Abstract

Because of rising global energy consumption, renewable energy sources have received increased attention. The use of algal biomass as feedstock for biodiesel production has been recognized for its relatively higher lipid productivity and lower impact compared to fossil fuels and other renewable sources. Yet, it faces challenges in its commercialization since fossil fuels are generally more inexpensive. The integration of various processes yielding different bioproducts has been encouraged to increase profitability and overall sustainability through algal biorefineries. Moreover, considering the goal to minimize waste, resource recirculation can be maximized to achieve economic and environmental sustainability. In this study, a multi-objective nonlinear optimization model for a closed-loop algal biorefinery simultaneously optimizing cost and environmental impact, integrating life cycle assessment to properly account for process unit environmental impacts, and incorporating quality degradation resulting from resource recirculation is developed. A case study is solved to demonstrate the validity and features of the proposed model. Furthermore, various scenarios are applied to understand the effects of environmental changes to the system. Results reveal important insights, which highlights the significance of quality as a driver of system behavior, and may be used by stakeholders to support the design and operations of algal biorefineries.

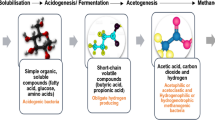

Graphical abstract

Similar content being viewed by others

Data availability

Enquiries about data availability should be directed to the authors.

References

Assacute L, Romagnoli F, Cappelli A, Ciocci C (2018) Algae-based biorefinery concept: an LCI analysis for a theoretical plant. Energy Procedia 147:15–24. https://doi.org/10.1016/j.egypro.2018.07.028

Barlow J, Sims RC, Quinn JC (2016) Techno-economic and life-cycle assessment of an attached growth algal biorefinery. Biores Technol 220:360–368. https://doi.org/10.1016/j.biortech.2016.08.091

BheringTrindade A, LuizaGrilloRenó M, José Rúa Orozco D, Martín Martinez Reyes A, AparecidoVitoriano Julio A, Carlos Escobar Palacio J (2021) Comparative analysis of different cost allocation methodologies in LCA for cogeneration systems. Energy Convers Manag 241:114230. https://doi.org/10.1016/j.enconman.2021.114230

Brütting J, Vandervaeren C, Senatore G, De Temmerman N, Fivet C (2020) Environmental impact minimization of reticular structures made of reused and new elements through life cycle assessment and mixed-integer linear programming. Energy Build. https://doi.org/10.1016/j.enbuild.2020.109827

Budzianowski WM (2017) High-value low-volume bioproducts coupled to bioenergies with potential to enhance business development of sustainable biorefineries. Renew Sustain Energy Rev 70:793–804. https://doi.org/10.1016/j.rser.2016.11.260

Bussa M, Eisen A, Zollfrank C, Röder H (2018) Life cycle assessment of microalgae products: state of the art and their potential for the production of polylactid acid. J Clean Prod 213:1299–1312. https://doi.org/10.1016/j.jclepro.2018.12.048

Caligan CJ, Garcia MM, Mitra JL, Mayol AP, San Juan JL, Culaba AB (2020) Multi-objective optimization of water exchanges between a wastewater treatment facility and algal biofuel production plant. IOP Conf Ser Earth Environ Sci 463:012050. https://doi.org/10.1088/1755-1315/463/1/012050

Caligan CJ, Garcia MM, Mitra JL, San Juan JL (2022) Multi-objective optimization for a wastewater treatment plant and sludge-to-energy network. J Clean Prod 368:133047. https://doi.org/10.1016/j.jclepro.2022.133047

Chandra R, Iqbal H, Vishal G, Lee H, Nagra S (2019) Algal biorefinery: a sustainable approach to valorize algal-based biomass towards multiple product recovery. Biores Technol 278:346–359. https://doi.org/10.1016/j.biortech.2019.01.104

Chowdhury R, Sadhukhan J, Traverso M, Keen PL (2018) Effects of residence time on life cycle assessment of bioenergy production from dairy manure. Bioresour Technol Rep 4:57–65. https://doi.org/10.1016/j.biteb.2018.08.011

Culaba AB, San Juan JL, Ching PL, Mayol AP, Sybingco E, & Ubando AT (2019) Optimal synthesis of algal biorefineries for Biofuel production based on techno-economic and environmental efficiency. In: 2019 IEEE 11th international conference on humanoid, nanotechnology, information technology, communication and control, Environment, and management (HNICEM ). https://doi.org/10.1109/hnicem48295.2019.9072730

Dantas J, Leal E, Cornejo DR, Kiminami RHGA, Costa ACFM (2020) Biodiesel production evaluating the use and reuse of magnetic nanocatalysts Ni0.5Zn0.5Fe2O4 synthesized in pilot-scale. Arab J Chem 13(1):3026–3042. https://doi.org/10.1016/j.arabjc.2018.08.012

