Abstract

Extraction of hazardous metals from dumped crystal glass waste was investigated for site decontamination and resource recovery. Mechanically activated glass waste was leached with biodegradable chelating agents of ethylenediamine-N,N′-disuccinic acid (EDDS) and nitrilotriacetic acid (NTA), where the concentration and reaction time were determined by using Box–Wilson experimental design. Hazardous metals of lead (Pb), arsenic (As), antimony (Sb) and cadmium (Cd) with concentrations higher than regulatory limits were extracted wherein the extraction yield was found to vary Pb > Sb > As > Cd. Extraction was influenced more by type and concentration of chelator rather than by reaction time. A maximum of 64% of Pb could be extracted by EDDS while 42% using NTA. It is found that increase of chelator concentrations from 0.05 M to 1 M did not show improved metal extraction and the extraction improved with reaction time until 13 h. This study provides sustainable alternative for treating hazardous glass waste by mechanical activation followed by extraction using biodegradable chelator, instead of acid leaching.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Heavy metal pollution is a global challenge, as approximately half of the polluted sites globally are contaminated by heavy metals and metalloids [1, 2]. These sites include closed and operational industrial sites, such as glassworks, where the use of toxic raw materials, like As, Cd, Pb and Sb, has resulted in hazardous emissions, effluents and other solid wastes [3, 4]. In south-eastern Sweden, dumped factory waste is the main source of environmental exposure to these metal contaminants around old, non-operational glassworks [5, 6]. Heavy metal pollution affects human health and the environment while presenting an annual global economic impact estimated at over US$ 10 billion [2]. Therefore, it is a complex challenge that requires a sustainable solution.

From the sustainability perspective, glass waste decontamination with metal recovery could potentially reduce environmental and human health effects and their associated economic impact while providing secondary metals [4]. Only very few studies are documented for decontamination and metal recovery from the actual crystal glass [7]. The reduction-melting technique used popularly is very energy intensive (1100 °C) with potential toxic emissions [8]. Therefore, there is a need to study the potential for decontamination and metal recovery from crystal glass waste in an economically and environmentally feasible way.

A potential alternative is a combination of mechanical activation and leaching of the glass waste with chelating agents. Mechanical activation is the application of external mechanical forces to a material in order to increase its reaction capabilities by changing its surface energy, structure and/or chemical properties while retaining its chemical inactivity [9]. A chelating agent, on the other hand, is a ligand that contains two or more electron donor groups so that more than one bond is formed between a metal ion and the ligand [10]. Therefore, the suggested metal extraction alternative would expose metal ions in glass waste for easier extraction by the chelating agents during the leaching.

Chelating agents are compounds with different numbers of binding sites capable of complexing heavy metals, and their stability increases with the number of binding sites available on the ligands [11, 12]. They are classified into aminopolycarboxylic acids (APCAs), such as ethylenediaminetetraacetic acid (EDTA), and low-molecular-weight organic acids (LMWOAs), such as citric acid (CA) [13]. EDTA is widely used in metal extraction studies due to its effectiveness in metal binding. However, EDTA is persistent in the environment due to its low-level biodegradability and hard to be effectively removed from water treatment [14]. Therefore, the biodegradable alternatives ethylenediamine-N,N′-disuccinic acid (EDDS) and nitrilotriacetic acid (NTA) were used in this study as they can reduce the exposure of heavy metal to environment but without introducing new pollution compared to other non-degradable agents. Both of EDDS and NTA are APCA type of complexing agents with characteristics of high stability constant and quick biodegradability in the environment (2.5–7 days) [13,14,15].

To the best of the authors’ knowledge, a combination of mechanical activation and biodegradable chelating agents in metal extraction from crystal glass waste is not documented. Therefore, this study aimed to assess the application of this method on contaminated crystal glass waste. Glass samples were mechanically activated and leached with EDDS and NTA at varying chelator concentration and reaction time, while temperature and solid to liquid ratio were kept constant.

