Abstract

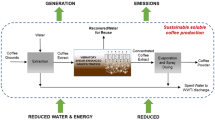

The performance of a dynamic vibratory membrane system for the recovery of usable water from soluble coffee processing wastewater has been investigated. Coffee wastewater is a complex food and beverage wastewater consisting of a variety of inorganic and organic constituents and dissolved and suspended solids. Manufacturing processes require high volumes of water, which leads to significant generation of wastewater. Effective design and scale-up of a recovery process are necessary to improve the sustainability of water draw for production. Rejections of COD, turbidity, and conductivity were observed to determine the purity of water recovered. A variety of membranes were initially screened for effective performance; a thin-film composite nanofiltration and a thin-film composite reverse osmosis membrane were selected for further studies. Process parameter studies for these membranes evaluated the effect of time, pressure, and vibration (shear). Steady-state flux was enhanced when vibration was introduced by factors of 4.5 and 1.6 when processing with the nanofiltration and reverse osmosis membranes, respectively. COD and turbidity rejection were above 97% for both the nanofiltration and reverse osmosis membranes in vibratory filtration. Conductivity rejection was 75 and 99% for the nanofiltration and reverse osmosis membranes, respectively, in vibratory filtration. The nanofiltration membrane was tested in a high-recovery simulation run and produced high flux at 85% total permeate recovery, indicating commercial-scale design is feasible.

(adapted from Slater et al. 2015)

Similar content being viewed by others

References

Akoum OA, Jaffrin MY, Ding L, Paullier P, Vanhoutte C (2002) An hydrodynamic investigation of microfiltration and ultrafiltration in a vibrating membrane module. J Membr Sci 197:37–52

Akoum O, Jaffrin MY, Ding L (2005) Concentration of total milk proteins by high shear ultrafiltration in a vibrating membrane module. J Membr Sci 247:211–220

Blomenhofer V, Groß F, Procelewska J, Delgado A, Becher T (2013) Water quality management in the food and beverage industry by hybrid automation using the example of breweries. Water Sci Technol 13:427–434

Bosak VK, VanderZaag AC, Crolla A, Kinsley C, Chabot D, Miller SS, Gordon RJ (2016) Treatment of potato farm wastewater with sand filtration. Environ Technol 37:1597–1604

Canizares P, Lobato J, Paz R, Rodrigo MA, Saez C (2007) Advanced oxidation processes for the treatment of olive-oil mills wastewater. Chemosphere 67:832–838

Cardenas A, Morales U, Saldago L, Zayas T (2009) Electrochemical oxidation of wastewaters from the instant coffee industry using a dimensionally stable RuIrCoOx anode. ECS Trans 20:291–299

Casani S, Rouhany M, Knochel S (2005) A discussion paper on challenges and limitations to water reuse and hygiene in the food industry. Water Res 39:1134–1146

Cassano A, Drioli E (2013) Integrated membrane operations: in the food production. De Gruyter Inc, Berlin

Chollangi A, Hossain MdM (2007) Separation of proteins and lactose from dairy wastewater. Chem Eng Process Process Intensif 46:398–404

Clarke RJ, Macrae R (1987) Coffee, vol 2. Elsevier Applied Sciences, London

Coskun T, Debik E, Demir NM (2010) Treatment of olive mill wastewaters by nanofiltration and reverse osmosis membranes. Desalination 259:65–70

De Haan A, Bosch H (2013) Industrial separation processes: fundamentals. Walter de Gruyer GmbH, Berlin

Devi R, Singh V, Kumar A (2008) COD and BOD reduction from coffee processing wastewater using Avacado peel carbon. Bioresour Technol 99:1853–1860

Dewettick K, Le Trung T (2011) Membrane separations in food processing. In: Proctor A (ed) Alternatives to conventional food processing. The Royal Society of Chemistry, Cambridge, pp 184–253

El Rayess Y, Albasi C, Bacchin P, Taillandier P, Raynal J, Mietton-Peuchot M, Devatine A (2011) Cross-flow microfiltration applied to oenology: a review. J Membr Sci 382:1–19

Field R, Bekassy-Molnar E, Lipnizki F, Vatai G (2017) Engineering aspects of membrane separation and application in food processing. CRC Press, Boca Raton

Frappart M, Jaffrin MY, Ding LH, Espina V (2008) Effect of vibration frequency and membrane shear rate on nanofiltration of diluted milk, using a vibratory dynamic filtration system. Sep Purif Technol 62:212–221

Gerschenson LN, Den Q, Cassano A (2015) Conventional macroscopic pretreatment. In: Galanakis CM (ed) Food waste recovery: processing technologies and industrial techniques. Academic Press, London, pp 85–103

Ho WSW, Sirkar KK (1992) Membrane handbook. Chapman & Hall, New York

Hu K, Dickson JM (2015) Membrane processing for dairy ingredient separation. Wiley and the Institute of Food Technologists, Chicago

Kertesz S, Laszlo Z, Forgacs E, Szabo G, Hodur C (2011) Dairy wastewater purification by vibratory shear enhanced processing. Desalin Water Treat 35:195–201

Klemes J, Smith R, Kim JK (2008) Handbook of water and energy management in food processing. Elsevier Science, Burlington

