Abstract

This paper follows a practical approach to evaluate particulate matter emissions from biomass-fuelled power plants and analysis measurement uncertainties. Sixty-seven measurement reports from 11 biomass power plants, all equipped with fabric filters as dust control device, were analysed. Particulate matter emission measurements by gravimetrical standard reference method were chosen to provide the most reliable values to investigate the influence of bag filter parameters, such as media age or bag filter length. 92.1% of total dust emission measurements were below lower BAT-associated emission levels (BAT-AELs) for waste incineration. Data also showed that bag filter media older than 6 years can still secure very low dust emission levels. This work also gives a summary of findings and problems with uncertainty of automated measuring systems for dust emissions in biomass combustion applications in practice and quality assurance level one (QAL1) process related to very low emission levels such as lower best available techniques reference document (BREF) values. Practical examples on issues of continuous dust emission monitoring devices are also given.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The burden of disease associated with ambient air pollution exposure is still large and growing. Although air quality has improved slightly in more economically developed countries in the past decades, pollutant concentrations still exceed the levels published by the World Health Organization in many regions. The 2021 particulate matter (PM) air quality guideline levels for annual mean concentration of PM10 are 15 µg/m3 and 5 µg/m3 for PM2.5 (WHO 2021). PM concentrations in the majority of European countries are still higher than above stated levels, whereby more than half of the countries exceeded annual PM10 levels of 20 µg/m3 in 2018 (European Environmental Agency 2020).

Particulate emission shares by sector in EU28 countries from 2019 based on National emissions reported to the Convention on Long-range Transboundary Air Pollution (LRTAP Convention) are shown in Fig. 1. Residential, commercial and institutional energy supply, manufacturing and extractive industry and general energy supply contribute to 65% of total PM emissions. Many emission sources in those groups are already equipped with PM control devices, such as electrostatic precipitators or fabric filters, and are continuously monitored by measurement systems. Further information on PM control techniques for large-scale plants can be found, for example, in Lecomte et al. (2017) or Neuwahl et al. (2019); for residential application, please refer to Jaworek et al. (2021).

Current lowest associated PM emission levels in best available techniques (BAT) reference documents are given with < 2–5 mg/Nm3 (Lecomte et al. 2017; Neuwahl et al. 2019) or even < 1–3 mg/Nm3 (Chronopoulos et al. 2020).

Such low emission levels require high-precision automated measurement systems (AMS) working in harsh industrial environments.

EN 14181:2014 (2015) describes three quality assurance levels (QAL) as main steps for quality assurance procedure for AMS (Fig. 2).

AMS have to meet uncertainty requirements on measured values given either by legislation (e.g. Directive 2010/75/EU 2010) at the European Level or (17. BImSchV 2021), (AVV BGBl. II Nr. 389/2002 2013) on national level) or international standards (EN 15267-3:2008 2008). It is important to note that AMS have to be calibrated by standard reference method (SRM) measurements during QAL2 step. Thus, SRM must even perform better in terms of accuracy than AMS.

In 2017 a comprehensive study (French National Institute for Industrial Environment and Risks (INERIS) 2017) for major air pollutants was done on the performance of AMS and SRM with regard to existing and lower emission limit values (ELV) and has shown problems to meet legislative requirements.

This paper additionally provides a detailed analysis of real PM emission levels from biomass power plant applications, measured with SRM to have an as precise and reliable data basis as possible. All biomass power plants integrated in this work are equipped with fabric filters as state-of-the-art PM control devises und thus represent best available technology. As a practical approach, the plant emission levels have been compared to operational aspects such as bag filter media age, filter bag length and others to support plant engineers and operators on their future work.