Materials and methods

Sampling

The crystal glass waste was sampled from Madesjö glass dump (56°44′45.9″N 15°52′13.9″E) in Nybro Municipality, southeast Sweden (Fig. 1). Madesjö glass dump is a heap of glass waste from Orrefors Glass Factory that is located about 15 km away. The factory was active from 1898 to 2012 and produced crystal and other household glass [4].

Sample preparation and treatment

The glass sample was crushed to smaller pieces and pulverised for 30 s in a planetary ball mill (Retsch S100, Germany) with ten agate balls of 15 mm diameter. The pulverised glass was sieved to <125 µm and oven dried at 105 °C for 24 h ± 30 min. To further reduce the size of glass samples and to enhance the surface energy, 40 g of the pulverised sample was mechanically activated in a 250 ml agate jar with ten agate balls of 15 mm diameter. The activation was done at 600 rpm for a total of 180 min, but in 15 min intervals. The activated sample was then oven dried at 105 °C for 24 h ± 30 min.

Metal extraction procedure

The chelating agents EDDS and NTA were used to extract metals from the activated glass sample at pH 7 in separate experiments. Batch leaching was achieved in 100 ml flasks by agitating 0.5 g of activated glass sample in 60 ml of EDDS or NTA. A thermostatically controlled shaking water bath (Grant OLS200) was used at constant leaching temperature (25 °C) and shaking speed (150 rpm). All experimental conditions were kept constant except chelating agent concentration and leaching time, which were varied as detailed in Table 1 as real variables. During preparation of chelating agents, the pH of the solution was adjusted to 7 using sodium hydroxide (NaOH) pellets (Fisher Scientific) and 1 M nitric acid (HNO3) (Sigma-Aldrich). After each extraction run, the flask contents were filtered through 0.45 µm filters and the filtrate was analysed for metals.

Sample characterisation

Metal content in the crushed glass sample was determined using a hand-held X-Ray Fluorescence (XRF) scanner (Bruker S1 Titan). Pulverised and activated glass sample morphologies were characterised by Scanning Electron Microscopy (SEM) using a Zeiss Ultra 55 SEM. Their particle sizes were determined using a Zeta Potential and Submicron Particle Size Analyser (Delsa™ Nano C, Beckman Coulter). Furthermore, an Accelerated Surface Area and Porosimetry System (ASAP 2020, Micromeritics) was used to determine sample pore size distribution, pore volume and specific surface area based on the Brunauer–Emmett–Teller (BET) method. During the leaching step, pH was measured using a Radiometer PHM 210 pH meter. Finally, an Inductively Coupled Plasma-Optical Emission Spectrometer (ICP-OES), iCAP 6500 (Thermo Scientific), was used to analyse metals leached from the activated glass.

Experimental design and statistical analyses

To understand the effects of mixing time and concentration of each chelating agent on metal extraction efficiency, the Box–Wilson experimental design was used [16], as it can evaluate the performance of each individual parameter and their interactions with a minimal number of experiments [5]. According to the design, 13 experiments were generated for each chelating agent, and the centre point (0,0) (i.e. 0.525 M of chelator concentration and 13 h of mixing time) was repeated five times in each case as shown in Table 1. The polynomial equation used to determine the extraction efficiency (theoretical) was

where y is the predicted extraction efficiency (%), a (0–5) are the model, linear and interaction constants, C is the acid concentration in moles (M) and t is the temperature in degrees celsius (°C) (coded variables in Table 1). The predicted and experimental optimum conditions were determined according to the least square method using STATISTICA version 6. Statistical significance of the model equation and other data was analysed by one-way ANOVA (analysis of variance).

Results and discussions

Physico-chemical characteristics of crystal glass waste

Chemical composition of the crystal glass sample (<125 µm) was analysed and compared with Swedish limits [17] for hazardous waste as shown in Table 2. Cu and Mo were lower than their detection limits in the sample, while cobalt (Co), chromium (Cr), manganese (Mn), nickel (Ni), silicon (Si) and zinc (Zn) were either lower than their respective guidelines or were not listed. On the other hand, arsenic (As), cadmium (Cd), lead (Pb) and antimony (Sb) were in hazardous quantities. These results are consistent with findings from previous studies on major contaminants around former glasswork sites in south-eastern Sweden [6, 8, 18, 19].

