Abstract

The “Bullwhip Effect” is a well-known example of supply chain inefficiencies and refers to demand amplification as moving up toward upstream echelons in a supply chain. This paper concentrates on representing a robust token-based ordering policy to facilitate information sharing in supply chains in order to manage the bullwhip effect. Takagi–Sugeno–Kang and hybrid multiple-input single-output fuzzy models are proposed to model the mechanism of token ordering in the token-based ordering policy. The main advantage of proposed fuzzy models is that they eliminate the exogenous and constant variables from the procedure of obtaining the optimal amount of tokens which should be ordered in every period. These fuzzy approaches model the mentioned mechanism through a push–pull policy. A four-echelon SC with fuzzy lead time and unlimited production capacity and inventory is considered to survey the outcomes. Numerical experiments confirm the effectiveness of proposed policies in alleviating BWE, inventory costs and variations.

Similar content being viewed by others

Notes

Lead times are endogenous variables in supply networks and can be affected mainly by information or transportation delays. Therefore, all delays in providing raw materials, production line, goods delivery, receiving demand information, etc. will be reflected in lead times; these delays may occur because of technical (systematic) issues or just by accident. Thus, lead times are imprecise and unknown in SCs. Fuzzy sets are successful in modeling vague and imprecise variables, so considering fuzzy lead times in supply networks leads to increasing the generality of the supply model [35, 40].

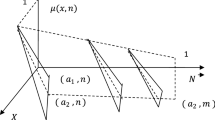

If there is an estimator for MU, based upon the past data in the system (for example seasonal data of the past year, or previous data in automated supply systems), MFs will be driven based on it. Otherwise, the MFs will be calculated based upon the known mean of demand (\(\upmu (t)\)); therefore, according to the fact that \(\upmu (t)\) is more sensitive on demand changes than the MU, using MU in MFs has a controlling effect on the supply system.

References

Agrawal S, Sengupta RN, Shanker K (2009) Impact of information sharing and lead time on bullwhip effect and on-hand inventory. Eur J Oper Res 192(2):576–593

Anderson EG, Morrice DJ (2000) A simulation game for teaching service-oriented supply chain management: Does information sharing help managers with service capacity decisions?*. Prod Oper Manag 9(1):40–55

Arda Y, Hennet J-C (2004) Optimizing the ordering policy in a supply chain. In: Actes 11th IFAC-INCOM

Asli C, Türksen IB (2009) Modeling uncertainty with fuzzy logic. Springer, Berlin

Barua A, Mudunuri LS, Kosheleva O (2014) Why trapezoidal and triangular membership functions work so well: towards a theoretical explanation. Uncertain Systems 8

Babuška R (1998) Fuzzy modeling for control. Kluwer, Dordrecht

Chen F (2003) Information sharing and supply chain coordination. In: De Kok AG, Graves SC (eds) Handbooks in operations research and management science, vol 11. Elsevier, Amsterdam

Chen F, Drezner Z, Ryan JK, Simchi-Levi D (2000) Quantifying the bullwhip effect in a simple supply chain: the impact of forecasting, lead times, and information. Manag Sci 46:436–443

Costantino F, Di Gravio G, Shaban A, Tronci M (2013) Information sharing policies based on tokens to improve supply chain performances. Logist Syst Manag 14:133–160

Croson R, Donohue K, Katok E, Sterman J (2004) Order stability in supply chains: coordination risk and the role of coordination stock. MIT Sloan School of Management, MIT Sloan working paper 4513-04

Disney SM, Lambrecht MR (2008) On replenishment rules, forecasting, and the bullwhip effect in supply chains. Foundations and Trends\({}^{\textregistered }\) in Technology, Information and Operations Management, 2(1):1–80

Dvořák A (1997) Computational properties of fuzzy logic deduction. Comput Intell Theory Appl 1226:189–196

Fazel Zarandi MH, Moghadam FS, Dorry F (2014) Fuzzy information sharing policy based on tokens for bullwhip effect management in supply chains. Norbert Wiener in the 21st Century (21CW), 2014 IEEE conference on, Boston, MA

Forrester JW (1958) Industrial dynamics—a major breakthrough for decision makers. Harv Bus Rev 36:37–66

González-R P, Framinan J, Pierreval H (2012) Token-based pull production control systems: an introductory overview. J Intell Manuf 23(1):5–22

Hopp WJ, Spearman ML (2000) Factory physics: foundations of manufacturing management. Irwin/McGraw-Hill, IrwinBurr Ridge