Materials and methods

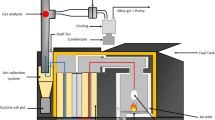

Biomass plants dust emissions: measurements with standard reference method

Sixty-seven QAL2 measurement reports of 11 biomass combustion plants, installed between 1997 and 2009 in the power range of 20–100 MW fuel heat input in Austria, Germany and Sweden were analysed. All plants were equipped with a fabric filter as PM control device and fuelled by waste wood, wood chips, bark or peat. Ten plants were equipped with sorbent dosing systems for acidic emission control (hydrated lime or sodium bicarbonate), one without sorbent dosing. Main plant and filter parameters, such as plant age, volume flow, flue gas temperature, filter supplier, differential pressure, filter media type and age, filter bag length and filter area, were also investigated.

A dataset of 496 half-hour average measurements of dust values with standard reference method (SRM) according to EN 13284-1:2017 (2017) or previous version of 2001 done by accredited institutes with corresponding AMS values was available in total.

Values measured with SRM were used as best available data for real dust emissions. Measurements below the limit of quantification (LoQ) stated in reports (typically varying from < 0.1 to < 0.5 mg/m3) were considered as 50% of LoQ for averaging calculations.

For calibration purposes, dust was intentionally injected in flue gas or filter bypass opened to simulate higher PM emissions in some plants. Those measurements were not considered for further assessments.

For further evaluations, arithmetic mean values per campaign were calculated. A campaign length was between 1 and 3 days with 3 up to 17 single half-hour average measurements.

Concentration values are given as mg/m3 at STP—standard temperature (273 K) and pressure (1013 hPa), dry gas and actual oxygen concentration in flue gas.

Dust analyser: QAL1 certificates and uncertainty

Three principles are typically used for continuous dust emission monitoring in flue gas; triboelectric, scattered light or the transmittance principle (e.g. Wiegleb 2016). Twenty-seven QAL1 certificates of market available dust analysers, available under qal1.de (TÜV Rheinland Energy GmbH 2022), were studied. Those products were certified according to EN 15267-3:2008 (2008) to be used as AMS. Combined standard uncertainty uc was calculated with

whereas uj represents the different parameters influencing the accuracy (e.g. repeatability, lack of fit, zero drift, influence of ambient temperature, etc.). The calculation of uncertainty uc can be found in the corresponding certificates of the different analysers.

Expanded measurement uncertainty U for 95% confidence level was then determined with

Results and discussion

Figure 3 gives an overview of the dust emission levels of all evaluated biomass power plants.

It has to be noted that plant 7 shows the highest PM emissions with only 11 single measurements during two campaigns. In the first campaign with six measurements, the average value was 10.5 mg/m3, in the second campaign 3 months later, average emissions were down to 0.22 mg/m3. AMS did not show equally high emissions during the first campaign. The reason for this could not be investigated, and thus, the first campaign was not considered as a valid measurement and was, hence, excluded from further analysis.

Plant 2 had also two high dust emission values slightly higher than 10 mg/m3 on one measurement campaign which may have been related to incorrect installed filter bags (noted in measurement report).

Classified measurements independent of plant origin are shown in Fig. 4. It can be concluded that 92.1% of all half-hourly average measurements were below lower BAT-associated emission levels (BAT-AELs) for waste incineration (Neuwahl et al. 2019), 96.8% were below upper BAT-AEL.

BAT-AELs are given as a daily average at oxygen reference of 11%, whereas the average oxygen level in flue gas of all biomass plants was 6.6% and thus representative.

Measurement campaign average emission values (MCAVs) were calculated and compared to plant data, which might influence emissions of fabric filter such as filter media type and age, filter bag length, filter area and air-to-cloth ratio, respectively.

The result of PM emissions versus filter media age is shown in Fig. 5 for four plants where filter bag lifetime was more than 4 years and sufficient measurements were available. Thus, 75 MCAVs representing more than 225 single half-hour average measurements could be taken into evaluation. No correlation between emissions and filter media age was found.

All 496 half-hour average measurements and all 11 plants were analysed for PM emission depending on filter bag length. Also no correlation was found (Fig. 6).

