Abstract

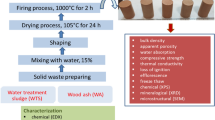

This paper presents an experimental study on the properties, structure and durability (frost resistance: one-side and all-sides freezing and thawing method) of fired clay bricks containing clay and municipal solid waste incineration (MSWI) bottom ash (BA). BA is a non-hazardous substance containing mainly CaO and SiO2, and also a low content of heavy metals. Clay was replaced with the BA up to 15% by weight. The bricks were fired at 1000 °C temperature and maintained at the maximum heat for 1 h. According to the research data, BA addition has an effect on the structure and properties of clay bricks. Higher content of BA in the mix of clay bricks leads to the increase of water absorption and total porosity and the decrease of density, and, therefore, lowers the durability (frost resistance) of clay bricks. In clay bricks with higher BA content the typical brick surface damages start appearing after the lower number of freezing and thawing cycles (both in one-side and all-sides freezing and thawing method). Nevertheless, all samples tested for resistance to freezing and thawing in one-side method is classified as F2 class according to the LST EN 772-22:2019 standard (severe weather resistance).

Similar content being viewed by others

References

Van Herck P, Van der Bruggen B, Vogels G, Vandecasteele C (2000) Application of computer modelling to predict the leaching behaviour of heavy metals from MSWI fly ash and comparison with a sequential extraction method. Waste Manage 20:203–210. https://doi.org/10.1016/S0956-053X(99)00321-9

Wunsch P, Greilinger C, Bieniek D, Kettrup A (1996) Investigation of the binding of heavy metals in thermally treated residues from waste incineration. Chemosphere 32:2211–2218. https://doi.org/10.1016/0045-6535(96)00123-3

Izquierdo M, López-Soler A, Ramonich EV, Barra M, Querol X (2002) Characterisation of bottom ash from municipal solid waste incineration in Catalonia. J Chem Technol Biotechnol 77:576–583. https://doi.org/10.1002/jctb.605

Chimenos JM, Segarra M, Fernández MA, Espiell F (1999) Characterization of the bottom ash in municipal solid waste incinerator. J Hazard Mater 64(3):211–222. https://doi.org/10.1016/S0304-3894(98)00246-5

Del Valle-Zermeño R, Giró-Paloma J, Formosa JCJ (2014) Glass content in MSWI bottom ash: effectiveness assessment of recycling over time. In: Cossu R (ed) Second symp. Urban min, Eurowaste Srl, Bergamo, Italy, pp 1–14

Pan JR, Huang C, Kuo JJ, Lin SH (2008) Recycling MSWI bottom and fly ash as raw materials for Portland cement. Waste Manage 28:1113–1118. https://doi.org/10.1016/j.wasman.2007.04.009

Andreola F, Barbieri L, Hreglich S, Lancellotti I, Morselli L, Passarini F, Vassura I (2008) Reuse of incinerator bottom and fly ashes to obtain glassy materials. J Hazard Mater 153:1270–1274. https://doi.org/10.1016/j.jhazmat.2007.09.103

Gines O, Chimenos JM, Vizcarro A, Formosa J, Rosell JR (2009) Combined use of MSWI bottom ash and fly ash as aggregate in concrete formulation: environmental and mechanical considerations. J Hazard Mater 169:643–650. https://doi.org/10.1016/j.jhazmat.2009.03.141

Shih PH, Chang JE, Chiang LC (2003) Replacement of raw mix in cement production by municipal solid waste incineration ash. Cem Concr Res 33:1831–1836. https://doi.org/10.1016/S0008-8846(03)00206-0

Saikia N, Kato S, Kojima T (2007) Production of cement clinkers from municipal solid waste incineration (MSWI) fly ash. Waste Manage 27:1178–1189. https://doi.org/10.1016/j.wasman.2006.06.004

Garcia-Lodeiro I, Carcelen-Taboada V, Fernández-Jiménez A, Palomo A (2016) Manufacture of hybrid cements with fly ash and bottom ash from a municipal solid waste incinerator. Constr Build Mater 105(15):218–226. https://doi.org/10.1016/j.conbuildmat.2015.12.079

Wongsa A, Boonserm K, Waisurasingha C, Sata V, Chindaprasirt P (2017) Use of municipal solid waste incinerator (MSWI) bottom ash in high calcium fly ash geopolymer matrix. J Clean Prod 148:49–59. https://doi.org/10.1016/j.jclepro.2017.01.147