Dasan YK, Lam MK, Yusup S, Lim JW, Lee KT (2019) Life cycle evaluation of microalgae biofuels production: effect of cultivation system on energy, carbon emission and cost balance analysis. Sci Total Environ 688:112–128. https://doi.org/10.1016/j.scitotenv.2019.06.181

De Bhowmick G, Sarmah AK, Sen R (2019) Zero-waste algal biorefinery for bioenergy and biochar: a green leap towards achieving energy and environmental sustainability. Sci Total Environ. https://doi.org/10.1016/j.scitotenv.2018.10.002

Galanopoulos C, Kenkel P, Zondervan E (2019) Superstructure optimization of an integrated algae biorefinery. Comput Chem Eng. https://doi.org/10.1016/j.compchemeng.2019.106530

García Prieto CV, Ramos FD, Estrada V, Villar MA, Diaz MS (2017) Optimization of an integrated algae-based biorefinery for the production of biodiesel, astaxanthin and PHB. Energy 139:1159–1172. https://doi.org/10.1016/j.energy.2017.08.036

Giwa A, Adeyemi I, Dindi A, García-Bañoz Lopez C, Lopresto C, Curcio S, Chakraborty S (2018) Techno-economic assessment of the sustainability of an integrated biorefinery from microalgae and Jatropha: a review and case study. Renew Sustain Energy Rev 88:239–257. https://doi.org/10.1016/j.rser.2018.02.032

Gnansounou E, Raman JK (2017) Life Cycle Assessment of algal biorefinery. In: Gnansounou E, Pandey A (eds) Life-cycle assessment of biorefineries. Elsevier, pp 199–219

Hingsamer M, & Jungmeier G (2019) Biorefineries. In The role of bioenergy in the emerging bioeconomy (pp 179–222). https://doi.org/10.1016/B978-0-12-813056-8.00005-4

International Energy Agency (2019) World Energy Outlook 2019. Retrieved from https://www.iea.org/reports/world-energy-outlook-2019

Ismail M, Al-Zuhair S (2020) Thermo-responsive switchable solvents for simultaneous microalgae cell disruption, oil extraction-reaction, and product separation for biodiesel production. Biocatal Agric Biotechnol. https://doi.org/10.1016/j.bcab.2020.101667

ISO. (2006). Environmental management—Life cycle assessment—Principles and framework. In Introduction

Khoo CG, Dasan YK, Lam MK, Lee KT (2019) Algae biorefinery: review on a broad spectrum of downstream processes and products. Bioresour Technol. https://doi.org/10.1016/j.biortech.2019.121964

Kim D, Oh Y, Park J, Kim B, Choi S, Han J (2015) An integrated process for microalgae harvesting and cell disruption by the use of ferric ions. Biores Technol 191:469–474. https://doi.org/10.1016/j.biortech.2015.03.020

Mitra M, Mishra S (2019) Multiproduct biorefinery from Arthrospira spp. towards zero waste: current status and future trends. Bioresour Technol. https://doi.org/10.1016/j.biortech.2019.121928

Moayedi H, Aghel B, Foong LK, Bui DT (2020) Feature validity during machine learning paradigms for predicting biodiesel purity. Fuel. https://doi.org/10.1016/j.fuel.2019.116498

Mohan S, Hemalatha M, Chakraborty D, Chatterjee S, Ranadheer P, Kona R (2019) Algal biorefinery models with self-sustainable closed loop approach: trends and prospective for blue-bioeconomy. Biores Technol. https://doi.org/10.1016/j.biortech.2019.122128

Morales M, Collet P, Lardon L, Hélias A, Steyer J, & Bernard O (2019) Life-cycle assessment of microalgal-based biofuel. In Biomass, Biofuels and Biochemicals (pp 507–550)

Narula V, Khan MF, Negi A, Kalra S, Thakur A, Jain S (2017) Low temperature optimization of biodiesel production from algal oil using CaO and CaO/Al2O3 as catalyst by the application of response surface methodology. Energy 140:879–884. https://doi.org/10.1016/j.energy.2017.09.028

Nayak M, Dhanarajan G, Dineshkumar R, Sen R (2018) Artificial intelligence driven process optimization for cleaner production of biomass with co-valorization of wastewater and flue gas in an algal biorefinery. J Clean Prod 201:1092–1100. https://doi.org/10.1016/j.jclepro.2018.08.048

O’Connell D, Savelski M, Slater CS (2012) Life cycle assessment of dewatering routes for algae derived biodiesel processes. Clean Technol Environ Policy 15(4):567–577. https://doi.org/10.1007/s10098-012-0537-7