Kotsanopoulos KV, Arvanitoyannis IS (2013) Membrane processing technology in the food industry: food processing, wastewater treatment, and effects on physical, microbiological, organoleptic, and nutritional properties of foods. Crit Rev Food Sci Nutr 55:1147–1175

Lee W, Okos MR (2011) Sustainable food processing systems: path to zero liquid discharge: reduction of water, waste and energy. Procedia Food Sci 1:1768–1777

Lipnizki F (2010) Cross-flow membrane applications in the food industry. In: Peinenmann K, Pereira Nunes S, Giorno L (eds) Membrane technology: membranes for food applications. Wiley-VCH Verlag GmbH & Co, Weinheim, pp 1–24

Luo J, Cao W, Ding L, Zhu Z, Wan Y, Jaffrin MY (2012) Treatment of dairy effluent by shear-enhanced membrane filtration: the role of foulants. Sep Purif Technol 96:194–203

Mekonnen MM, Hoekstra AY (2011) The green, blue and grey water footprint of crops and derived crop products. Hydrol Earth Sci 15:1577–1600

Miller DJ, Dreyer DR, Bielawski CW, Paul DR, Freeman BD (2017) Surface modification of water purification membranes. Angew Chem Int Ed 56:4662–4711

Mulder M (1996) Basic principles of membrane technology. Kluwer Academic Publishers, Dordrecht

New Logic Research, Inc (2017) VSEP technology. http://www.vsep.com/technology/index.html. Accessed 1 Mar 2018

Noghabi MS, Razavi SM, Mousavvi SM, Elahi M, Miazmand R (2011) Effect of operating parameters on performance of nanofiltration of sugar beet press water. Procedia Food Sci 1:160–164

Pouliot Y, Conway V, Leclerc P-L (2014) Separation and concentration technologies in food processing. In: Clark S, Jung S, Lamsal B (eds) Food processing: principles and applications, 2nd edn. Wiley, Chichester, pp 33–60

Pujol D, Liu C, Gominho J, Olivella MA, Fiol N, Villaescusa I, Pereira H (2013) The chemical composition of exhausted coffee waste. Ind Crops Prod 50:423–429

Rattan S, Parande AK, Nagaraju VD, Ghiwari GK (2015) A comprehensive review on utilization of wastewater from coffee processing. Environ Sci and Pollut Res Int 22:6461–6472

Rice EW, Barid RB, Eaton AD, Cleceri LS (2012) Standard methods for the examination of water and wastewater. American Public Health Association, American Water Works Association, Water Environment Federation, Washington

Rousseau RW (1987) Handbook of separation process technology. Wiley, New York

Sadr SM, Saroj DP (2015) Membrane technologies for municipal wastewater treatment. In: Basile A, Cassano A, Rastogi NK (eds) Advances in membrane technologies for water treatment. Woodhead Publishing, Cambridge, pp 443–463

Shete BS, Shinkar NP (2013) Dairy industry wastewater sources, characteristics and its effects on environment. Int J Curr Eng Technol 3:1611–1615

Shi W, Benjamin MM (2011) Effect of shear rate on fouling in a vibratory shear enhanced processing (VSEP) RO system. J Membr Sci 366:148–157

Slater CS, Savelski MJ, Kostetskyy P, Johnson M (2015) Shear-enhanced microfiltration of microalgae in a vibrating membrane module. Clean Technol Environ Policy 17:1743–1755

Sparks T, Chase G (2016) Filters and filtration handbook. Butterworth-Heinemann, Oxford

SUEZ Water Technologies & Solutions (2017) Filtration and separation spectrum. https://www.suezwatertechnologies.com/kcpguest/document-library.do. Accessed 12 June 2017

U.S. Department of Energy (2011) Cooling towers: understanding key components of cooling towers and how to improve water efficiency. https://www.energy.gov/sites/prod/files/2013/10/f3/waterfs_coolingtowers.pdf. Accessed 1 Mar 2018

Vourch M, Balannec B, Chaufer B, Dorange G (2008) Treatment of dairy wastewater by reverse osmosis for water reuse. Desalination 219:190–202

Wisniewski CM, Savelski MJ, Slater CS (2017) Membrane-based water recovery in coffee manufacture. Proc Water Environ Fed. https://doi.org/10.2175/193864717822155623

Acknowledgements

The authors acknowledge the support of the U.S. Environmental Protection Agency through the Pollution Prevention Grant Program (NP-96271316-1). The authors also acknowledge the Rowan Engineering Clinic students: Richard Bartell, John Borovilas, Don Dunner, Brandon Lawrence, and Andrew Warne. The authors also appreciate the support of Jim Barden, Fredéric Bodo, Daniel Donhowe, Erica Grun, John Morton, Mike Moscatiello, and Eugene Williford of Nestlé, USA. We would also like to thank Landon Graham of New Logic Research for his help.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wisniewski, C.M., Slater, C.S. & Savelski, M.J. Dynamic vibratory membrane processing for use in water recovery from soluble coffee product manufacturing wastewater. Clean Techn Environ Policy 20, 1791–1803 (2018). https://doi.org/10.1007/s10098-018-1569-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-018-1569-4