Abstract

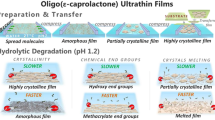

Increasing the surface hydrophilicity of polyetherimide (PEI) through partial hydrolysis of the imide groups while maintaining the length of the main-chain was explored for adjusting its function in biomedical and membrane applications. The outcome of the polymer analogous reaction, i.e., the degree of ring opening and chain cleavage, is difficult to address in bulk and microstructured systems, as these changes only occur at the interface. Here, the reaction was studied at the air–water interface using the Langmuir technique, assisted by atomic force microscopy and vibrational spectroscopy. Slow PEI hydrolysis sets in at pH > 12. At pH = 14, the ring opening is nearly instantaneous. Reduction of the layer viscosity with time at pH = 14 suggested moderate chain cleavage. No hydrolysis was observed at pH = 1. Hydrolyzed PEI films had a much more cohesive structure, suggesting that the nanoporous morphology of PEI can be tuned via hydrolysis.

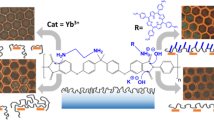

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Polyetherimide (PEI) (Fig. 1A) is a high performance polymer sought after for its excellent mechanical and thermal stability [1]. Besides from structural applications, it has been investigated as material for membranes with applications in gas separation [2], medical devices [3, 4], nanofiltration [5], fuel cells [6], and batteries [7]. Especially the latter three applications can present chemically aggressive conditions where the phthalimide groups in the polymer backbone might be attacked by nucleophiles, raising questions about long-term stability. On the other hand, the reactivity of the phthalimide groups can be exploited for post-functionalization of PEI. Two relatively popular functionalization approaches are cross-linking using bifunctional amines [8], and ring opening of the phthalimide groups vial alkaline hydrolysis [9]. While the former approach is intended to enhance the solvent resistance of the material, the latter aims at making it more hydrophilic. Hydrophilicity is important for application as membrane material in aqueous media, where hydrophobic interactions drive the fouling via adsorption of organic solutes [10]. Here, a surface-modification of PEI via alkaline hydrolysis could help to enhance the long-term performance. The products formed by such a procedure differ depending on the degree of hydrolysis achieved. According to the alkaline hydrolysis mechanism, which is depicted in Fig. 1B, the reaction could either stop at the ring opening stage, providing a negatively charged material with unchanged chain length, or in a second step also lead to hydrolysis of the amides formed by ring opening. The second step results in chain cleavage, reduction of mechanical strength and generation of free amine groups leaving the surface amphiprotic. Kinetic studies on phthalimide hydrolysis suggest that in alkaline aqueous solution, the ring-opening is fast, while chain cleavage through hydrolysis of the resulting amide is slow. In aqueous acids, where the hydrolysis mechanism is different, as shown in Fig. 1C, ring-opening is slow. However, if any amides are formed by the slow acidic hydrolysis of the imides, their hydrolysis is much faster under acidic than alkaline conditions [11]. In hydrolysis experiments with PEI, depending on the exact conditions and measurement methods, very different observations regarding the degree of hydrolysis were made. For example, in about 1 M KOH, hydrolysis during coagulation of PEI particles at room temperature resulted in almost complete disappearance of the imide signals in Raman spectra, while post treatment of PEI-particles with 1 M KOH at elevated temperatures showed no decrease of the characteristic imide Raman bands. Yet, the results were very different when the particle surfaces were investigated with X-ray photoelectron spectroscopy, where substantial hydrolysis and even free amines were observed [9]. When thicker sheets were investigated with attenuated transmission reflection Fourier transform infrared spectroscopy (ATR-FTIR), a highly concentrated alkaline solution at elevated temperature was needed to observe ring-opening [12]. These conditions were much harsher than those reported for hydrolysis of polyimides [13]. Whether the treatment also afforded some degree of chain-cleavage was not elaborated.

