Abstract

There is currently an urgent need to further address environmental issues of pharmaceutical production as their production volume has steadily been increasing in the last decade and is expected to reach greater annual production volume in the future. Freshwater ecotoxicity due to production of Active Pharmaceutical Ingredients (APIs) due to wastewater generation and high cumulative primary energy demand due to complex upstream supply chains involved for the production of APIs and solvents are two main environmental issues that requires further appraisal in the literature. This study analyzes pharmaceutical production as a potential source of ecotoxicity and primary energy depletion due to API production and wastewater generation through a case study of a liquid pharmaceutical product. Upstream supply chain of APIs and Freshwater Ecotoxicity Potential (FEP) were analyzed. Raw material requirements for 17 upstream chemicals were quantified through the examination of production pathways. It was determined that the two APIs contained in the liquid product have high freshwater ecotoxicity potential compared to high production volume chemicals. Impact tree analysis for FEP showed that high FEP of APIs was linked to both organic and inorganic chemicals including benzoic acid, aniline, benzaldehyde and sodium. Similar to the case for FEP, Cumulative Energy Demand (CED) for the APIs was determined to be have much greater energy demand (249 and 218 MJ/kg) than high production volume chemicals. Analysis of FEP due to wastewater generation showed that the highest FEP contributor was API chlorhexidine gluconate. Research for alternative chemical components in the upstream supply chain showed that substitution alternatives are available and may be adopted by chemical producers and guidance tools that may enable this assessment is urgently needed.

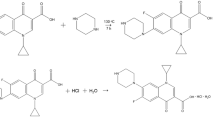

Graphical abstract

Similar content being viewed by others

Availability of data and materials

This manuscript has data included as electronic supplementary material.

References

Alfonsi K, Colberg J, Dunn PJ, Fevig T, Jennings S, Johnson TA, Stefaniak M (2008) Green chemistry tools to influence a medicinal chemistry and research chemistry based organisation. Green Chem 10(1):31–36

Alviz PLA, Alvarez AJ (2017) Comparative life cycle assessment of the use of an ionic liquid ([Bmim] Br) versus a volatile organic solvent in the production of acetylsalicylic acid. J Clean Prod 168:1614–1624

Amelio A, Genduso G, Vreysen S, Luis P, Van der Bruggen B (2014) Guidelines based on life cycle assessment for solvent selection during the process design and evaluation of treatment alternatives. Green Chem 16(6):3045–3063

Ankley GT, Brooks BW, Huggett DB, Sumpter AJP (2007) Repeating history: pharmaceuticals in the environment. Environ Sci Technol 41(24):8211–8217

Bertrand P, Bonnarme V, Piccirilli A, Ayrault P, Lemée L, Frapper G, Pourchez J (2018) Physical and chemical assessment of 1, 3 Propanediol as a potential substitute of propylene glycol in refill liquid for electronic cigarettes. Sci Rep 8(1):1–10

Bradbury WC (1966) Manufacture of para-chloroaniline and para-aminophenol.U.S. Patent No. 3,265,735A. Washington, DC: U.S. Patent and Trademark Office

Brunet R, Guillén-Gosálbez G, Jiménez L (2014) Combined simulation–optimization methodology to reduce the environmental impact of pharmaceutical processes: application to the production of Penicillin V. J Clean Prod 76:55–63

Cespi D, Beach ES, Swarr TE, Passarini F, Vassura I, Dunn PJ, Anastas PT (2015) Life cycle inventory improvement in the pharmaceutical sector: assessment of the sustainability combining PMI and LCA tools. Green Chem 17(6):3390–3400

Daughton CG, Ternes TA (1999) Pharmaceuticals and personal care products in the environment: Agents of subtle change? Environ Health Perspect 107(suppl 6):907–938

De García SO, García-Encina PA, Irusta-Mata R (2017) The potential ecotoxicological impact of pharmaceutical and personal care products on humans and freshwater, based on USEtox™ characterization factors. A Spanish case study of toxicity impact scores. Sci Total Environ 609:429–445