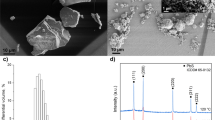

Physical characteristics of the glass sample, such as morphology, particle size and specific surface area, were considerably changed following the mechanical activation process. As shown in the SEM images in Fig. 2, mechanical attrition during activation reduces the particle sizes considerably. The initial sample showed smooth surfaces and sharp edges with particle sizes ranging between 50 and 100 µm, whereas the activated sample had truncated edges and much reduced particle sizes at 200–300 nm or 1–2 µm. The activated sample was agglomerated as shown in Fig. 2b, which is normally observed in activated glass samples [8, 20]. Hydrodynamic size distribution of activated glass sample determined by photocorrelation spectroscopy (Fig. 2c) was found in two ranges, i.e. 250–350 nm and 1–3 µm indicating, respectively, the dispersed and agglomerated glass particles with high surface energy, correlating well with the SEM studies. A similar size distribution pattern was also observed in a recent study on mechanical activation and metal extraction from crystal glass waste [8].

The friction energy during the activation process changes the surface energy and structure of the glass samples by inflicting structural defects that cause particles and ions to be in a disorderly state [9, 21]. In addition, the sample surface area increased considerably from 0.10 m2 g−1 to 3.98 m2 g−1, implying that the exo-diffusion of ions into the chelating agents would be enhanced.

Metal extraction

Extraction focussed on elements that were in hazardous quantities (As, Cd, Pb and Sb) in the glass sample, based on Table 2. In our previous study, blank experiment of water leaching of mechanically activated glass samples resulted in 3.04 mg l−1 of Pb (corresponding to ca. 0.0144% of total Pb content in glass sample) in leachate at room temperature. However, acid leaching using 0.5 M, 1 M and 3 M HNO3 resulted in ca. 26–28% of Pb extraction after 12 h [8]. In the current study, the magnitude of extraction was in the sequence Pb > Sb > As > Cd, and their maximum extraction efficiencies in EDDS and NTA, respectively, were found to be 63.6% and 42.2% for Pb, 10.4% and 8.6% for Sb, 6.3% and 3.4% for As, while Cd was lower than 1% when either of the chelators was used. The better extraction of Pb than other elements is probably due to its higher initial concentration in the glass samples (Table 2). Elements with smaller total concentrations may be more tightly bound to the material matrix, and thus may be more difficult to extract [11]. This is further signified by the lower extraction (<11%) of all elements in smaller total concentrations (As, Cd and Sb).

The lower extraction of these elements compared to Pb could also be due to their potentially low solubility in the two chelating agents, as well as due to differences in chelator-metal complex stability, which differs among elements [10, 22]. For instance, chelators are ineffective in extraction of As due to its anionic forms that do not allow the formation of stable chelator complexes [15]. Regarding the stability constant, although the content of Cd is about 5 times than Zn (Table 2), higher percentage of Zn was extracted than Cd owing to higher stability constant of metal complexes for Zn (i.e. log K of Zn-EDDS is higher than that of Cd-EDDS) [23]. In addition, there could be elemental competition for complexation sites, where an element not at equilibrium in a chelate complex can be replaced by another [24]. On the other hand, enhanced mobility of iron oxides by chelator action could result in increased release of bound As and other trace elements [5]. Therefore, extraction of these elements is also affected by the material type and chemical composition [11].