The highest PM emissions were found for a filter bag length of about 2.8 m. This bag length was installed in three of the plants. In two of those, PM average emissions were above 2 mg/m3 with 2.1 and 2.7 mg/m3, while the third plant had only average emissions of 0.2 mg/m3. It can be concluded that short bag length per se does not contribute to higher PM emissions. Due to higher numbers of bags installed for a given plant size and filtration area, respectively, also sealing area increases (see Fig. 7) and might be a possible leak source when bags are installed poorly.

PTFE membrane on glas fibre (PM/Gl) or PTFE, PPS, PTFE/PI, PPS/PTFE needlefelt filter media was installed in the different plants. For PPS and PPS/PTFE needlefelt media, only two and four MCAVs, respectively, were available for analysis. No clear correlation could be found as shown in Table 1.

Analysis of PM emissions versus air-to-cloth ratio or filter differential pressure could not be performed due to a lack of reliable values. Differential pressure was, if at all, only given as an indicative value for a complete measurement campaign. Volume flow was measured at emission point (stack) more often, but biomass plants almost exclusively have flue gas recirculation systems installed and thus actual flow over bag filters and air-to-cloth ratios, respectively, could not be determined.

SRM: measurement uncertainty and LoQ

Appendix G in EN 13284-1:2017 (2017) states an example of how to determine measurement uncertainty. Uncertainty and LoQ obviously depends on numerous factors, e.g. sample preparation including weighing or accuracy of measurement instruments and thus are individual for each measurement. In Appendix A (EN 13284-1:2017 2017) the results of validation measurements at municipal solid waste incinerators are given, one validation in dry flue gas at 140 °C and one in saturated flue gas at 60 °C.

Expanded measurement uncertainty is given at 4.0 mg/m3 for dry and 1.8 mg/m3 for wet flue gas. The LoQ is 0.3 mg/m3 for dry and ~ 2 mg/m3 for wet flue gas which is also cited in Brinkmann et al. (2018). It is also stated that extending the sampling time to 60 or 90 min would increase repeatability significantly.

In most of the analysed measurement reports, LoQ and measurement uncertainty were given. LoQ levels typically fluctuated between 0.1 and 0.5 mg/m3 (only one report stated < 1.9 mg/m3) and uncertainties ranged from 0.2 to 2 mg/m3, while one report stated an uncertainty of 10% of emission limit value (ELV) which would end up in that particular case in 3.3 mg/m3.

Dust analyser: QAL1 measurement uncertainty

Figure 8 shows expanded measurement uncertainties from QAL1 certificates for the three different measurement principles. Scattered light analysers are divided into those with extractive and in situ measurement, respectively.

The dust probes based on triboelectric principle have the lowest expanded measurement uncertainty of about 0.3 mg/m3, whereas optical systems fluctuate more and show an average value of about 0.7 mg/m3. In French National Institute for Industrial Environment and Risks (INERIS) (2017), two triboelectric systems showed average values of approx. 0.7 mg/m3, whereas optical systems (transmittance and scattered light) vary between 0.2 and 1.3 mg/m3.

Figure 9 shows sorted uncertainties of all 27 analysers.

Average measurement uncertainty over all analysed systems was 0.64 mg/m3 in this study as well as in French National Institute for Industrial Environment and Risks (INERIS) (2017) as majority of the systems had been the same. 75% percentile value is 0.82 mg/m3.

Industrial emission directive (Directive 2010/75/EU 2010) states a maximum expanded uncertainty for AMS of 30% of ELV. According to EN 15267-3:2008 (2008) measurement uncertainty of AMS has to be 25% lower than maximum uncertainty which demands a maximum AMS uncertainty during QAL1 certification of 22.5% of ELV.

Current emission limit value as daily average for dust for biomass combustion plants fuelled by waste wood is 10 mg/m3 STP, dry at 11% O2. Thus, maximum AMS uncertainty for QAL1 based on this ELV is 2.25 mg/m3 and is fulfilled by all investigated analysers.

Assuming that 75% of all market available analysers should be able to fulfil QAL1 uncertainty precondition for a newly ELV, emission limit value cannot be set lower than 3.7 mg/m3.