We tentatively attribute such incongruent observations to the interplay between reactant penetration and observation depth. IR-spectroscopy penetrates several micrometers into the material, and still hundreds of nanometers in ATR configuration [14]. It is therefore not a surface sensitive technique. For a very porous PEI particle, the alkaline solution might have a similar or greater penetration depth even at room temperature, but when PEI is forming more compact objects, much harsher conditions may be required for the reactant to penetrate as deep as the electromagnetic waves. In that sense, distinguishing between chemical reactivity and morphological effects requires highly surface specific characterization techniques and ideally also ultrathin films.

We therefore suggest that the Langmuir-technique is ideally suited to investigate the hydrolysis of PEI surfaces. In ultrathin films at the air–water interface, all phthalimide units are in direct contact with the reactant, so there is no overlay of molecular reaction kinetics and diffusion processes. Still, observing the progress of the reaction might be challenging in the case of PEI hydrolysis. In contrast to hydrolytically degradable polyesters [15], it is very unlikely that substantial mass loss can be observed, since this requires a considerable number of chain cuts to generate very short and water-soluble chain fragments. Therefore, here several approaches are combined to characterize the chemical and morphological changes of PEI ultrathin films after alkaline and acidic hydrolysis. An increase in surface pressure is expected when carboxylate groups are formed, as the latter induce a comparably long ranged repulsive interaction. Also, the surface potential of the layers may change when bonds are hydrolyzed. A decrease of the viscosity resulting from chain cleavage can be measured by interfacial rheology, while polarization modulated infrared reflection absorption spectroscopy (PM-IRRAS) can detect the conversion of functional groups. Transferring the films before and after hydrolysis enables to characterize the morphological changes via atomic force microscopy (AFM), as well as complimentary chemical analysis via surface-enhanced Raman scattering microscopy (SERS).

Materials and methods

Materials

Polyetherimide, potassium hydroxide (anhydrous grade) and hydrochloric acid (37 wt%, analysis grade) were purchased from Sigma (Darmstadt, Germany) and used without any further purification. For all experiments, water was purified with a MiliQ system (Merck, Darmstadt, Germany).

General procedure for Langmuir monolayer experiments

Experiments were carried out on “medium” area Langmuir troughs with A = 243 cm2 (Biolin Scientific, Espoo, Finland) with a subphase capacity of 180 mL, except for surface potential measurements (see below). For rheology, the area was A = 223 cm2 due to the area of the bicone with radius r = 25.5 mm. The surface pressure was measured with metal Wilhelmy plates, which were calibrated against air and pure water. The polymer was spread from a chloroform solution with c ~ 0.1 mg·mL−1. Compression rates were on the order of 10 mm·min−1. For degradation experiments, the starting pH corresponds to MiliQ water, which has a pH of about 6. The pH of the subphase was adjusted by injecting either concentrated HCL or KOH solution when the target surface pressure was reached and compression had stabilized. For the experiment at pH = 14, the experiment was started at this pH because of the impractical amounts of KOH solution required to change the pH from 6 to 14. Surface levelling tools from Biolin Scientific were used for all experiments to compensate water evaporation. All experiments were carried out at room temperature without temperature control.

Surface potential

The surface potential ΔV, was measured with a MicroSpot Surface Potentiometer (Kibron, Helsinki, Finland) consisting of a vibrating plate potentiometer coupled to a MicroTrough G2 from the same company, with dimensions 80 × 405 × 5 mm3 (W x L x D), available surface area of 280 cm2, and a subphase capacity of 200 mL. The vibrating plate was placed approximately 2 mm above the water surface. An internal height compensation of the surface potentiometer was performed against the bare surface before spreading the polymer solution. The surface potentiometer’s value was set to zero before deposition of the monolayer on the surface.