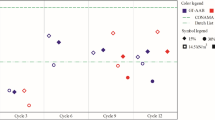

Extraction of As, Cd and Sb was not optimised due to low extraction efficiency (within 5% statistical error allowance), and the results are shown in Supplementary information. For Pb, extraction was obtained as shown in Fig. 3. It was higher in EDDS than NTA in all 13 experiments carried out during this study, and in each case the extraction pattern was similar for either of the chelators. The observed differences between the extraction efficiency of the two chelators are due to their inherent differences in complexation characteristics, based on their chemical structures. The stability of the metal–ligand complex, which is dictated by the number of donor atoms in each chelator, influences the extraction ability of each chelator. Therefore, EDDS, a structural isomer of EDTA, is more stable than NTA as it has more binding sites and thus is a better chelating agent for crystal glass waste [15, 25]. Meanwhile, in current study, solid to liquid ratio was kept constant at 1:120. In our previous study on mechanochemical extraction of lead from crystal glass waste [8], solid to liquid ratio was 1:250, and the highest extraction of Pb achieved was 78% in 3 M HNO3 and at 95 °C. At higher solid content and operation at room temperature, the current study shows 63% Pb recovery with the help of EDDS, which indicates the advantage of using biodegradable chelating agent.

The observed differences could also be explained in terms of differences in the chelator stability constants [11, 26]. EDDS has slightly higher equilibrium constants for trace elements than NTA, the stability constants (log K) of Pb complexes specifically being 12.7 and 11.3 for EDDS and NTA, respectively [24]. Thus, equilibrium concentration of the products (trace elements) during the extraction process should be higher in EDDS than in NTA. However, the effect of stability constants on extraction could also be a function of pH. For instance, Tandy et al. [24] observed that NTA extracted more Pb than EDDS in acidic conditions, despite EDDS having a higher stability constant. On the other hand, competition kinetics between metal binding by surface sites of the material and metal complexation by the chelating agent could be another explanation for the higher efficiency of EDDS than of NTA. Polettini, et al. [15] observed reduced competition between major cations and trace elements for complex formation in favour of EDDS than of EDTA and NTA, which could be the case in the current study as well.

Extraction efficiency in this study is lower than what was reported in previous studies on cathode ray tube (CRT) glass [27, 28]. The main influencing factors could be pH, chelator to target trace elements ratio (i.e. liquid to solid ratio) and efficiency of the mechanical activation step. Previous studies have shown pH-related effects on extraction due to buffering capacity of each material systems [11, 22, 29]. In the present study, pH was tuned to 7 at the beginning of extraction process and there was no noticeable variation of pH observed during and at the end of extraction. This is due to the relatively low concentration of metals in the extraction solution and also because of high chelator to metal ratios. Therefore, pH was not considered as a variable in experimental design. On the other hand, the higher the chelator to trace element ratio, the more uncomplexed ligand is present in the extraction solution, and thus, the faster and more complete is the extraction [24]. For mechanical activation, an ‘in-situ’ mechanical activation-extraction system results in enhanced metal extraction due to prolonged sample milling, and increased surface area and temperature during the reaction [27, 28]. In the current study, all the parameters were kept constant, and the metal extraction was ‘ex-situ’ (carried out separately after mechanical activation).

Effect of chelator concentration on extraction efficiency

Within a certain concentration range, metal extraction is known to increase with concentration of chelators until a critical concentration point at which almost all mobile metals are extracted, and thus, any further increase in chelator concentration is insignificant for metal ion extraction [30]. In one study, increase in chelator concentration from 0.005 M to 0.1 M only triggered marginal increase in Cd, Pb and Zn extraction, while another study assessing concentration effect from 0.001 M to 0.05 M observed no significant improvement in metal extraction beyond 0.01 M [21, 31], which is similar to the reported work of Zou et al. [30] in a study of concentration variation from 0.05 M to 0.1 M. In the current study, increase in concentration did not improve Pb extraction as shown in Fig. 4a, b. For both EDDS and NTA, there was a sharp decrease in extraction at higher chelator concentrations (from 0.05 M to 0.525 M). Towards 1 M concentration, there was a slight increase in extraction for EDDS, whereas for NTA the decrease continued gradually. The differences in extraction efficiency at the three concentrations in each chelating agent were found to be statistically significant (p < 0.05). As discussed earlier, extraction is affected by stability constant (log K) of chelator-metal complex and pH. Both EDDS and NTA are aminopolycarboxylic acid type of chelating agents. EDDS has more binding site than NTA; NTA tends to form 2:1 (ligand:metal) complexes with metal ions, whereas EDDS forms 1:1 complexes. Therefore, EDDS extracts more Pb than NTA. In the current study, the concentration range (0.05 M–1 M) most probably surpasses the range where an increase in extraction could be observed by increasing the chelator concentration. This could be due to that chelators of access amount are self-interacted, and thus, the number of active sites available for metal chelation is reduced.