Taurino R, Karamanov A, Rosa R, Karamanova E, Barbieri L, Atanasova S, Avdeev G, Leonelli C (2017) New ceramic materials from MSWI bottom ash obtained by an innovative microwave-assisted sintering process. J Eur Ceram Soc 37(1):323–331. https://doi.org/10.1016/j.jeurceramsoc.2016.08.011

Dou X, Ren F, Nguyen MQ, Ahamed A, Yin K, Chan WP, Wei-Chung Chang V (2017) Review of MSWI bottom ash utilization from perspectives of collective characterization, treatment and existing application. Renew Sustain Energy Rev 79:24–38. https://doi.org/10.1016/j.rser.2017.05.044

Lin CF, Wu CH, Ho HM (2006) Recovery of municipal waste incineration bottom ash and water treatment sludge to water permeable pavement materials. Waste Manage 26(9):970–978. https://doi.org/10.1016/j.wasman.2005.09.014

Wei Y, Shimaoka T, Saffarzadeh A, Takahashi F (2011) Mineralogical characterization of municipal solid waste incineration bottom ash with an emphasis on heavy metal-bearing phase. J Hazard Mater 187:534–543. https://doi.org/10.1016/j.jhazmat.2011.01.070

Yang MJ, Wang HJ, Liang CF (2014) Effects of strengths of cement mortar when using incinerator bottom ash as fine aggregate. World J Eng Technol 2:42–47. https://doi.org/10.4236/wjet.2014.23B007

Bethanis S, Sollars CJ, Cheeseman CR (2002) Properties and microstructure of sintered incinerator bottom ash. Ceram Int 28:881–886. https://doi.org/10.1016/S0272-8842(02)00068-8

Cheeseman CR, Monteiro da Rocha S, Sollars C, Bethanis S, Boccaccini AR (2003) Ceramic processing of incinerator bottom ash. Waste Manage 23:907–916. https://doi.org/10.1016/S0956-053X(03)00039-4

Schabbach LM, Andreola F, Lancellotti I, Barbieri L (2011) Minimization of Pb content in a ceramic glaze by reformulation the composition with secondary raw materials. Ceram Int 37:1367–1375. https://doi.org/10.1016/j.ceramint.2010.12.009

Vichaphund S, Jiemsirilers S, Thavorniti P (2012) Sintering of municipal solid waste incineration bottom ash. J Eng Sci 8:51–59

Giro-Paloma J, Ribas-Manero V, Maldonado-Alameda A, Formosa J, Chimenos JM (2017) Use of municipal solid waste incineration bottom ash and crop by-product for producing lightweight aggregate. IOP Conf Ser Mater Sci Eng 251(1):121–126

Long Lin K (2006) Feasibility study of using brick made from municipal solid waste incinerator fly ash slag. J Hazard Mater 137(3):1810–1816. https://doi.org/10.1016/j.jhazmat.2006.05.027

Andreola F, Barbieri L, Lancelloti I, Pozzi P (2005) Recycling industrial waste in brick manufacture. Part 1. Mater Constr 55:5–16

Taurino R, Karamanova E, Barbieri L, Atanasova S, Andreola F, Karamanov A (2017) New fired bricks based on municipal solid waste incinerator bottom ash. Waste Manage Res 35(10):124–128. https://doi.org/10.1177/0734242X17721343

Netinger Grubeša I, Vračević M, Ducman V, Marković B, Szenti I, Kukovecz A (2020) Influence of the size and type of pores on brick resistance to freeze-thaw cycles. Materials 13(17):3717. https://doi.org/10.3390/ma13173717

Ducman V, Sever Škapin A, Radeka M, Ranogajec J (2011) Frost resistance of clay roofing tiles: case study. Ceram Int 37(1):85–91. https://doi.org/10.1016/j.ceramint.2010.08.012

Sánchez de Rojas MI, Marín EP, Frías M, Valenzuela E, Rodríguez O (2011) Influence of freezing test methods, composition and microstructure on frost durability assessment of clay roofing tiles. Constr Build Mater 25(6):2888–2897. https://doi.org/10.1016/j.conbuildmat.2010.12.041

Perrin B, Vu NA, Multon S, Voland T, Ducroquetz C (2011) Mechanical behaviour of fired clay materials subjected to freeze–thaw cycles. Constr Build Mater 25(2):1056–1064. https://doi.org/10.1016/j.conbuildmat.2010.06.072

