Abstract

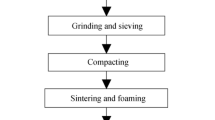

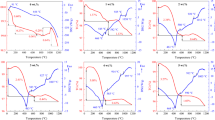

Iron ore tailings (IOT) are common wastes in industrial iron processes, which are harmful to the environmental and industrial development. Therefore, developing an efficient process for the recycling and utilization of IOT is of extreme importance. In this work, the influences of the sintering temperature and SiC content on the material properties of foam ceramics developed from IOT were investigated. More specifically, bulk density, water absorption, and microstructure of the materials were discussed. In addition, the foaming mechanism was analyzed. The experimental results showed that the average pore size of the material gradually increased and the bulk density decreased with increasing sintering temperature. On the other hand, the bulk density of the samples decreased and the water absorption increased with increasing SiC content. An optimal lightweight foam ceramic was fabricated from 55 wt.% IOT and 0.10 wt.% SiC at 1130 °C. Finally, foam ceramics as construction materials were produced with excellent material performance, including a bulk density of 0.77 g/cm3 and a uniform pore size distribution. This study describes a cleaner technology for the value-added utilization of IOT.

Graphic Abstract

Similar content being viewed by others

References

Lee J, Branth Pedersen A, Thomsen M (2014) Are the resource strategies for sustainable development sustainable? Downside of a zero waste society with circular resource flows. Environ Technol Inno 1:46–54

Zhou M, Jiang T, Yang ST, Xue XX (2015) Vanadium-titaniummagnetiteoreblendoptimizationforsinterstrengthbased on iron ore basic sintering characteristics. Int J Miner Process 142:125–133

Zhang CQ, Li SQ (2018) Utilization of iron ore tailing for the synthesis of zeolite A by hydrothermal method. J Mater Cycles Waste 20:1605–1614. https://doi.org/10.1007/s10163-018-0724-7

Long JY, Zheng Z, Gao XQ, Gong YM (2014) Production planning system for the whole steelmaking process of Panzhihua iron and steel corporation. J Iron Steel Res Int 21:44–50

Li L, Jiang T, Chen BJ, Zhou M, Chen C (2020) Overall utilization of vanadium-titanium magnetite tailings to prepare lightweight foam ceramics. Process Saf Environ Prod 139:305–314

Zake-Tiluga I, Svinka V, Svinka R, Zierath B, Greil P, Fey T (2016) Thermal conductivity and microstructure characterisation of lightweight alumina and alumina–mullite ceramics. J Eur Ceram Soc 36:1369–1377

Khademi H, Abbaspour A, Martínez-Martínez S, Gabarrón M, Shahrokh V, Faz A, Acosta JA (2018) Provenance and environmental risk of windblown materials from mine tailing ponds. Murcia Spain Environ Pollut 241:432–440

Sadenova MA, Utegenova ME, Klemeš JJ (2019) Synthesis of new materials based on metallurgical slags as a contribution to the circular economy. Clean Technol Envir 21:2047–2059. https://doi.org/10.1007/s10098-019-01761-6

Zhang Y, Hu YH, Sun N, Liu RQ, Wang Z, Wang L, Sun W (2018) Systematic review of feldspar beneficiation and its comprehensive application. Miner Eng 128:141–152

Yan ZD, Feng FQ, Tiao J, Liu YF (2019) Effect of high titanium blast furnace slag on preparing foam glass–ceramics for sound absorption. J Porous Mat 26:1209–1215. https://doi.org/10.1007/s10934-019-00722-0

Liu YS, Du F, Yuan L, Hui Z, Kong SF (2010) Production of lightweight ceramisite from iron ore tailings and its performance investigation in a biological aerated filter (BAF) reactor. J Hazard Mater 178:999–1006

Lemougna PN, Yliniemi J, Ismailov A, Levanen E, Tanskanen E, Kinnunen P, Roning J, Illikainen M (2019) Spodumene tailings for porcelain and structural materials: effect of temperature (1050–1200 °C) on the sintering and properties. Miner Eng 141:105843

Ye CQ, He F, Shu H, Qi H, Zhang QP, Song PY, Xie JL (2015) Preparation and properties of sintered glass-ceramics containing Au-Cu tailing waste. Mater Design 86:782–787

Xi CP, Zheng F, Xu JH, Yang WG, Peng YQ, Li Y, Li P, Zhen Q, Bashir Q, Liu JL (2018) Preparation of glass-ceramics foam using extracted titanium tailing and glass waste as raw materials. Constr Build Mater 190:896–909

Liu TY, Tang Y, Han L, Song J, Luo ZW, Lu AX (2017) Recycling of harmful waste lead-zinc mine tailings and fly ash for preparation of inorganic porous ceramics. Ceram Int 43:4910–4918