Effect of reaction time on extraction efficiency

The effect of reaction time on Pb extraction is discussed for constant, mid-point concentration (0.525 M) and three time points (2 h, 13 h and 24 h), as shown in Fig. 4. Extraction in EDDS (Fig. 4a) increased between 2 and 13 h and then decreased thereafter. The pattern was almost similar in NTA (Fig. 4b), though the increased extraction before 13 h and a reduction thereafter were negligible. The differences in extraction at the three times were statistically significant (p < 0.05) for EDDS, whereas for NTA the differences were only statistically significant between 2 and 13 h. The increase in trace ion extraction from 2 to 13 h was only 8% and 2% in EDDS and NTA, respectively. Within the first 2 h of each experiment, 85% and 95% of the final extraction was already achieved in EDDS and NTA, respectively. Extraction of trace elements by chelating agents is based on a two-stage kinetic equilibrium rate, i.e. the rapid desorption stage from the onset of extraction until reaction equilibrium, and the slow leaching stage after equilibrium [5, 30]. Thus, the current results in the experimental setting signify that the extraction was already in the slow, post-equilibrium leaching stage after 2 h. Previous studies have shown similar trends of reaching equilibrium within the first 2 h of extraction [5, 8, 30].

Statistical analysis and optimisation

Extraction of Pb by EDDS and NTA was achieved as shown by the statistical and polynomial model results in Table 3. The correlation coefficients (R2) indicate the correlation between predicted (theoretical) and observed (experimental) extraction efficiencies of Pb, which was high for both chelators (0.965 and 0.976). This high correlation is shown in Fig. 5a, b for EDDS and NTA, respectively, confirming the suitability of the proposed model equation in fitting the experimental data as well as existence of a significant correlation among chelator concentration, reaction time and extraction efficiencies.

According to the Least Square method (STATISTICA) in the identification of optimum process conditions, it was established that the maximum predicted values for Pb extraction by EDDS and NTA were 63.2% and 42.3%, respectively, with 0.05 M of each chelator and 13 h reaction time as the optimum process conditions. For the experimental part, however, under the same optimum process conditions (0.05 M and 13 h), Pb extraction by EDDS and NTA was found to be 63.6% and 42.2%, respectively, which is similar to the prediction.

Conclusions

This study investigated extraction of hazardous metals from contaminated crystal glass waste using biodegradable chelating agents EDDS and NTA to achieve decontamination and sustainable resource recovery. The glass waste contained hazardous concentrations of As, Cd, Pb and Sb which were extracted in the sequence Pb > Sb > As > Cd. Mechanically activated glass samples were leached with the chelating agents at different concentrations and reaction times. Increase in chelator concentration did not enhance Pb extraction, whereas increase in reaction time enhanced extraction efficiency until 13 h for the extraction at certain concentration of chelator. Overall, chelator concentration was more important for Pb extraction than the reaction time. Ultimately, the optimum extraction conditions were 0.05 M and 13 h, although within 2 h more than 85% of the extraction was achieved in each case. EDDS was more effective than NTA in extracting the metals due to its higher stability constant. The maximum Pb extraction efficiency achieved (64%) was not high enough to achieve complete decontamination and full metal recovery potential. However, it could be improved through further optimisation of variables, like solid to liquid ratio, temperature, pH and further mechanical activation steps. This investigation could facilitate more research on decontamination and resource recovery potential from hazardous dumped waste for a circular economy.