Barnat-Hunek D, Smarzewski P, Suchorab Z (2016) Effect of hydrophobisation on durability related properties of ceramic brick. Constr Build Mater 111:275–285. https://doi.org/10.1016/j.conbuildmat.2016.02.078

Franke L, Bentrup H (1993) Evaluation of the frost resistance of bricks in regard to long service life. Part 1. Ziegelindustr Int 7–8:483–492

Franke L, Bentrup H (1993) Evaluation of the frost resistance of bricks in regard to long service life. Part 2. Ziegelindustr Int 9:528–536

Koroth SR, Feldman D, Fazio P (1998) Development of new durability index for clay bricks. J Archit Eng 4:87–93. https://doi.org/10.1061/(ASCE)1076-0431(1998)4:3(87)

Sadunas A (1999) Aluminosilicate products burning process in the reducing-oxidizing gas medium. Vilnius: ISBN 9986-869-51-X, p 188

Christogerou A, Lampropoulou P, Panagiotopoulos E (2021) Increase of frost resistance capacity of clay roofing tiles with boron waste addition. Constr Build Mater 280:122493. https://doi.org/10.1016/j.conbuildmat.2021.122493

Eliche-Quesada D, Corpas-Iglesias FA, Pérez-Villarejo L, Iglesias-Godino FJ (2012) Recycling of sawdust, spent earth from oil filtration, compost and marble residues for brick manufacturing. Constr Build Mater 34:275–284. https://doi.org/10.1016/j.conbuildmat.2012.02.079

Sutcu M, Erdogmus E, Gencel O, Gholampour A, Atan E, Ozbakkaloglu T (2019) Recycling of bottom ash and fly ash wastes in eco-friendly clay brick production. J Clean Prod 233:753–764. https://doi.org/10.1016/j.jclepro.2019.06.017

Cimmers A, Svinka R, Svinka V, Moertel H (2005) Pore structure of porous building ceramic materials from illite containing raw materials. Ce Ca 35:9–13

Stryszewska T, Kanka S (2019) Forms of damage of bricks subjected to cyclic freezing and thawing in actual conditions. Materials 12:1165. https://doi.org/10.3390/ma12071165

Cultrone G, Sebastian E, Elert K, De la Torre MJ, Cazalla O, Rodriguez-Navarro C (2004) Influence of mineralogy and firing temperature on the porosity of bricks. J Eur Ceram Soc 24:547–564. https://doi.org/10.1016/S0955-2219(03)00249-8

Grubeša N, Vračević M, Ranogajec J, Vučetić V (2020) Influence of pore-size distribution on the resistance of clay brick to freeze-thaw cycles. Materials 13(10):2364. https://doi.org/10.3390/ma13102364

Nadeem H, Habib NZ, Ng CA, Zoorob SE, Mustaffa Z, Yong Chee S, Younas M (2017) Utilization of catalyzed waste vegetable oil as a binder for the production of environmentally friendly roofing tiles. J Clean Prod 145(1):250–261. https://doi.org/10.1016/j.jclepro.2017.01.028

Abdullah MJ, Zakiah A, Atikah FD, Nur KM (2015) Compressive Strength and water absorption characteristics of brick using quarry dust. InCIEC 2015:51–64. https://doi.org/10.1007/978-981-287-290-6_5

Vračević M, Ranogajec J, Vučetić S, Netinger I (2014) Evaluation of brick resistance to freeze/thaw cycles according to indirect procedures. Građevinar 66(3):197–209. https://doi.org/10.14256/JCE.956.2013

Šveda M (2003) Effect of water absorption on frost resistance of clay roofing tiles. Br Ceram Trans 102:43–45. https://doi.org/10.1179/096797803225009210

Bauluz B, Mayayo MJ, Fernández-Nieto C, Cultrone G, González López JM (2003) Assessment of technological properties of calcareous and non-calcareous clays used for the brick-making industry of Zaragoza (Spain). Appl Clay Sci 24(1–2):121–126. https://doi.org/10.1016/S0169-1317(03)00152-2

Raimondo M, Dondi M, Gardini D, Guarini G, Mazzanti F (2009) Predicting the initial rate of water absorption in clay bricks. Constr Build Mater 23(7):2623–2630. https://doi.org/10.1016/j.conbuildmat.2009.01.009

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kizinievič, O., Voišnienė, V., Kizinievič, V. et al. Impact of municipal solid waste incineration bottom ash on the properties and frost resistance of clay bricks. J Mater Cycles Waste Manag 24, 237–249 (2022). https://doi.org/10.1007/s10163-021-01314-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-021-01314-4