Abstract

Hydrogen-bonded polymer complex films with the thickness ranging from 50 nm to 2400 nm were prepared by layer-by-layer (LbL) assembly of poly(2-ethyl-2-oxazoline) (PEOX) and poly(acrylic acid) (PAA). The dewetting behavior of PEOX/PAA films under hydrothermal condition was investigated. It was found that the dewetting occurred at solid-liquid interface, and the typical morphologies such as holes, irregular cellular structure, and droplets were observed. Atomic force microscopy (AFM) revealed the initial rupture of the film. Microscopic Raman and infrared (IR) imaging demonstrated that the PEOX and PAA chains remained association during the dewetting process.

Similar content being viewed by others

References

Thiele, U. Open questions and promising new fields in dewetting. Eur. Phys. J. E 2003, 12(3), 409–416.

Herminghaus, S.; Brinkmann, M.; Seemann, R. Wetting and dewetting of complex surface geometries. Annu. Rev. Mater. Res. 2008, 38(1), 101–121.

Xue, L.; Han, Y. Pattern formation by dewetting of polymer thin film. Prog. Polym. Sci. 2011, 36(2), 269–293.

Meredith, J. C.; Smith, A. P.; Karim, A.; Amis, E. J. Combinatorial materials science for polymer thin-film dewetting. Macromolecules 2000, 33(26), 9747–9756.

Koplik, J. Molecular simulations of dewetting. Phys. Rev. Lett. 2000, 84(19), 4401–4404.

Higgins, A. M.; Jones, R. A. L. Anisotropic spinodal dewetting as a route to self-assembly of patterned surfaces. Nature 2000, 404(6777), 476–478.

Wang, J. Z.; Zheng, Z. H.; Li, H. W.; Huck, W. T. S.; Sirringhaus, H. Dewetting of conducting polymer inkjet droplets on patterned surfaces. Nat. Mater. 2004, 3(3), 171–176.

Powell, M. R.; Cleary, L.; Davenport, M.; Shea, K. J.; Siwy, Z. S. Electric-field-induced wetting and dewetting in single hydrophobic nanopores. Nat. Nanotech. 2011, 6(12), 798–802.

Seemann, R.; Herminghaus, S.; Jacobs, K. Gaining control of pattern formation of dewetting liquid films. J. Phys. Condens. Matter 2001, 13(13), 4925–4938.

van Hameren, R.; Schön, P.; van Buul, A. M.; Hoogboom, J.; Lazarenko, S. V.; Gerritsen, J. W.; Engelkamp, H.; Christianen, P. C. M.; Heus, H. A.; Maan, J. C.; Rasing, T.; Speller, S.; Rowan, A. E.; Elemans, J. A. A. W.; Nolte, R. J. M. Macroscopic hierarchical surface patterning of porphyrin trimers via self-assembly and dewetting. Science 2006, 314(5804), 1433–1436.

Liu, J. C.; Shang, Y. Y.; Zhang, D. J.; Xie, Z.; Hua, R. X.; Wang, J. J. Single-material solvent-sensitive fluorescent actuator from carbon dots inverse opals based on gradient dewetting. Chinese J. Polym. Sci. 2017, 35(9), 1043–1050.

Wang, W. C.; Shi, K.; Pan, Y. X.; Peng, C.; Zhao, Z. L.; Liu, W.; Liu, Y. G.; Ji, X. L. Fabrication of polymersomes with controllable morphologies through dewetting W/O/W double emulsion droplets. Chinese J. Polym. Sci. 2016, 34(4), 475–482.

Brochard-Wyart, F. “Droplet: capillarity and wetting”. Soft Matter Phys., Spinger-Verlag Berlin Heidelberg, 1999, p. 29

Vrij, A. Possible mechanism for the spontaneous rupture of thin, free liquid films. Discuss. Faraday Soc. 1966, 42, 23–33.

Redon, C.; Brochardwyart, F.; Rondelez, F. Dynamics of dewetting. Phys. Rev. Lett. 1991, 66(66), 715–718.

Reiter, G. Dewetting of thin polymer-films. Phys. Rev. Lett. 1992, 68(1), 75–78.

Reiter, G. Dewetting as a probe of polymer mobility in thin films. Macromolecules 1994, 27(11), 3046–3052.

Mukherjee, R.; Sharma, A. Instability, self-organization and pattern formation in thin soft films. Soft Matter 2015, 11(45), 8717–8740.

Mitlin, V. S. Dewetting of solid surface: analogy with spinodal decomposition. J. Colloid Interface Sci. 1993, 156(2), 491–497.

Redon, C.; Brzoska, J. B.; Brochardwyart, F. Dewetting and slippage of microscopic polymer films. Macromolecules 1994, 27(2), 468–471.

Xie, R.; Karim, A.; Douglas, J. F.; Han, C. C.; Weiss, R. A. Spinodal dewetting of thin polymer films. Phys. Rev. Lett. 1998, 81(6), 1251–1254.