Brewster angle microscopy (BAM)

Brewster angle microscopy is based on the physical principle that at a certain angle of incidence, p-polarized light is not reflected from the interface of two dielectrica. The Brewster angle depends on the refractive indices of both media, and is 53° for the air–water interface. When observing the interface at this angle with p-polarized light, the image is black, while any layer covering the interface is brighter, depending on its refractive index and thickness [16].

BAM images were recorded using a nanofilm_ultrabam. (Accurion, Göttingen, Germany). A 658 nm class IIb laser source with a 10 × lens and a CCD camera (1360 × 1024 pixel) were used to record all images. The angle of incidence was 53.2°.

Rheology

Rheology was carried out with a bicone-geometry on a MCR 502 Rheometer (Anton-Paar, Graz, Austria). The bicone had a radius of r = 25.5 mm and was immersed in a medium area Langmuir trough. The angle of the tip of the bicone was 166.8°. Measurements were carried out at controlled strain of 1% (assuming an edge-wall distance of 3.5 mm, see below) and an oscillation frequency of \(f = 1\)/s. We did not use a ring arround the bicone, because we observed that the layer was too stiff to effectively enter into a circular slit. To account for this, the diameter of the slit was set to 100 mm when calculating the interfacial moduli using the algorithm from the rheocompass software (Anton-Paar). Yet, the results are mainly of qualitative nature.

Polarization Modulation Infrared Reflection Absorption Spectroscopy (PM-IRRAS)

PM-IRRAS spectroscopy is a modified version of Reflection–Absorption Infrared Spectroscopy, where a photoelastic modulator is used to switch the polarization of the incoming beam with a high frequency between p- and s-polarization. By subtracting the spectra in both polarizations, the signal from molecules without preferential orientation is strongly reduced and surface sensitivity is enhanced, while the orientation of the molecules at the surface becomes observable. The optimal sensitivity of the signal to the orientation of the molecules is found at an angle of incidence between 70 and 80°[17].

The vibrational bands of the film assembled at the air–water interface were recorded by a PM-IRRAS system from Biolin Scientific. An IR beam was reflected from the air–water interface at a gracing angle of 74°. The polarization of the incoming beam was modulated with high frequency (2700 kHz) between s- and p-polarization, and a normalized differential intensity was calculated via \(I_{{PM}} = \frac{{I_{P} - I_{s} }}{{I_{P} + I_{S} }} = \frac{\Delta }{\Sigma }.\) The signal of the layer was compared to the bare subphase to remove these contributions: \(S = \frac{{I_{{sample}} }}{{I_{{bare}} }} - 1.\) Further details can be found in previous works [18].

Atomic force microscopy (AFM)

The layers were transferred to silicon substrates at a surface pressure of 2 mN/m using the Langmuir-Schäfer technique. The AFM measurements were carried out on a MultiMode 8 (Bruker Corp., Billercia, USA) in tapping mode. Bruker RTESPW 150 Tips were used. All images were flattened by subtracting the median of the differences between scanning lines.

Surface enhanced Raman scattering (SERS)

For SERS measurements of degraded PEI, the film was transferred 10 times onto fresh silver SERS substrates (AtoID, Vilnius, Lithuania) using the Langmuir-Schäfer method. For comparison, a film of pristine PEI was prepared on a SERS substrate by dropcasting of the PEI / chloroform solution used for Langmuir monolayer experiments. Time-dependent SERS measurements showed drastic signal changes, therefore, both films were investigated immediately after preparation. Spectra were obtained with the confocal Raman microscope SENTERRA (Bruker Optik GmbH, Ettlingen Germany). Raman spectra were measured at room temperature with a 532 nm laser source at a power of 2 mW in the spectral range of 70—3700 cm−1 with a 50 × 1000 µm2 aperture. An objective with magnification of 50 × was used to collect the scattered light. The charge-coupled device (CCD) exposure time was 1 s, and an average of 128 cycles was used to increase signal to noise ratio. Samples were fixed on computer controlled xyz stage allowing increment stepping down to 0.1 μm in all directions. Spectra analysis was performed with OPUS software (version 8.2, Bruker Optik GmbH). For baseline correction, the concave rubber band method was used (8 iterations, 64 baseline points).

