijac.13634

Marvila MT, Alexandre J, de Azevedo ARG, Zanelato EB (2019) Evaluation of the use of marble waste in hydrated lime cement mortar based. J Mater Cycles Waste Manag. https://doi.org/10.1007/s10163-019-00878-6

Marvila MT, Azevedo ARG, Barroso LS, Barbosa MZ, de Brito J (2020) Gypsum plaster using rock waste: a proposal to repair the renderings of historical buildings in Brazil. Constr Build Mater 250:118786. https://doi.org/10.1016/j.conbuildmat.2020.118786

de Azevedo ARG, Marvila MT, Barroso LS, Zanelato EB, Alexandre J, Xavier GC, Monteiro SN (2019) Effect of granite residue incorporation on the behavior of mortars. Mater (Basel). https://doi.org/10.3390/ma12091449

França BR, Azevedo ARG, Monteiro SN, Da Costa F, Filho G, Marvila MT, Alexandre J, Zanelato EB (2018) Durability of soil-Cement blocks with the incorporation of limestone residues from the processing of marble. Mater Res 21:1–6. https://doi.org/10.1590/1980-5373-MR-2017-1118

Girondi GD, Marvila MM, de Azevedo ARG, de Souza CC, Souza D, de Brito J, Vieira CMF (2020) Recycling potential of powdered cigarette waste in the development of ceramic materials. J Mater Cycles Waste Manag 22:1672–1681. https://doi.org/10.1007/s10163-020-01058-7

Mohajerani A, Kadir AA, Larobina L (2016) A practical proposal for solving the world’s cigarette butt problem: Recycling in fired clay bricks. Waste Manag. https://doi.org/10.1016/j.wasman.2016.03.012

Areias IOR, Vieira CMF, Intorne AC (2017) Incorporação de lodo da estação de tratamento de esgoto (ETE) em cerâmica vermelha (incorporation of sludge of the sewage treatment station). Cerâmica 63:343–349

de Azevedo ARG, Alexandre J, Zanelato EB, Marvila MT (2017) Influence of incorporation of glass waste on the rheological properties of adhesive mortar. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2017.04.208

de Oliveira HA, dos Santos CP, Oliveira RMPB, de Jesus E, Macedo ZS (2019) Produção de agregado sintético de argila com reaproveitamento de resíduo de vidro. Matéria (Rio Janeiro). https://doi.org/10.1590/s1517-707620190001.0653

Lu J-X, Zheng H, Yang S, He P, Poon CS (2019) Co-utilization of waste glass cullet and glass powder in precast concrete products. Constr Build Mater 223:210–220. https://doi.org/10.1016/j.conbuildmat.2019.06.231

Liu G, Florea MVA, Brouwers HJH (2019) Characterization and performance of high volume recycled waste glass and ground granulated blast furnace slag or fly ash blended mortars. J Clean Prod 235:461–472. https://doi.org/10.1016/j.jclepro.2019.06.334

Khan MNN, Saha AK, Sarker PK (2020) Reuse of waste glass as a supplementary binder and aggregate for sustainable cement-based construction materials: a review. J Build Eng 28:101052. https://doi.org/10.1016/j.jobe.2019.101052

de Azevedo ARG, Teixeira Marvila M, de Barbosa OL, Macario Ferreira W, Colorado H, Rainho Teixeira S, Mauricio Fontes VC (2021) Circular economy and durability in geopolymers ceramics pieces obtained from glass polishing waste. Int J Appl Ceram Technol. https://doi.org/10.1111/ijac.13780

Azevedo ARG, Marvila MT, Rocha HA, Cruz LR, Vieira CMF (2020) Use of glass polishing waste in the development of ecological ceramic roof tiles by the geopolymerization process. Int J Appl Ceram Technol. https://doi.org/10.1111/ijac.13585

de Mejía Gutiérrez R, Villaquirán-Caicedo MA, Guzmán-Aponte LA (2020) Alkali-activated metakaolin mortars using glass waste as fine aggregate: mechanical and photocatalytic properties. Constr Build Mater 235:117510. https://doi.org/10.1016/j.conbuildmat.2019.117510

Raut AN, Gomez CP (2020) Utilization of glass powder and oil palm fibers to develop thermally efficient blocks. Arab J Sci Eng 45:3959–3972. https://doi.org/10.1007/s13369-019-04316-5

Vieira CMF, Morais ASC, Monteiro SN, Delaqua GCG (2016) Teste industrial de cerâmica vermelha incorporada com resíduo de vidro de lâmpada fluorescente. Cerâmica 62:376–385. https://doi.org/10.1590/0366-69132016623642035

ABNT NBR 7181 (2016) - Soil - Grain size analysis. associate Brazil Technical Norms, Rio de Janeiro (In Portuguese).