Roy, S.; Mukherjee, R. Ordered to isotropic morphology transition in pattern-directed dewetting of polymer thin films on substrates with different feature heights. ACS Appl. Mater. Interfaces 2012, 4(10), 5375–5385.

Seemann, R.; Herminghaus, S.; Jacobs, K. Dewetting patterns and molecular forces: areconciliation. Phys. Rev. Lett. 2001, 86(24), 5534–5537.

Bhandaru, N.; Das, A.; Salunke, N.; Mukherjee, R. Ordered alternating binary polymer nanodroplet array by sequential spin dewetting. Nano Lett. 2014, 14(12), 7009–7016.

Bhandaru, N.; Goohpattader, P. S.; Faruqui, D.; Mukherjee, R.; Sharma, A. Solvent-vapor-assisted dewetting of prepatterned thin polymer films: control of morphology, order, and pattern miniaturization. Langmuir 2015, 31(10), 3203–3214.

Bhandaru, N.; Das, A.; Mukherjee, R. Confinement induced ordering in dewetting of ultra-thin polymer bilayers on nanopatterned substrates. Nanoscale 2016, 8(2), 1073–1087.

Chen, D.; Zhao, W.; Wei, D.; Russell, T. P. Dewetting on curved interfaces: a simple route to polymer nanostructures. Macromolecules 2011, 44(20), 8020–8027.

Xia, T.; Ogawa, H.; Inoue, R.; Nishida, K.; Yamada, N. L.; Li, G.; Kanaya, T. Dewetting process of deuterated polystyrene and poly(vinyl methylether) blend thin films via phase separation. Macromolecules 2013, 46(11), 4540–4547.

Li, S. J.; Zhang, W. X.; Jiang, F.; Lu, Y. Y.; Shi, T. F.; An, L. J. Dynamics of hole growing in polymer thin films during dewetting. Acta Polymerica Sinica (in Chinese) 2014, 24(9), 1174–1181.

Che, J.; Jawaid, A.; Grabowski, C. A.; Yi, Y.; Louis, G. C.; Ramakrishnan, S.; Vaia, R. A. Stability of polymer grafted nanoparticle monolayers: impact of architecture and polymer-substrate interactions on dewetting. ACS Macro Lett. 2016, 5(12), 1369–1374.

Chandran, S.; Reiter, G. Transient cooperative processes in dewetting polymer melts. Phys. Rev. Lett. 2016, 116(8), 088301.

Liu, P.; Huang, X.; Zhou, R.; Berne, B. J. Observation of a dewetting transition in the collapse of the melittin tetramer. Nature 2005, 437(7055), 159–162.

Farrell, R. A.; Kehagias, N.; Shaw, M. T.; Reboud, V.; Zelsmann, M.; Holmes, J. D.; Torres, C. M. S.; Morris, M. A. Surface-directed dewetting of a block copolymer for fabricating highly uniform nanostructured microdroplets and concentric nanorings. ACS Nano 2011, 5(2), 1073–1085.

Besancon, B. M.; Green, P. F. Dewetting dynamics in miscible polymer-polymer thin film mixtures. J. Chem. Phys. 2007, 126(22), 224903.

Ma, M.; He, Z.; Yang, J.; Wang, Q.; Chen, F.; Wang, K.; Zhang, Q.; Deng, H.; Fu, Q. Vertical phase separation and liquid-liquid dewetting of thin PS/PCL blend films during spin coating. Langmuir 2011, 27(3), 1056–1063.

Merola, F.; Grilli, S.; Coppola, S.; Vespini, V.; Nicola, S. D.; Maddalena, P.; Carfagna, C.; Ferraro, P. Reversible fragmentation and self-assembling of nematic liquid crystal droplets on functionalized pyroelectric substrates. Adv. Funct. Mater. 2012, 22(15), 3097–3097.

Fowlkes, J. D.; Kondic, L.; Diez, J.; Wu, Y.; Rack, P. D. Self-assembly versus directed assembly of nanoparticles via pulsed laser induced dewetting of patterned metal films. Nano Lett. 2011, 11(6), 2478–2485.

Krishna, H.; Sachan, R.; Strader, J.; Favazza, C.; Khenner, M.; Kalyanaraman, R. Thickness-dependent spontaneous dewetting morphology of ultrathin Ag films. Nanotechnolgy 2010, 21(15), 155601.

Péron, N.; Brochard-Wyart, F.; Duval, H. Dewetting of low-viscosity films at solid/liquid interfaces. Langmuir 2012, 28(45), 15844–15852.

Verma, A.; Sharma, A. Enhanced self-organized dewetting of ultrathin polymer films under water-organic solutions: fabrication of sub-micrometer spherical lens arrays. Adv. Mater. 2010, 22(46), 5306–5309.

Verma, A.; Sharma, A. Submicrometer pattern fabrication by intensification of instability in ultrathin polymer films under a water-solvent mix. Macromolecules 2011, 44(12), 4928–4935.

Decher, G. Fuzzy nanoassemblies: toward layered polymeric multicomposites. Science 1997, 277(5330), 1232–1237.