De Soete W, Dewulf J, Cappuyns P, Van der Vorst G, Heirman B, Aelterman W, Van Langenhove H (2013) Exergetic sustainability assessment of batch versus continuous wet granulation based pharmaceutical tablet manufacturing: a cohesive analysis at three different levels. Green Chem 15(11):3039–3048

De Soete W, Boone L, Willemse F, De Meyer E, Heirman B, Van Langenhove H, Dewulf J (2014) Environmental resource footprinting of drug manufacturing: effects of scale-up and tablet dosage. Resour Conserv Recycl 91:82–88

De Soete W, Jiménez-González C, Dahlin P, Dewulf J (2017) Challenges and recommendations for environmental sustainability assessments of pharmaceutical products in the healthcare sector. Green Chem 19(15):3493–3509

Denčić I, Ott D, Kralisch D, Noël T, Meuldijk J, de Croon M, Perrichon P (2014) Eco-efficiency analysis for intensified production of an active pharmaceutical ingredient: a case study. Org Process Res Dev 18(11):1326–1338

Fiume MM, Heldreth B, Bergfeld WF, Belsito DV, Hill RA, Klaassen CD, Snyder PW (2013) Safety assessment of decyl glucoside and other alkyl glucosides as used in cosmetics. Int J Toxicol 32(5_suppl), 22S–48S

Gamiz AGR, De Soete W, Heirman B, Dahlin P, De Meester S, Dewulf J (2019) Environmental sustainability assessment of the manufacturing process of a biological active pharmaceutical ingredient. J Chem Technol Biotechnol 94(6):1937–1944

Geisler G, Hofstetter TB, Hungerbühler K (2004) Production of fine and speciality chemicals: procedure for the estimation of LCIs. Int J Life Cycle Assess 9(2):101–113

Gervajio, G. C., Withana‐Gamage, T. S., & Sivakumar, M. (2005). Fatty acids and derivatives from coconut oil. Bailey's industrial oil and fat products, 1–45.

Grimaldi F, de Leon Izeppi GA, Kirschneck D, Lettieri P, Escribà-Gelonch M, Hessel V (2020) Life cycle assessment and cost evaluation of emerging technologies at early stages: the case of continuous flow synthesis of Rufinamide. J Adv Manuf Process 2(2):e10043

Henderson RK, Jiménez-González C, Preston C, Constable DJ, Woodley JM (2008) PEER REVIEW ORIGINAL RESEARCH: EHS & LCA assessment for 7-ACA synthesis: a case study for comparing biocatalytic & chemical synthesis. Ind Biotechnol 4(2):180–192

Huijbregts MA, Steinmann ZJ, Elshout PM, Stam G, Verones F, Vieira M, Zijp M, Hollander A, van Zelm R (2017) ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int J Life Cycle Assess 22(2):138–147

Jeswani HK, Azapagic A (2019) Life cycle environmental impacts of inhalers. J Clean Prod 237:117733

Jiménez-González C, Kim S, Overcash MR (2000) Methodology for developing gate-to-gate life cycle inventory information. Int J Life Cycle Assess 5(3):153–159

Jiménez-González C, Curzons AD, Constable DJ, Cunningham VL (2004) Cradle-to-gate life cycle inventory and assessment of pharmaceutical compounds. Int J Life Cycle Assess 9(2):114–121

Jödicke G, Zenklusen O, Weidenhaupt A, Hungerbühler K (1999) Developing environmentally-sound processes in the chemical industry: a case study on pharmaceutical intermediates. J Clean Prod 7(2):159–166

Kastens ML, McBurney WG (1951) Calcium cyanamide. Ind Eng Chem 43(5):1020–1033

Kim S, Jiménez-González C, Dale BE (2009) Enzymes for pharmaceutical applications—a cradle-to-gate life cycle assessment. Int J Life Cycle Assess 14(5):392–400

Kumar A, Zavadskas EK, Mangla SK, Agrawal V, Sharma K, Gupta D (2019) When risks need attention: adoption of green supply chain initiatives in the pharmaceutical industry. Int J Prod Res 57(11):3554–3576

Luo Y, Guo W, Ngo HH, Nghiem LD, Hai FI, Zhang J, Wang XC (2014) A review on the occurrence of micropollutants in the aquatic environment and their fate and removal during wastewater treatment. Sci Total Environ 473:619–641