ABNT NBR 6459 (2016) - Soil — Determination of the liquidity limit. associate Brazil Technical Norms, Rio de Janeiro (In Portuguese).

ABNT NBR 7180 (2016) - Soil — Determination of plasticity limit. associate Brazil Technical Norms, Rio de Janeiro (In Portuguese).

ABNT NBR 15270-1 (2005) - Ceramic components. Part 1: Ceramic Blocks for Sealing Masonry - Terminology and Requirements. associate Brazil Technical Norms, Rio de Janeiro (In Portuguese).

ABNT NBR 15270-2 (2017) - Ceramic components ― blocks and bricks for masonry, Part 2: Test methods. associate Brazil Technical Norms, Rio de Janeiro (In Portuguese).

ABNT NBR 15310 (2005) - Ceramic components — Tiles — Terminology, requirements and test methods. associate Brazil Technical Norms, Rio de Janeiro (In Portuguese).

Vieira CMF, Pinheiro RM (2011) Avaliação de argilas cauliníticas de campos dos goytacazes utilizadas para fabricação de cerâmica vermelha. Ceramica 57:319–323. https://doi.org/10.1590/s0366-69132011000300010

Monteiro SN, Silva FAN, Vieira CMF (2006) Microstructural evaluation of a clay ceramic incorporated with petroleum waste. Appl Clay Sci 33:171–180. https://doi.org/10.1016/j.clay.2006.04.005

Chin CL, Ahmad ZA (2020) Optimization of ceramic tile properties from three malaysian clays via statistical mixture design. Arab J Sci Eng 45:275–290. https://doi.org/10.1007/s13369-019-04150-9

Amaral LF, De Carvalho JPRG, Da Silva BM, Delaqua GCG, Monteiro SN, Vieira CMF (2019) Development of ceramic paver with ornamental rock waste. J Mater Res Technol. https://doi.org/10.1016/j.jmrt.2018.05.009

Vigneron TQG, Vieira CMF, Delaqua GCG, Vernilli Júnior F, Cristante NÂ (2019) Incorporation of mold flux waste in red ceramic. J Mater Res Technol. https://doi.org/10.1016/j.jmrt.2019.09.038

Eliche-Quesada D, Corpas-Iglesias FA, Pérez-Villarejo L, Iglesias-Godino FJ (2012) Recycling of sawdust, spent earth from oil filtration, compost and marble residues for brick manufacturing. Constr Build Mater 34:275–284. https://doi.org/10.1016/j.conbuildmat.2012.02.079

Kiefer P, Balzer R, Deubener J, Behrens H, Waurischk T, Reinsch S, Müller R (2019) Density, elastic constants and indentation hardness of hydrous soda-lime-silica glasses. J Non Cryst Solids 521:119480. https://doi.org/10.1016/j.jnoncrysol.2019.119480

Zang N, Zhu J, Wang X, Liao Y, Cao G, Li C, Liu Q, Yang Z (2022) Eutrophication risk assessment considering joint effects of water quality and water quantity for a receiving reservoir in the South-to-North water transfer project China. J Clean Prod 331:129966. https://doi.org/10.1016/j.jclepro.2021.129966

Cui J, Jin Z, Wang Y, Gao S, Fu Z, Yang Y, Wang Y (2021) Mechanism of eutrophication process during algal decomposition at the water/sediment interface. J Clean Prod 309:127175. https://doi.org/10.1016/j.jclepro.2021.127175

Marvila MT, Alexandre J, Azevedo ARG, Zanelato EB, Xavier GC, Monteiro SN (2019) Study on the replacement of the hydrated lime by kaolinitic clay in mortars. Adv Appl Ceram. https://doi.org/10.1080/17436753.2019.1595266

Chen Y, Zhang Y, Chen T, Zhao Y, Bao S (2011) Preparation of eco-friendly construction bricks from hematite tailings. Constr Build Mater 25:2107–2111. https://doi.org/10.1016/j.conbuildmat.2010.11.025