References

Fedje KK, Strömvall AM (2019) Enhanced soil washing with copper recovery using chemical precipitation. J Environ Manag 236:68–74. https://doi.org/10.1016/j.jenvman.2019.01.098

He Z, Shentu J, Yang X, Baligar VC, Zhang T, Stoffella PJ (2015) Heavy metal contamination of soils: sources, indicators and assessment. In: 21st International Conference on Environmental Indicators, Windsor, Canada

Giusti L, Polo MC (2002) A review of the glass-making industry of Murano (Venice, Italy) under an environmental perspective. Environ Manage Health 13(1):40–54. https://doi.org/10.1108/09566160210417813

Mutafela RN, Marques M, Jani Y, Kriipsalu M, Hogland W (2019) Physico-chemical characteristics of fine fraction materials from an old crystal glass dumpsite in Sweden. Chem Ecol 35(9):877–890. https://doi.org/10.1080/02757540.2019.1648442

Jani Y, Hogland W (2018) Chemical extraction of trace elements from hazardous fine fraction at an old glasswork dump. Chemosphere 195:825–830. https://doi.org/10.1016/j.chemosphere.2017.12.142

Mutafela RN, Mantero J, Jani Y, Thomas R, Holm E, Hogland W (2020) Radiometrical and physico-chemical characterisation of contaminated glass waste from a glass dump in Sweden. Chemosphere 241:124964. https://doi.org/10.1016/j.chemosphere.2019.124964

Jani Y, Hogland W (2017) Reduction-melting extraction of trace elements from hazardous waste glass from an old glasswork’s dump in the southeastern part of Sweden. Environ Sci Pollut Res Int 24(34):26341–26349. https://doi.org/10.1007/s11356-017-0243-4

Mutafela RN, Ye F, Jani Y, Dutta J, Hogland W (2020) Efficient and low-energy mechanochemical extraction of lead from dumped crystal glass waste. Environ Chem Lett. https://doi.org/10.1007/s10311-020-01096-5

Ceganac Z, Acimovic Z, Andric L, Petrov M, Mihajlovic S (2003) Mechanical activation of ceramic powders and its influence on the quality of the refractory linings. In: Proceedings of 3rd Balkan Metallurgical Conference, Macedonia

Peters RW (1999) Chelant extraction of heavy metals from contaminated soils. J Hazard Mater 66(1–2):151–210. https://doi.org/10.1016/s0304-3894(99)00010-2

Neale CN, Bricka RY, Chao AC (1997) Evaluating acids and chelating agents for removing heavy metals from contaminated soils. Environ Prog 16(4):274–280. https://doi.org/10.1002/ep.3300160416

Manahan SE (1994) Environmetal Chemistry, 6th edn. CRC Press Inc., Florida

Song Y, Ammami M-T, Benamar A, Mezazigh S, Wang H (2016) Effect of EDTA EDDS, NTA and citric acid on electrokinetic remediation of As, Cd, Cr, Cu, Ni, Pb and Zn contaminated dredged marine sediment. Environ Sci Pollut Res 23(11):10577–10586. https://doi.org/10.1007/s11356-015-5966-5

Attinti R, Barrett KR, Datta R, Sarkar D (2017) Ethylenediaminedisuccinic acid (EDDS) enhances phytoextraction of lead by vetiver grass from contaminated residential soils in a panel study in the field. Environ Pollut 225:524–533. https://doi.org/10.1016/j.envpol.2017.01.088

Polettini A, Pomi R, Rolle E, Ceremigna D, De Propris L, Gabellini M, Tornato A (2006) A kinetic study of chelant-assisted remediation of contaminated dredged sediment. J Hazard Mater 137(3):1458–1465. https://doi.org/10.1016/j.jhazmat.2006.04.022

Montgomery DC (2001) Design and analysis of experiments, 5th edn. Wiley, New York