Borges, J.; Mano, J. F. Molecular interactions driving the layer-by-layer assembly of multilayers. Chem. Rev. 2014, 114(18), 8883–8942.

Richardson, J. J.; Bjornmalm, M.; Caruso, F. Technology-driven layer-by-layer assembly of nanofilms. Science 2015, 348(6233), aaa2491.

Zhang, L.; Zheng, M.; Liu, X.; Sun, J. Layer-by-layer assembly of salt-containing polyelectrolyte complexes for the fabrication of dewetting-induced porous coatings. Langmuir 2011, 27(4), 1346–1352.

Shim, B. S.; Podsiadlo, P.; Lilly, D.G.; Agarwal, A.; Lee, J.; Tang, Z.; Ho, S.; Ingle, P.; Paterson, D.; Lu, W.; Kotov, N. A. Nanostructured thin films made by dewetting method of layer-by-layer assembly. Nano Lett. 2007, 7(11), 3266–3273.

Cao, Y. Fluorescence staining and confocal laser scanning microscopy study of hydrogen-bonded poly(vinylpyrrolidone)/poly(acrylic acid) film. Colloids Surf. A 2011, 392(1), 83–87.

Yang, S.; Li, Y.; Li, X.; Li, Y.; Zhang, X.; Xu, J. Patterning of hydrogen-bonded assembly film through ionization in vapor. Thin Solid Films 2009, 517(9), 3024–3027.

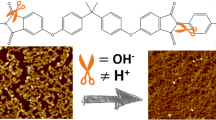

Ma, S.; Qi, X.; Cao, Y.; Yang, S.; Xu, J. Hydrogen bond detachment in polymer complexes. Polymer 2013, 54(20), 5382–5390.

Decher, G.; Hong, J. D. Buildup of ultrathin multilayer films by a self-assembly process (1), consecutive adsorption of anionic and cationic bipolar amphiphiles on charged surfaces. Macromol. Symposia 1991, 46(11), 321–327.

Stockton, W. B.; Rubner, M. F. Molecular-level processing of conjugated polymers. 4. layer-by-layer manipulation of polyaniline via hydrogen-bonding interactions. Macromolecules 1997, 30(9), 2717–2725.

Wang, L.; Wang, Z.; Zhang, X.; Shen, J.; Chi, L.; Fuchs, H. A new approach for the fabrication of an alternating multilayer film of poly(4-vinylpyridine) and poly(acrylic acid) based on hydrogen bonding. Macromol. Rapid Commun. 1997, 18(6), 509–514.

Kharlampieva, E.; Sukhishvili, S. A. Hydrogen-bonded layer-by-layer polymer films. Polym. Rev. 2006, 46(4), 377–395.

Yang, S.; Ma, S.; Wang, C.; Xu, J.; Zhu, M. Polymer complexation by hydrogen bonding at the interface. Aust. J. Chem. 2014, 67(1), 11–21.

Su, C.; Sun, J.; Zhang, X.; Shen, D.; Yang, S. Hydrogen-bonded polymer complex thin film of poly(2-oxazoline) and poly(acrylic acid). Polymers 2017, 9(8), 363.

Yang, S.; Tan, S.; Zhang, Y.; Xu, J.; Zhang, X. Interferometric study onhydrogen-bonded assembly film. Thin Solid Films 2008, 516, 4018–4024.

Ma, J.; Yang, S.; Li, Y.; Xu, X.; Xu, J. Effect of temperature on build-up and post hydrothermal processing of hydrogen-bonded PVPON/PAA film. Soft Matter 2011, 7(19), 9435–9443.

Wang, Z.; Xu, J.; Wu, L.; Chen, X.; Yang, S.; Liu, H.; Zhou, X. Dissolution, hydrolysis and crystallization behavior of polyamide 6 in superheated water. Chinese J. Polym. Sci. 2015, 33(9), 1334–1343.

Zhang, Y.; Li, F.; Valenzuela, L. D.; Sammalkorpi, M.; Lutkenhaus, J. L. Effect of water on the thermal transition observed in poly(allylamine hydrochloride)-poly(acrylic acid) complexes. Macromolecules 2016, 49(19), 7563–7570.

Zhai, L.; Nolte, A. J.; Cohen, R. E.; Rubner, M. F. pH-gated porosity transitions of polyelectrolyte multilayers in confined geometries and their application as tunable bragg reflectors. Macromolecules 2004, 37(16), 6113–6123.

Yang, S.; Zhang, Y.; Guan, Y.; Tan, S.; Zhang, X.; Cheng, S.; Xu, J. Water uptake behavior of hydrogen-bonded PVPON/PAA LbL film. Soft Matter 2006, 2(8), 699–704.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51373032).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Su, C., Ma, SM., Liu, GX. et al. Dewetting Behavior of Hydrogen Bonded Polymer Complex Film under Hydrothermal Condition. Chin J Polym Sci 36, 1036–1042 (2018). https://doi.org/10.1007/s10118-018-2109-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10118-018-2109-8