Niskanen J, Anshelm J, McLaren D (2020) Local conflicts and national consensus: the strange case of circular economy in Sweden. J Clean Prod 261:121117

Zheng WM, Sun HJ, Peng TJ, Zheng TJ (2020a) Novel preparation of foamed glass-ceramics from asbestos tailings and waste glass by self-expansion in high temperature. J Non-crystal Solid 529:119767

Han L, Wang JK, Li FL, Wang HF, Deng HG, Zhang HJ, Zhang SW (2018) Low-temperature preparation of Si3N4 whiskers bonded/reinforced SiC porous ceramics via foam-gelcasting combined with catalytic nitridation. J Eur Ceram Soc 38:1210–1218

Sun LF, Shi JJ, Yu Z, Jiang MF (2019) Phase equilibria and liquid us surface of CaO-SiO2-5wt% MgO-Al2O3-TiO2 slag system. Ceramics Int 45:481–487

Xi CP, Zhou JM, Zheng F, Gao JM, Hu PF, Li Y, Zhen Q, Bashir S, Louise Liu JB (2020) Conversion of extracted titanium tailing and waste glass to value-added porous glass ceramic with improved performances. J Environ Manage 261:110197

Battistella A, van Schijndel SJG, Baltussen MW, Roghair I, van Sint AM (2020) On the terminal velocity of single bubbles rising in non-Newtonian power-law liquids. J Non-Newton Fluid 278:104249

Kanchika S, Wakai F (2018) Surface tension-pressure superposition principle for anisotropic shrinkage of an ellipsoidal pore in viscous sintering. J Eur Ceram Soc 38:4283–4289

Nie BS, He XQ, Zhang RM, Chen WX, Zhang JF (2011) The roles of foam ceramics in suppression of gas explosion overpressure and quenching of flame propagation. J Hazard Mater 192:741–747

Lemougna PN, Yliniemi J, Adesanya E, Tanskanen P, Kinnunen P, Roning J, Illikainen M (2020) Reuse of copper slag in high-strength building ceramics containing spodumene tailings as fluxing agent. Miner Eng 155:106448

Wang RF, Zhang B, Liu CJ, Jiang MF (2020) Physical modelling of dynamic evolution of metallurgical slag foaming. Exp Therm Fluid Sci 113:110041

Lemougna PN, Yliniemi J, Nguyen H, Adesanya E, Tanskanen P, Kinnunen P, Roning J, Illikainen M (2020) Utilisation of glass wool waste and mine tailings in high performance building ceramics. J Build Eng 31:101383

Vijayan S, Wilson P, Prabhakaran K (2016) Porosity and cell size control in alumina foam preparation by thermo-foaming of powder dispersions in molten sucrose. J Asian Ceram Soc 4:344–350

Wang H, Chen Z, Ji Z, Liu LL, Wang XD (2018) Integrated utilization of high alumina fly ash for synthesis of foam glass ceramic. Ceram Int 44:13681–13688

Chen Z, Yan W, Schafföner W, Ma SB, Dai YJ, Li N (2018) Effect of SiC powder content on lightweight corundum-magnesium aluminate spinel castables. J Alloy Compd 764:210–215

Rincon A, Desideri D, Bernarod E (2018) Functional glass-ceramic foams from ‘inorganic gel casting’ and sintering of glass/slag mixtures. J Clean Prod 187:250–256

Chen ZW, Wang H, Ru J, Schafföner W, Wang XD (2019) Reuse of mineral wool waste and recycled glass in ceramic foams. Ceram Int 45:15057–15064

Liu TY, Tang Y, Li Z, Wu T, Lu AX (2016) Red mud and fly ash incorporation for lightweight foamed ceramics using lead-zine mine tailing as foaming agent. Mater. Lett 183:362–364

Zheng L, Sun HJ, Peng TJ, Zheng WM (2020b) Preparation of porous glass-ceramics from coal fly ash and asbestos tailings by high-temperature pore-forming. Waste Manage 106:184–192

Varbanov PS (2019) The policy debate on sustainability: issues and strategy. Clean Technol Envir 21:1515–1516

Acknowledgements

This work was financially supported by National Natural Science Foundation of China (51874077 and 51604065), the China Geological Survey Project (DD20189501) and the Fundamental Research Funds for the Central Universities (No.N2025040).

Funding

This work was supported by the National Natural Science Foundation of China (51874077 and 51604065), the China Geological Survey Project (DD20189501) and the Fundamental Research Funds for the Central Universities (No.N2025040).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that we have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Availability of data and material

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, L., Jiang, T., Zhou, M. et al. The influence of temperature and SiC content on the recycling of iron ore tailings for the preparation of value-added foam ceramics. J Mater Cycles Waste Manag 23, 330–340 (2021). https://doi.org/10.1007/s10163-020-01135-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-020-01135-x