Polyportis A, Mugge R, Magnier L (2022) Consumer acceptance of products made from recycled materials: a scoping review. Resour Conserv Recycl 186:106533. https://doi.org/10.1016/j.resconrec.2022.106533

Prasad R, Gupta SK, Shabnam N, Oliveira CYB, Nema AK, Ansari FA, Bux F (2021) Role of microalgae in global CO2 sequestration: Physiological mechanism, recent development, challenges, and future prospective. Sustainability (switzerland) 13(23):13061. https://doi.org/10.3390/su132313061

Rollan CD, Li R, San Juan JL, Dizon L, Ong KB (2018) A planning tool for tree species selection and planting schedule in forestation projects considering environmental and socio-economic benefits. J Environ Manag 206:319–329. https://doi.org/10.1016/j.jenvman.2017.10.044

San Juan J, Sy C (2021) Multi-objective target-oriented robust optimization of biomass Co-firing networks under quality uncertainty. J Sustain Dev Energy, Water Environ Syst 9(2):1–26. https://doi.org/10.13044/j.sdewes.d8.0364

San Juan JG, Sy CL, Tan R (2018) A multi-objective optimization model for the design of a biomass co-firing supply network. Chem Eng Trans 70:223–228. https://doi.org/10.3303/CET1870038

San Juan JL, Aviso KB, Tan RR, Sy CL (2019) A multi-objective optimization model for the design of biomass co-firing networks integrating feedstock quality considerations. Energies 12:2252–2274. https://doi.org/10.3390/en12122252

San Juan JL, Caligan CJ, Garcia MM, Mitra J, Mayol AP, Sy C, Ubando A, Culaba A (2020a) Multi-objective optimization of an integrated algal and sludge-based bioenergy park and wastewater treatment system. Sustainability 12(18):7793. https://doi.org/10.3390/su12187793

San Juan JL, Mayol AP, Sybingco E, Ubando AT, Culaba AB, Chen WH, Chang JS (2020b) A scheduling and planning algorithm for microalgal cultivation and harvesting for biofuel production. IOP Conf Ser Earth Environ Sci 463:012010. https://doi.org/10.1088/1755-1315/463/1/012010

Sandin G, Røyne F, Berlin J, Peters GM, Svanström M (2015) Allocation in LCAs of biorefinery products: implications for results and decision-making. J Clean Prod 93:213–221. https://doi.org/10.1016/j.jclepro.2015.01.013

Solis CA, Mayol AP, San Juan JG, Ubando AT, Culaba AB (2020) Multi-objective optimal synthesis of algal biorefineries toward a sustainable circular bioeconomy. IOP Conf Ser Earth Environ Sci. https://doi.org/10.1088/1755-1315/463/1/012051

Solis CMA, San Juan JLG, Mayol AP, Sy CL, Ubando AT, Culaba AB (2021) A multi-objective life cycle optimization model of an integrated algal biorefinery toward a sustainable circular bioeconomy considering resource recirculation. Energies 14(5):1416. https://doi.org/10.3390/en14051416

Sy CL, Ubando AT, Aviso KB, Tan RR (2018) Multi-objective target oriented robust optimization for the design of an integrated biorefinery. J Clean Prod 170:496–509. https://doi.org/10.1016/j.jclepro.2017.09.140

Wu W, Chang J (2019) Integrated algal biorefineries from process systems engineering aspects: a review. Bioresour Technol. https://doi.org/10.1016/j.biortech.2019.121939

Wu W, Lin K, Chang J (2018) Economic and life-cycle greenhouse gas optimization of microalgae-tobiofuels chains. Biores Technol 267:550–559. https://doi.org/10.1016/j.biortech.2018.07.083

Yew GY, Lee SY, Show PL, Tao Y, Law CL, Nguyen TTC, Chang J (2019) Recent advances in algae biodiesel production: From upstream cultivation to downstream processing. Bioresour Technol Rep. https://doi.org/10.1016/j.biteb.2019.100227

Funding

No funding was received for this work.

Author information

Authors and Affiliations

Contributions

CMS—Conceptualization, Methodology, Data curation, Writing—Original draft preparation, Validation; JLSJ and JGU—Writing—Reviewing and Editing; JLSJ—Conceptualization, Supervision, Writing—Reviewing and Editing

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

See Tables 12, 13, 14, 15, 16, 17, 18, 19, 20.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Solis, C.M., Juan, J.L.S., Uy, J.G. et al. Multi-objective optimization of algal biofuel production integrating resource recirculation and quality considerations. Clean Techn Environ Policy 26, 1107–1133 (2024). https://doi.org/10.1007/s10098-023-02663-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-023-02663-4