QAL2 calibration: practical issues

From a practical point of view and also mentioned in EN 14181:2014 (2015), concentrations during calibration shall vary as much as possible to ensure calibration of the AMS over as large a range as possible to cover most operational situations.

With fabric filters as PM control devices, emissions are according to previous analysis (Fig. 4) lower than 1 mg/m3 for more than 83% of the time and lower than 2 mg/m3 for more than 92% of operation time.

This leads in practice to calibration curves only valid in a very narrow range, whereas ELV and measurement range of analyser are much higher (Fig. 10).

EN 13284-2:2017 (2017) states possibilities to increase dust concentrations to extend calibration range. The most common option is artificial dosing of dust in flue gas ducts.

Injected dust has to have same relevant properties as dust in case of reduced separation efficiency (e.g. damaged filter bags) and homogenous dust distribution must be ensured.

Most relevant dust properties for optical systems according to Wiegleb (2016) are:

-

Particle size distribution

-

Parameters determining optical behaviour (colour, shape, surface, reflection/absorption)

Most relevant dust properties for triboelectric probes according to Wiegleb (2016) are:

-

Particle size distribution

-

Particle charge

-

Gas velocity (can be compensated)

Figure 11 shows examples of such QAL2 calibrations for a scattered light analyser and triboelectric dust probe. It can be seen that increased dust concentration points perfectly fit for scattered light analyser, whereas they are far off for a triboelectric probe in the given example. The reason for the lower fit with triboelectric probe could be due to different particle charge, e.g. agglomerated dust was injected.

Comparing the same measurement system over two consecutive years does not necessarily mean that data fit would be in the same range as can be seen in Fig. 12 for a triboelectric probe.

Based on the QAL2 measurements shown in Fig. 13, significantly different calibration curves for dust probe current signal (4–20 mA) also occur in the two consecutive years, as shown in Fig. 13. It should be highlighted that a probe signal of 6 mA in this specific case equals a dust concentration of 3.5 mg/m3 in 2019 and only 1.6 mg/m3 in 2020 when integrating the new calibration function.

Conclusions

Based on particulate matter measurements from biomass power plants obtained by the gravimetric standard reference method, 92.1% of evaluated measurements were below 2 mg/m3. This threshold represents lower BREF limits for large combustion plants (Lecomte et al. 2017) and waste incineration (Neuwahl et al. 2019) respectively.

It was also shown that bag filter media can fulfil strict emission limit values up to a lifetime of seven and even more years in operation.

The limit of quantification in measurement reports was given at 0.1 up to 0.5 mg/m3 and measurement uncertainty from 0.2 to 3.3 mg/m3. Based on this data, it is concluded that lower BREF limit of 2 mg/m3 can be measured with sufficient assurance by standard reference method. Biomass power plants with bag filters as a control device can and currently already do comply with such low emission limit values under normal operation.

Setting 2 mg/m3 as the emission limit value would result in a maximum expanded uncertainty limit for QAL1 process of 0.45 mg/m3 which can only be fulfilled by 37% of evaluated dust analysers on the market. Considering that in practice discrepancies between SRM and AMS measurements are in many cases > 1 mg/m3, it seems questionable that these low levels could be continuously monitored. Exceedances indicated by AMS might be likely without verification by gravimetric measurements.

Based on these findings, emission limit values below about 5 mg/m3 do not contribute to lower dust emissions in reality as bag filters do emit lower concentrations under normal operating conditions anyway but will lead to higher uncertainties in continuous monitoring. This information may help authorities as well as plant engineers and operators to define practical emission limit values for new biomass power plants.

The given examples on QAL2 calibration issues can support measurement laboratories as well as plant operators on designing future calibration campaigns.

Data availability

The participants of this study did not give written consent for their data to be shared publicly, so due to the sensitive nature of the research supporting data is not available. Nevertheless, special equiries can be addressed to the author as written under data availability note.