Data analysis, experimental error and reproducibility consideration

The raw rheology data were converted to interfacial values with the algorithm included in the Rheocompass software. The sensitivity limit of the rheometer in the applied geometry is ca. \(2\; \times \;10^{{ - 5}} \;{\text{Pa}}\star\;{\text{s}}\;\star{\text{m}}\) for the modulus, translating to \(2\; \times \;10^{{ - 5}} \;{\text{Pa}}\;\star{\text{s}}\;\star{\text{m}}\) at a frequency for 1 Hz. The main error of the surface pressure measurement is caused by the calibration procedure and is about 1%. The pH values were adjusted and measured with an exactness of ± 0.2. PM-IRRAS experiments are strongly dependent on a background subtraction procedure and affected by signal drift. Therefore, only strong peaks were used for qualitative evaluation. The random fluctuation of the surface potential was ca. ± 50 mV. Raman microscopic measurements were repeated at several positions to ensure repeatability. Layer preparation was repeated more than ten times, with variations of the MMA of ± 2% at pH = 6 and π = 2 mN/m. Reproducibility was checked for the alkaline hydrolysis, in particular at pH = 12.5. Here, an increase in surface pressure and viscosity over several hours was observed each time. AFM images were taken at different positions and of several samples.

Results and discussion

The preparation of Langmuir films of PEI has not yet been reported, so a characterization of the layers was carried out prior to the degradation experiments. The length of the repeat unit in an all-trans conformation would be on the order of 25 Å, and with typical van der Waals radii being on the order of 3 Å, one would expect a close packing of the chains at a mean molecular area (MMA, from here on defined as area per repeat unit) of 75 Å2. The compression isotherm on a MiliQ water subphase (Fig. 2A) shows a steep increase around that mark, indicating that PEI is indeed forming a film of close to monomolecular thickness. The very steep increase in surface pressure shows that the molecules are in a collapsed state and interact more like hard spheres than deformable chains. Interestingly, both the interfacial viscosity (Fig. 2A) and the surface potential (Fig. 2B) increase steeply at a higher MMA than the surface pressure.

Brewster angle microscopy (Fig. 3) clearly shows that PEI forms slabs upon spreading, which are compacted during compression. An increase in surface pressure is observed when further compaction of the slabs requires a measurable force. Here, the surface potential is more sensitive to the presence of the layer. For a monolayer without change in orientation or conformation, a linear increase of the surface potential with the inverse area is expected, which is not observed for PEI. Rather, the surface pressure increases linearly with the inverse area.

The onset of alkaline hydrolysis was studied by increasing the pH in a stepwise fashion (data not shown). An effect was observed once the pH exceeded 12, when the surface pressure started to increase slowly. Therefore, hydrolytic stability was tested at pH 12.5. After injection, the surface pressure started to increase continuously from 2 mN/m to 16 mN/m (Fig. 4A). Therefore, studying hydrolysis under isobaric conditions was not possible. From the increase in surface pressure, we infer that the phthalimide groups were getting hydrolyzed, creating carboxyl groups, which are negatively charged. Then, a long-ranged repulsive interaction leads to an increase of the surface pressure. The increased hydrophilicity of the hydrolyzed PEI also affects the mechanical properties of the layer. An increase of the viscosity is observed upon hydrolysis (Fig. 4A), showing clearly that the chains are not being broken and that the reaction only proceeds to the ring-opening stage. The reorganization of the more hydrophilic chains leads to an enhanced chain overlap and more entanglements. To study conversion of the phthalimide groups, PM-IRRRAS spectra were recorded before and during hydrolysis. The spectra acquired during compression are required to identify the characteristic bands of the polymer given the high noise level of PM-IRRAS spectra (Fig. 4B). In the case of PEI Langmuir films, the CNC vibration at ca. 1350 cm−1 and the asymmetric and symmetric CO vibrations of the phthalimide carbonyl groups at 1720 and 1760 cm−1 [9] are of interest and well visible. After increasing the pH, the intensity of these bands clearly decreases with time (Fig. 4C), confirming an at least partial hydrolysis of the phthalimide groups. Here, one has to take into account that the pH of the subphase decreases with time due to dissolution of carbon dioxide. This explains the incomplete ring opening of the phthalimide groups indicated by the presence of the CNC vibration in the last spectrum. The results from alkaline hydrolysis at pH 12.5 are in line with postmodification treatments of PEI membranes based on degradative modification, where substantial morphological reorganization was observed [19]. The aqueous amine solutions used for these procedures were of similar basicity.