McAlister S, Ou Y, Neff E, Hapgood K, Story D, Mealey P, McGain F (2016) The Environmental footprint of morphine: a life cycle assessment from opium poppy farming to the packaged drug. BMJ Open 6(10):e013302

Ott D, Borukhova S, Hessel V (2016) Life cycle assessment of multi-step rufinamide synthesis–from isolated reactions in batch to continuous microreactor networks. Green Chem 18(4):1096–1116

Ott-Reinhardt D, Kralisch D, Denčić I, Hessel V, Laribi Y, Perrichon PD, Loeb P (2014) Life cycle analysis within pharmaceutical process optimization and intensification: case study of active pharmaceutical ingredient production. Chemsuschem 7(12):3521–3533

Parvatker AG, Tunceroglu H, Sherman JD, Coish P, Anastas P, Zimmerman JB, Eckelman MJ (2019) Cradle-to-gate greenhouse gas emissions for twenty anesthetic active pharmaceutical ingredients based on process scale-up and process design calculations. ACS Sustain Chem Eng 7(7):6580–6591

Perez-Vega S, Ortega-Rivas E, Salmeron-Ochoa I, Sharratt PN (2013) A system view of solvent selection in the pharmaceutical industry: towards a sustainable choice. Environ Dev Sustain 15(1):1–21

Ponder C, Overcash M (2010) Cradle-to-gate life cycle inventory of vancomycin hydrochloride. Sci Total Environ 408(6):1331–1337

Raymond MJ, Slater CS, Savelski MJ (2010) LCA approach to the analysis of solvent waste issues in the pharmaceutical industry. Green Chem 12(10):1826–1834

Research and Markets (2018). https://www.prnewswire.com/news-releases/global-mid-size-pharmaceutical-market-2016-2018--2021-market-is-projected-to-grow-from-approximately-1-1-trillion-in-2016-to-1-5-trillion-in-2021--300666386.html. Last access June 2018

Riazi B, Zhang J, Yee W, Ngo H, Spatari S (2019) Life cycle environmental and cost implications of isostearic acid production for pharmaceutical and personal care products. ACS Sustain Chem Eng 7(18):15247–15258

Roschangar F, Sheldon RA, Senanayake CH (2015) Overcoming barriers to green chemistry in the pharmaceutical industry–the Green Aspiration Level™ concept. Green Chem 17(2):752–768

Roschangar F, Zhou Y, Constable DJ, Colberg J, Dickson DP, Dunn PJ, Kopach ME (2018) Inspiring process innovation via an improved green manufacturing metric: iGAL. Green Chem 20(10):2206–2211

Savelski MJ, Slater CS, Tozzi PV, Wisniewski CM (2017) On the simulation, economic analysis, and life cycle assessment of batch-mode organic solvent recovery alternatives for the pharmaceutical industry. Clean Technol Environ Policy 19(10):2467–2477

SciFinder (2018a) Benzydamine hydrochloride. https://scifinder.cas.org/scifinder/view/link_v1/reaction.html?l=T5OKcO0Ri0Vxs5SgbYOjGs_REPxn1Ry1NLPJYVKomWtImowdVc8BGbf8aW7nA_cA. Last accessed November 2020

SciFinder (2018b) Sorbitan, monododecanoate. https://scifinder.cas.org/scifinder/view/link_v1/reaction.html?l=T5OKcO0Ri0Vxs5SgbYOjGqawMBvz1XOJNLPJYVKomWtImowdVc8BGa2i7FsWjk4Q. Last accessed November 2020

SciFinder (2018c) Hexamethylene bi-cyanoguanidine. https://scifinder.cas.org/scifinder/view/link_v1/reaction.html?l=T5OKcO0Ri0Vxs5SgbYOjGtU5sonlByMSNLPJYVKomWtImowdVc8BGe8X23aIXpj5. Last accessed November 2020

SciFinder (2018d) Chlorhexidine. https://scifinder.cas.org/scifinder/view/link_v1/reaction.html?l=T5OKcO0Ri0Vxs5SgbYOjGhGzbE_kINVjNLPJYVKomWtImowdVc8BGV7qN60bv2xb. Last accessed November 2020