References

AVV BGBl. II Nr. 389/2002 (2013) Verordnung des BMLFUW und des BMWFJ über die Verbrennung von Abfällen (Abfallverbrennungsverordnung—AVV) zuletzt geändert durch BGBl. I Nr. 127/2013

BimSchV (2021) Verordnung über die Verbrennung und die Mitverbrennung von Abfällen vom 2. Mai 2013 (BGBl. I S. 1021, 1044, 3754), die durch Artikel 2 der Verordnung vom 6. Juli 2021 (BGBl. I S. 2514) geändert worden ist

Brinkmann T, Both R, Scalet BM, Roudier S, Sancho LD (2018) JRC reference report on monitoring of emissions to air and water from IED installations. European Union, Luxembourg

Chronopoulos G et al. (2020) Best available techniques (BAT) reference document on surface treatment using organic solvents including preservation of wood and wood products with chemicals. EUR 30475 EN, Luxembourg: Publications Office of the European Union

Directive 2010/75/EU (2010) Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on industrial emissions (integrated pollution prevention and control)

EN 13284-1:2017 (2017) Stationary source emissions—determination of low range mass concentration of dust—part 1: manual gravimetric method. Austrian Standards Institute, Vienna

EN 13284-2:2017 (2017) Stationary source emissions—determination of low range mass concentration of dust—part 2: quality assurance of automated measuring systems. Austrian Standards Institute, Vienna

EN 14181:2014 (2015) Stationary source emissions―quality assurance of automated measuring systems. Austrian Standards Institute, Vienna

EN 15267-3:2008 (2008) Air quality—certification of automated measuring systems—part 3. Austrian Standards Institute, Vienna

European Environmental Agency (2022) Air pollutant emissions data viewer. n.d. https://www.eea.europa.eu/data-and-maps/dashboards/air-pollutant-emissions-data-viewer-4. Accessed 03 10

European Environmental Agency (2020) Air quality in Europe—2020 report. European Environmental Agency, Copenhagen, p 160

French National Institute for Industrial Environment and Risks (INERIS) (2017) Study of the performances of existing and under development AMSs and SRMs for air emissions at the level of and below existing ELVs and BATAELs for Waste Incineration, Co-incineration and Large Combustion Plants. Report No. DRC-17-168319-02463B, on behalf of CEWP, ESWET and FEAD, Brussels

Jaworek A et al (2021) Particulate matter emission control from small residential boilers after biomass combustion. A review. Renewable and Sustainable Energy Reviews, Volume 137. https://doi.org/10.1016/j.rser.2020.110446

Lecomte T et al. (2017) Best available techniques (BAT) reference document for large combustion plants. EUR 28836 EN;, 2017: Publications Office of the European Union.

Neuwahl F, Cusano G, Benavides JG, Holbrook S, Roudier S (2019) Best available techniques (BAT) reference document for waste incineration. EUR 29971 EN, Luxembourg: Publications Office of the European Union

TÜV Rheinland Energy GmbH (2022) https://qal1.de.n.d. Accessed 26 Mar

WHO (2021) WHO global air quality guidelines. Particulate matter (PM2.5 and PM10), ozone, nitrogen dioxide, sulfur dioxide and carbon monoxide. Word Health Organization, Geneva, p 276

Wiegleb G (2016) Gasmesstechnik in Theorie—Messgeräte, Sensoren, Anwendungen. Springer, Wiesbaden

Acknowledgements

Acquisition and analysis of biomass emission data was supported under the “Öko-Scheck” programme No. 38991036 of Österreichische Forschungsförderungsgesellschaft mbH (FFG).

Funding

Open access funding provided by University of Applied Sciences Upper Austria.

Author information

Authors and Affiliations

Contributions

DS conceived the idea of this paper. He was also responsible for data acquisition, data analysis and presentation. CL was involved in conceptualization of data analysis and paper draft. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Steiner, D., Lanzerstorfer, C. Particulate emissions from biomass power plants: a practical review and measurement uncertainty issues. Clean Techn Environ Policy 26, 1039–1048 (2024). https://doi.org/10.1007/s10098-023-02645-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-023-02645-6