(A) Alkaline hydrolysis of PEI: Surface pressure and interfacial viscosity at constant area. pH is changed from 6 to 12.5 at t = 0. (B) Surface pressure dependent PM-IRRAS spectroscopy of PEI films. The CNC and CO vibrations characteristic of the imide group are marked. (C) Evolution of PEI PM-IRRAS spectra at constant area after changing pH from 6 to 12.5. Initial surface pressure was 5 mN/m. The arrows denote the decreasing signal intensities of CO and CNC vibrations. Spectra were recorded from 1 to 7 with a time difference of ca. 20 min between each.

Previous works reporting the hydrolysis of PEI were using very high pH, where potentially the chains could also get cut, resulting in weakening or even dissolution of PEI. To mimic such a treatment, PEI was spread directly on a subphase with pH = 14. Figure 5A shows that the compression isotherm is altered substantially at this pH. Compared to neutral conditions, the surface pressure increases at higher MMA and also not as abruptly. Such a behavior indicates that the chains are adopting more extended conformations than at neutral pH, so the repulsive interactions set in at a higher MMA. The energy penalty for layer compression has an electrostatic contribution from the charged carboxyl groups. These interactions are more long-ranged and increase more gradually with compression than the steric repulsion of the collapsed chains at neutral pH. When left for further hydrolysis at a surface pressure of 2 mN/m, the area remains almost constant (Fig. 5B), indicating that the ring-opening of the phthalimide groups is essentially complete right after spreading. Interestingly, the interfacial viscosity decreases by a factor of 3, which indicates that at least some chain-cleavage is happening at pH = 14.

The alkaline hydrolysis was compared to acidic hydrolysis (Fig. 5C). According to the reactivity of the phthalimide groups, here, only very slow hydrolysis was expected. After changing the pH from 6 to 1, a sudden increase in the surface pressure was observed. This was a short-lived but reproducible effect. Potentially, the imide-nitrogen could be protonated resulting in long ranged repulsion, but then, it remains questionable why this effect was so short lived. The interfacial viscosity was essentially constant during the waiting time of more than ten hours (data not shown), which proves that chain cleavage was negligible. By combining rheology and surface pressure measurements, a ring-opening of the imide groups cannot be excluded with absolute certainty. Since the resulting carboxyl groups would not be charged at pH = 1, one would not expect a similarly clear effect on the surface pressure under acidic hydrolysis as under basic conditions. Still, considering the reactivity of the phthalimide group, a ring opening is unlikely. The hydrolysis of the amides is much faster than the hydrolysis of the imides under acidic conditions. As no hydrolysis of the amides was observed, we can infer that the imides were not hydrolyzed and no amides were formed.