Elert M, Jones C, Broms S (2019) Uppdaterade bedömningsgruder för förorenade massor (in Swedish). Avfall Sverige AB, Malmö

Höglund LO, Fanger G, Yesilova H (2007) Slutrapport—Glasbruksprojektet 2006–2007 (in Swedish). Kemakta Konsult AB, Kalmar

Mutafela RN, Lopez EG, Dahlin T, Kaczala F, Marques M, Jani Y, Hogland W (2020) Geophysical investigation of glass ‘hotspots’ in glass dumps as potential secondary raw material sources. Waste Manage 106:213–225. https://doi.org/10.1016/j.wasman.2020.03.027

Yuan W, Li J, Zhang Q, Saito F (2012) Innovated application of mechanical activation to separate lead from scrap cathode ray tube funnel glass. Environ Sci Technol 46(7):4109–4114. https://doi.org/10.1021/es204387a

Baláž P (2008) Mechanochemistry in nanoscience and minerals engineering. Springer, Berlin

Naghipour D, Gharibi H, Taghavi K, Jaafari J (2016) Influence of EDTA and NTA on heavy metal extraction from sandy-loam contaminated soils. J Environ Chem Eng 4(3):3512–3518. https://doi.org/10.1016/j.jece.2016.07.034

Quartacci MF, Irtelli B, Baker AJM, Navari-Izzo F (2007) The use of NTA and EDDS for enhanced phytoextraction of metals from a multiply contaminated soil by Brassica carinata. Chemosphere 68(10):1920–1928. https://doi.org/10.1016/j.chemosphere.2007.02.058

Tandy S, Bossart K, Mueller R, Ritschel J, Hauser L, Schulin R, Nowack B (2004) Extraction of heavy metals from soils using biodegradable chelating agents. Environ Sci Technol 38(3):937–944. https://doi.org/10.1021/es0348750

Miessler GL, Fischer PJ, Tarr DA (2014) Inorganic chemistry, 5th edn. Pearson, Boston

Elliott HA, Brown GA (1989) Comparative evaluation of NTA and EDTA for extractive decontamination of Pb-polluted soils. Water Air Soil Pollut 45(3–4):361–369. https://doi.org/10.1007/bf00283464

Singh N, Li J, Zeng X (2016) An innovative method for the extraction of metal from waste cathode ray tubes through a mechanochemical process using 2-[bis(carboxymethyl)amino]acetic acid chelating reagent. ACS Sustain Chem Eng 4(9):4704–4709. https://doi.org/10.1021/acssuschemeng.6b00875

Sasai R, Kubo H, Kamiya M, Itoh H (2008) Development of an eco-friendly material recycling process for spent lead glass using a mechanochemical process and Na2EDTA reagent. Environ Sci Technol 42(11):4159–4164. https://doi.org/10.1021/es0719576

Kim EJ, Jeon E-K, Baek K (2016) Role of reducing agent in extraction of arsenic and heavy metals from soils by use of EDTA. Chemosphere 152:274–283. https://doi.org/10.1016/j.chemosphere.2016.03.005

Zou Z, Qiu R, Zhang W, Dong H, Zhao Z, Zhang T, Wei X, Cai X (2009) The study of operating variables in soil washing with EDTA. Environ Pollut 157(1):229–236. https://doi.org/10.1016/j.envpol.2008.07.009

Qiao J, Sun H, Luo X, Zhang W, Mathews S, Yin X (2017) EDTA-assisted leaching of Pb and Cd from contaminated soil. Chemosphere 167:422–428. https://doi.org/10.1016/j.chemosphere.2016.10.034

Acknowledgements

The authors would like to thank Nybro municipality for issuance of sampling permits.

Funding

Open access funding provided by Royal Institute of Technology.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mutafela, R.N., Ye, F., Jani, Y. et al. Sustainable extraction of hazardous metals from crystal glass waste using biodegradable chelating agents. J Mater Cycles Waste Manag 24, 692–701 (2022). https://doi.org/10.1007/s10163-022-01351-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-022-01351-7