SciFinder (2018e) Carbonochloridic acid, ethyl ester. https://scifinder.cas.org/scifinder/view/link_v1/reaction.html?l=T5OKcO0Ri0Vxs5SgbYOjGguSI9Prh9dMNLPJYVKomWtImowdVc8BGUVmkNl1K3zi. Last accessed November 2020

SciFinder (2018f) Tween 20. https://scifinder.cas.org/scifinder/view/link_v1/reaction.html?l=T5OKcO0Ri0Vxs5SgbYOjGhWCsQdaIC-ANLPJYVKomWtImowdVc8BGc3hcsy4gxNT. Last accessed November 2020

SciFinder (2018g) 1-Propanamine, 3-chloro-N,N-dimethyl-. https://scifinder.cas.org/scifinder/view/link_v1/reaction.html?l=T5OKcO0Ri0Vxs5SgbYOjGiWBUwom_U3gNLPJYVKomWtImowdVc8BGc29E2JKp2aa. Last accessed November 2020.

SciFinder (2018h). Benzenemethanamine, N-phenyl. https://scifinder.cas.org/scifinder/view/link_v1/reaction.html?l=T5OKcO0Ri0Vxs5SgbYOjGrNw219vS-WRNLPJYVKomWtImowdVc8BGYch7ZB8r-rt. Last accessed November 2020

Sharma RK, Sarkar P, Singh H (2020) Assessing the sustainability of a manufacturing process using life cycle assessment technique—a case of an Indian pharmaceutical company. Clean Technol Environ Policy 22(6):1269–1284

Slater CS, Savelski MJ, Ruiz-Felix MN (2013) Life cycle analysis of solvent reduction in pharmaceutical synthesis using continuous adsorption for palladium removal. J Environ Sci Health Part A 48(13):1602–1608

Van der Vorst G, Dewulf J, Aelterman W, De Witte B, Van Langenhove H (2011) A systematic evaluation of the resource consumption of active pharmaceutical ingredient production at three different levels. Environ Sci Technol 45(7):3040–3046

Veleva VR, Cue BW Jr, Todorova S (2018) Benchmarking green chemistry adoption by the global pharmaceutical supply chain. ACS Sustain Chem Eng 6(1):2–14

Wen JP, Wang CL, Liu YX (2004) Preparation of sorbitol from D-glucose hydrogenation in gas–liquid–solid three-phase flow airlift loop reactor. J Chem Technol Biotechnol 79(4):403–406

Wernet G, Conradt S, Isenring HP, Jiménez-González C, Hungerbühler K (2010) Life cycle assessment of fine chemical production: a case study of pharmaceutical synthesis. Int J Life Cycle Assess 15(3):294–303

Wikipedia (2020). Calcium cyanamide URL: https://en.wikipedia.org/wiki/Calcium_cyanamide. Last accessed August 2020

Yaseneva P, Hodgson P, Zakrzewski J, Falß S, Meadows RE, Lapkin AA (2016) Continuous flow Buchwald–Hartwig amination of a pharmaceutical intermediate. React Chem Eng 1(2):229–238

Acknowledgements

The authors thank three reviewers for their meticulous review and attention. The authors thank to Ms. Semra Evirgen and Mr. Teoman Kalafatoğlu, Prof. Dr. Vildan Adar Gürsoy, Assoc. Prof. Dr. Müge Andaç and Assoc. Prof. Dr. İlknur Durukan Temuge, Dr. Hüdai Kara for sharing their valuable time, knowledge and experience.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

Ç.E.G. and H.Ş. contributed to conceptualization; Ç.E.G. contributed to methodology; Ç.E.G contributed to software; Ç.E.G. and H.Ş contributed to writing—original draft preparation; H.Ş contributed to writing—review and editing; Ç.E.G. and H.Ş. contributed to visualization; H.Ş. supervised the study. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interests

The authors declare they have no financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Güneş, Ç.E., Şengül, H. Cradle-to-gate life cycle assessment of a liquid pharmaceutical product through analysis of chemical production pathways. Clean Techn Environ Policy 24, 1741–1755 (2022). https://doi.org/10.1007/s10098-022-02283-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-022-02283-4