Understanding the influence of hydrolysis on the nanoscale morphology of PEI is of particular importance with regard to applications in membranes or microparticles. To this end, films were transferred to silicon wafers at a surface pressure of 2 mN/m and investigated with AFM. The films transferred at neutral pH (Fig. 6A) consist of percolating granular structures separated by large (diameter ca. 50 nm) voids. The thickness of the polymer particles is ca. 2 nm, and the surface coverage is ca. 50%. We suggest that these films are formed by aggregation of the collapsed chains during spreading. The more or less homogeneous thickness indicates the involvement of a physical mechanism. Here, we suspect that the thickness of the granules reflects the thickness dependence of the glass transition temperature [20]: When the chains aggregate, the thickness of the granules grows, causing an increase of the glass transition temperature. Once the glass transition temperature exceeds room temperature, the chain motions are frozen and thickening stops. Compared to the films at neutral conditions, the films transferred at pH = 14 look very different (Fig. 6C). The granules, and also the voids in the film, are far finer. The phase image shows a continuous film, so the features appearing as voids in the height image may actually only be depressions or pits. The drastic difference in film morphology confirms the findings from rheology, where the interfacial viscosity increased upon increasing the pH (Fig. 4A). This is clearly an effect of the much denser and coherent morphology of the hydrolyzed films.

(A) AFM height images of PEI film on Si wafer transferred at \(\user2{\pi }\) = 2 mN/m. (B) SERS-Raman spectra of PEI on RandaS substrates. Dropcasted film vs. film hydrolyzed at pH = 14 for 2 h (10 × LS transfer) C) AFM height and phase images of PEI film on SI wafer transferred at \(\user2{\pi }\) = 2 mN/m after hydrolysis at pH = 14 for ca. 2 h.

In addition to the morphology, also the chemical structure of the films was investigated by SERS (Fig. 6B). The SERS spectra look very different from Raman Spectra of PEI particles [9] and films [21]. In particular, much fewer bands can be seen, as for example the usually strong carbonyl stretching bands are only present as a weak shoulder in the spectrum of drop-casted PEI. The primary reason for the shifted intensity is the dependence of the SERS intensity on the orientation of the vibrational dipole moments [22]. There is also a clear effect of sample preparation, with the degraded films prepared via Langmuir-Schäfer (LS) transfer showing much sharper peaks. The SERS spectrum of the hydrolyzed PEI confirms the hypothesis that the chains are not broken while the phthalimide groups are hydrolyzed. The resulting polyamide has the characteristic amide II and amide III vibrations at 1520 and 1320 cm−1. Vibrations of primary amines, which would be expected if the chains were cut, are not observed at ca. 3300 cm−1. The strong peak at 1055 fits well with a characteristic strong peak in the Raman spectrum of PEI [9] ( breathing mode of substituted aromatic rings). Then, the appearance of this peak in the spectrum of the hydrolyzed PEI is an effect of differences in chain orientation between films prepared via LS and drop casting.

Conclusion and outlook

Ultrathin films of PEI at the air–water interface were prepared and exposed to acidic and basic conditions. Basic hydrolysis sets in at a pH greater than 12, which is an important aspect to consider when carrying out polymer analogous modification or crosslinking involving amines in water. Here, buffered solutions should be used. While the hydrolysis went on for several hours at pH = 12, it was nearly instantaneous at pH = 14. Chain cleavage was negligible at pH = 12, while a reduction of the film viscosity at pH = 14 indicated a certain degree of hydrolysis. No hydrolysis was observed at pH = 1. To confirm these findings and potentially also quantify the ring opening and chain scission kinetics in dependence on pH, we suggest further hydrolysis studies with PEI particles, which, after dissolution, can be analyzed with gel permeation chromatography and nuclear magnetic resonance spectroscopy.

Alkaline hydrolysis has favorable effects on PEI films. The hydrolyzed films are much more compact and cohesive than the as-prepared films. As a result, they exhibit a higher shear modulus. The long-ranged repulsion of the charged carboxyl groups further increases the compression modulus of the layer. The PEI Langmuir-films prepared via alkaline hydrolysis can be seen as nanoporous membranes, and a characterization of their permeability and selectivity would be a logical next step. It should also be verified if the lessons learned from the Langmuir-technique can be applied to the preparation of PEI-membranes. Then, alkaline hydrolysis, either during phase inversion or as post-modification, can be used to tailor the nanoporous structure.