Mahmoudi S, Srasra E, Zargouni F (2014) composition and ceramic properties of carbonate-bearing: illitic clays from North-Eastern Tunisia. Arab J Sci Eng 39:5729–5737. https://doi.org/10.1007/s13369-014-1145-0

Menezes RR, Ferreira HS, Neves GA, de Lira HL, Ferreira HC (2005) Use of granite sawing wastes in the production of ceramic bricks and tiles. J Eur Ceram Soc 25:1149–1158. https://doi.org/10.1016/j.jeurceramsoc.2004.04.020

Li L, Wang F, Liao Q, Wang Y, Zhu H, Zhu Y (2020) Synthesis of phosphate based glass-ceramic waste forms by a melt-quenching process: the formation process. J Nucl Mater 528:151854. https://doi.org/10.1016/j.jnucmat.2019.151854

Mehta A, Ashish DK (2020) Silica fume and waste glass in cement concrete production: a review. J Build Eng 29:100888. https://doi.org/10.1016/j.jobe.2019.100888

Chen X, Zheng W, Zhang J, Liu C, Han J, Zhang L, Liu C (2020) Enhanced thermal properties of silica-based ceramic cores prepared by coating alumina/mullite on the surface of fused silica powders. Ceram Int 46:11819–11827. https://doi.org/10.1016/j.ceramint.2020.01.216

Karamanov A, Dzhantov B, Paganelli M, Sighinolfi D (2013) Glass transition temperature and activation energy of sintering by optical dilatometry. Thermochim Acta 553:1–7. https://doi.org/10.1016/j.tca.2012.10.006

Marvila MT, Azevedo ARG, Alexandre J, Zanelato EB, Azeredo NG, Simonassi NT, Monteiro SN (2019) Correlation between the properties of structural clay blocks obtained by destructive tests and ultrasonic pulse tests. J Build Eng. https://doi.org/10.1016/j.jobe.2019.100869

Kaczmarczyk K, Partyka J (2019) Effect of ZrSiO4 addition on sintering and selected physicochemical parameters of glass-ceramic materials from the SiO2-Al2O3-Na2O-K2O-CaO-MgO system in the presence of barium oxide. Ceram Int 45:22813–22820. https://doi.org/10.1016/j.ceramint.2019.07.323

Dondi M, Raimondo M, Zanelli C (2014) Clays and bodies for ceramic tiles: reappraisal and technological classification. Appl Clay Sci 96:91–109. https://doi.org/10.1016/j.clay.2014.01.013

Enríquez E, Fuertes V, Cabrera MJ, Seores J, Muñoz D, Fernández JF (2019) Absence of surface flaking in hierarchical glass-ceramic coating: high impact resistant ceramic tiles. J Eur Ceram Soc 39:4450–4456. https://doi.org/10.1016/j.jeurceramsoc.2019.05.047

Muñoz Velasco P, Morales Ortíz MP, Mendívil Giró MA, Muñoz Velasco L (2014) Fired clay bricks manufactured by adding wastes as sustainable construction material–a review. Constr Build Mater 63:97–107. https://doi.org/10.1016/j.conbuildmat.2014.03.045

Girondi GD, Marvila MM, de Azevedo ARG, de Souza CC, Souza D, de Brito J, Vieira CMF (2020) Recycling potential of powdered cigarette waste in the development of ceramic materials. J Mater Cycle Waste Manag. https://doi.org/10.1007/s10163-020-01058-7

Vieira CMF, Pinheiro RM, Rodriguez RJS, Candido VS, Monteiro SN (2016) Clay bricks added with effluent sludge from paper industry: technical, economical and environmental benefits. Appl Clay Sci 132–133:753–759. https://doi.org/10.1016/j.clay.2016.07.001

Funding

CNPq, 301634/2018.1, Carlos Maurício F. Vieira, FAPERJ, E-26/202.773/2017, Carlos Maurício F. Vieira.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Faria Busch, P., Marvila, M.T., Girondi Delaqua, G.C. et al. Recycling of waste glass extracted from a WTP into ceramic materials. J Mater Cycles Waste Manag 24, 763–774 (2022). https://doi.org/10.1007/s10163-022-01358-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-022-01358-0