Hussain M, Ajmal MM (2013) Information sharing as a remedy to demand amplification in supply chains San Francisco State University, CA, USA. Int J Soft Comput Softw Eng JSCSE 3:137–145

Jin Z, Bose BK (2002) Evaluation of membership functions for fuzzy logic controlled induction motor drive. IECON 02 [Industrial Electronics Society, IEEE 2002 28th annual conference of the]

Lee HL, Padmanabhan V, Whang S (1997) The bullwhip effect in supply chains. Manag Sci 43:546–558

Lee HL, Padmanabhan V, Whang S (1997a) Information distortion in a supply chain: the bullwhip effect. Manag Sci 43(4):546–558

Lee HL, So KC, Tang CS (2000) The value of information sharing in a two-level supply chain. Manag Sci 46:43–62

Mamdani EH, Assilian S (1974) An experiment in linguistic synthesis with a fuzzy logic controller. Int J Man Mach Stud 7:1–13

Mingming Leng MP (2009) Allocation of cost savings in a three-level supply chain with demand information sharing: a cooperative-game approach. Oper Res 57:200–213

Moyaux T, Chaib-draa B, D’Amours S (2007) Information sharing as a coordination mechanism for reducing the bullwhip effect in a supply chain. IEEE Trans Syst Man Cybern Part C Appl Rev 37:396–409

Moyaux T, Chaib-draa B, D’Amours S (2003) Multi agent coordination based on tokens: reduction of the bullwhip effect in a forest supply chain. In: Proceedings of the second international joint conference on autonomous agents and multiagent systems Melbourne, Australia

Porteus EL (2000) Responsibility tokens in supply chain management. Manuf Serv Oper 2:203–219

Ranjan Bhattacharya SB (2011) A review of the causes of bullwhip effect in a supply chain. Springer, Berlin

Rief D, van Dinther C (2010) Negotiation for cooperation in logistics networks: an experimental study. Springer, Berlin

Sadeghi J, Mousavi SM, Niaki STA, Sadeghi S (2013) Optimizing a multi-vendor multi-retailer vendor managed inventory problem: two tuned meta-heuristic algorithms. Knowl Based Syst 50:159–170

Sarkar BB, Cortesi A, Chaki N (2013) Modeling the Bullwhip effect in a multi-stage multi-tier retail network by Generalized Stochastic Petri nets. In: Computer science and information systems (FedCSIS), 2013 Federated conference on

Shirazi MA, Soroor J (2007) An intelligent agent-based architecture for strategic information system applications. Knowl Based Syst 20(8):726–735

Simchi-Levi D, Kaminsky P, Simchi-Levi E (1998) Designing and managing the supply chain: concepts, strategies and case studie. McGraw-Hill International Edition, New York

Sterman JD (1989) Modeling managerial behavior: misperceptions of feedback in a dynamic decision making experiment. Manag Sci 35:321–339

Stubbings P, Virginas B, Owusu G, Voudouris C (2008) Modular neural networks for recursive collaborative forecasting in the service chain. Knowl Based Syst 21(6):450–457

Sudiarso A, Putranto RA (2010) Lead time estimation of a production system using fuzzy logic approach for various batch sizes. In: Lecture notes in engineering and computer science, pp 2231–2233

Sugeno M, Kang G (1988) Structure identification of fuzzy model. Fuzzy Sets Syst 26:15–33

Takagi T, Sugeno M (1985) Fuzzy identification of systems and its applications to modeling and control. IEEE Trans Syst Man Cybern SMC 15(1):116–132

Wu DY (2013) The impact of repeated interactions on supply chain contracts: a laboratory study. Int J Prod Econ 142(1):3–15

Xu L, Lingling L, Qian H, Ying D (2009) Systems thinking solving bullwhip effect in supply chain: from the perspective of system dynamics. In: Management and service science, 2009. MASS ’09. International conference on

Yavuz M (2010) Fuzzy lead time management. In: Kahraman C, Yavuz M (eds) Production engineering and management under fuzziness, vol 252. Springer, Berlin, pp 77–94

Zadeh LA (1965) Fuzzy sets. Inf Control 8(3):338–353

Acknowledgments

Authors would like to thank dear reviewers for their constructive viewpoints that helped to improving the paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zarandi, M.H.F., Moghadam, F.S. Fuzzy knowledge-based token-ordering policies for bullwhip effect management in supply chains. Knowl Inf Syst 50, 607–631 (2017). https://doi.org/10.1007/s10115-016-0954-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10115-016-0954-8