Hydrolyzed PEI is also an attractive material for post-functionalization. In the future, we will explore esterification and amidation using multivalent amines and alcohols.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

R.O. Johnson, H.S. Burlhis, J. Polym. Sci. 70(1), 129–143 (1983)

D. Wang, K. Li, W.K. Teo, J. Membr. Sci. 208(1), 419–426 (2002)

A.T. Neffe, M. von Ruesten-Lange, S. Braune, K. Luetzow, T. Roch, K. Richau, F. Jung, A. Lendlein, Macromol. Biosci. 13(12), 1720–1729 (2013)

B. Seifert, G. Mihanetzis, T. Groth, W. Albrecht, K. Richau, Y. Missirlis, D. Paul, G. Von Sengbusch, Artif. Organs 26(2), 189–199 (2002)

I.-C. Kim, K.-H. Lee, T.-M. Tak, J. Membr. Sci. 183(2), 235–247 (2001)

B.H. Oh, A.R. Kim, D.J. Yoo, Int. J. Hydrogen Energy 44(8), 4281–4292 (2019)

D. Li, H. Zhang, X. Li, J. Membr. Sci. 565, 42–49 (2018)

K. Vanherck, A. Cano-Odena, G. Koeckelberghs, T. Dedroog, I. Vankelecom, J. Membr. Sci. 353(1), 135–143 (2010)

S. Basu, M. Heuchel, T. Weigel, K. Kratz, A. Lendlein, Polym. Adv. Technol. 26(12), 1447–1455 (2015)

N. Maximous, G. Nakhla, W. Wan, J. Membr. Sci. 339(1), 93–99 (2009)

M.N. Khan, J. Org. Chem. 61(23), 8063–8068 (1996)

D.E. Watson, J.H. Ng, K.E. Aasmundtveit, M.P.Y. Desmulliez, IEEE Trans. Nanotechnol. 13(4), 736–742 (2014)

K. Akamatsu, S. Ikeda, H. Nawafune, Langmuir 19(24), 10366–10371 (2003)

P. Luan, G.S. Oehrlein, Langmuir 35(12), 4270–4277 (2019)

R. Machatschek, B. Schulz, A. Lendlein, Macromol. Rapid Commun. 40(1), 1800611 (2019)

D. Vollhardt, Curr. Opin. Colloid Interface Sci. 19(3), 183–197 (2014)

D. Blaudez, J.-M. Turlet, J. Dufourcq, D. Bard, T. Buffeteau, B. Desbat, J. Chem. Soc. Faraday Trans. 92(4), 525–530 (1996)

R. Machatschek, S. Saretia, A. Lendlein, Adv. Mater. Interfaces 8(6), 2001926 (2021)

W. Albrecht, F. Santoso, K. Lützow, T. Weigel, R. Schomäcker, A. Lendlein, J. Membr. Sci. 292(1), 145–157 (2007)

J.H. Kim, J. Jang, W.-C. Zin, Langmuir 17(9), 2703–2710 (2001)

S. Devasahayam, D.J.T. Hill, J.W. Connell, J. Appl. Polym. Sci. 101(3), 1575–1582 (2006)

J.A. Creighton, Surf. Sci. 124(1), 209–219 (1983)

Acknowledgments

The authors acknowledge Manuela Keller for assisting with Langmuir monolayer experiments and AFM, as well as Daniela Radzik with SERS measurements. This work was supported by the Helmholtz Association through programme-oriented funding.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Machatschek, R., Heuchel, M. & Lendlein, A. Hydrolytic stability of polyetherimide investigated in ultrathin films. Journal of Materials Research 36, 2987–2994 (2021). https://doi.org/10.1557/s43578-021-00267-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00267-6